Patents

Literature

212results about How to "Avoid teleportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

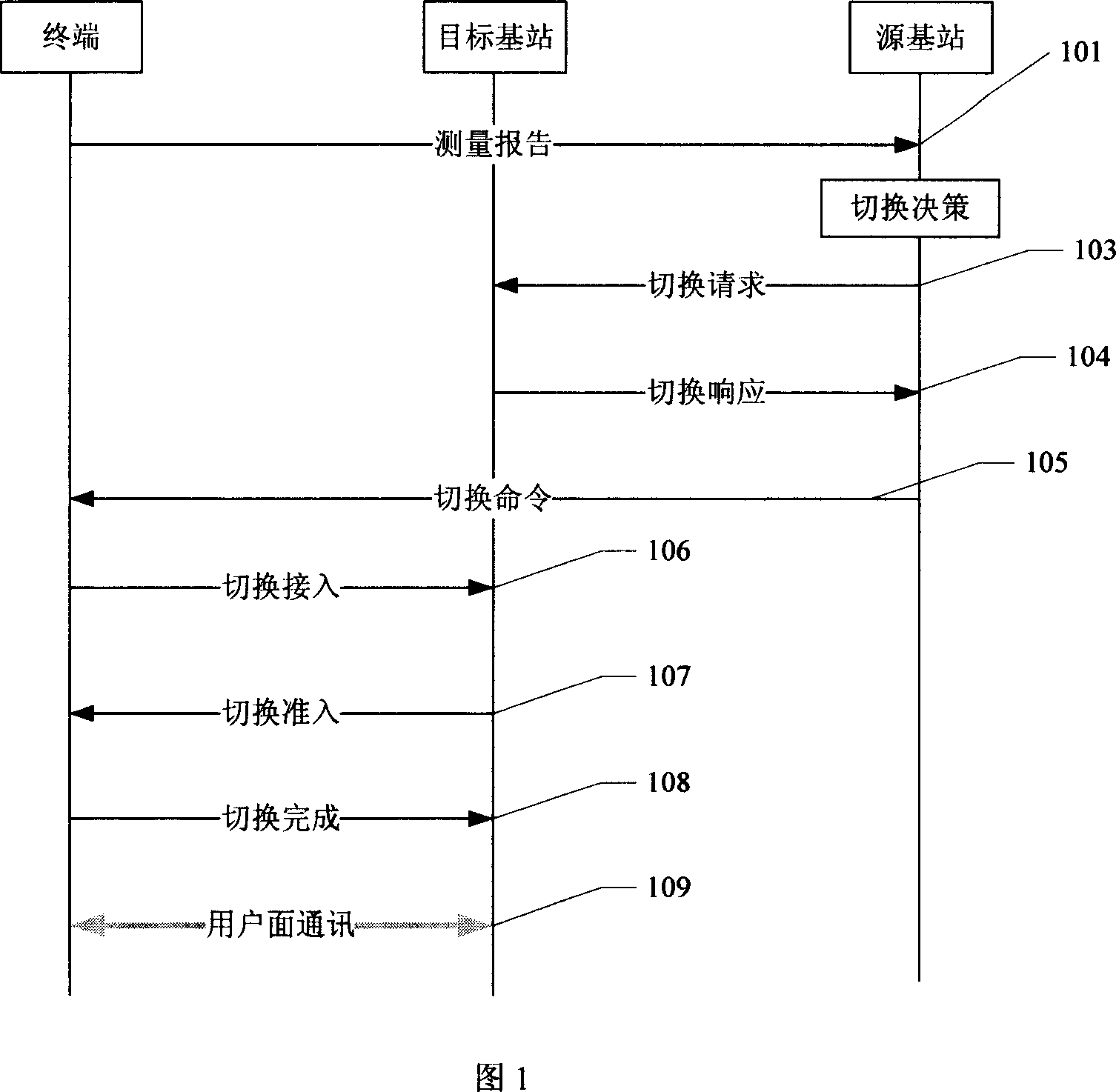

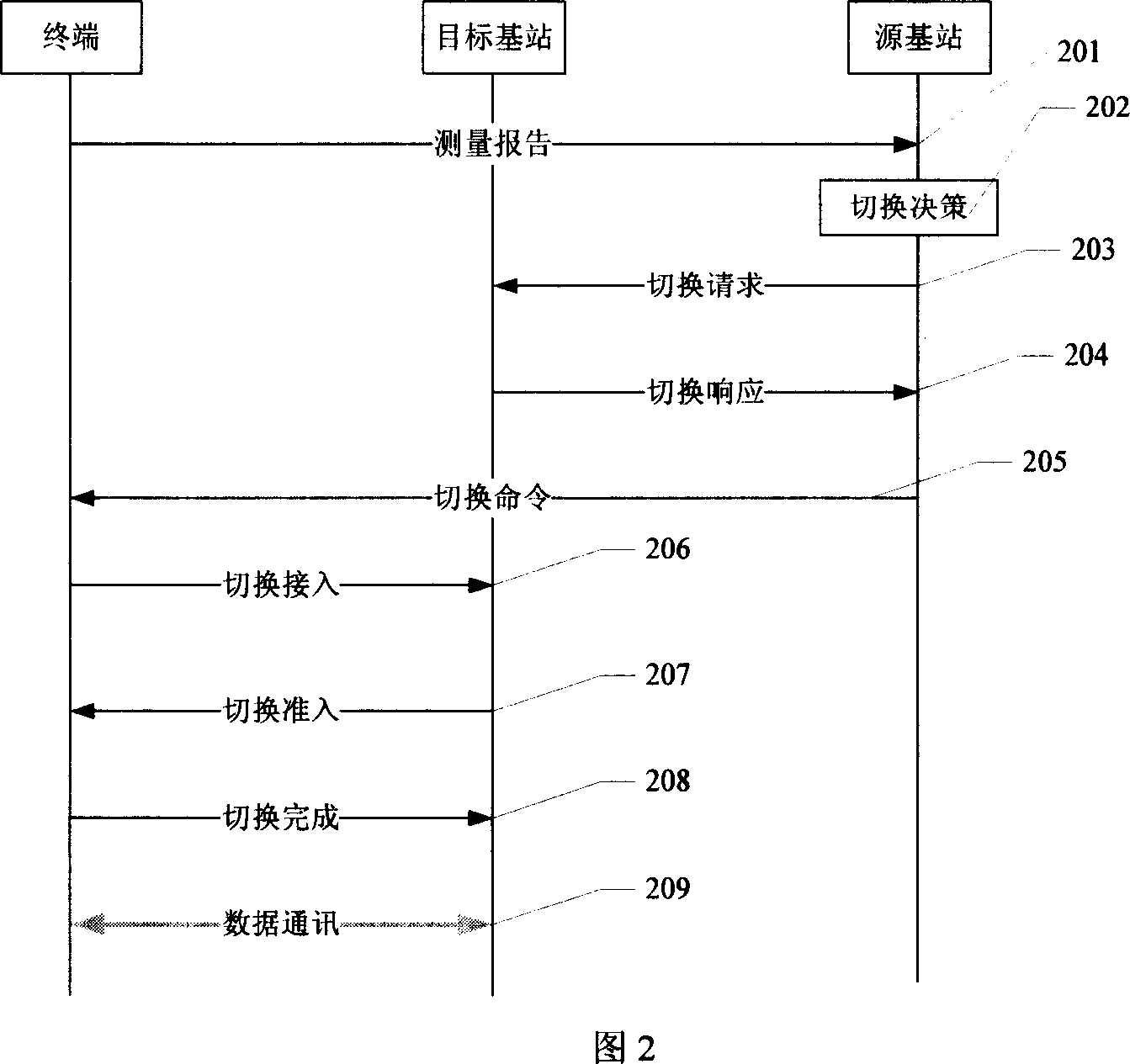

Method for switching uplink random channel or sharing channel between mobile communication systems

InactiveCN101064943AAvoid teleportationHigh speedRadio/inductive link selection arrangementsWireless communicationControl channelMobile communication systems

The invention discloses a switching method for ascending random channel or shared channel between base stations of mobile communication system. The aim of invention is used to solve the problems that the reliable coding can not be used caused by the complicated switch method and complicated switch accessing message. The invention includes: when the base stations need to be switched, target section distributes ID identify code and preserves source for terminals; target section sends the switch messages by control channels in source section; the messages include at least ID identify codes for terminals, source allocating information of target section and ascending dispatching messages; the terminals send switching commands to target base station according to switching command messages. The switching flow is terse, and reduces the switching time, and the reduced switching access messages can be presented by more bytes, and the switching access messages can use the reliable coding technology, and the receiver of base station can decode easily.

Owner:无锡中太数据通信股份有限公司

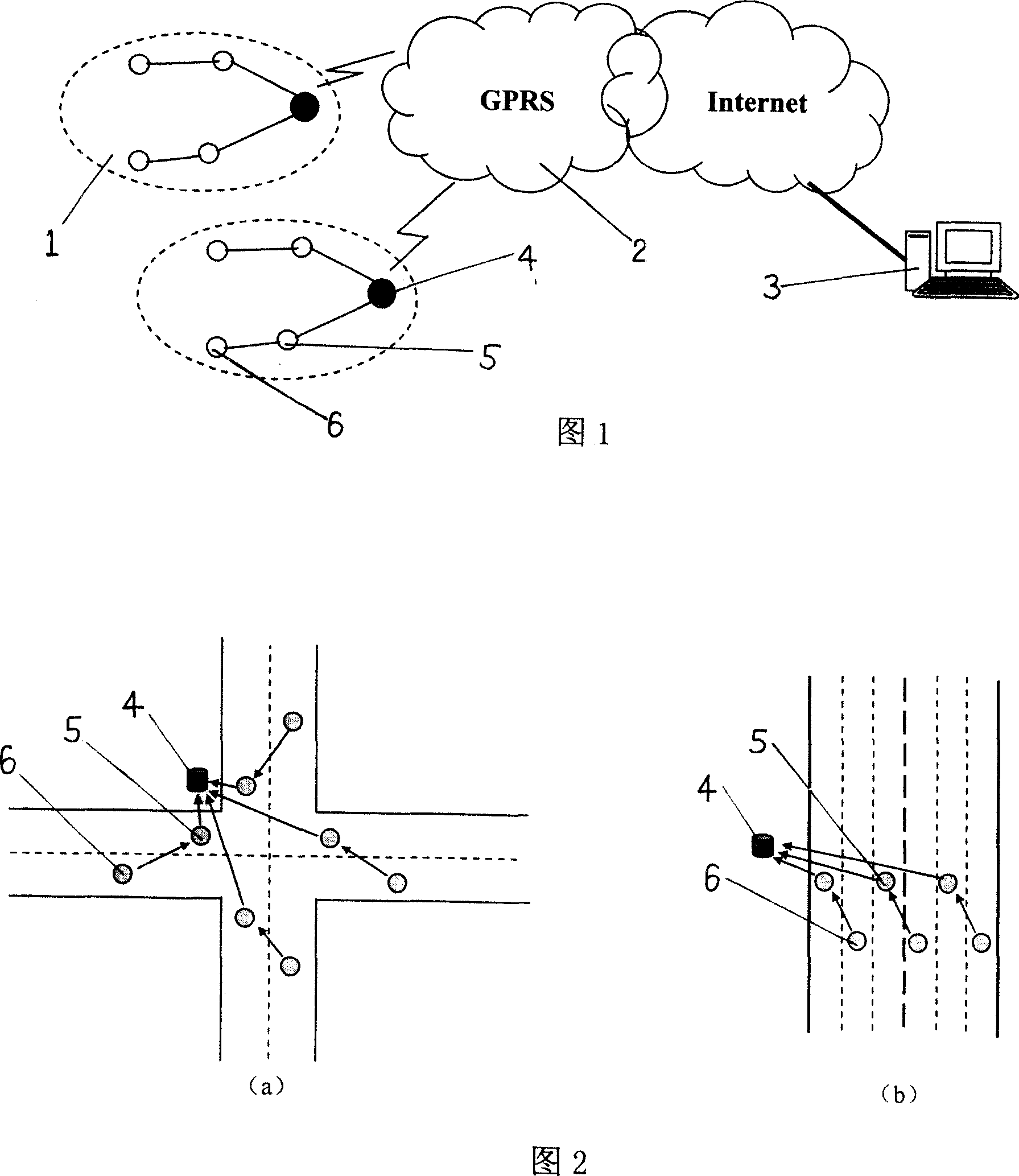

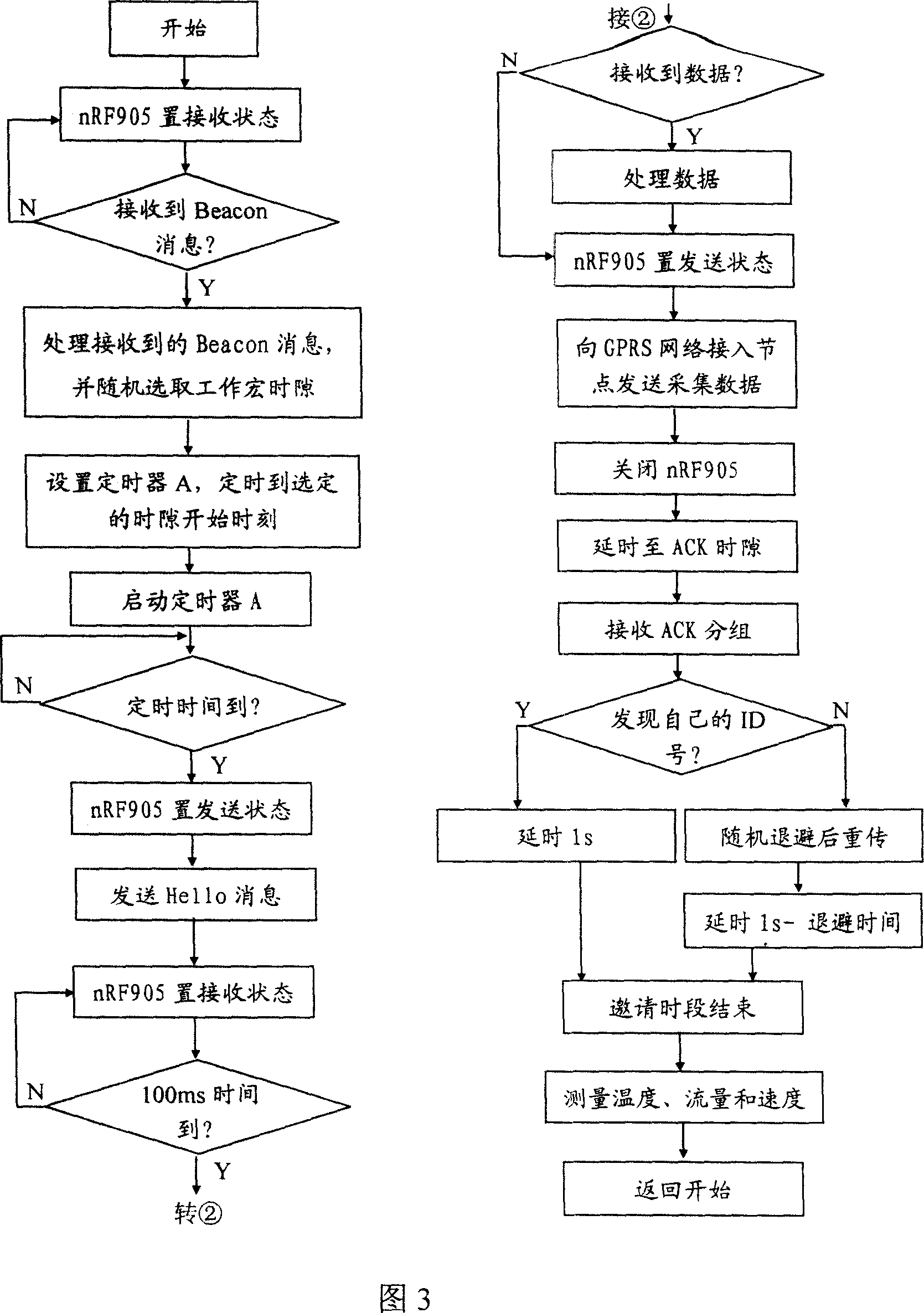

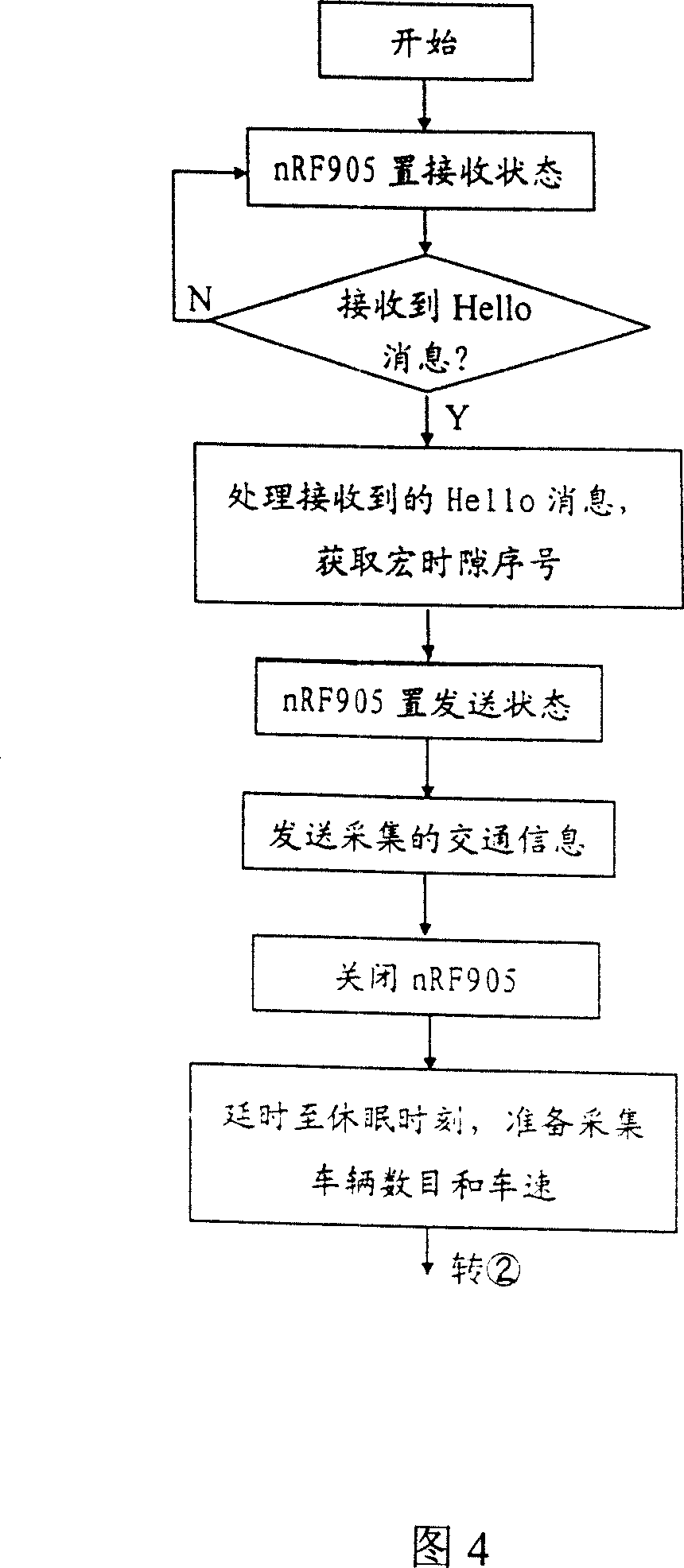

System of monitoring road traffic

InactiveCN101004859AExpand the scope of monitoringRealize large-scale monitoringDetection of traffic movementRadio/inductive link selection arrangementsTraffic capacityNetwork on

A monitoring system of road traffic is prepared for erecting radio transducer on lanes to measure traffic flow rate and driving speed and to transmit measured information to control node, organized control node and radio transducer distributed at a region to be a multi-jump star type of network being used to obtain information from radio transducer node network on one hand and on the other hand to send obtained information to control center through GPRS communication module.

Owner:DALIAN CHANGFU RUIHUA GRP CO LTD

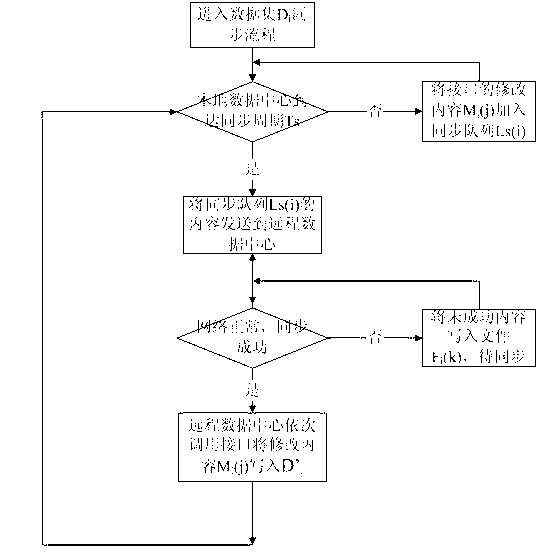

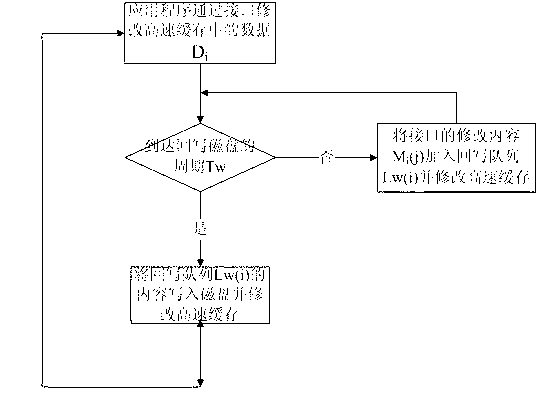

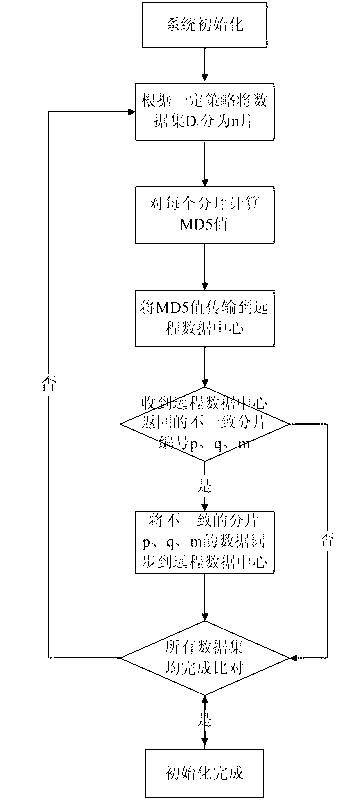

Method for synchronizing wide area data between data centers based on cache

ActiveCN103023879AImprove synchronization efficiencyOccupies less bandwidthTransmissionWide areaComplete data

The invention discloses a method for synchronizing wide area data between data centers based on a cache. The method is characterized by comprising the following steps of: (1) initializing synchronous systems, namely filling data frequently accessed by the systems into a memory according to the configuration by a server of a local data center, communicating with each remote data center required to be synchronized, comparing the difference of the data, and then performing synchronization; (2) performing read-write access on the data, namely directly reading and writing the cache in the memory through an interface, and writing the data in the memory into a hard disk by one or more independent threads in a service program of a background; and (3) performing remote synchronization on the data, namely periodically and directly synchronizing the contents called and modified by the interface from the memory to a remote data center, and executing the same interface calling by the remote data center to complete data synchronization. The method has the advantages of high synchronizing efficiency, small occupied bandwidth, high reliability, good transplantability and simple deployment, and solves the problem of inconsistency of other abnormities when the systems run.

