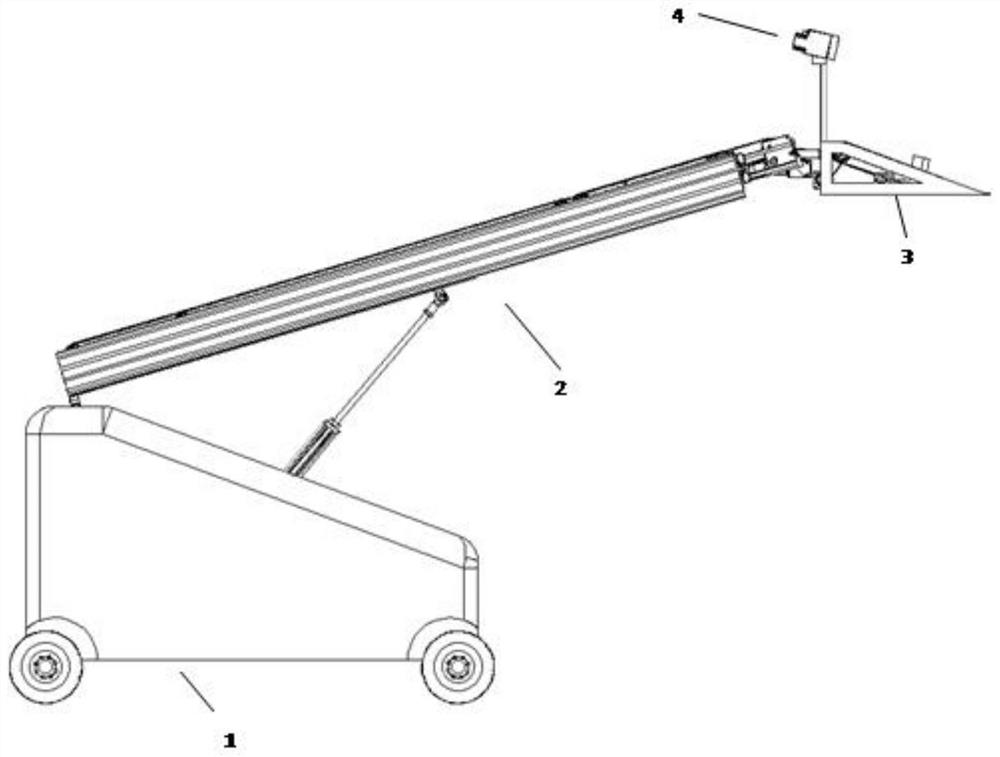

Intelligent loading and unloading vehicle system based on visual servo

A technology of visual servoing and loading and unloading trucks, which is applied in the direction of loading/unloading, motor vehicles, and object stacking, etc. It can solve the problems of unsuitable moving spaces for palletizers, and achieve the effect of compact structure and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] Specifically, the process of unstacking the goods 11 from the van compartment 10 and transferring the goods to the platform for stacking is as follows:

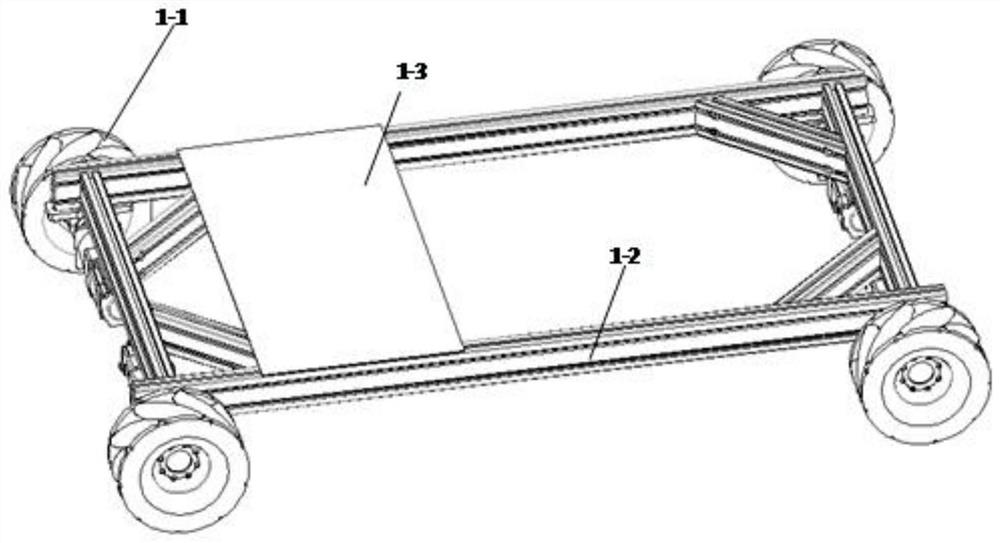

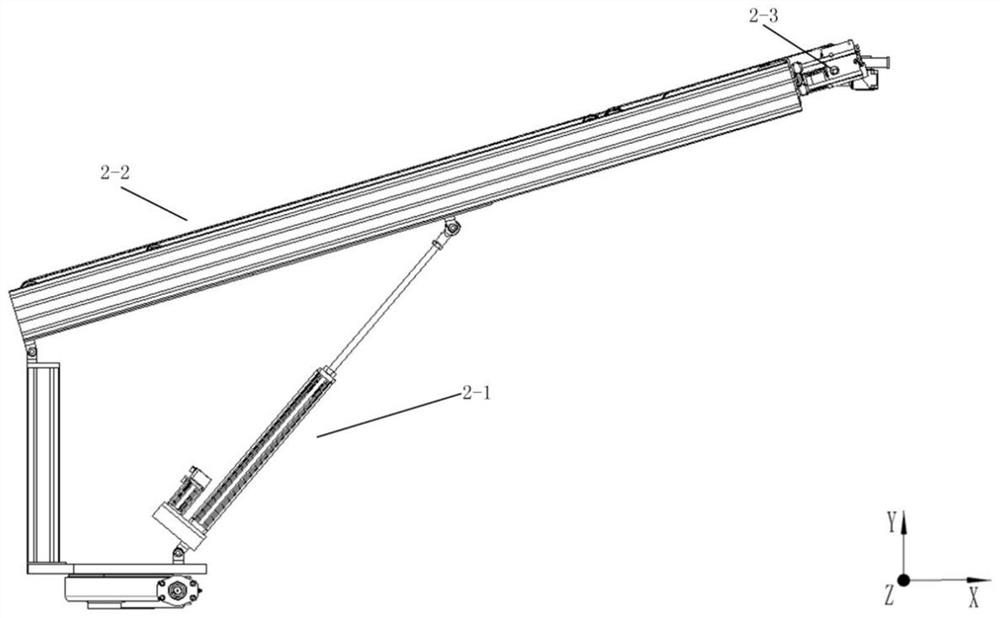

[0142] After the loading and unloading robot enters the compartment, the loading and unloading robot is moved to the designated position by the AGV trolley 1, and the multi-station camera viewing angle adjustment device captures the image information in the van in the top view mode, top down shooting mode or / and side shooting mode , based on the image information, when the posture adjustment device receives an instruction, it first rotates the chassis to drive the posture adjustment device to rotate, and pushes the first transmission device on the connecting plate and the posture adjustment device on the first transmission device to pitch through the push rod; After pitching and rotating, the first deceleration motor cooperates with the rack, so that the guide rail drives the connecting plate and the first deceleration ...

Embodiment 2

[0151] The goods are unpacked from the platform and transported to the van compartment 10 for stacking of the goods 11. The specific process is as follows:

[0152] The unpacking of palletizing mechanism 5 is similar to the stacking process,

[0153] After the three-coordinate machine 5-2 is adjusted in the X' axial direction, the goods 11 to be unstacked are placed on the material code tray 5-1-8, and are fed by the drum assembly 5-1-6. At this time, the second camera 5-4 on the top of the frame of the three-coordinate machine 5-2 obtains the specific image data of the goods to be unstacked, outputs the position and attitude information of the goods to the control background, and controls the translation in the direction of the Y' axis The lifting motor 5-2-5 of motor 5-2-21 and Z axis direction is adjusted. The translation motor 5-2-21 controls the movement in the direction of the Y' axis, and adjusts the grabbing mechanism to be directly above the goods to be unstacked. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com