Owner:NARI TECH CO LTD

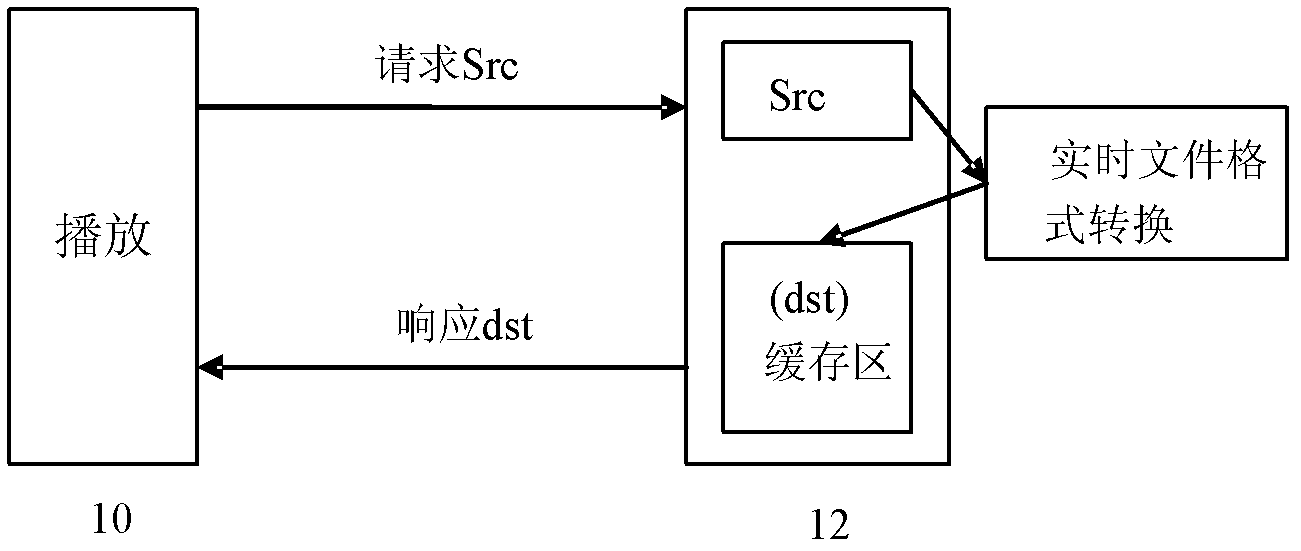

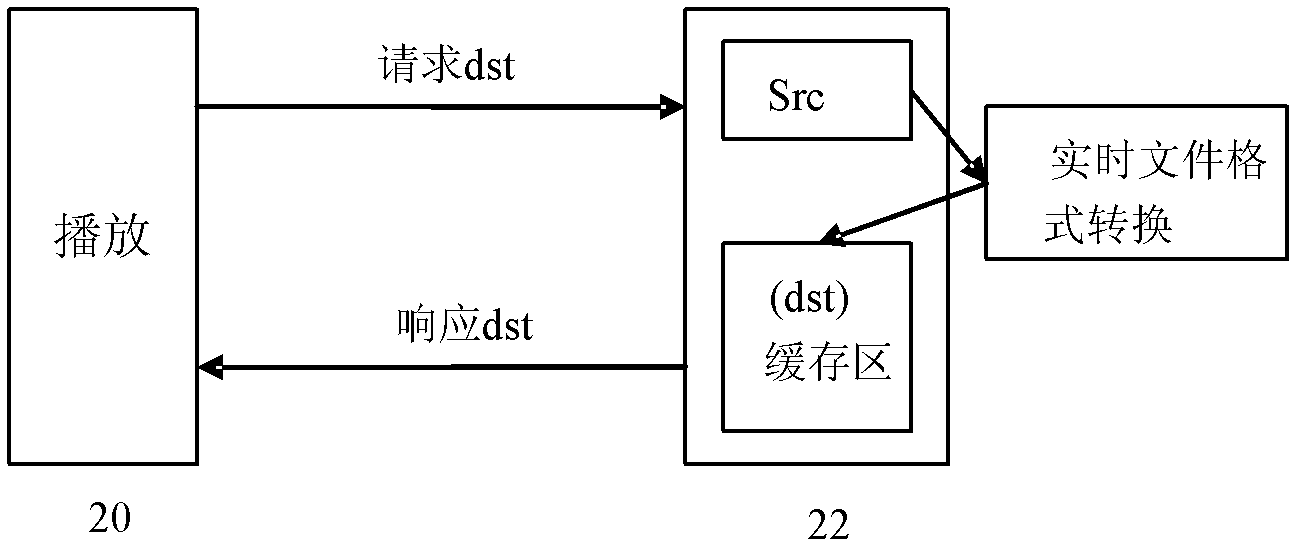

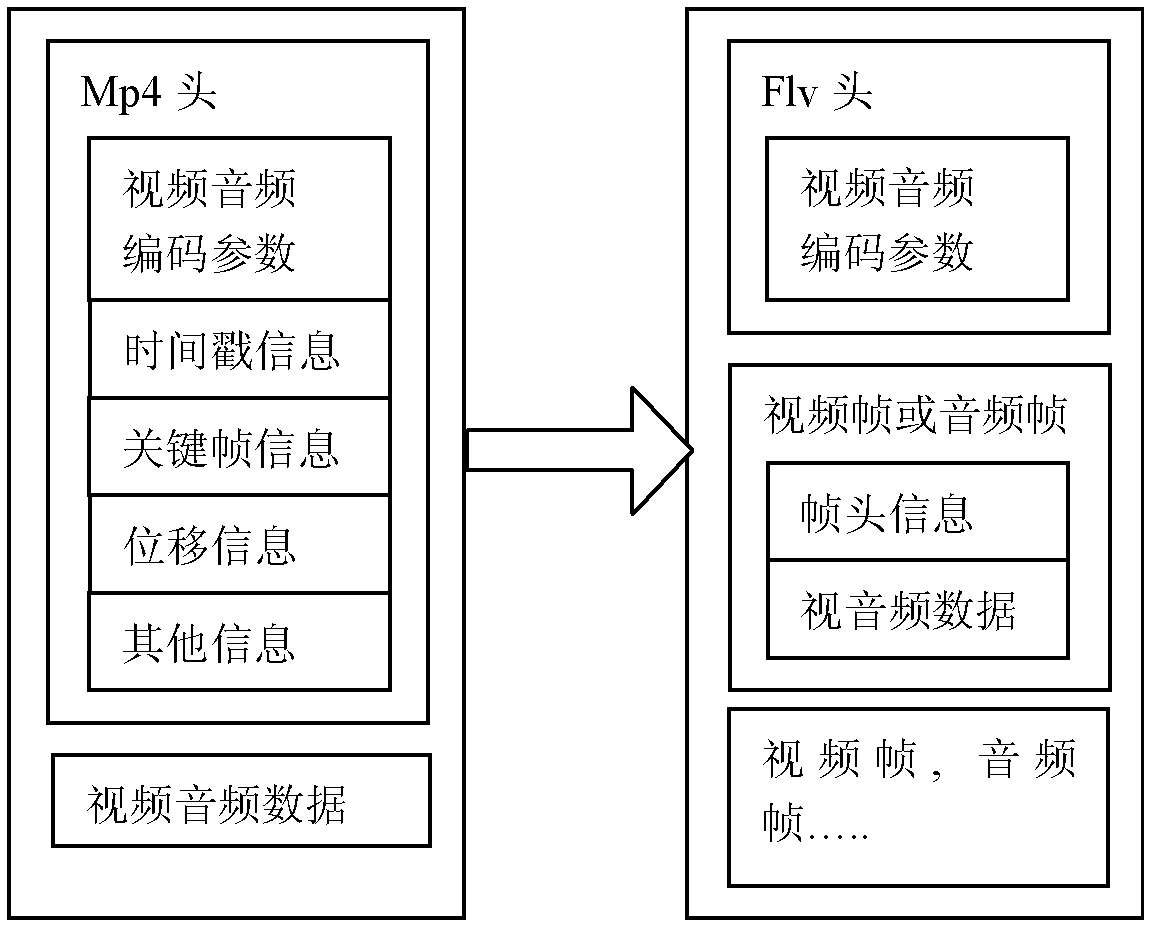

Method and system for optimizing media-on-demand based on real-time file format conversion

ActiveCN102256162AAvoid teleportationFast response timeTelevision systemsSelective content distributionClient-sideFile transfer

The invention discloses a method and system for optimizing media-on-demand based on real-time file format conversion, and realizes transmission of a small data set video file header through quick file format conversion, so that the repeated multiplexing of a file by a server can be realized. The method adopts a technical scheme as follows: a client transmits an http request of a file to a server; and after receiving the http request, the server analyzes the http request to find out the file corresponding to the http request; and after determining that the network broadcasting quality of the file is lower than an expected value, the server starts real-time file format conversion, converts the data encapsulation format of the file to maintain basic coding and decoding information in accordance with file transmission in a file header, and transmits the file subjected to the data encapsulation format conversion to the client to play.

Owner:CHINANETCENT TECH

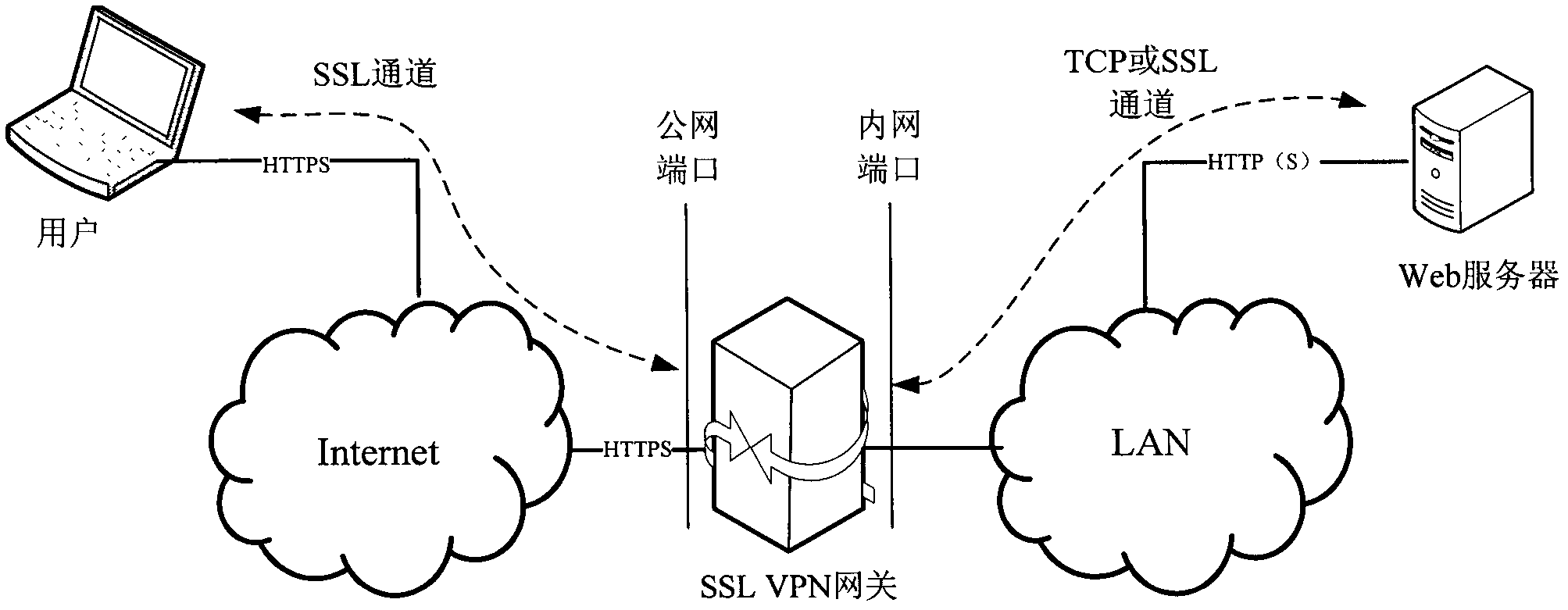

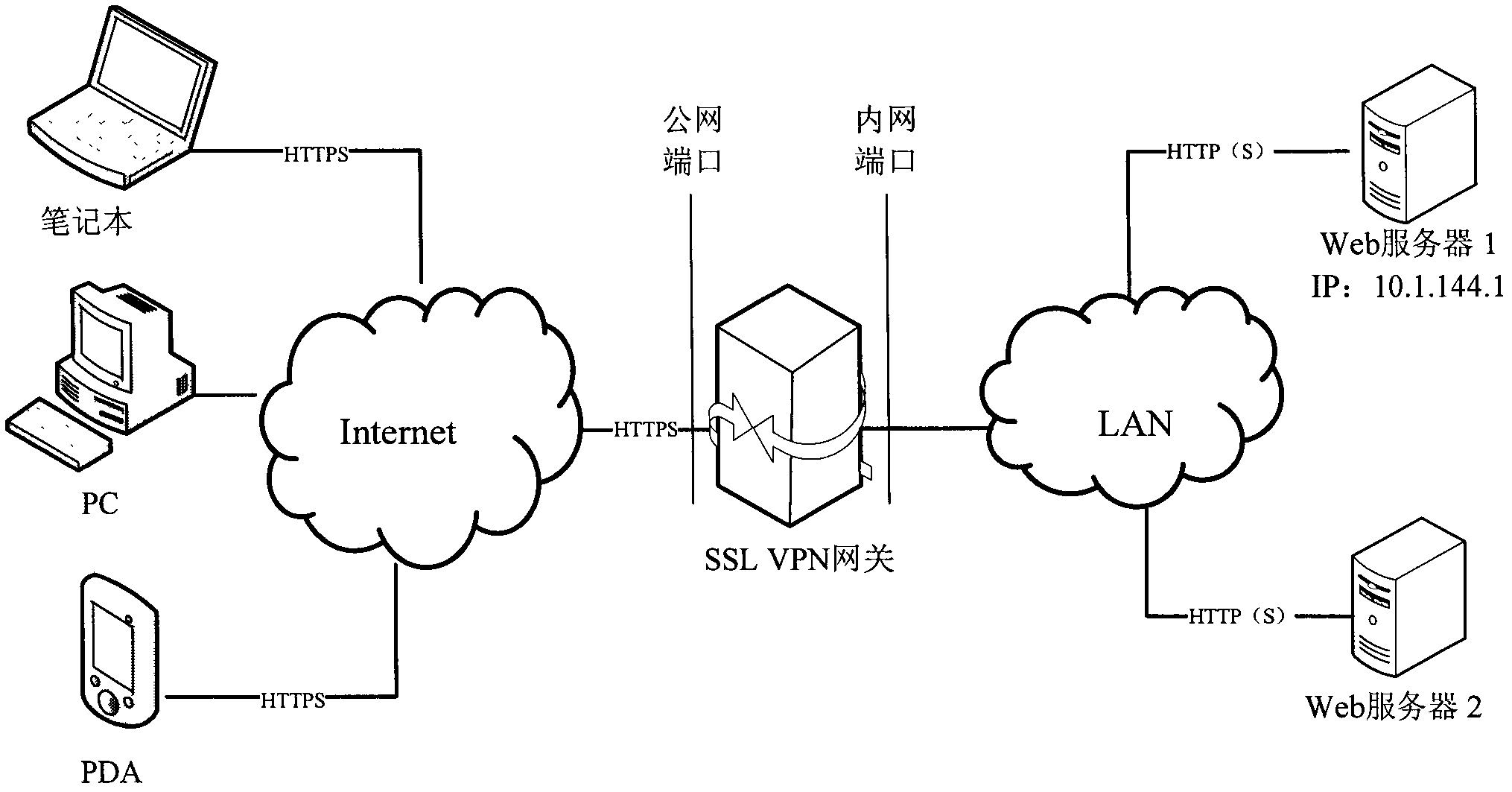

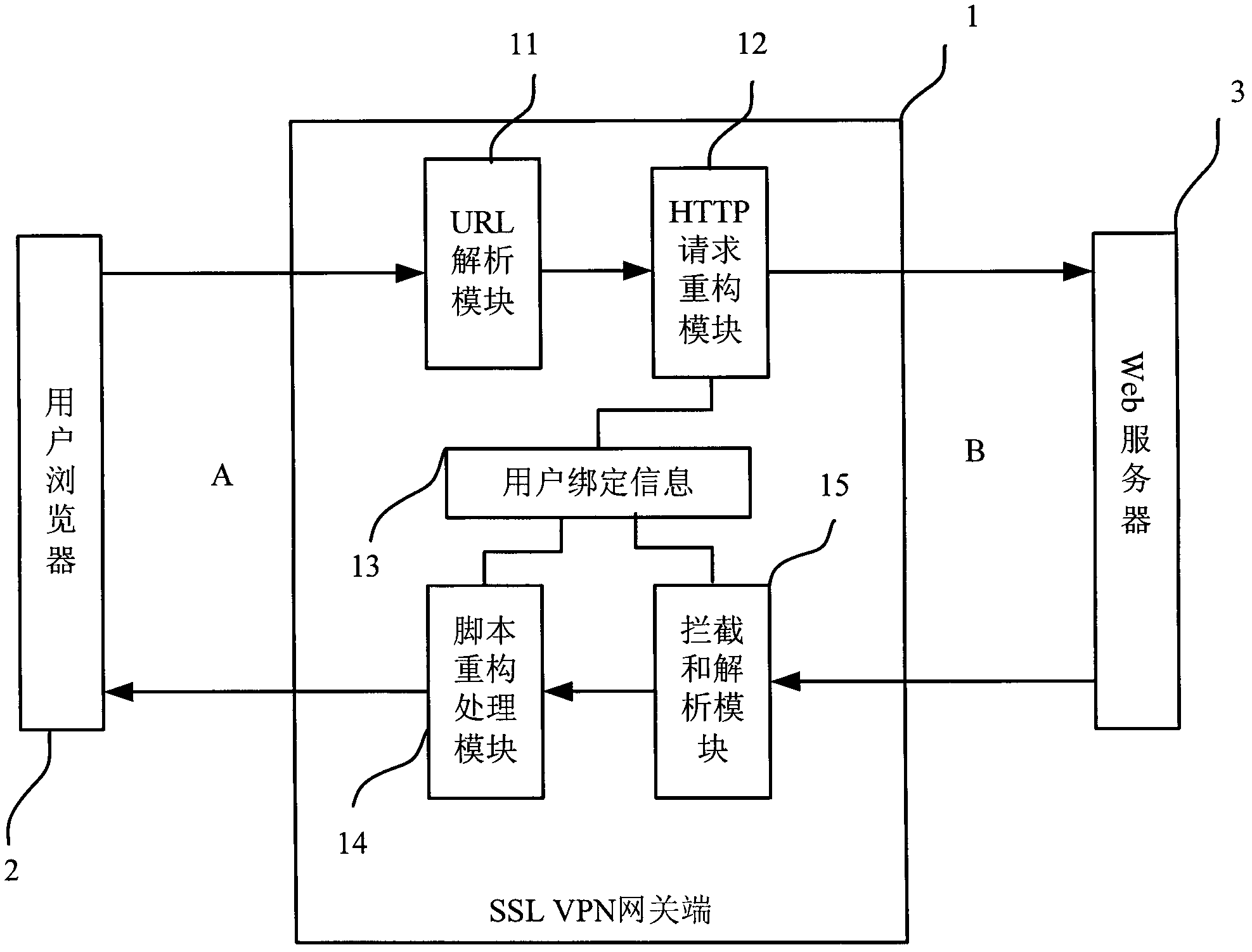

SSL VPN equipment-based Web resource authentication information management method

ActiveCN101977224AAvoid teleportationSafety managementNetworks interconnectionDomain namePrivate network

The invention discloses a method for safely managing Web resource authentication information at a gateway end in a unified way when the web resource is accessed based on security socket layer virtual private network (SSL VPN) remote accessing equipment. In the method, web resource access authentication cookie information is saved at the gateway end of the SSL VPN and the content is reconstructed, so that the operation of the cookie by a script in the page content of a browser end can be updated to the gateway end in real time, and the correctness of cookie processing is ensured; the method breaks through the limitation of a browser on the cookie number of the same domain name and the length of a cookie item, so that the authenticated web resource of gateway configuration does not need to be limited to the browser end in cookie; and the authenticated cookie information of gateway intranet resource is not leaked to a public network and the intranet resource is protected well.

Owner:北京神州数码云科信息技术有限公司

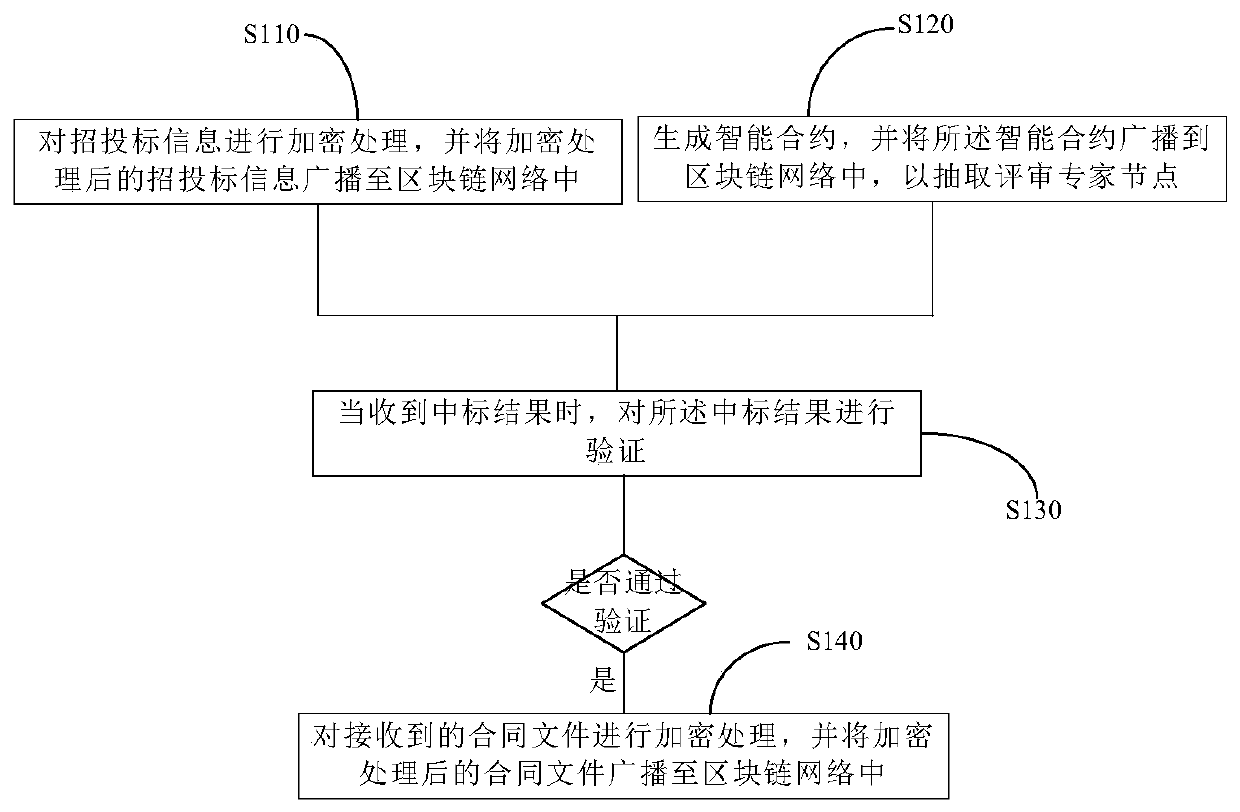

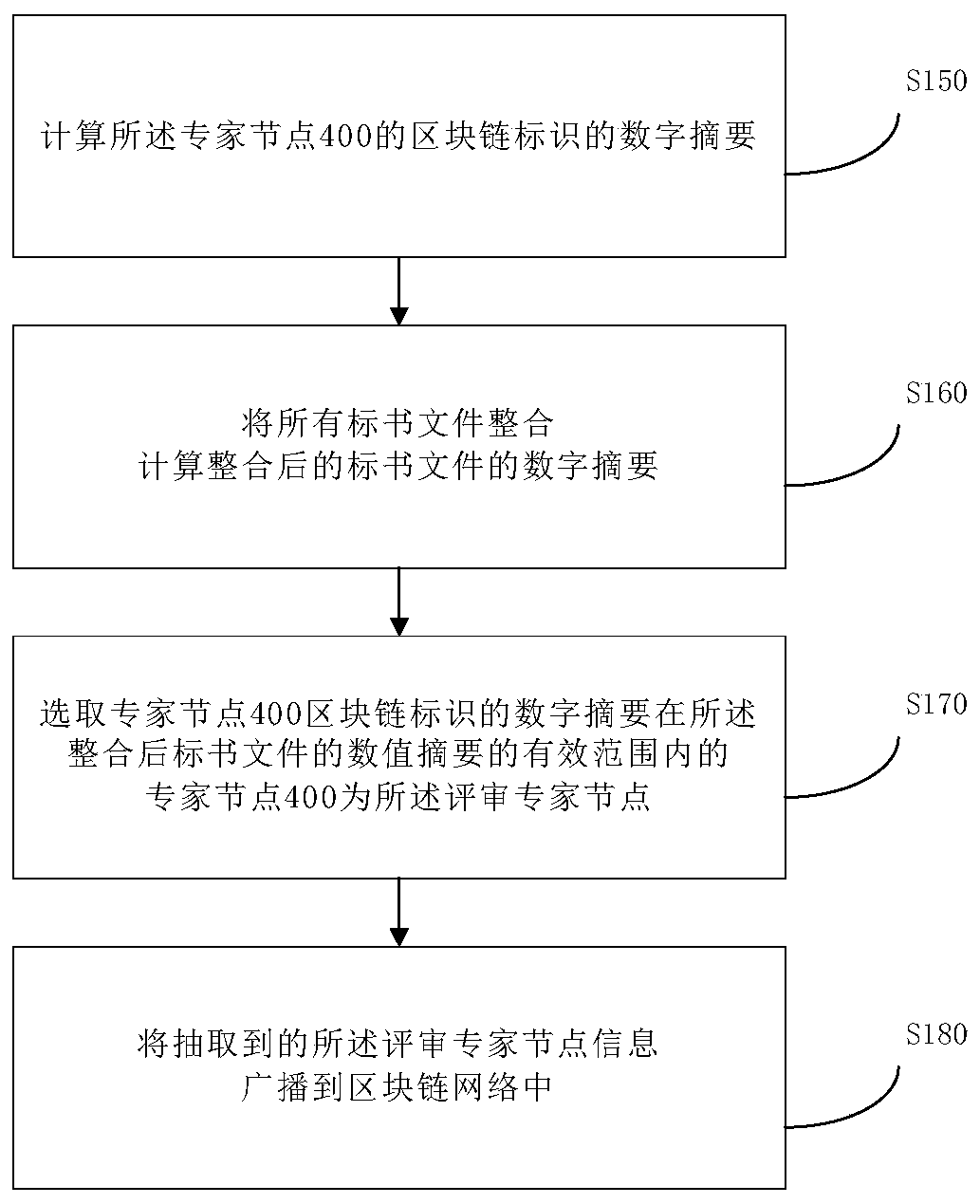

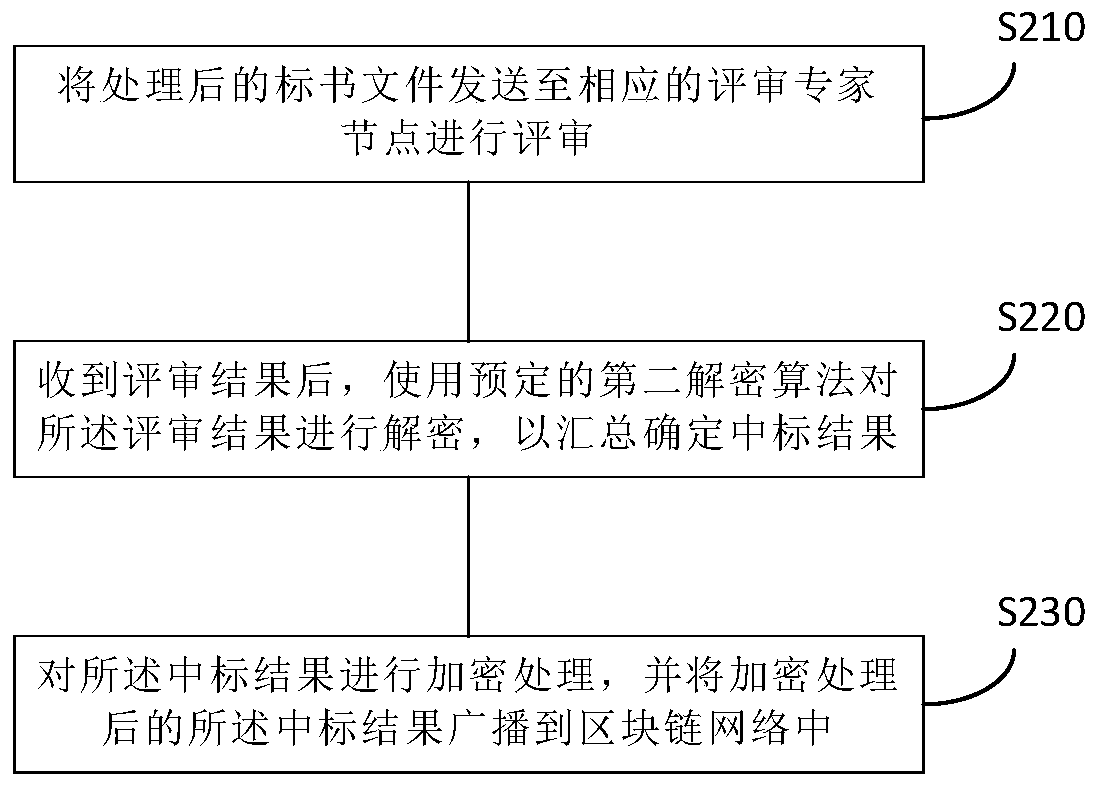

Bidding information, supervision information and bid evaluation information processing method, terminal and system

InactiveCN110751544AHigh transparencyAvoid lostDigital data protectionCommerceInformation processingComputer network

The invention provides a bidding and tendering information processing method and terminal based on a block chain, a bidding and tendering supervision information processing method and terminal, a bidevaluation information processing method and terminal and a bidding and tendering system based on the block chain. The block chain comprises a bidding node, a bidding node, an expert node and a supervision institution node, and the bidding information processing method comprises the following steps: encrypting bidding information, and broadcasting the encrypted bidding information to a block chainnetwork; generating an intelligent contract, and broadcasting the intelligent contract to the blockchain network to extract review expert nodes; and when a bid winning result is received, verifying the bid winning result, if the verification is passed, encrypting the received contract file, and broadcasting the encrypted contract file to the blockchain network. According to the invention, the transparency of bidding and tendering is improved, and heavy loss caused by tampering of bidding and tendering information is avoided.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

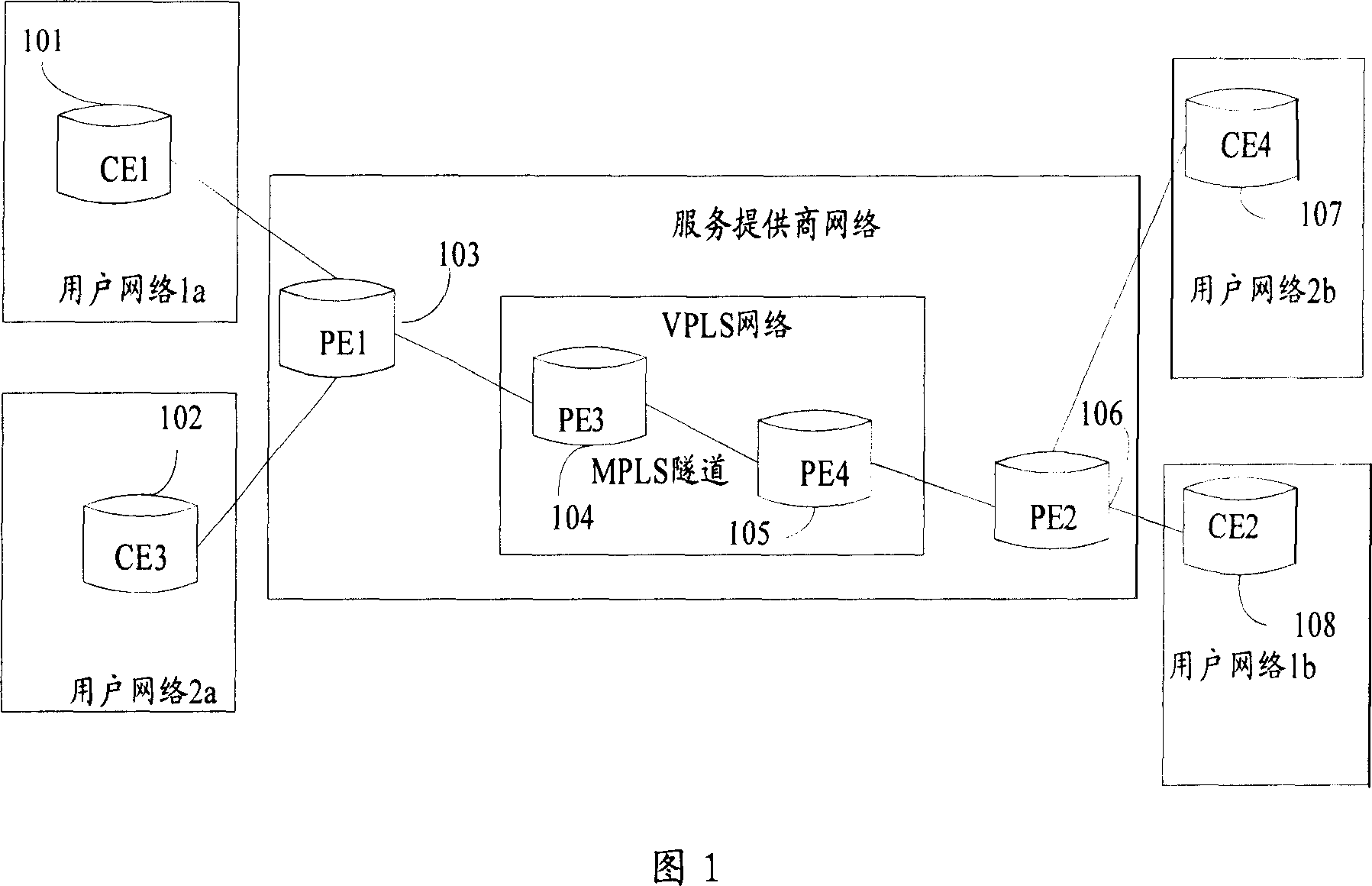

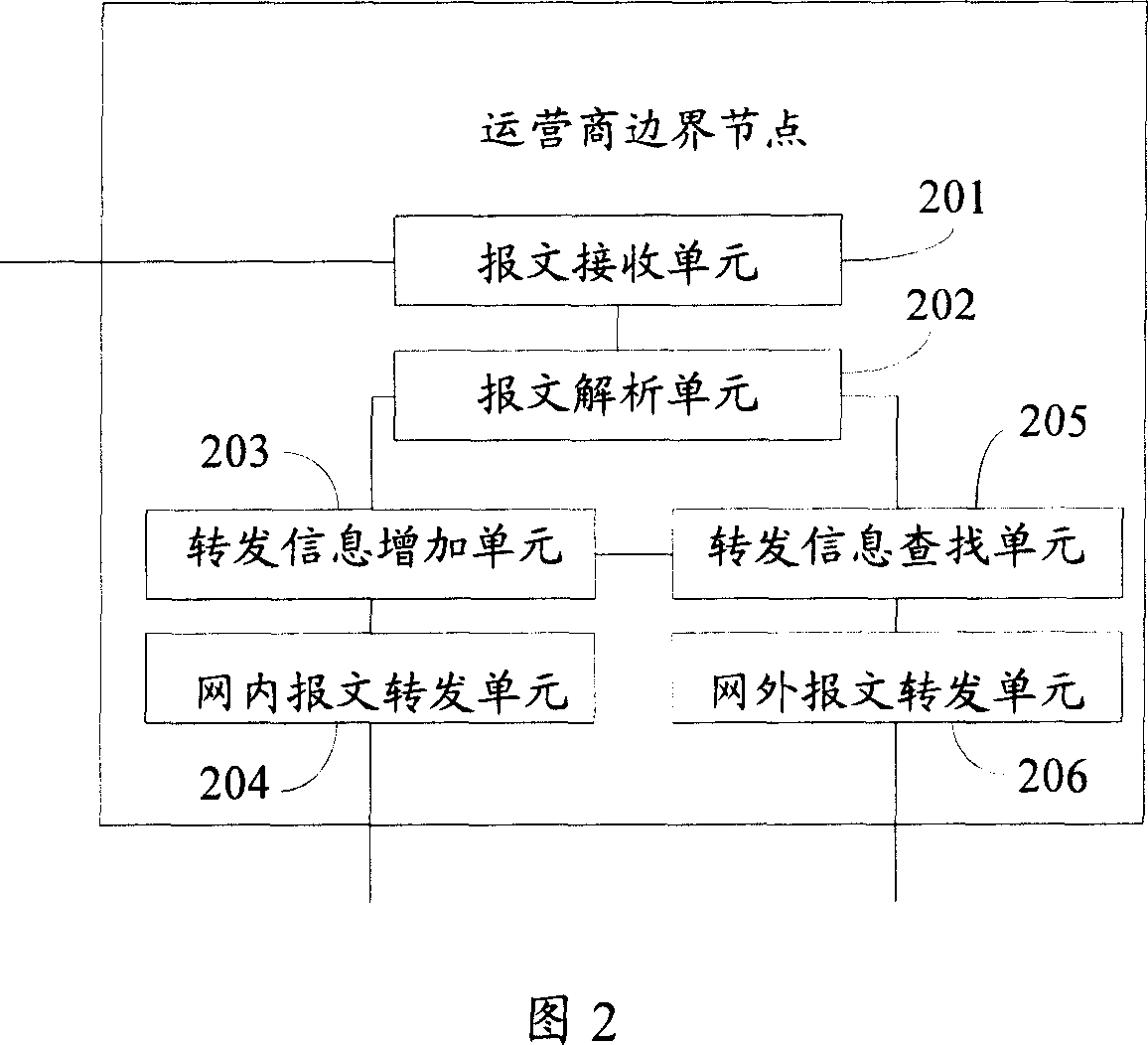

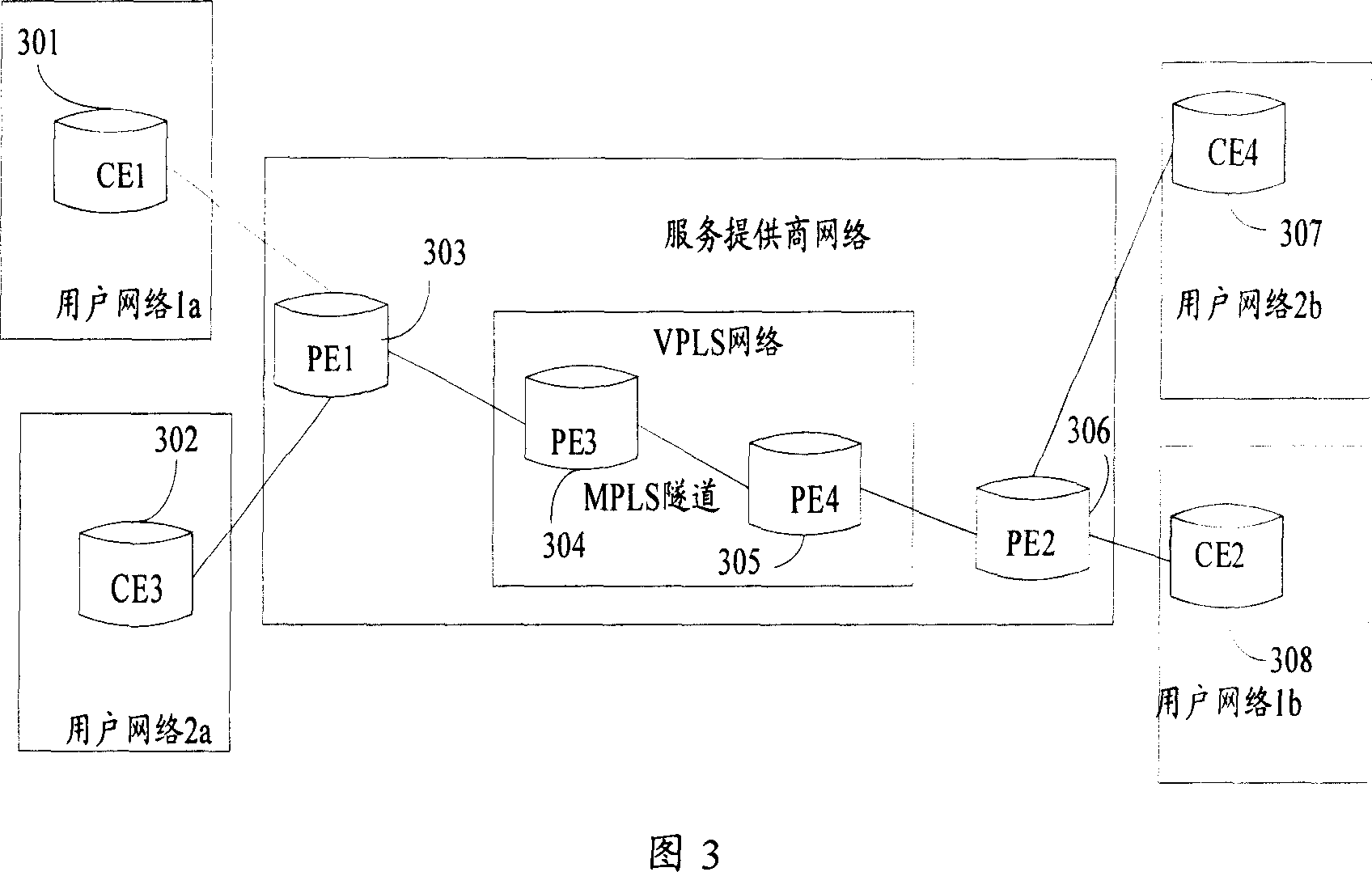

Operator's boundary notes, virtual special LAN service communication method and system

InactiveCN1929444AImprove securityReduce the number of message copiesData switching networksPoint of entryLocal area network

This invention discloses one operator boundary point, virtual special local network communication method and system, wherein the method comprises the following steps: symmetric interfacing virtual special local network service user point to entrance operator by QinQ form type to analyze message two layers of head and common labels; according to analysis head part and common label adding relative transfer information in self MAC transfer list and sending the message tot eh operator boundary point; exit operator boundary point receives message to analyze label and sends the message to user point; user boundary point analyzes private network label.

Owner:HUAWEI TECH CO LTD

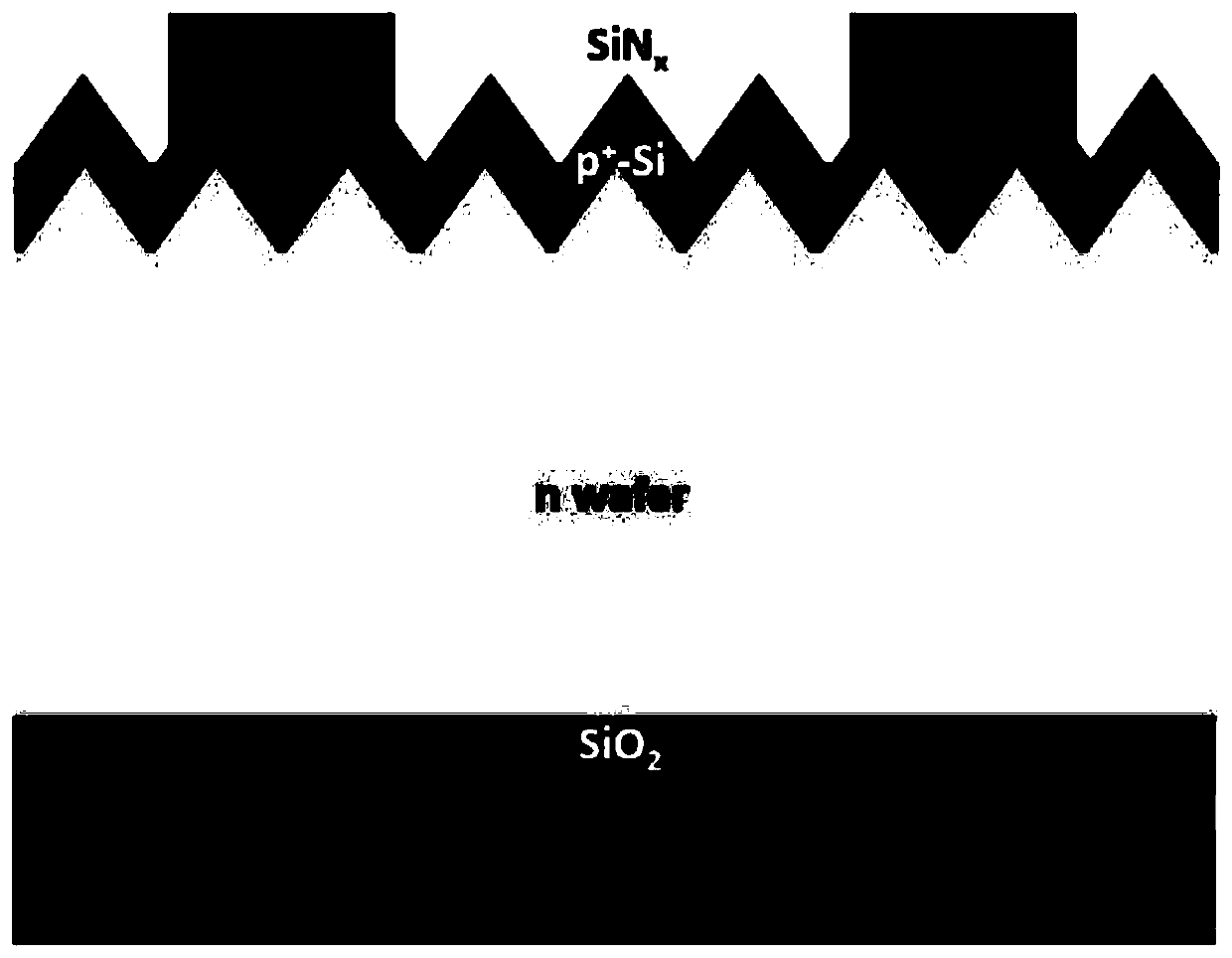

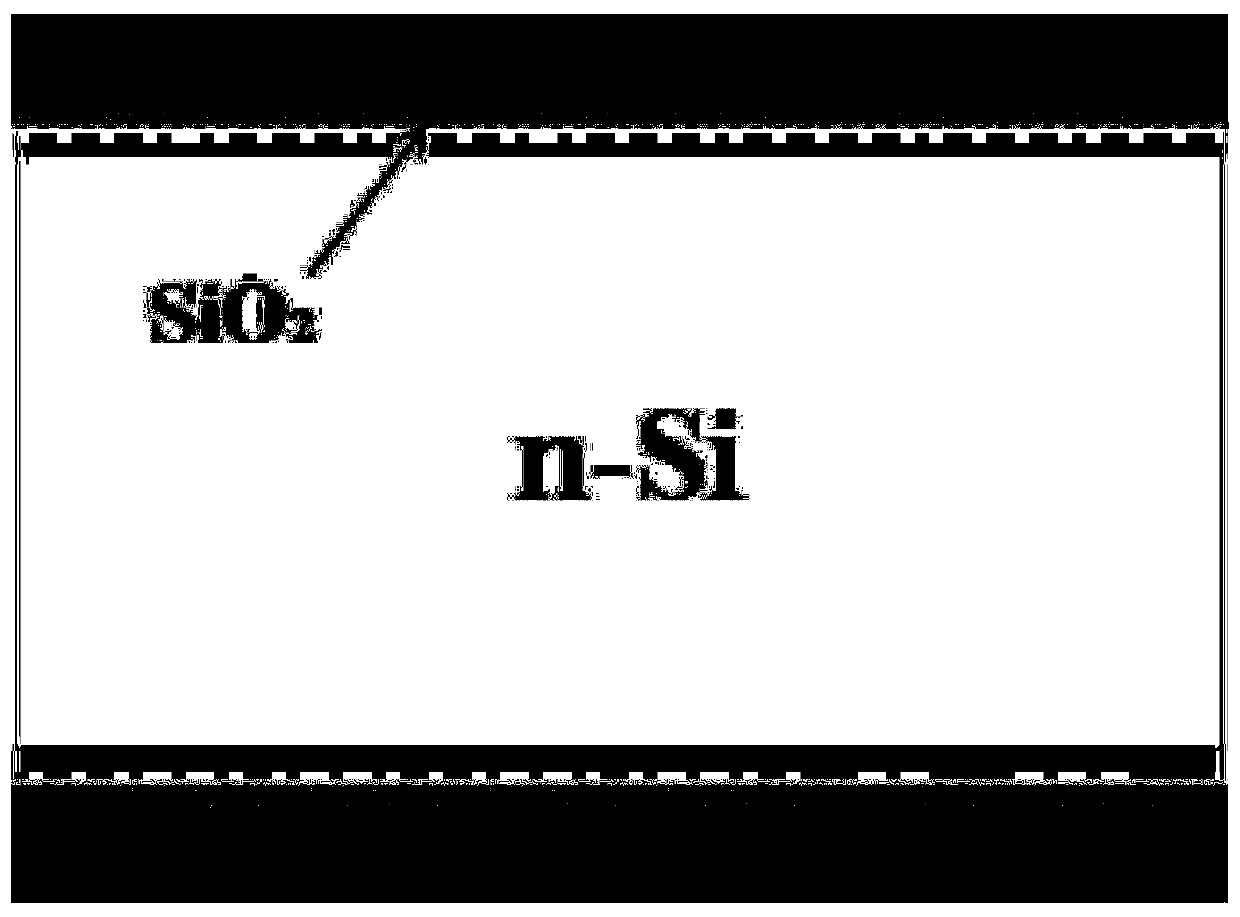

Method for preparing polycrystalline silicon passivation contact structure through tubular PECVD

ActiveCN109802007ACore process steps are reducedReduce the number of processesFinal product manufacturePhotovoltaic energy generationAmorphous siliconNitride

The invention discloses a method for preparing a polycrystalline silicon passivation contact structure through tubular PECVD. The method includes the following steps that: a doped amorphous silicon film is prepared on the surface of an oxide and / or nitride of silicon through adopting the tubular PECVD; and a polycrystalline silicon passivation contact structure is obtained through high-temperaturecrystallization annealing. With the method of the invention adopted, a high-quality TOPCon structure can be prepared; the passivation efficiency of the TOPCon structure is completely equivalent to that of an LPCVD technology, in particular, the iVoc of an n-type silicon wafer adopting n-type TOPCon double-sided passivation can reach 720 to 750mV; and a production process can be greatly simplified.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

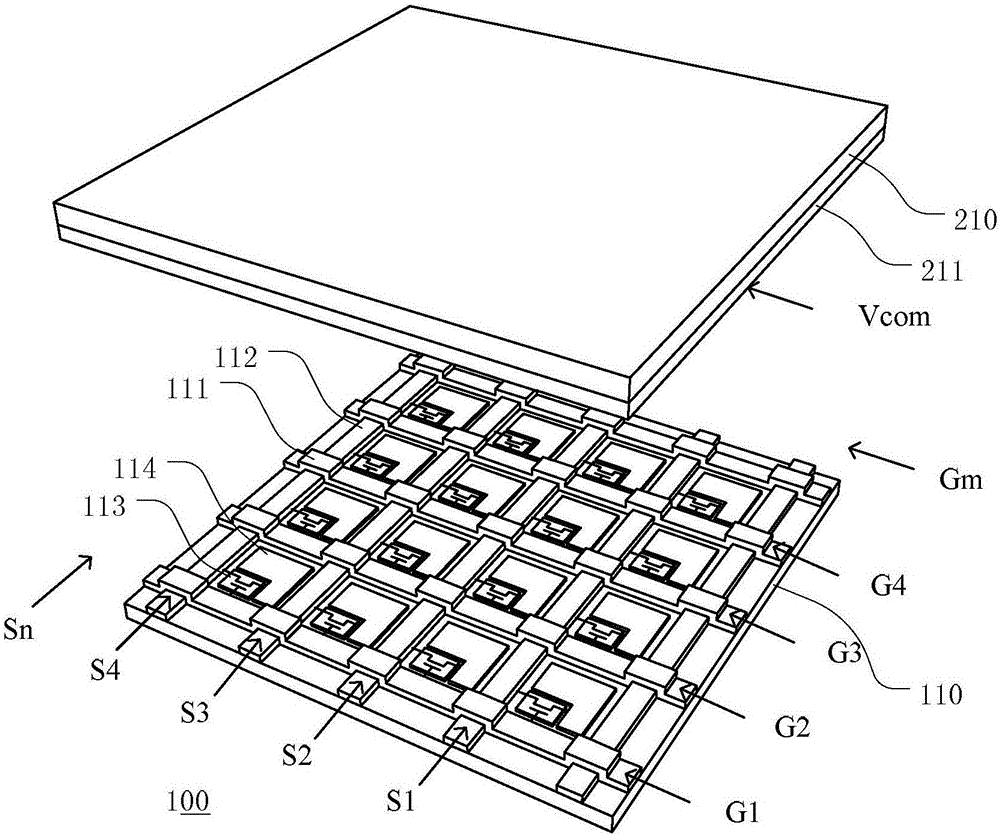

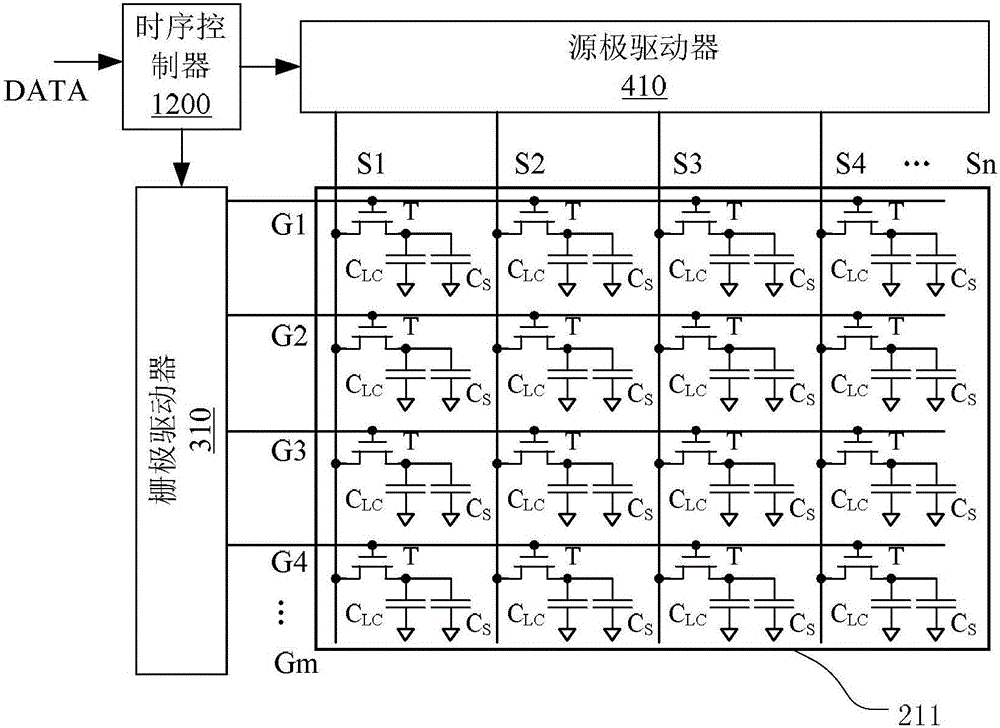

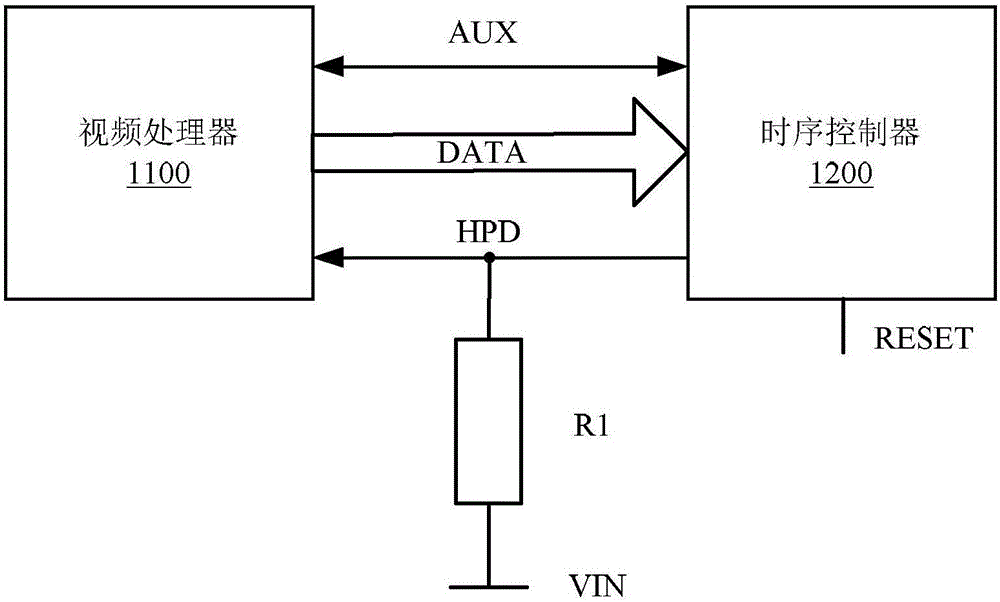

Liquid crystal display device and drive method thereof

ActiveCN106782410AAvoid teleportationPrevent image anomaliesStatic indicating devicesLiquid-crystal displayEngineering

The invention discloses a liquid crystal display device and a drive method thereof. The liquid crystal display device comprises a plurality of pixel units, a public electrode, a time sequence controller, a grid driver, a source driver and a state detecting circuit, wherein each pixel unit comprises a pixel electrode and a thin-film transistor which are connected with each other; pixel capacitors are formed between the public electrode and the pixel electrodes; the time sequence controller is used for generating a time sequence signal and a grayscale drive signal according to video data; the grid driver is used for gating the thin-film transistors of the pixel units; the source driver is used for providing grayscale voltage for the pixel electrodes; the state detecting circuit generates a state detecting signal according to the power supply voltage and reset signal of the time sequence controller, and the time sequence controller receives the video data when the state detecting signal is effective. The liquid crystal display device uses the reset signal of the time sequence controller to clamp the state detecting signal so as to prevent image abnormity.

Owner:KUSN INFOVISION OPTOELECTRONICS

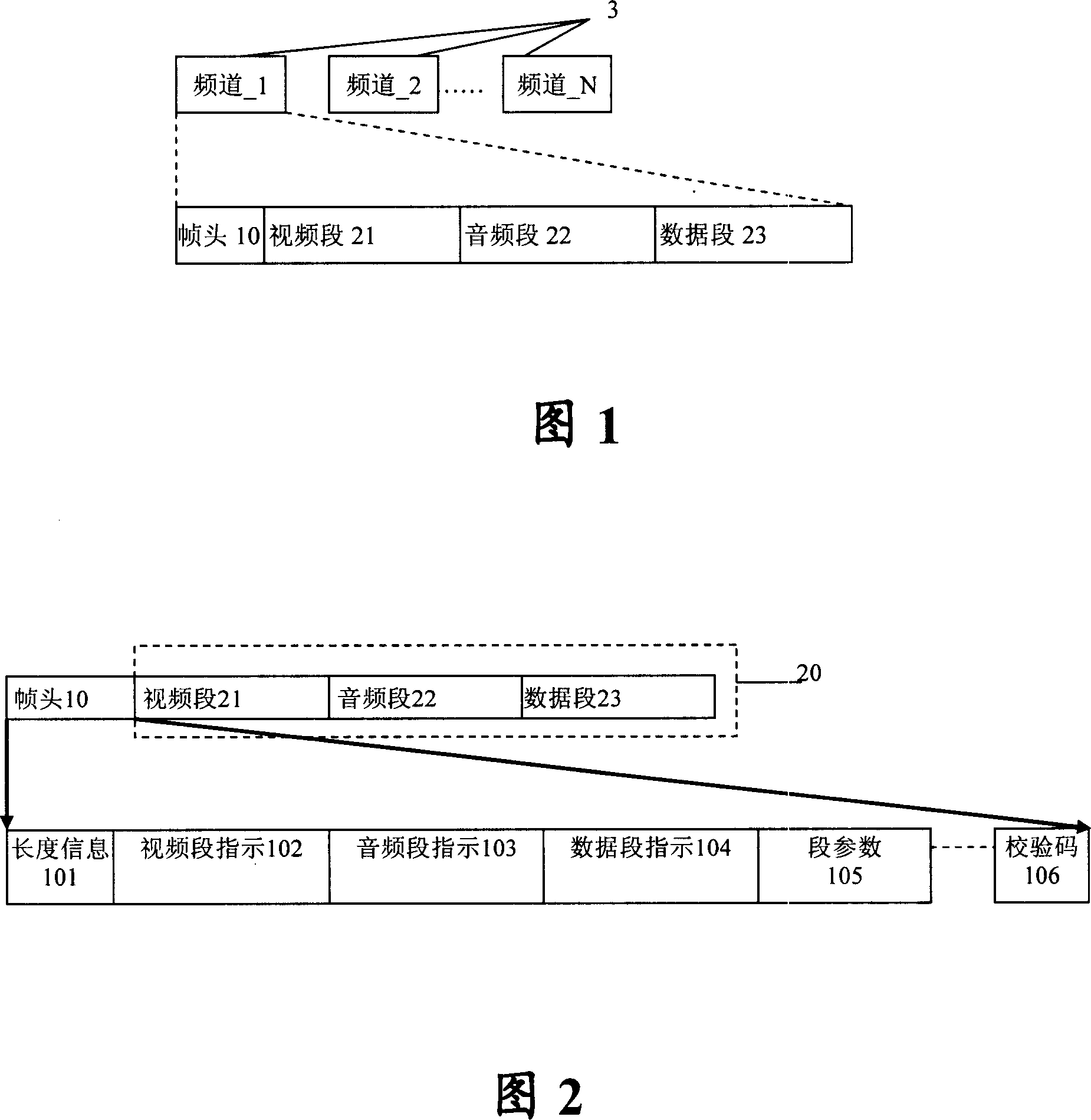

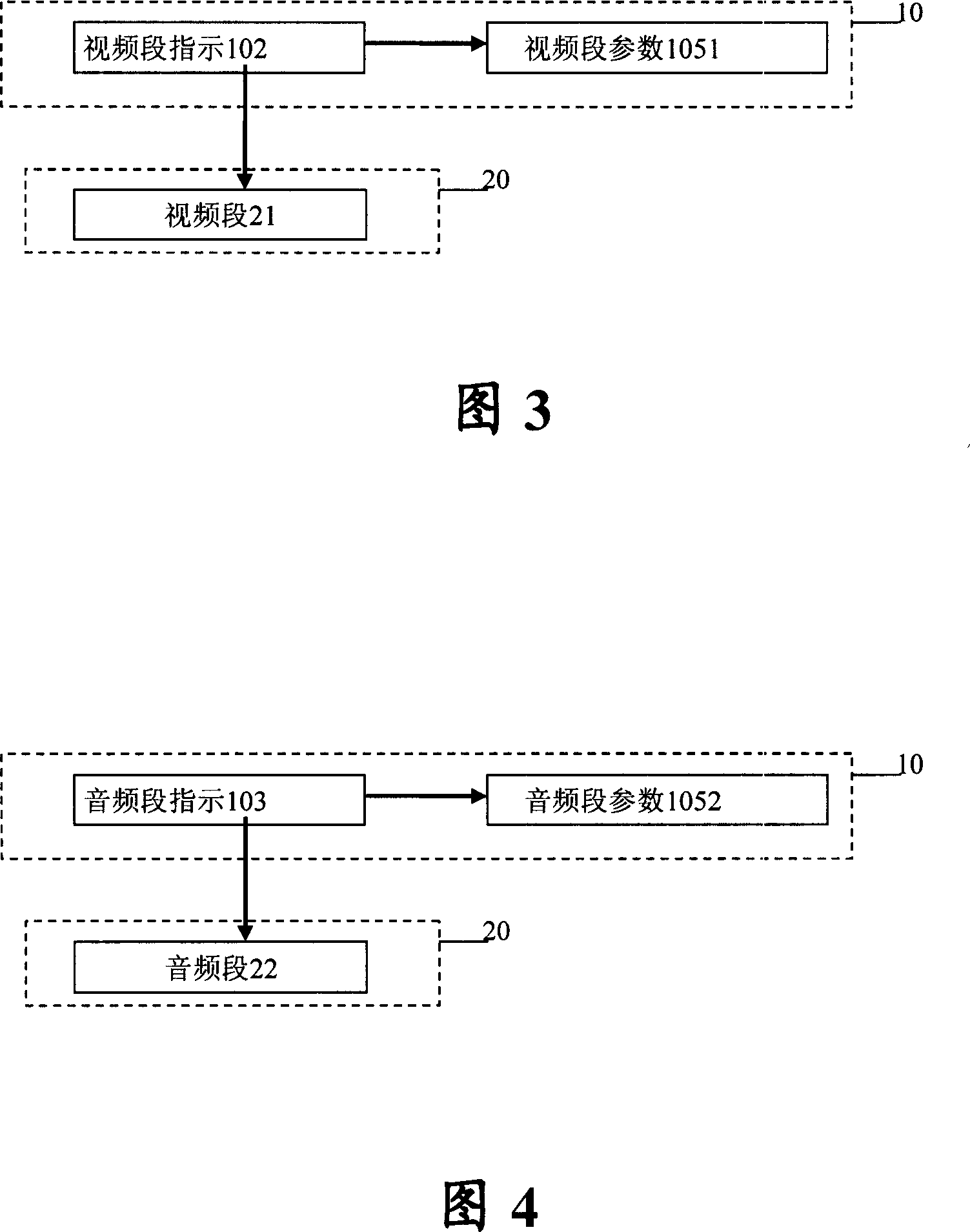

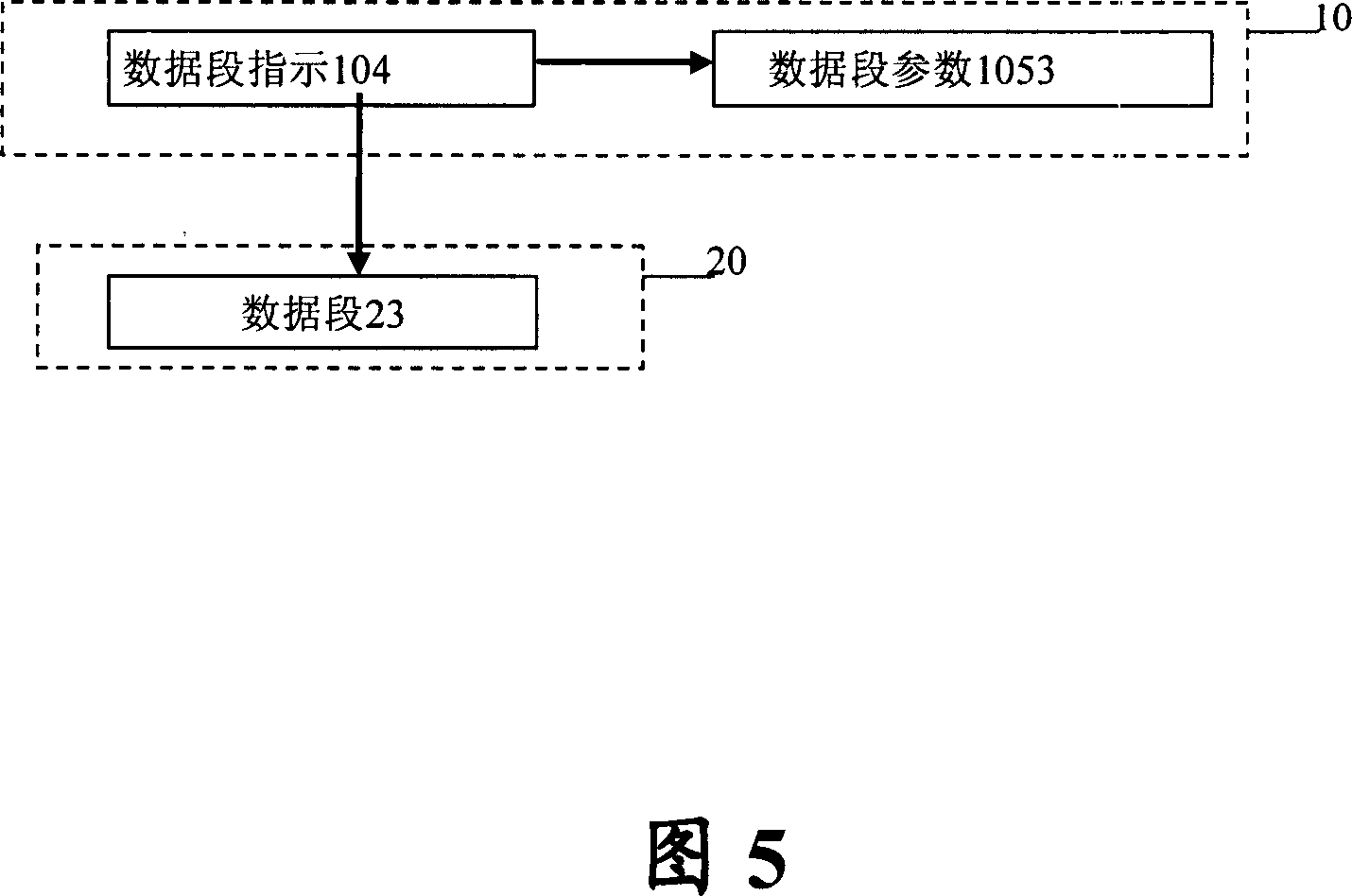

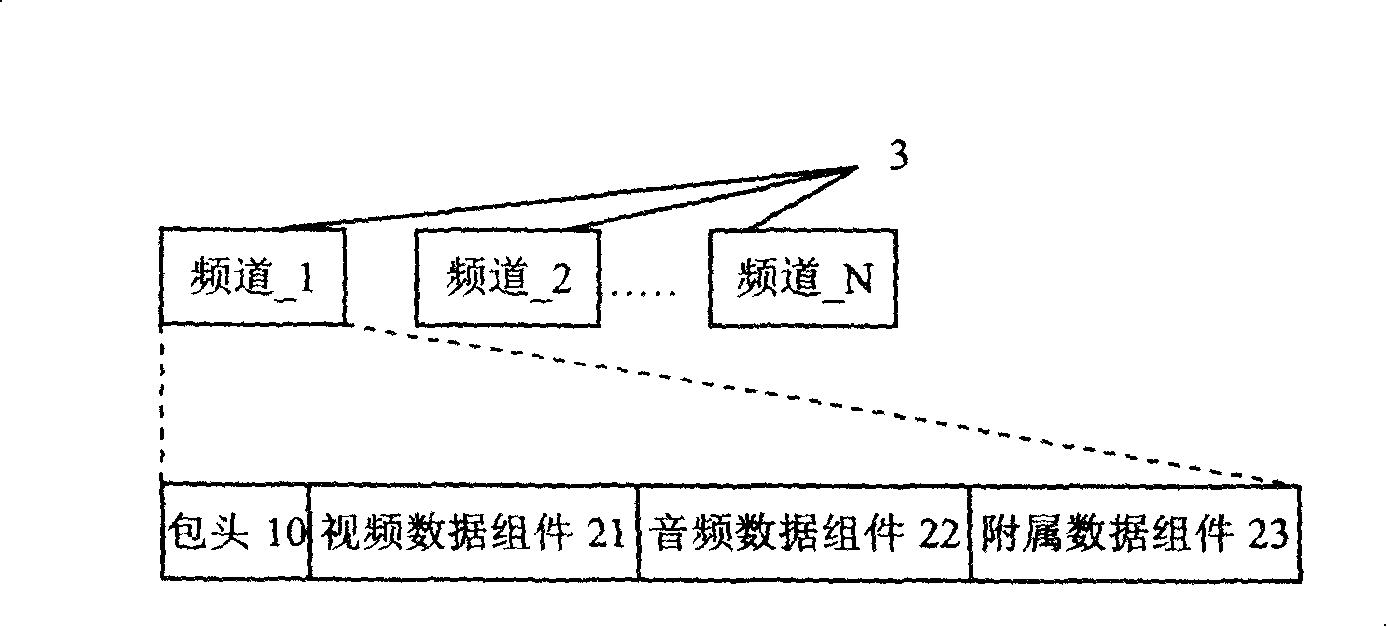

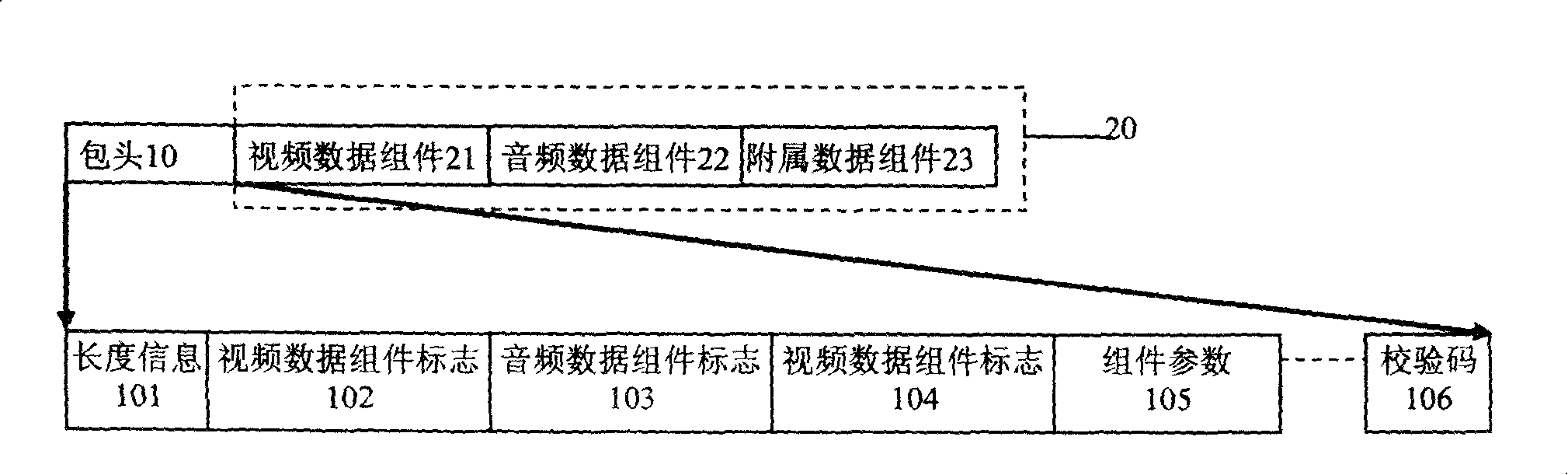

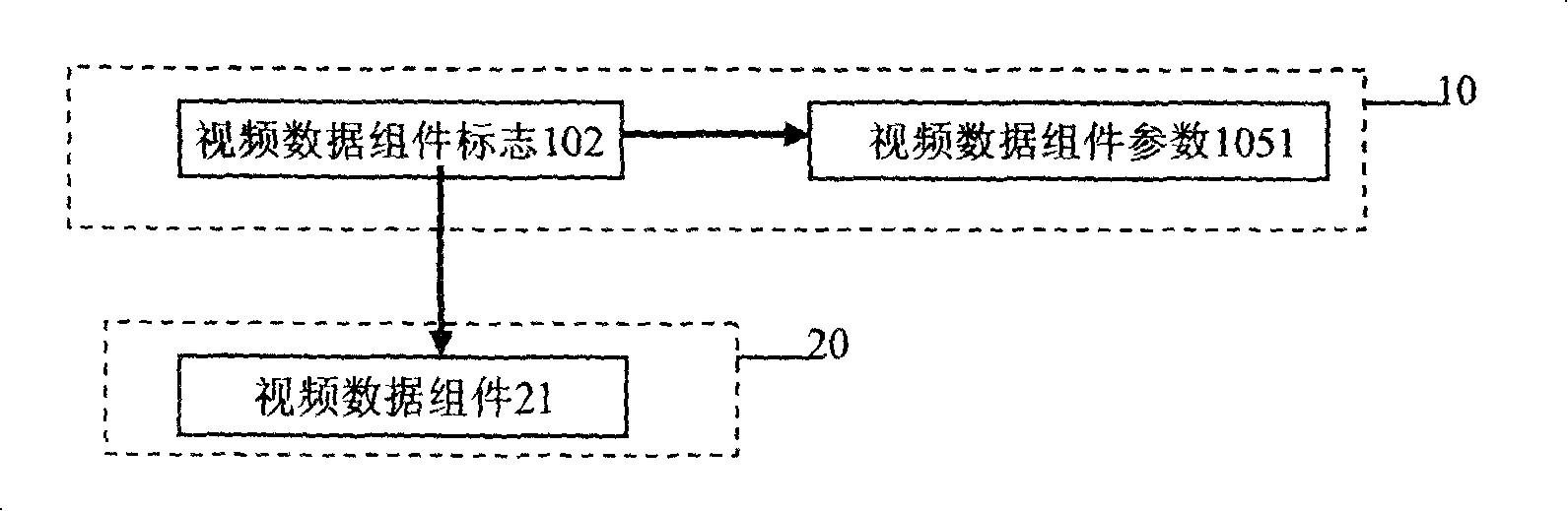

A data flow packaging method of mobile multimedia broadcasting system

InactiveCN1972453AReduce overheadAvoid teleportationBroadcast with distributionPulse modulation television signal transmissionData segmentMultimedia data streams

This invention relates to mobile multi-media broadcasting flow sealing method, which si characterized by the following: adopting data frame structure to seal multi-media data composed of frame head , visual section, audio section and data section ; the said frame head comprises visual section indication, audio section indication and data section, wherein, the visual section represents whether is ones in data frame; the said audio indication presents whether there is ones and the data section for ones in the data frame.

Owner:ZTE CORP

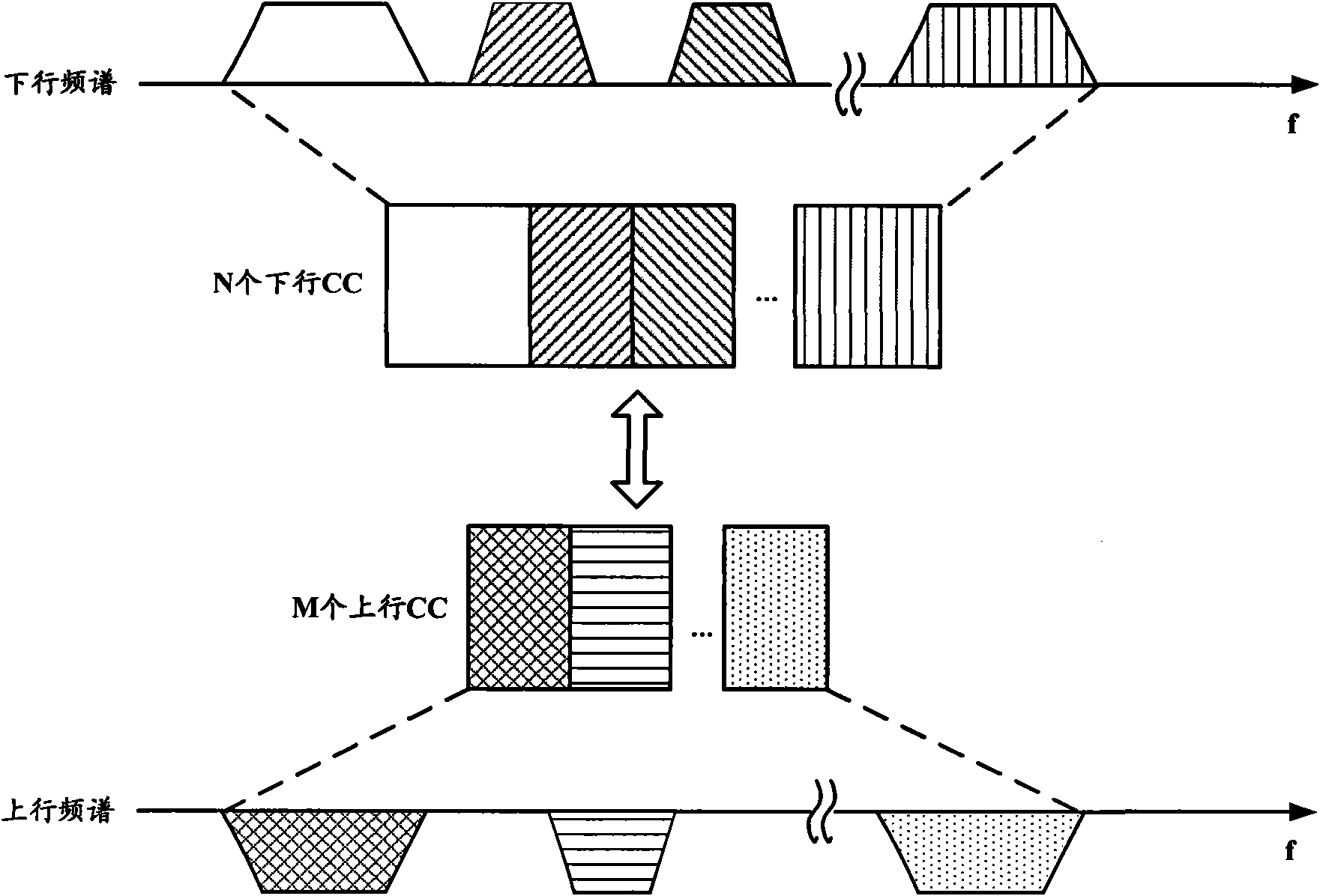

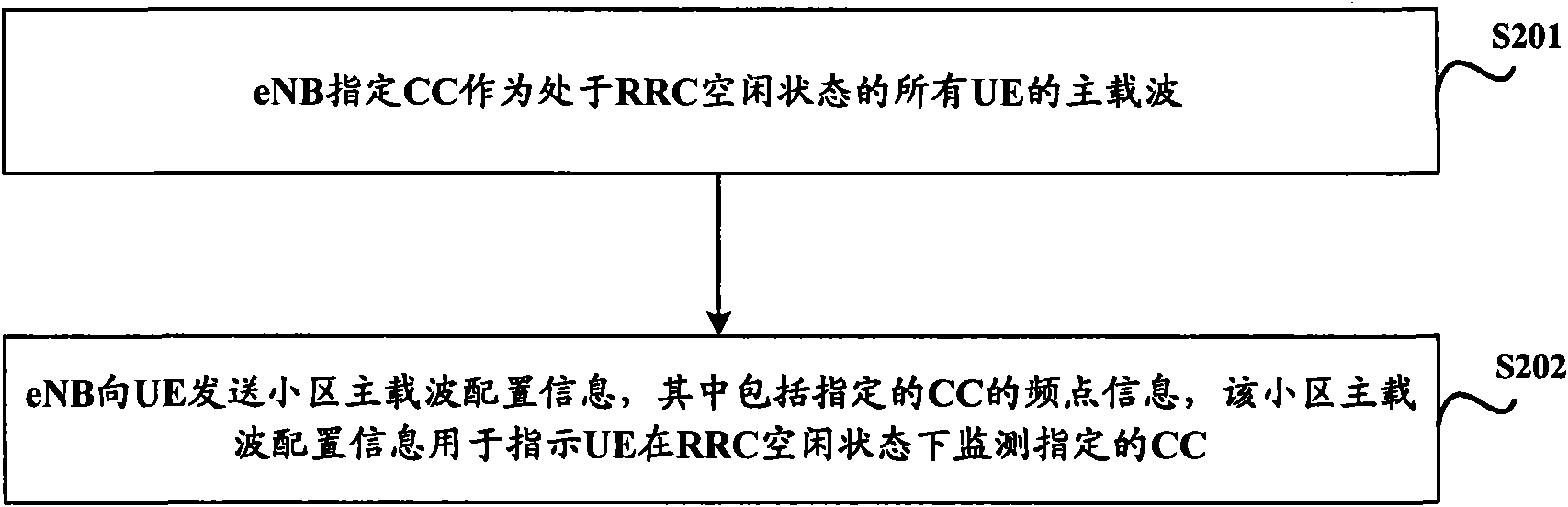

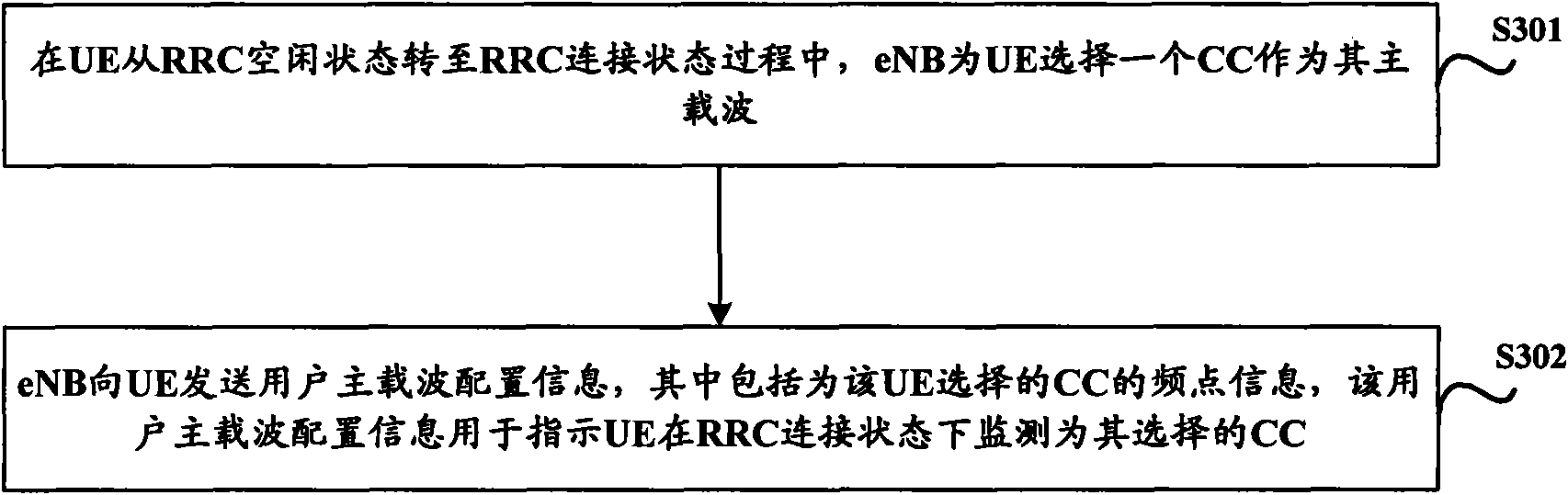

Method for selecting a main carrier and related equipment

InactiveCN101873667AAvoid teleportationReduce overheadEnergy efficient ICTAssess restrictionCarrier signalRadio Resource Control

The invention discloses a method for selecting a main carrier and related equipment, which are used for solving the problem of selecting a proper main carrier for user equipment. The method for selecting the main carrier of the invention comprises that: a base station designates member carriers as the main carriers of all sets of user equipment (UE) in a radio resource control (RRC) idle state; and the base station sends cell main carrier configuration information to the UE, wherein the cell main carrier configuration information comprises the frequency point information of the designated member carriers and is used for instructing the UE to monitor the designated member carriers in the RRC idle state. In the invention, the base state adopts a cell main carrier mode for the UE in the RRC idle state, so the system signaling cost and UE power consumption are reduced effectively.

Owner:CHINA MOBILE COMM GRP CO LTD

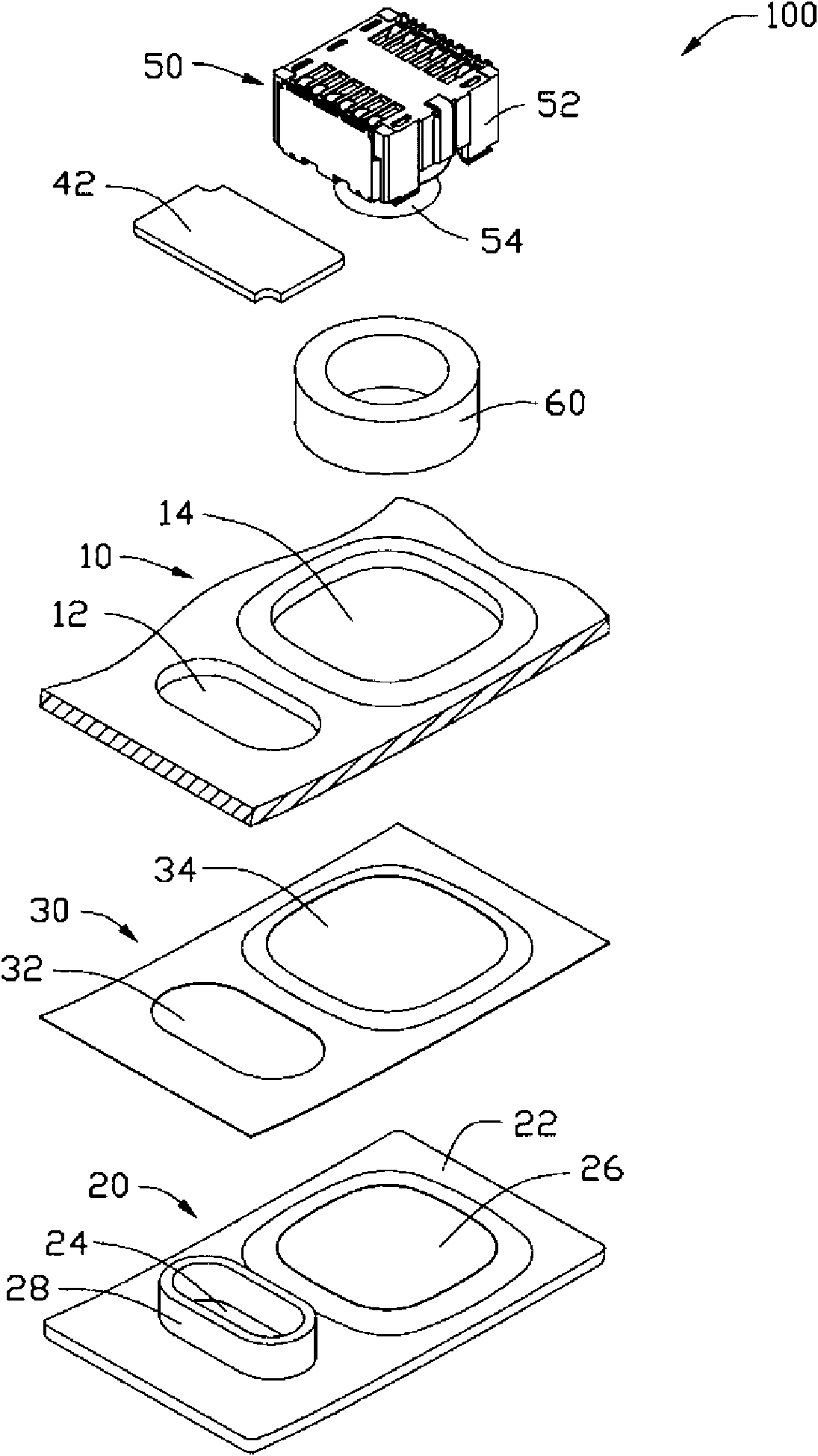

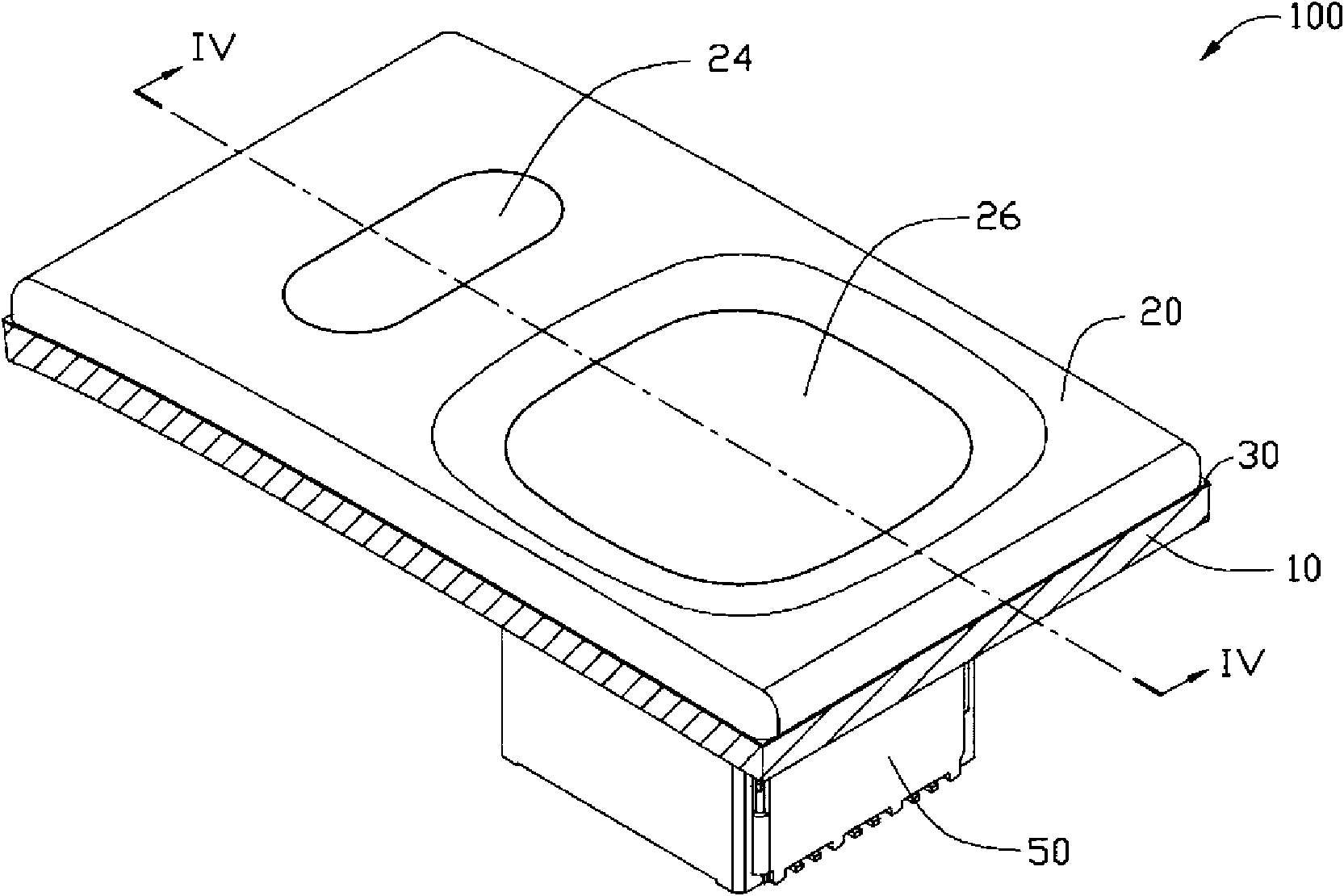

Window and portable electronic device using same

InactiveCN101997942AEasy to assembleAvoid teleportationDetails for portable computersTelephone set constructionsComputer science

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Packaging method of multimedia broadcasting system media data flow

InactiveCN101179735ASave channel resourcesImprove transmission efficiencyPulse modulation television signal transmissionDigital video signal modificationComputer hardwareBroadcast system

The invention relates to a method for encapsulation of media data stream in a multimedia broadcasting system, and the media data stream of each channel of the broadcasting system selectively comprises video frequency components, audio frequency components and accessory data components, which comprises the following steps: choosing and encapsulating one or more components among the video frequencycomponents, audio frequency components or accessory data components in need of sending in the data frame of each channel; settling the data and parameters of the selected data components; collocatingthe header and recording the length of the header therein; recording the symbol information and the parameter information of the selected data component type in the header. The method sends multi-media data stream effectively in a channel via the encapsulation components, and sends only the components in need of sending and correspondingly transferring the component broadcasting program needed inthe mobile terminal via the component symbols, which can enhance the sending efficiency, save the mobile terminal power supply and better satisfy the demands of mobile multimedia industry.

Owner:ZTE CORP

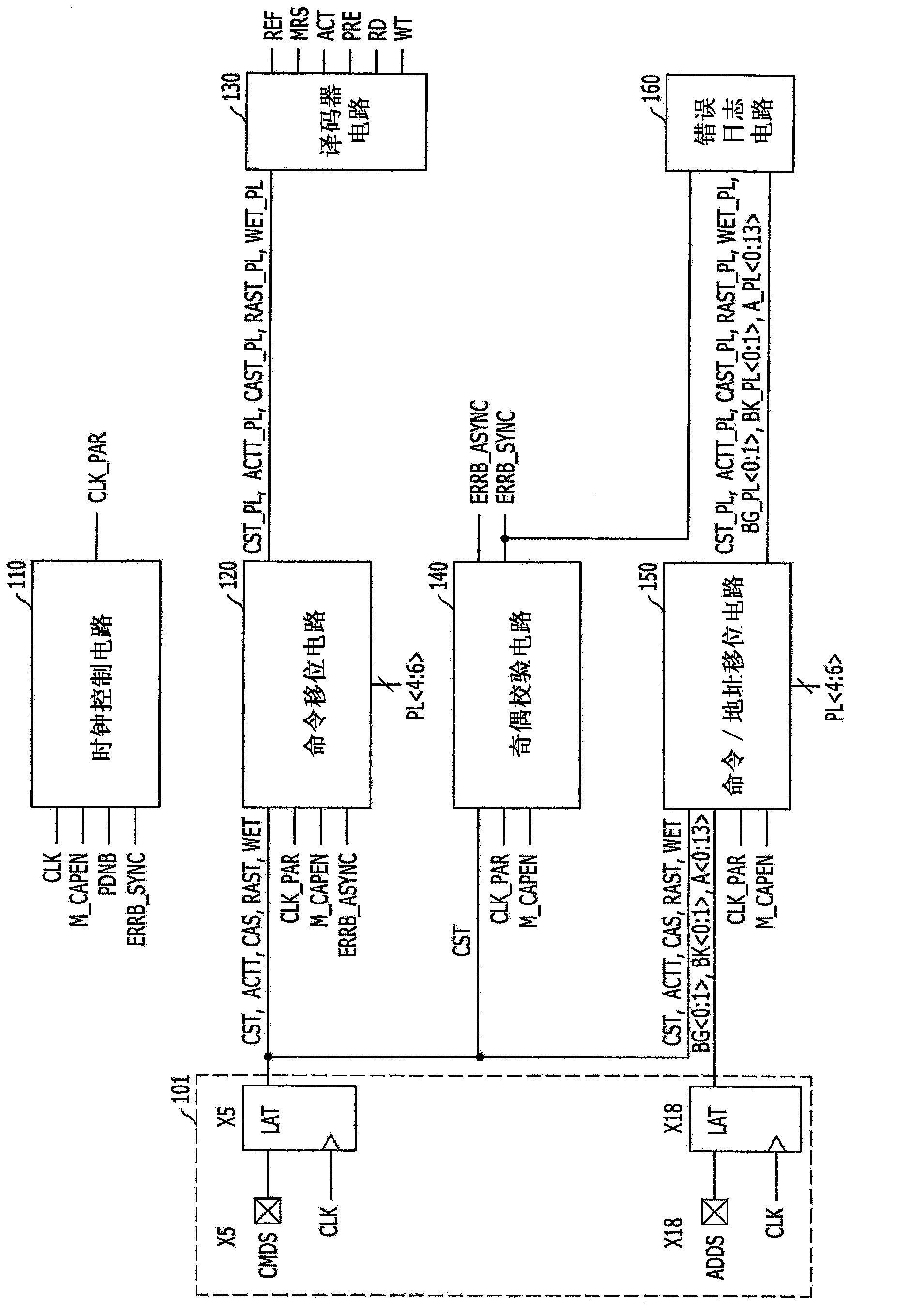

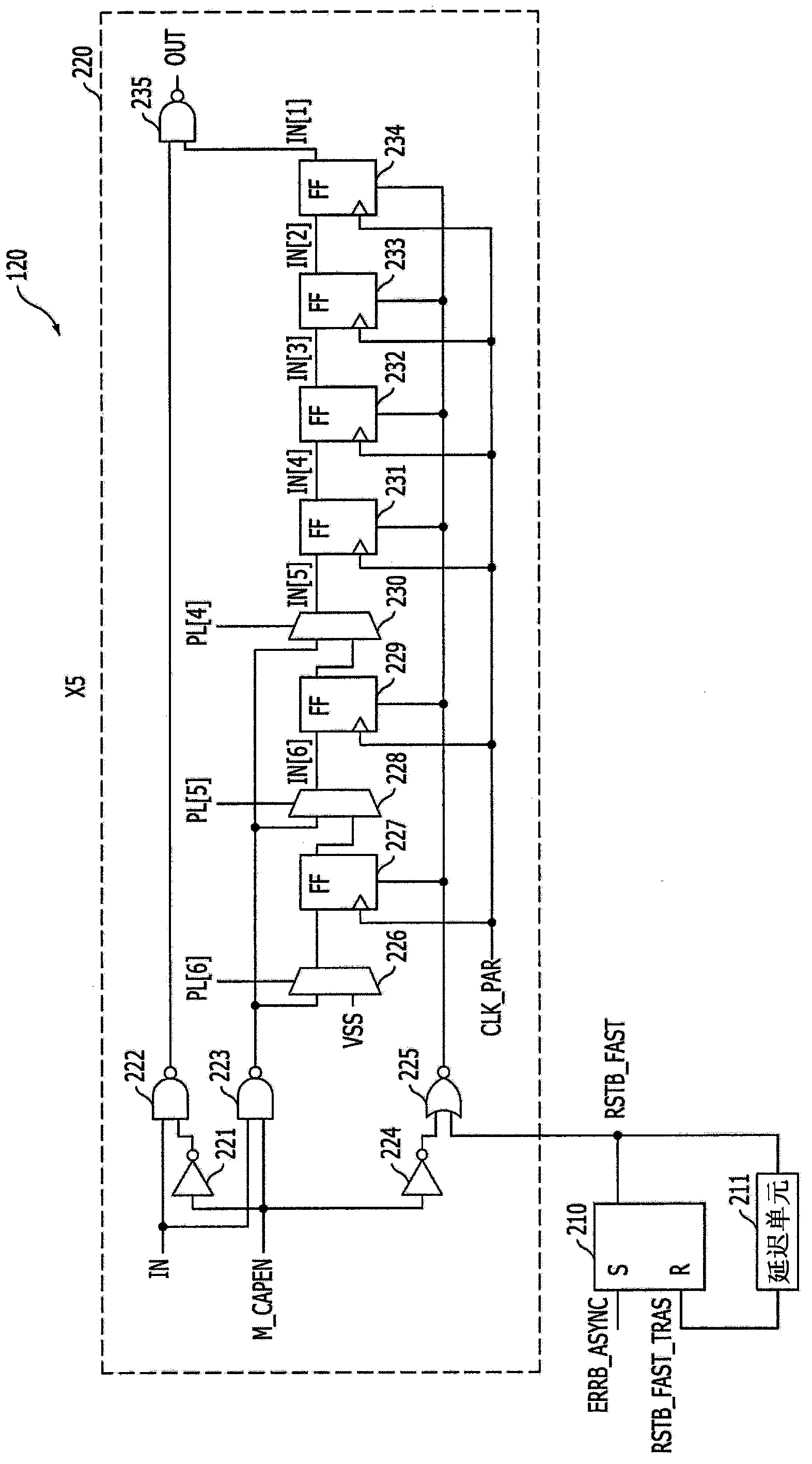

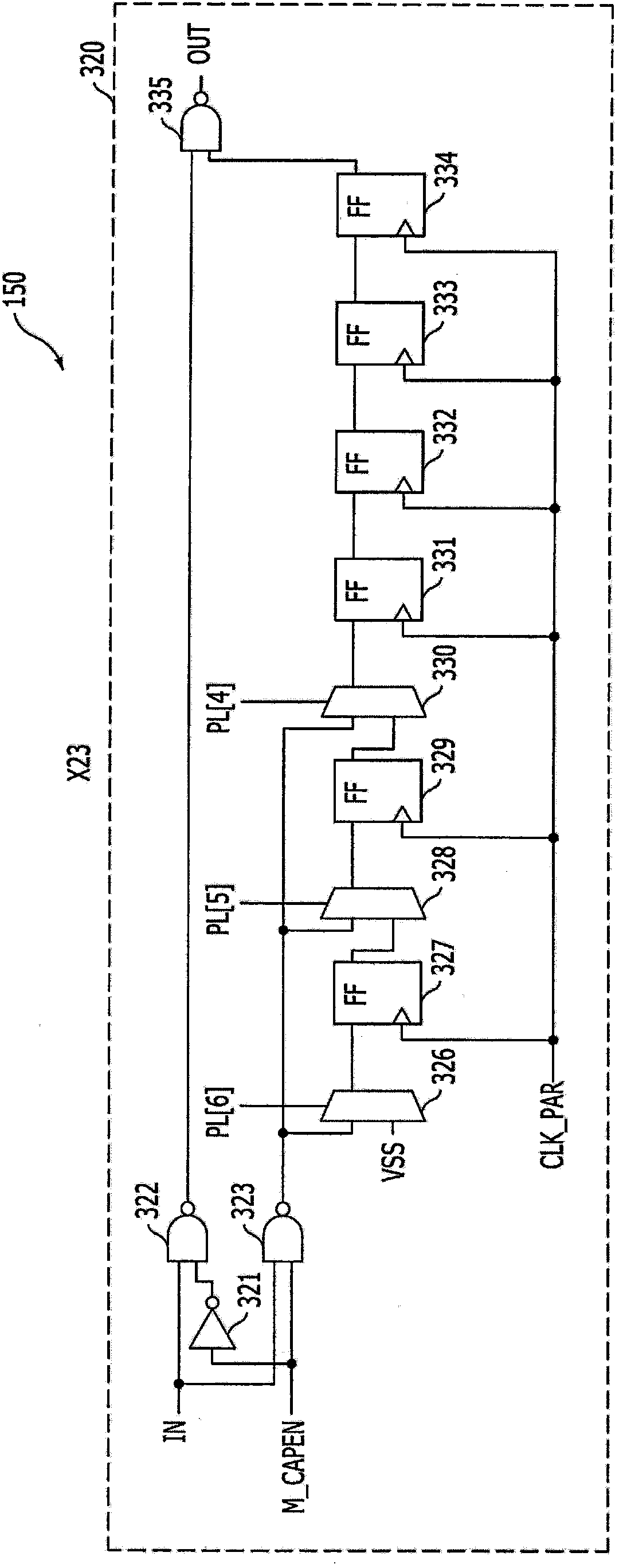

Memory device

ActiveCN103514960AAvoid teleportationReduce current consumptionDigital storageRedundant data error correctionComputer scienceClock synchronization

A memory device includes a parity circuit configured to detect presence or absence of an error using a plurality of command signals and a plurality of address signals, a command shift circuit configured to shift the plurality of command signals by a preset delay value in synchronization with a control clock, a clock control circuit configured to deactivate the control clock when there is no valid command signal in command signals being shifted in the command shift circuit, and a decoder circuit configured to decode a plurality of command signals output from the command shift circuit.

Owner:SK HYNIX INC

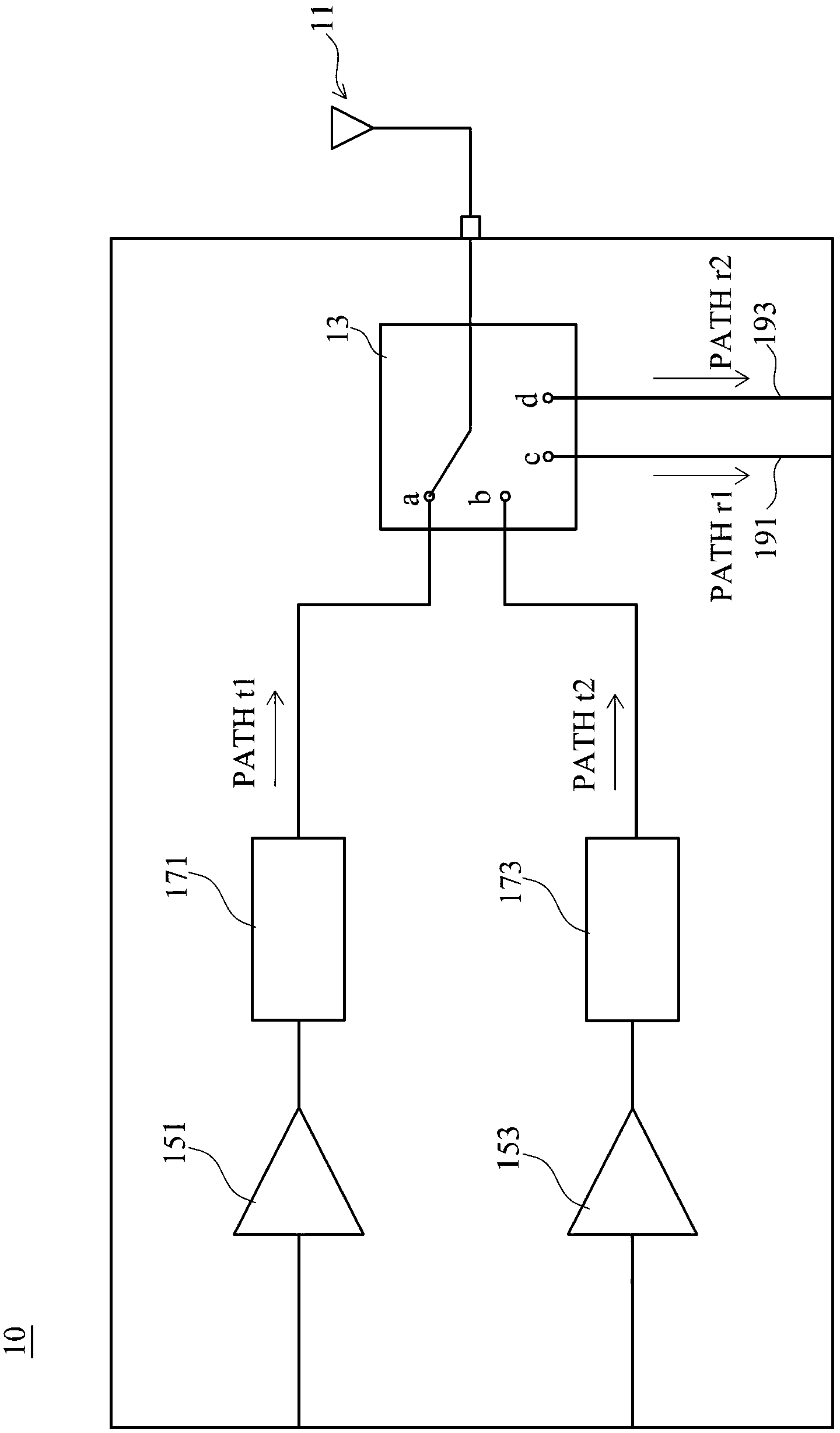

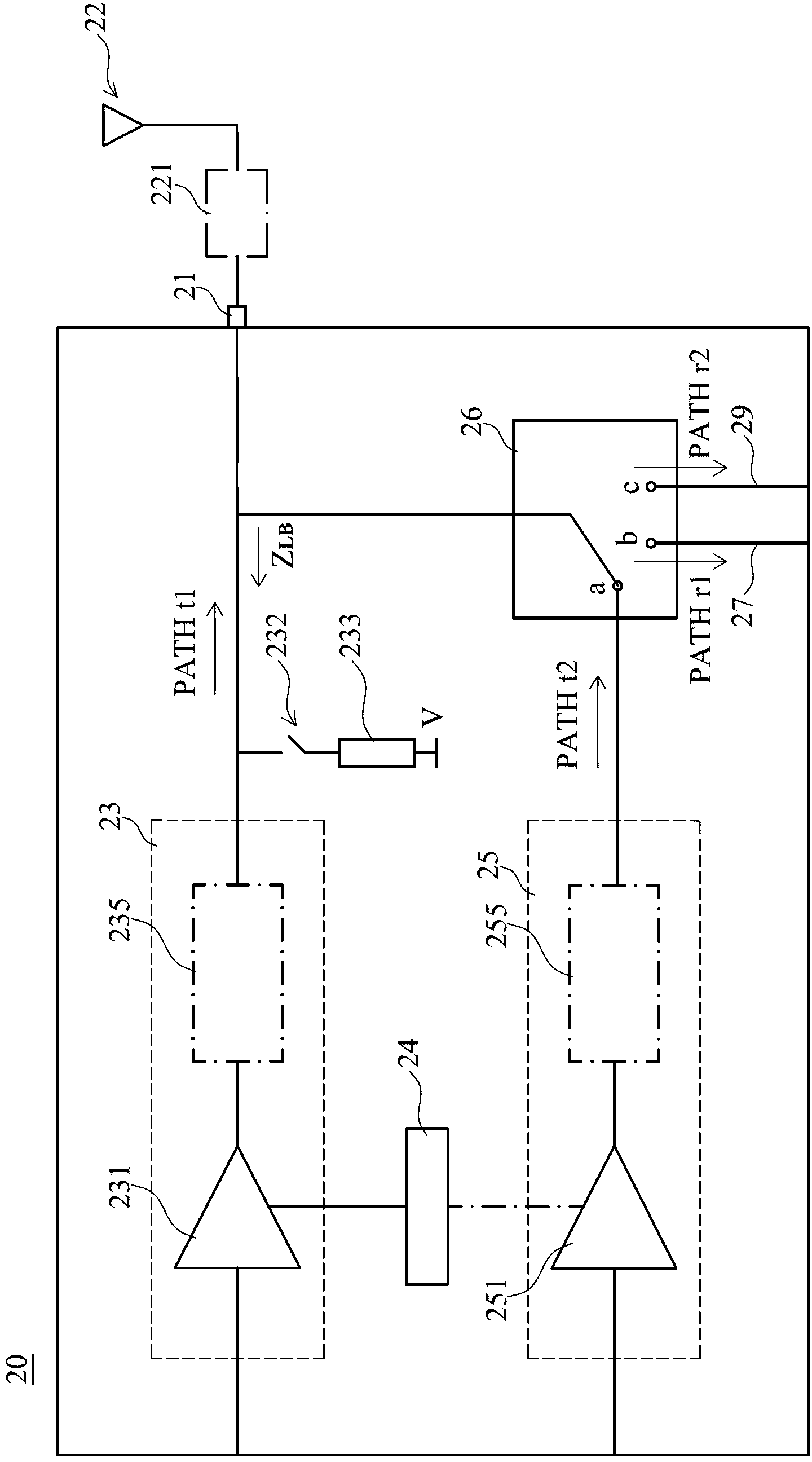

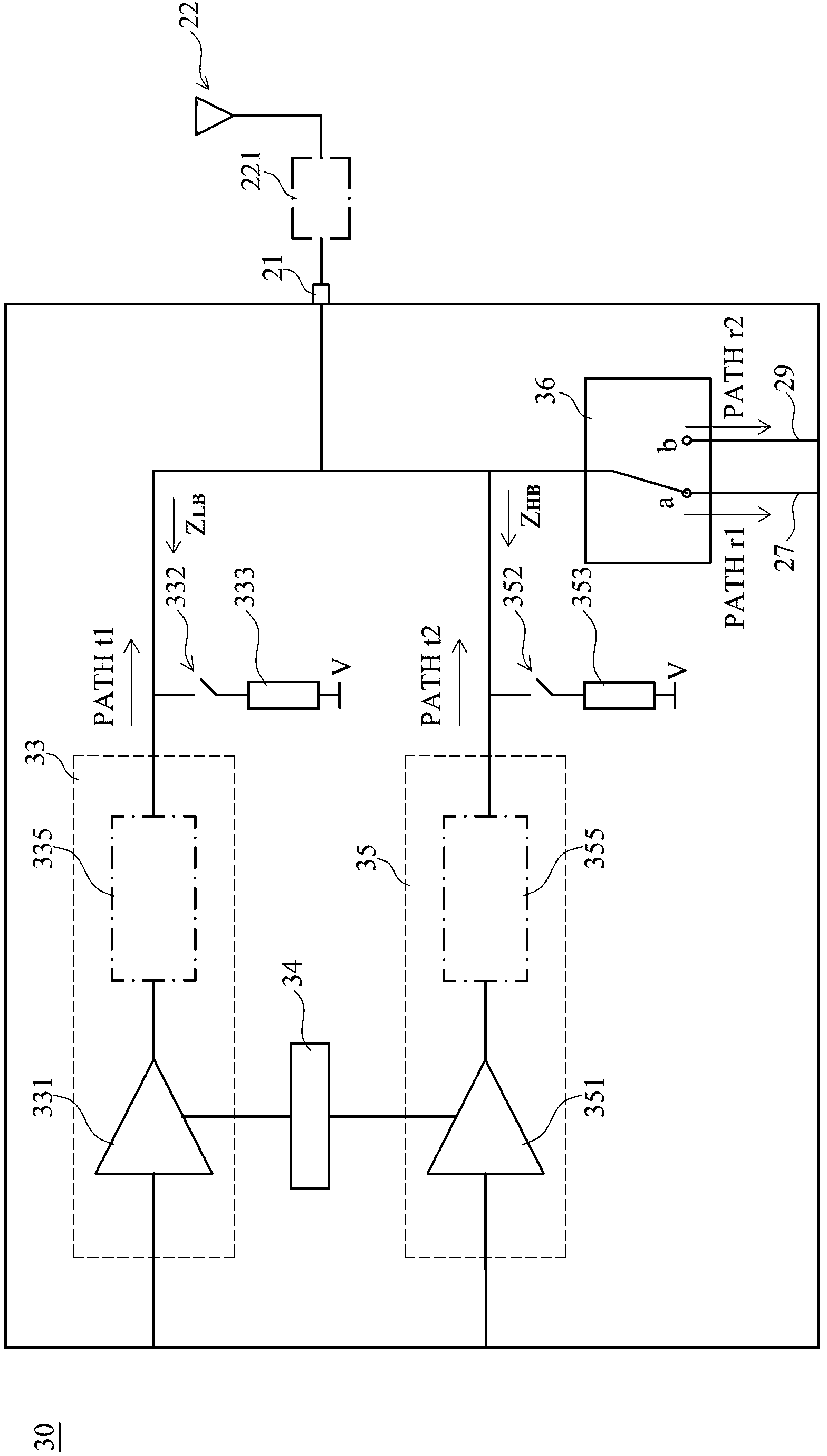

Radio frequency front-end module

ActiveCN103227657AReduce sensitivityAvoid loss of signal strengthTransmissionComputer moduleRadio frequency front end

The invention discloses a radio frequency front-end module which comprises a receiving and transmitting end, a control unit, a first transmitting block and a second transmitting block, wherein the first transmitting block and the second transmitting block are connected with the receiving and transmitting end and the control unit; and the control unit is used for controlling the opening or the closing of the first transmitting block and the second transmitting block, so that the first transmitting block and the second transmitting block can directly transmit signals to the receiving and transmitting end, and loss of the signal intensity caused by the fact that the signals pass through an opening and closing unit is avoided.

Owner:AIROHA TECHNOLOGY CORPORATION

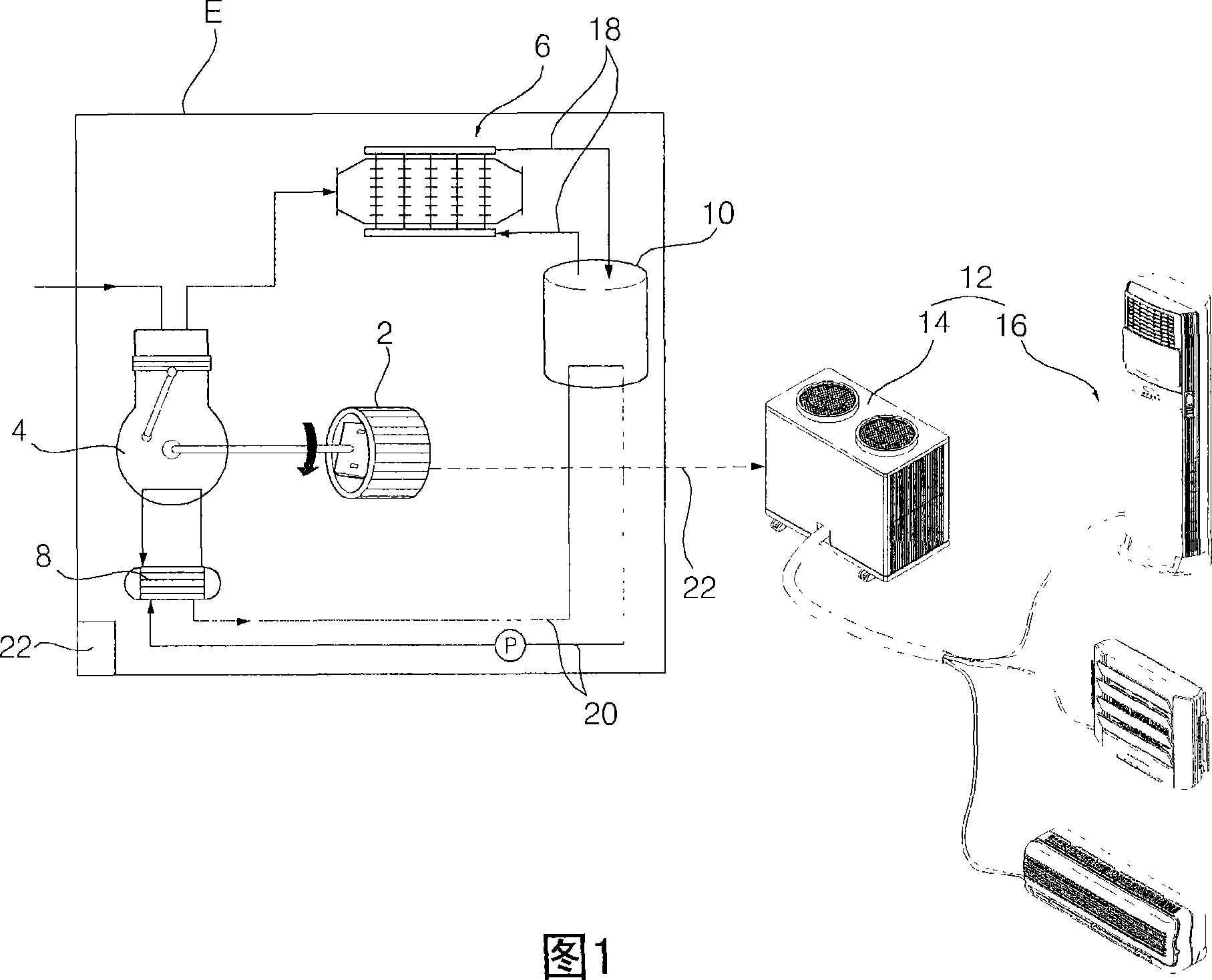

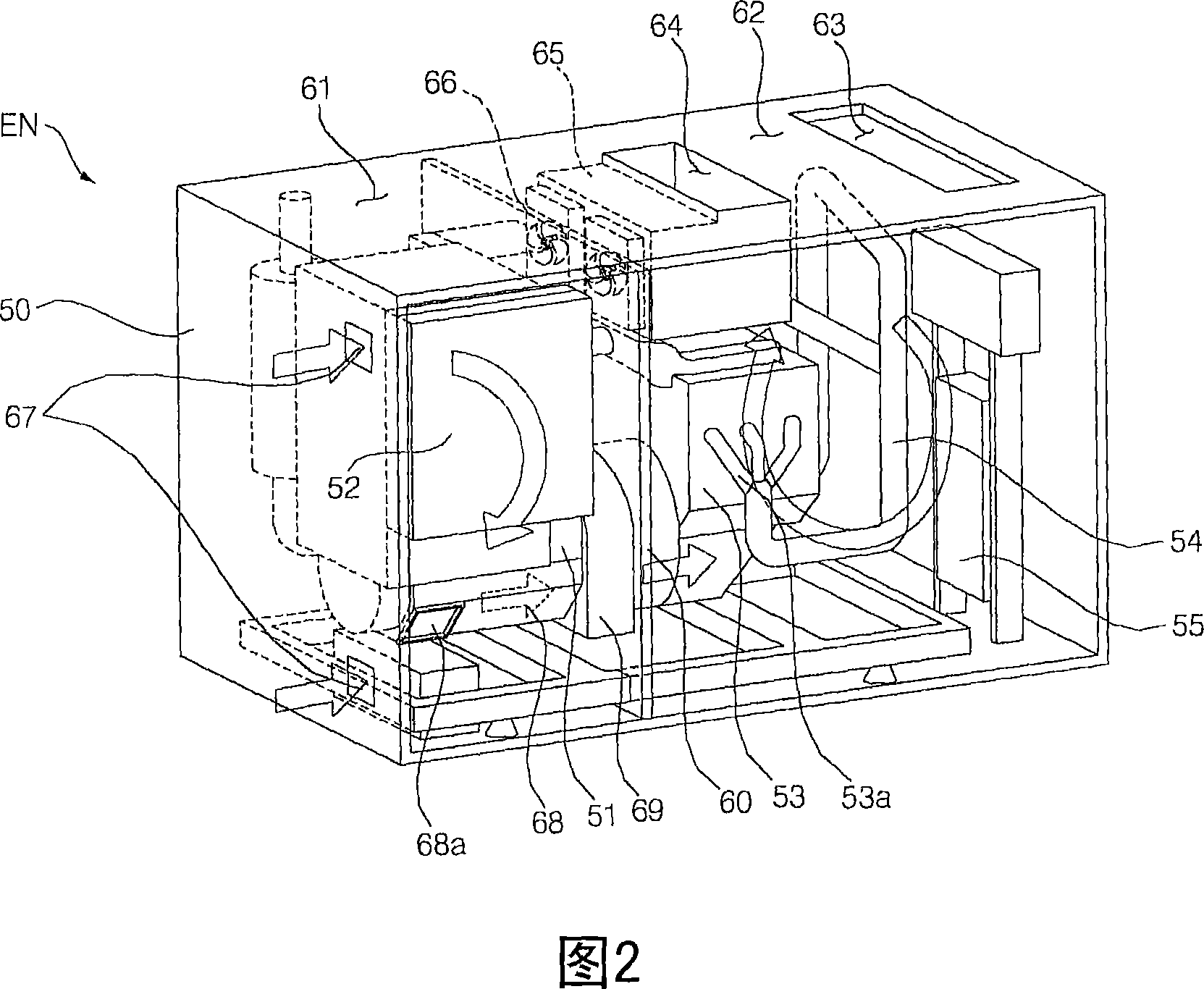

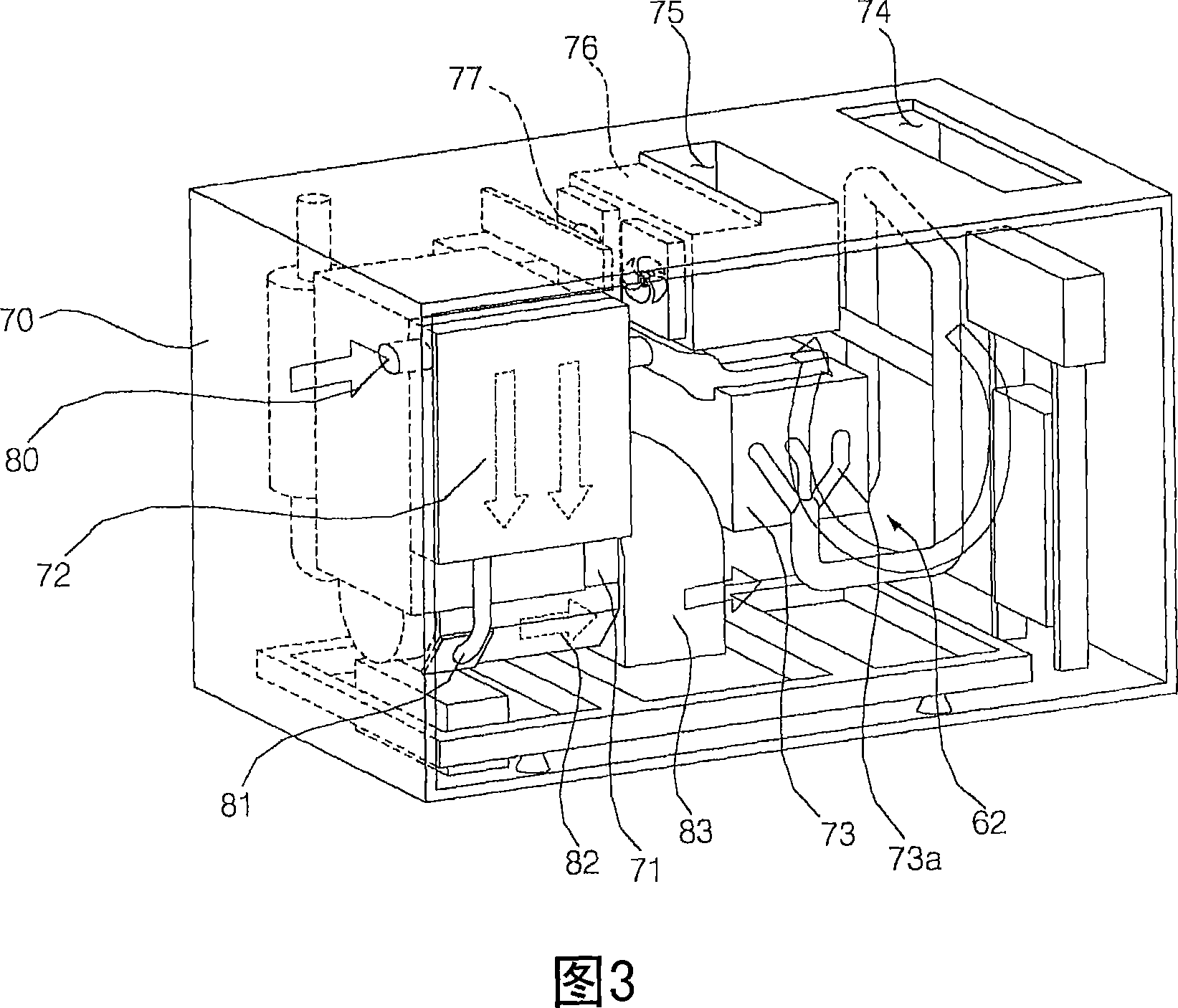

Cogeneration system

InactiveCN101117925AAvoid overall overheatingAvoid teleportationCoolant flow controlInternal combustion piston enginesWaste heat recovery unitThermal energy

Owner:INTELLECTUAL DISCOVERY CO LTD

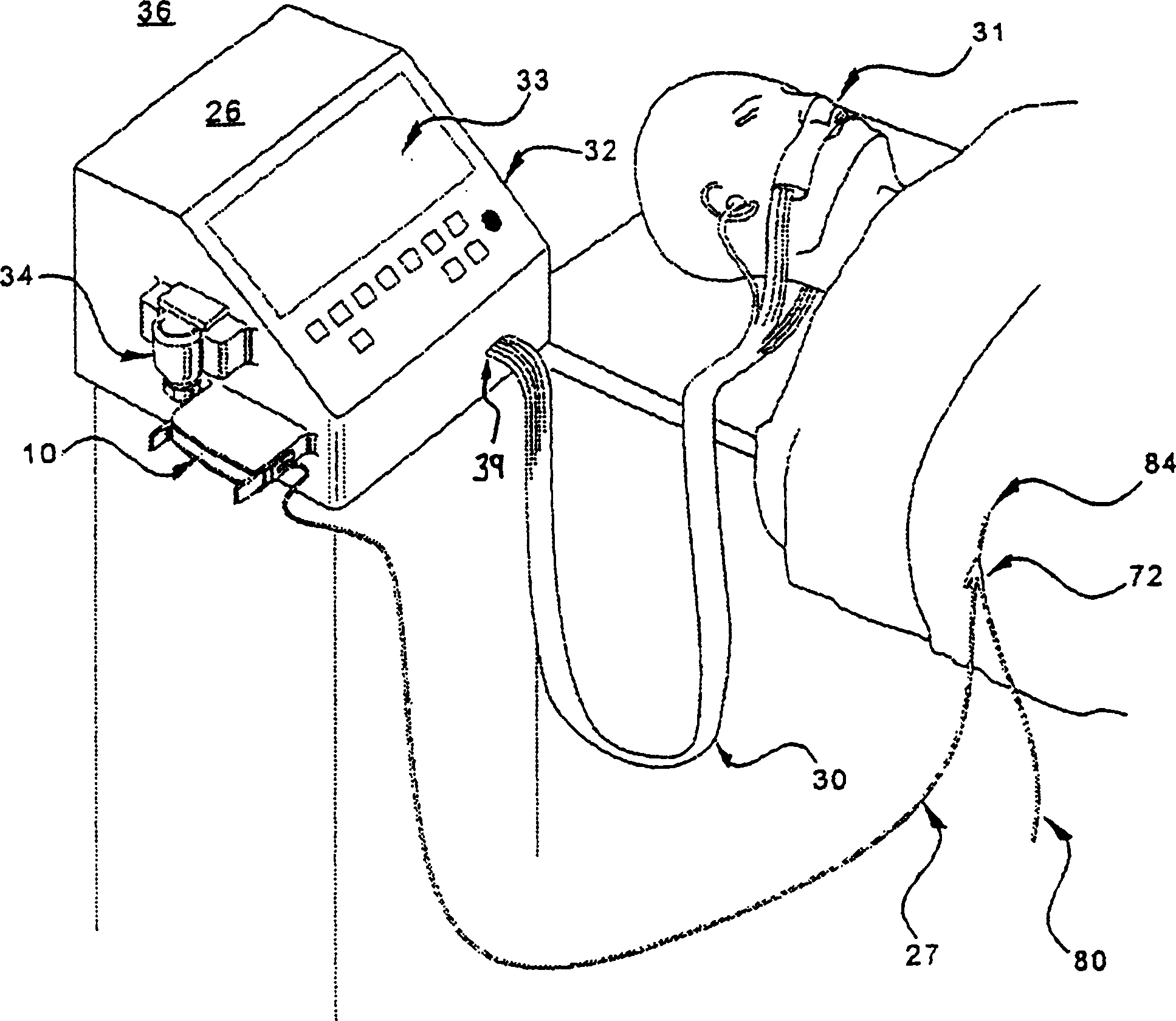

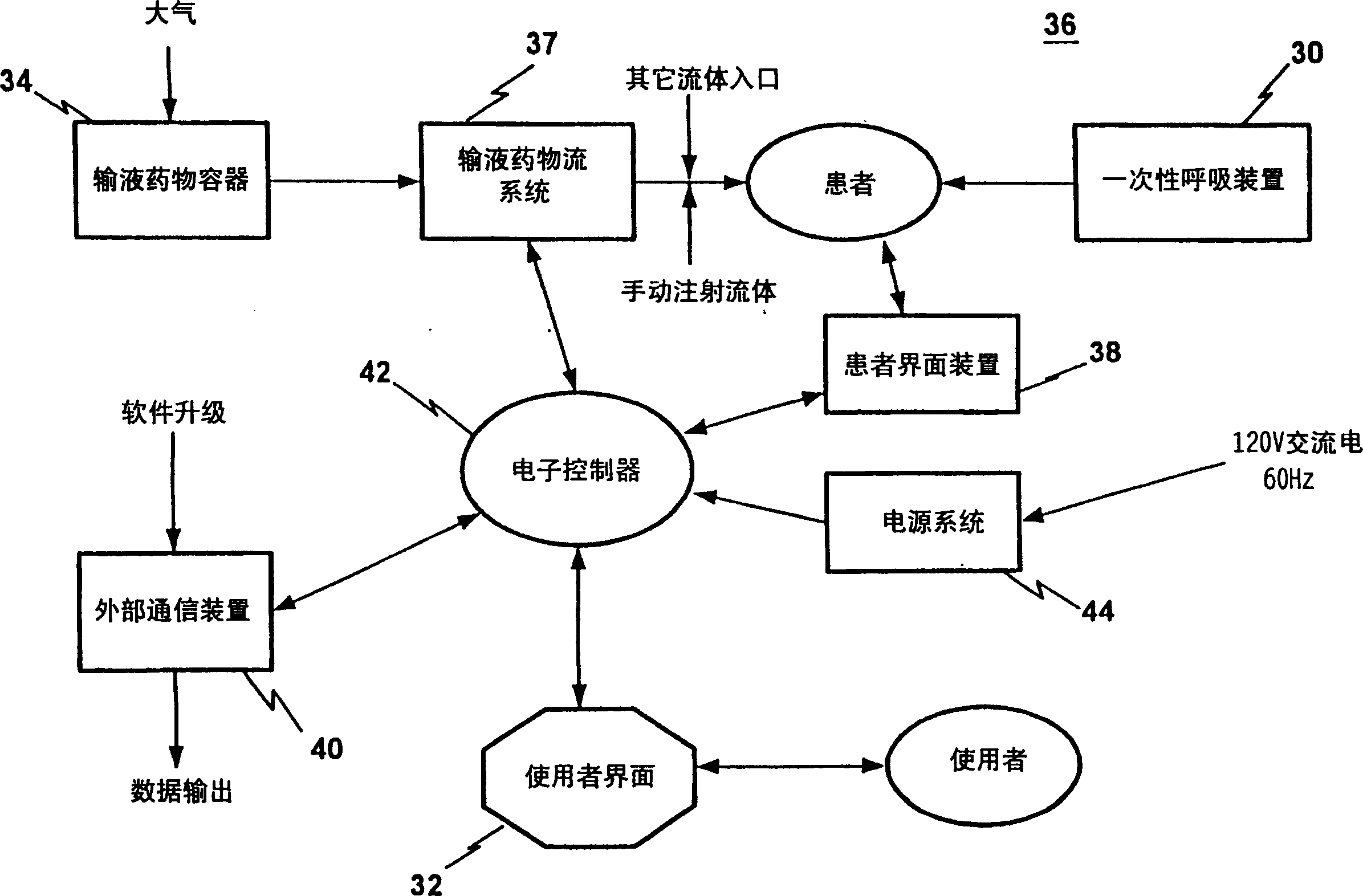

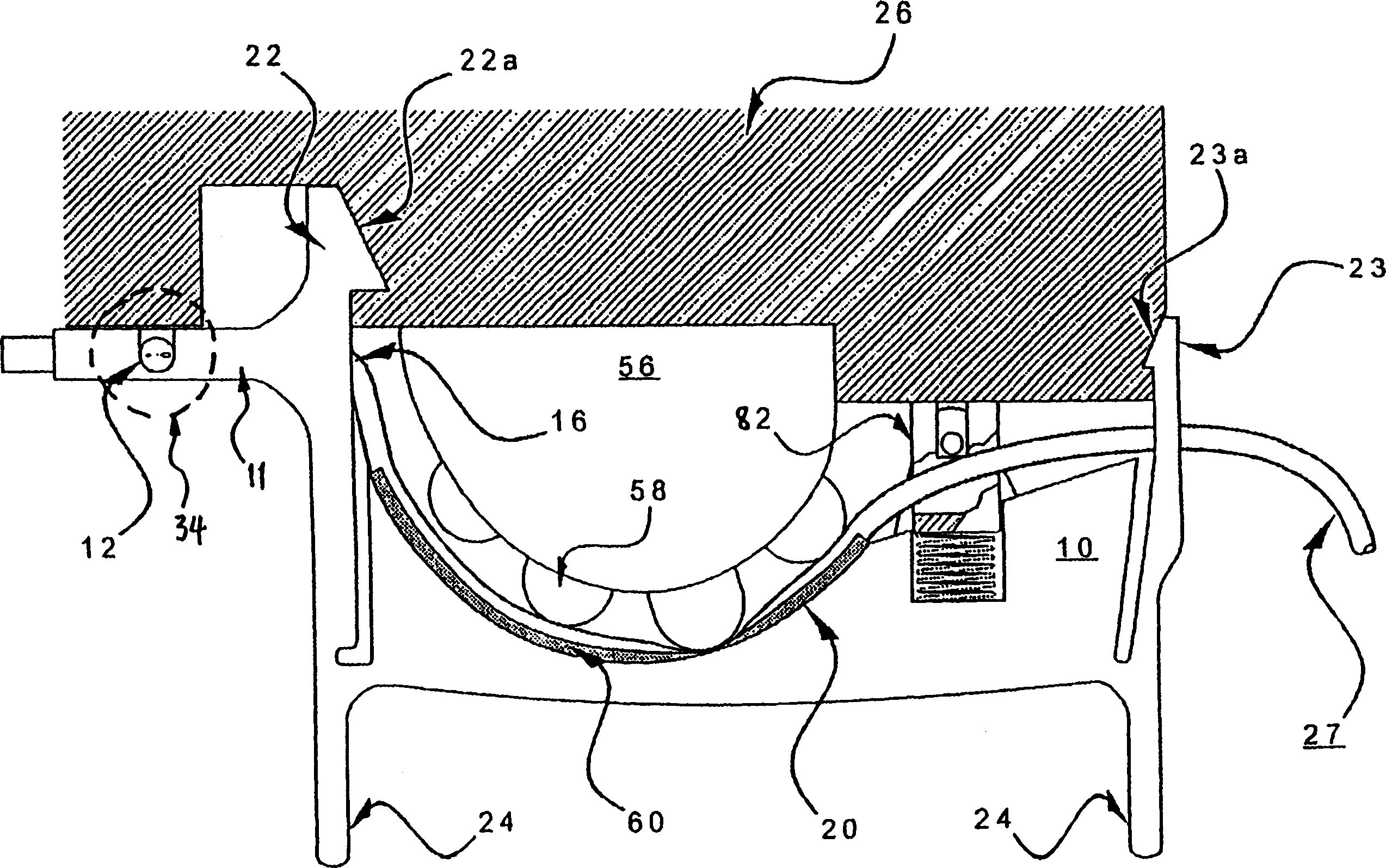

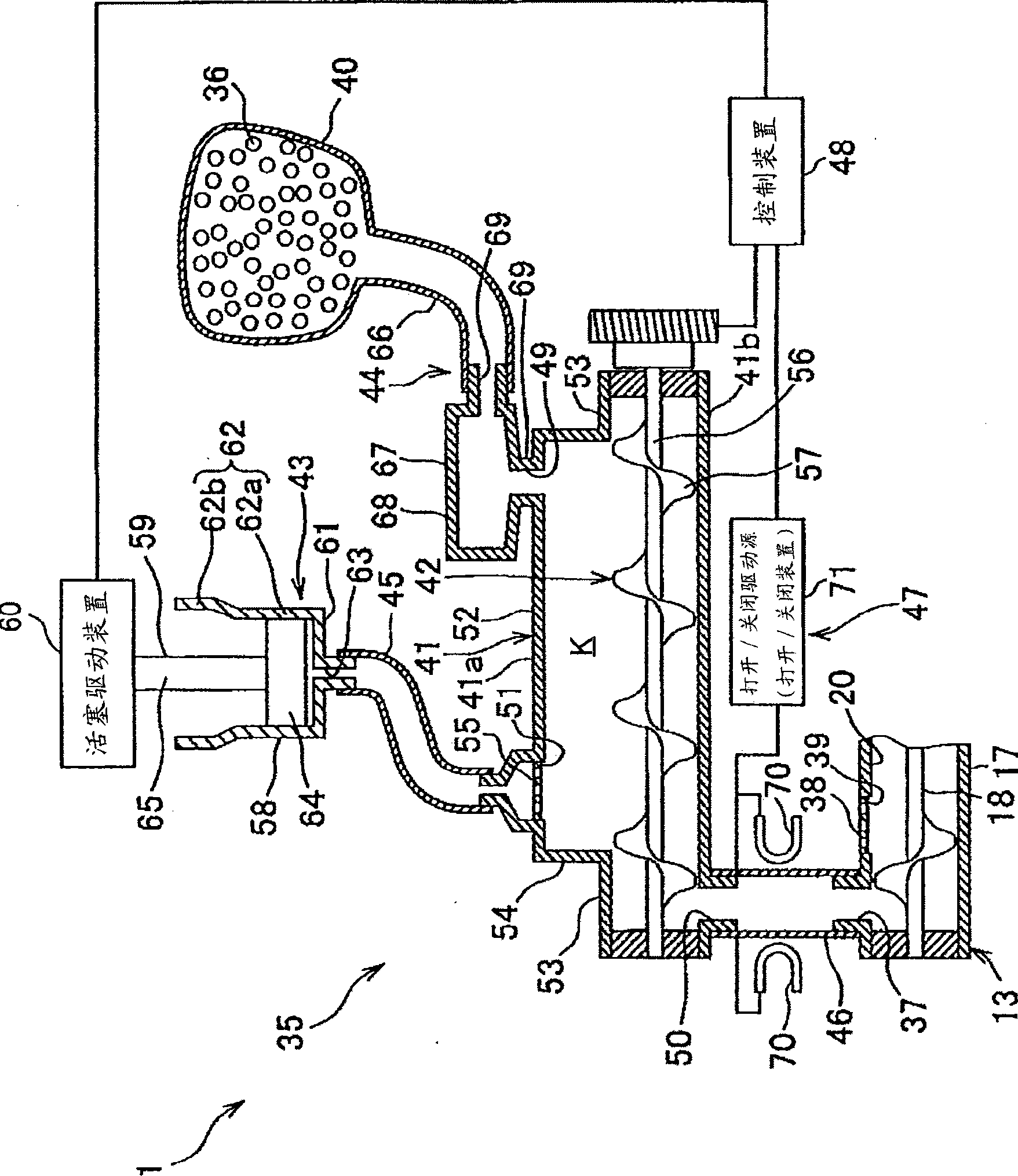

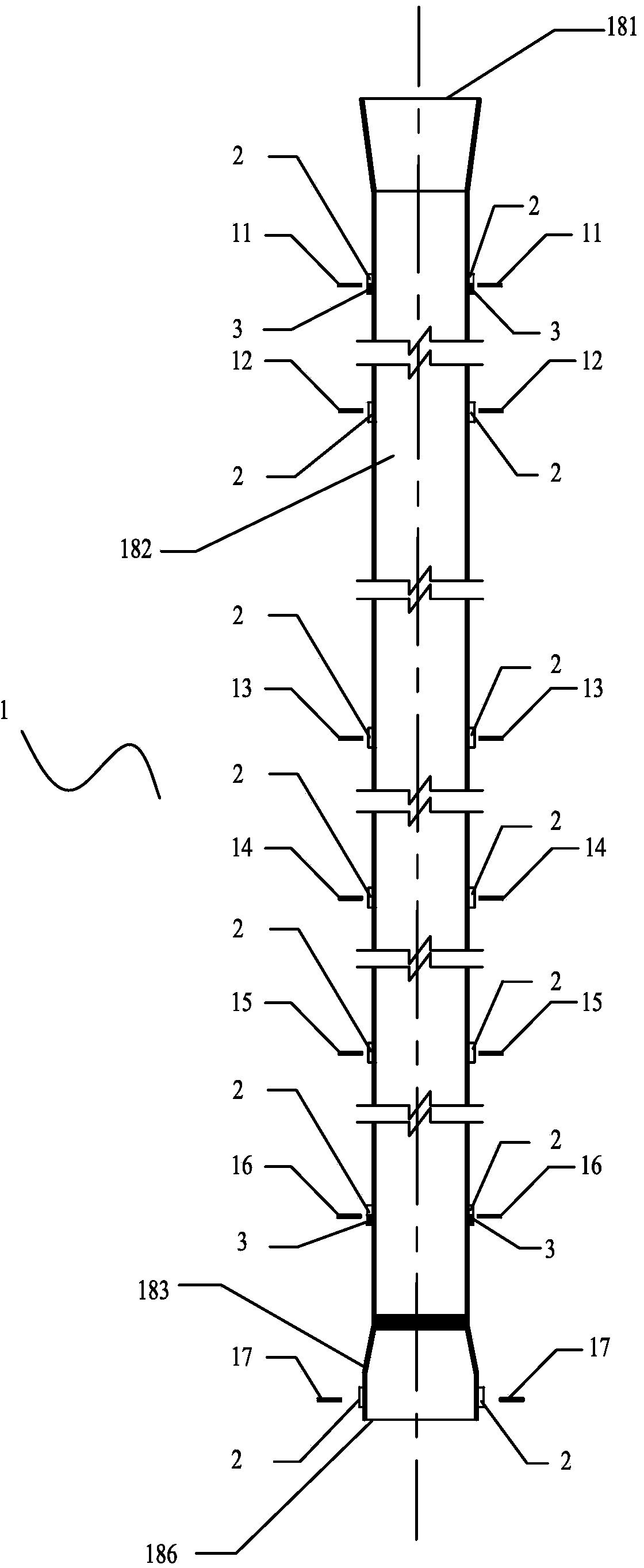

Apparatuses and methods for providing IV infusion administration

InactiveCN1561237APrevent removalAvoid teleportationDrug and medicationsMedical devicesQuality assuranceIV Infusion

An infusate cassette is described for use with an IV infusion system which controls the process of administering a drug to a patient. The cassette and other aspects of the infusion system may include disposable components, external redundant volume tracking, air removal and automated purge and prime capabilities, component removal lockout mechanisms, and / or redundant automated anti-free flow devices. An IV manifold comprising an imbedded high cracking pressure anti-free flow valve is also described for use with the infusion system. The cassette, IV manifold, and other aspects of the infusion system may be provided with quality assurance mechanisms for use with integrated IV infusion.

Owner:SCOTT LAB

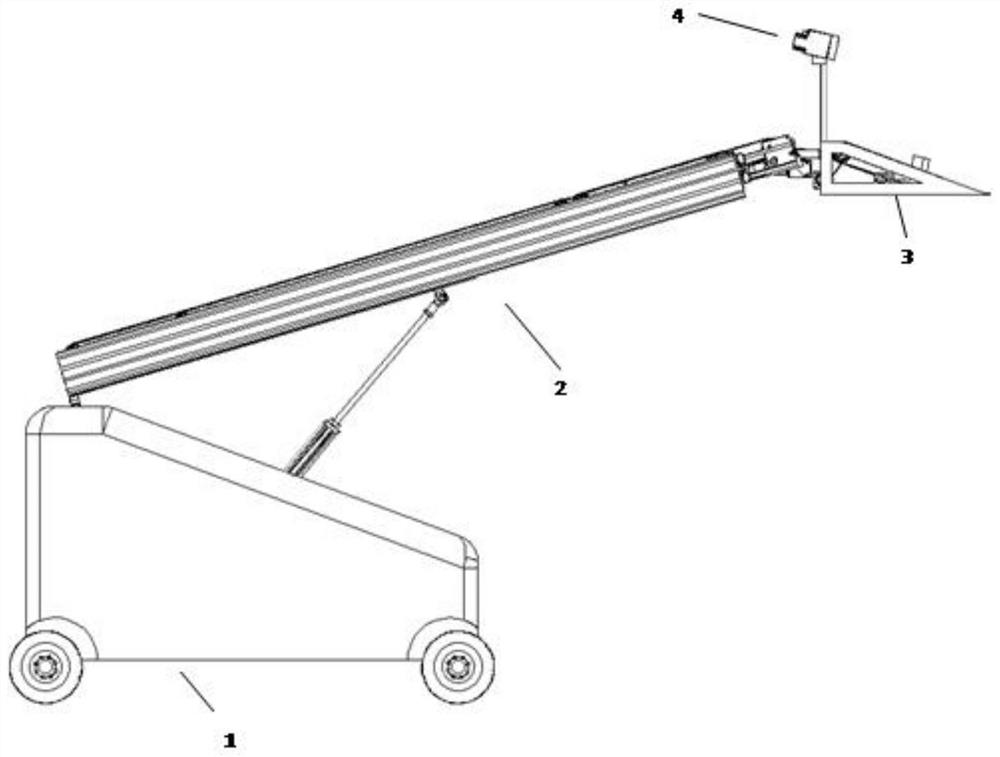

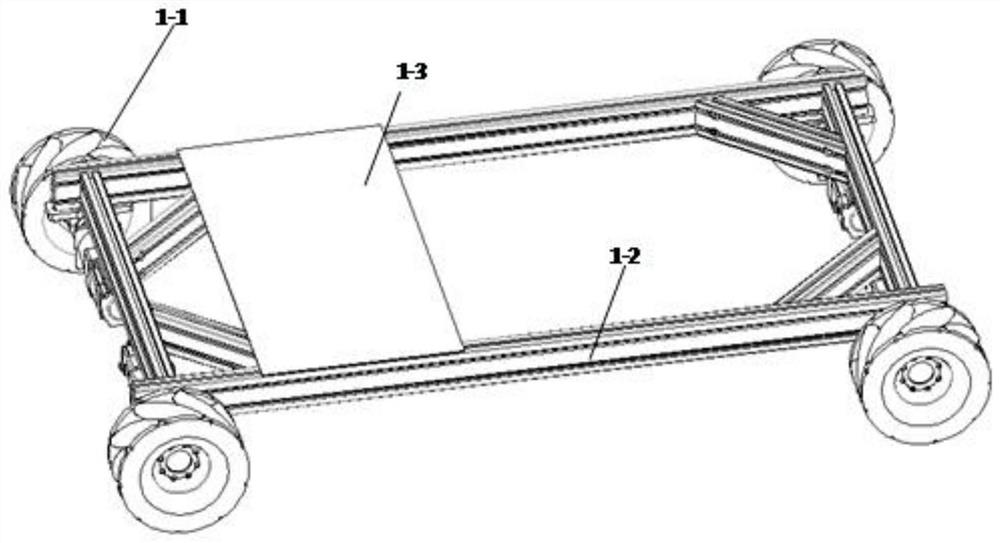

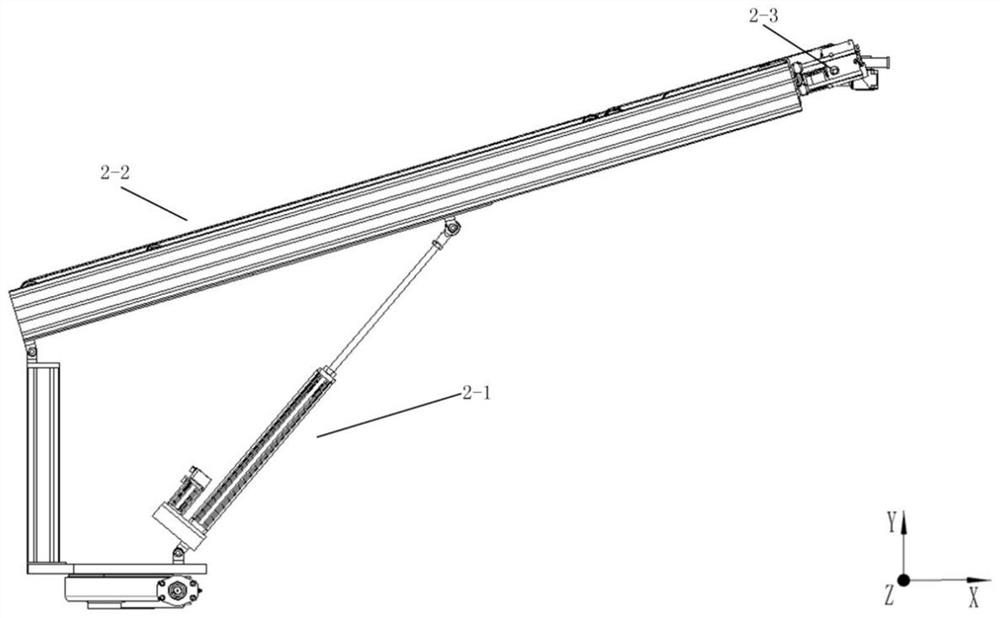

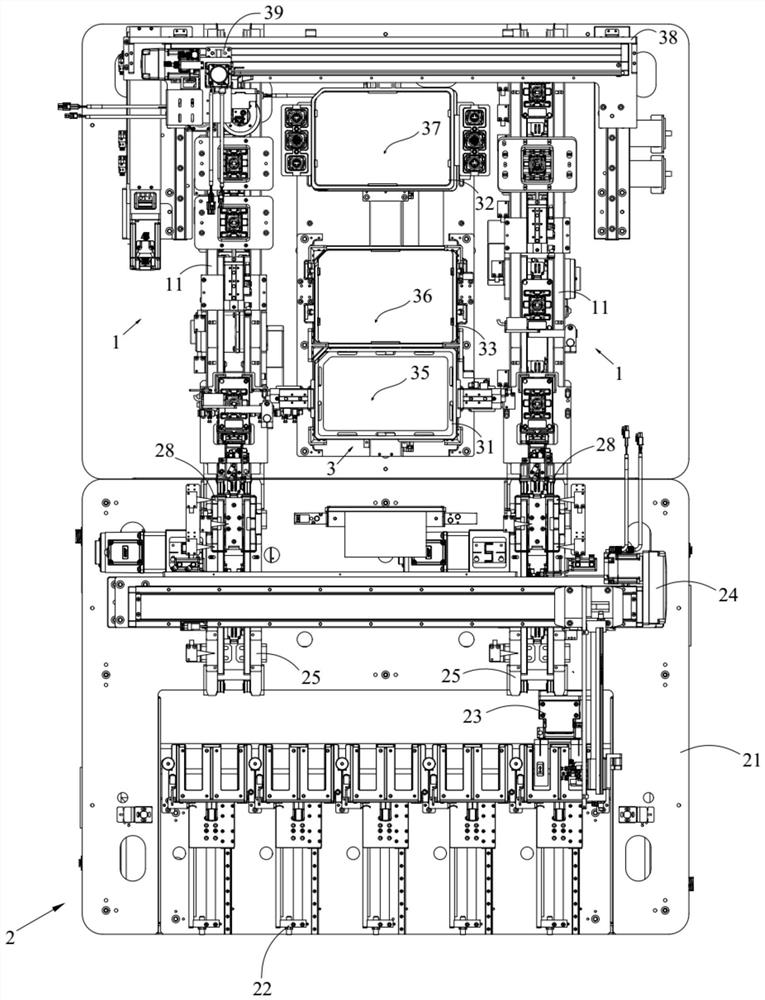

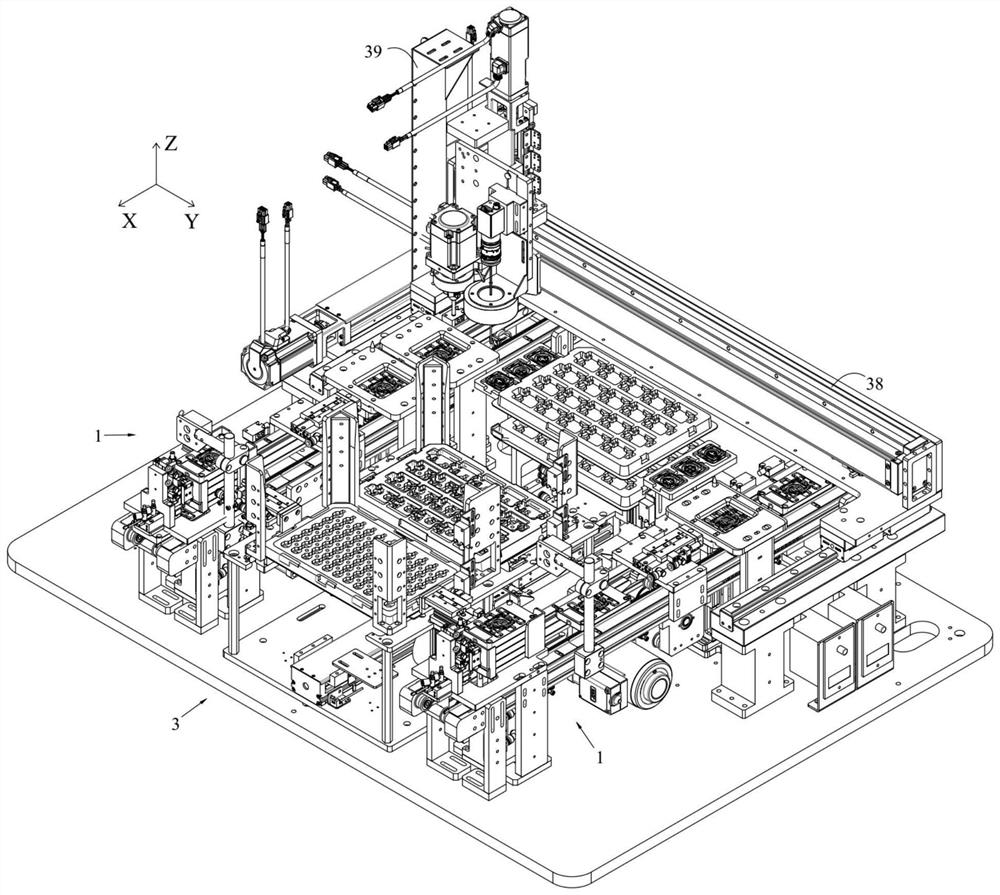

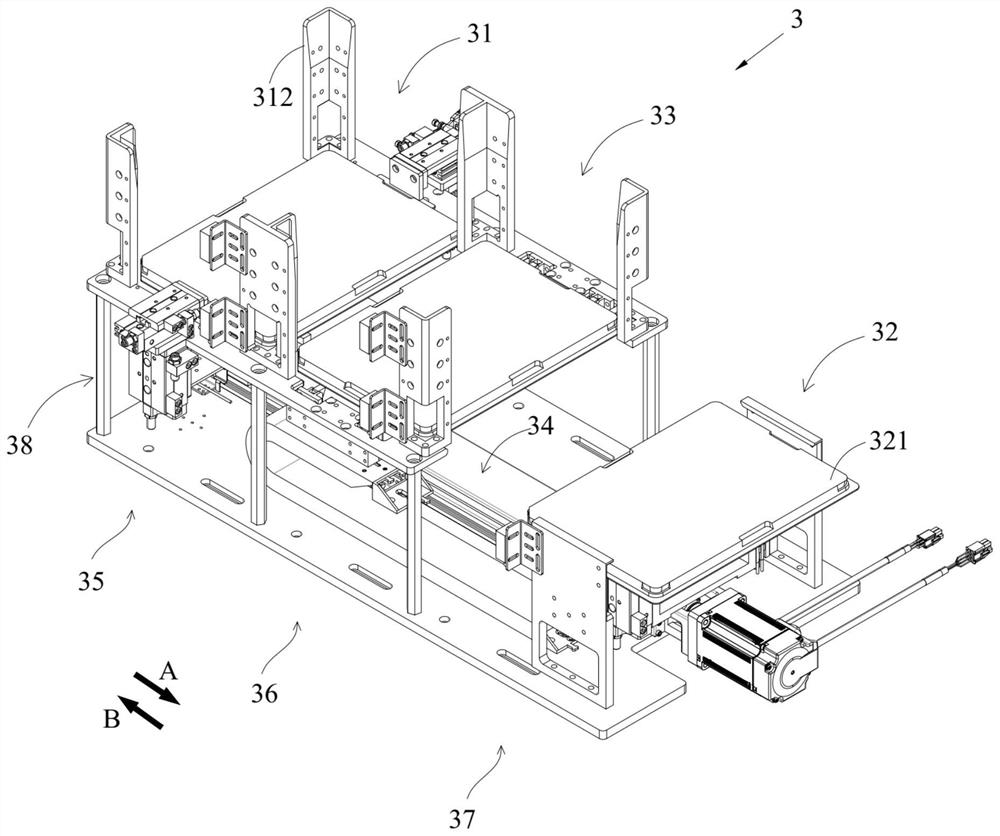

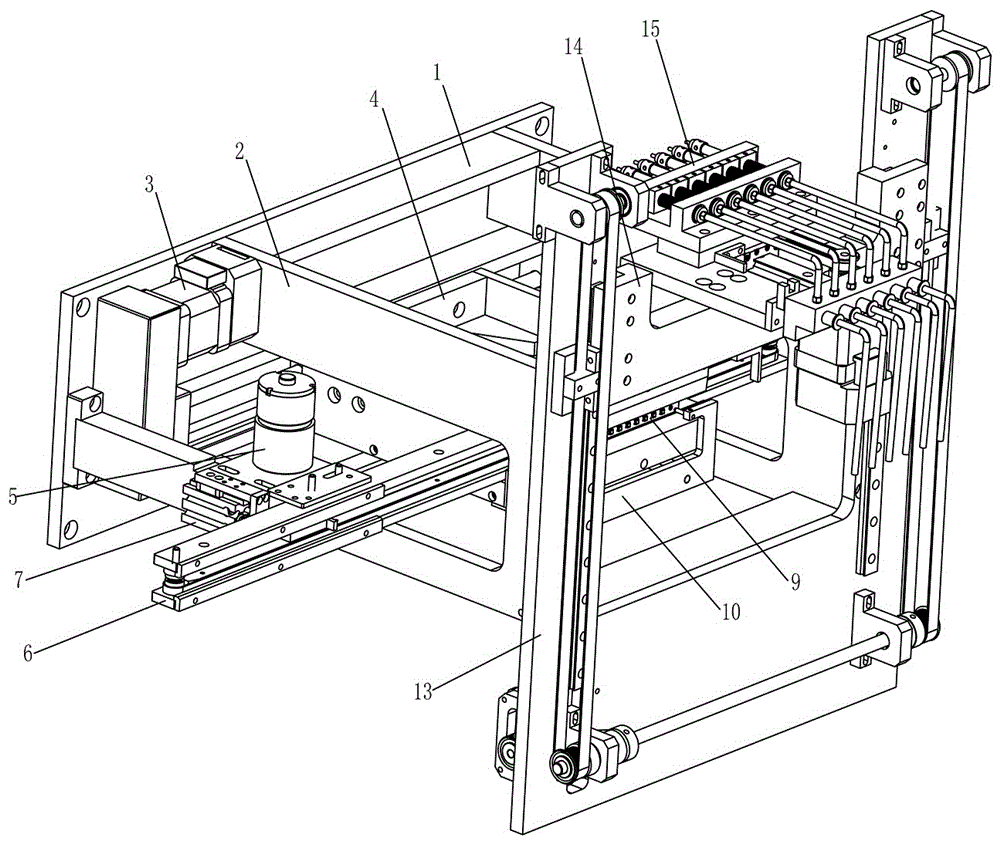

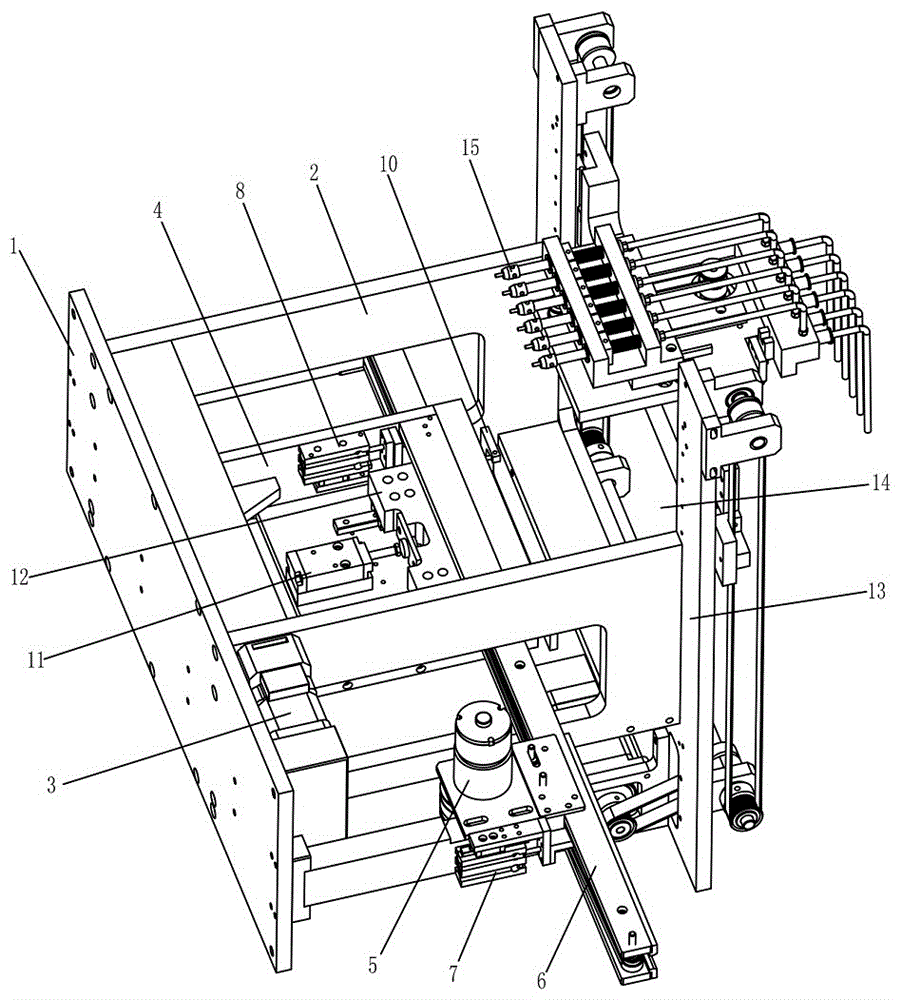

Intelligent loading and unloading vehicle system based on visual servo

PendingCN111847004ACompact structurePrecise positioningConveyorsControl devices for conveyorsVisual servoingPalletizer

The invention discloses an intelligent loading and unloading vehicle system based on visual servo, and belongs to the technical field of intelligent loading and unloading vehicle robots. The intelligent loading and unloading vehicle system comprises an unstacking and stacking mechanism, a conveying mechanism and an AGV loading and unloading mechanism, wherein the two ends of the conveying mechanism are connected to the unstacking and stacking mechanism and the AGV loading and unloading mechanism correspondingly; the AGV loading and unloading mechanism comprises an AGV trolley capable of achieving front-back, left-right and rotation displacement, a pose adjusting device arranged on the AGV trolley, a flexible grabbing device arranged on the pose adjusting device, and a first image obtainingmechanism arranged on the flexible grabbing device; and the unstacking and stacking mechanism comprises a movable carrying platform, a three-coordinate machine arranged on the carrying platform, anda second image obtaining mechanism arranged on the three-coordinate machine. The intelligent loading and unloading vehicle system solves the problem that an unstacking and stacking machine is not suitable for narrow space and space needing to be moved, full-automatic loading and unloading of goods in limited space such as a van are achieved, and manpower replacement is achieved.

Owner:李宏亮

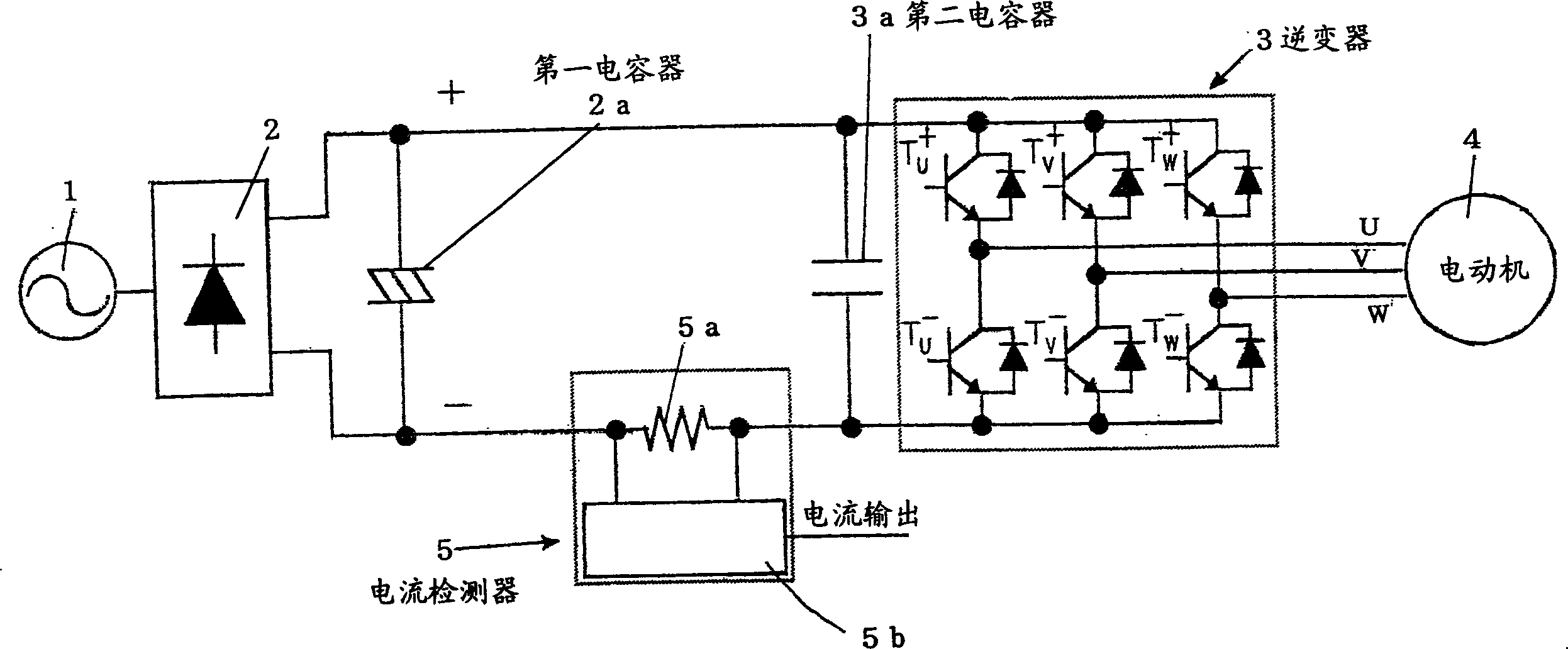

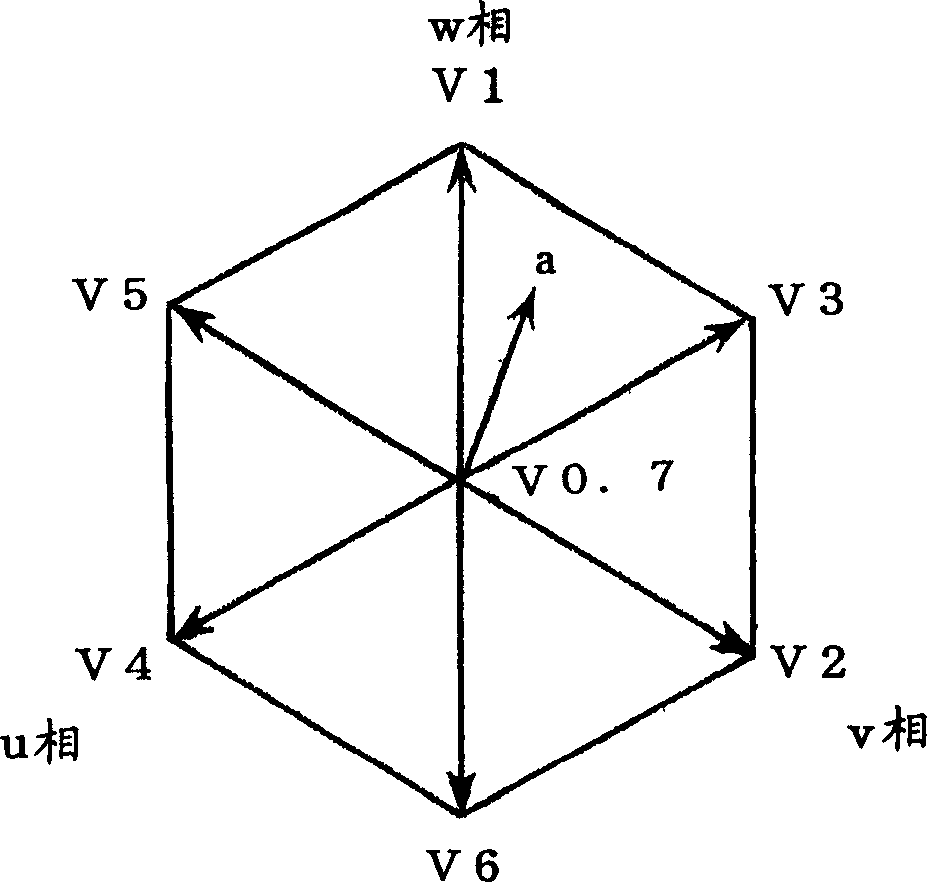

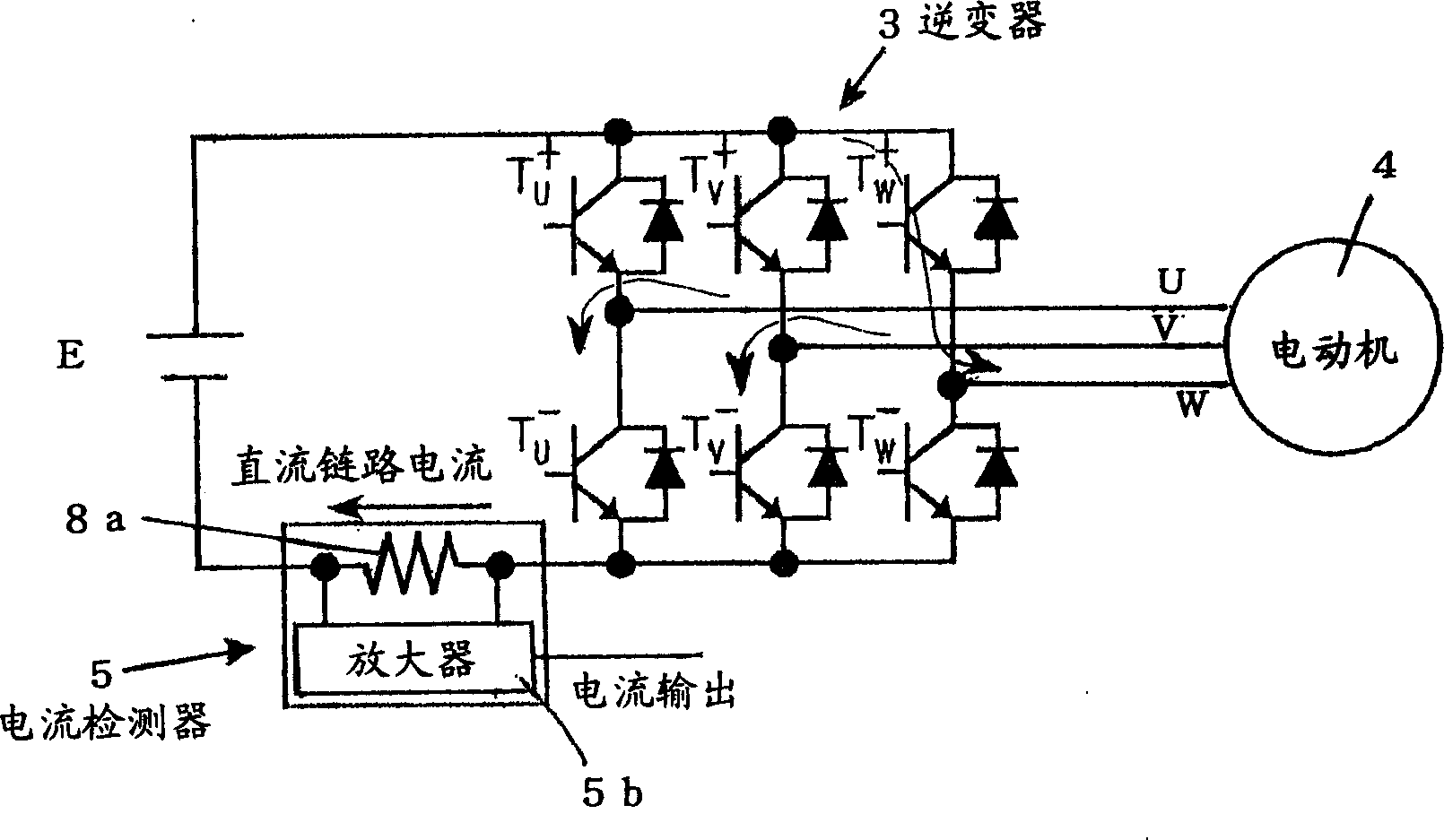

Phase current detector

InactiveCN1478319AReduce overshootReduce the effects of ringingElectronic commutation motor controlVector control systemsPhase currentsCapacitance

A first condenser (2a) is connected between output terminals of a rectifier circuit (2) which receives an AC power (1) as an input, and a three phase inverter (3) is connected in parallel with respect to the first condenser (2a), and output of the three phase inverter (3) is supplied to a motor (4), and a second condenser (3a) is connected in parallel to the input side of the three phase inverter (3), and a current detector (5) is connected between the first condenser (2a) and the second condenser (3a), and a third condenser is connected in parallel to the first condenser (2a) at a position slightly power side with respect to the current detector (5), and the capacitance of the second condenser (3a) is determined as small as possible within the range in which power devices are not destroyed by surge voltage due to switching, therefore, ringing is suppressed, and taking of current is performed rapidly and with high accuracy.

Owner:DAIKIN IND LTD

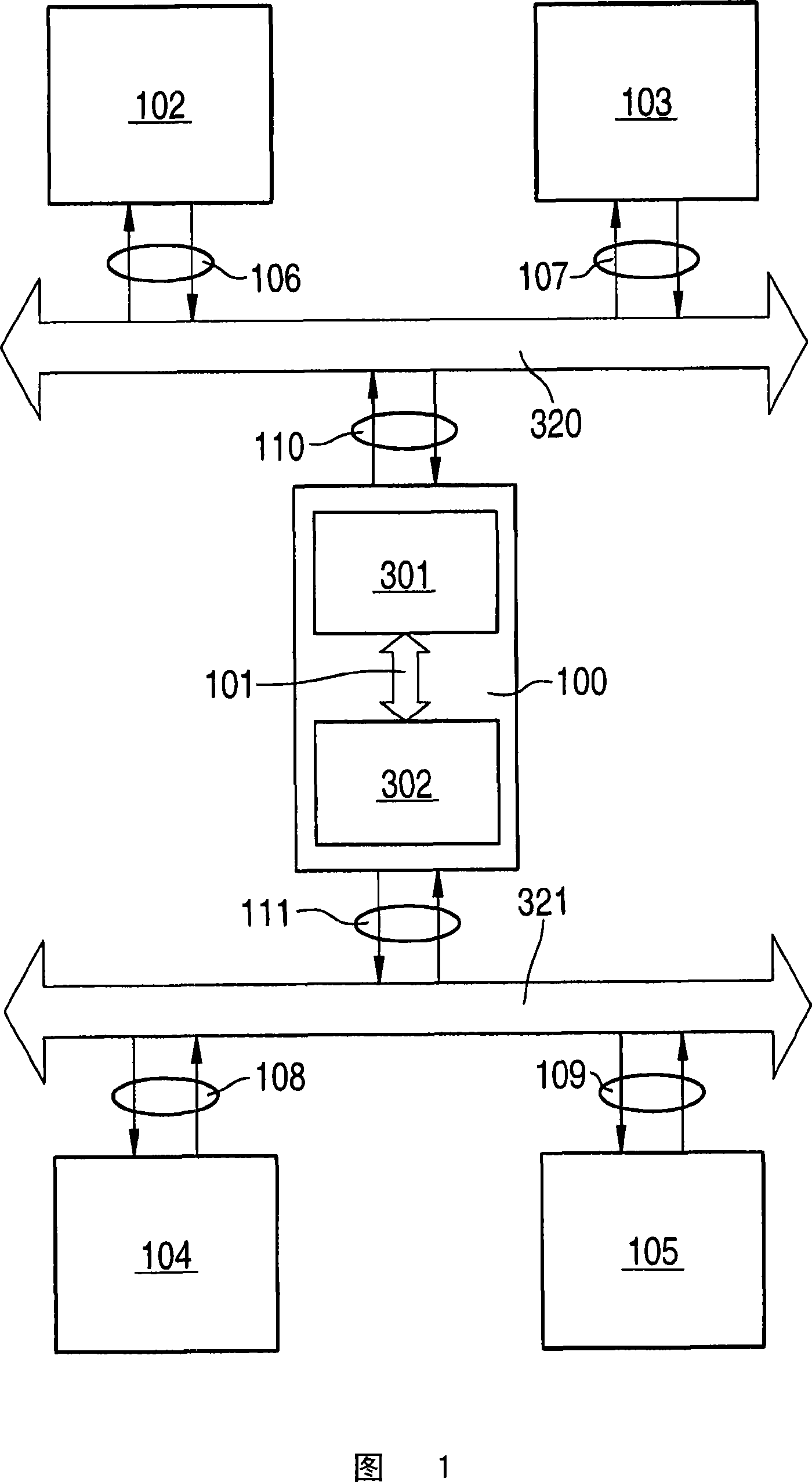

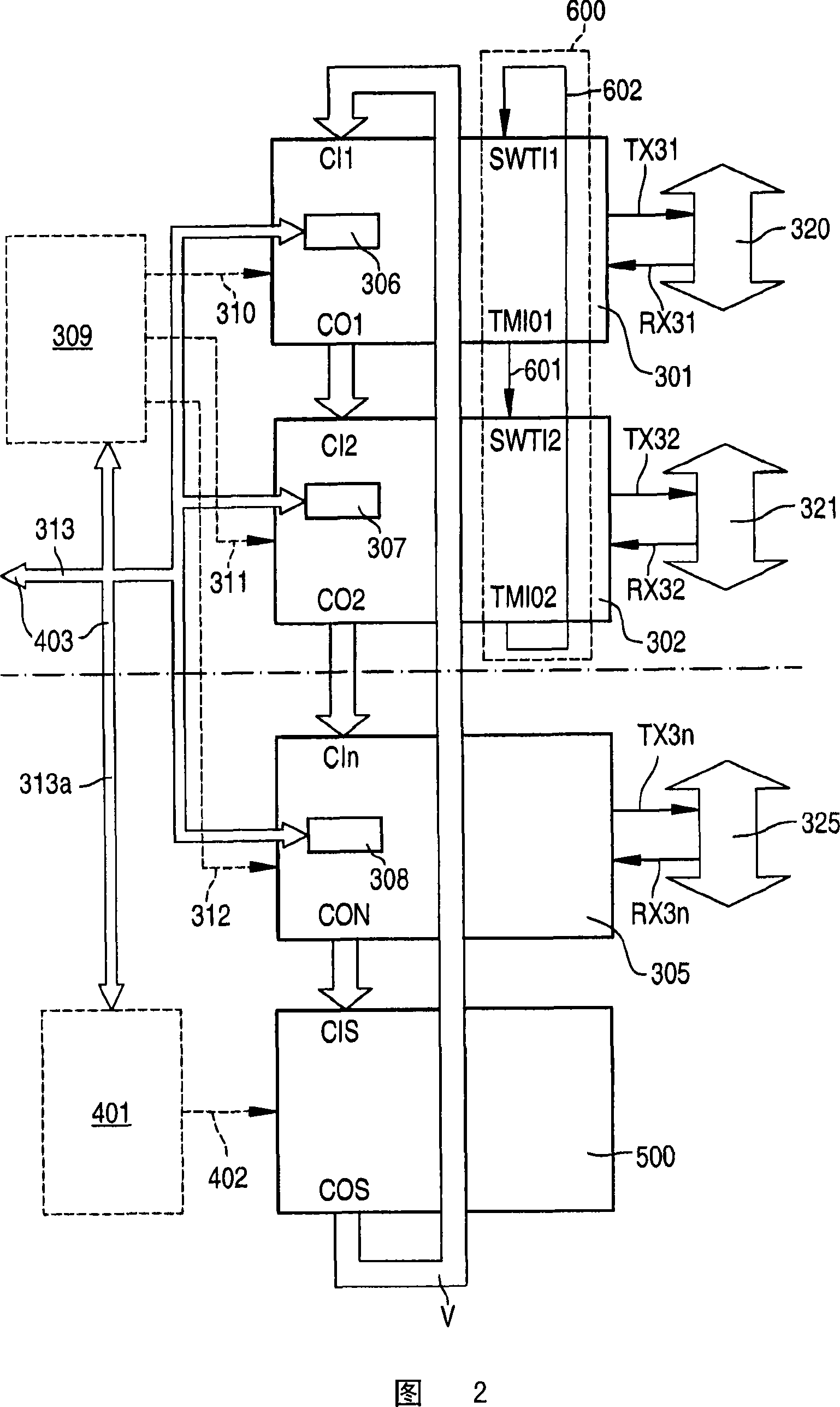

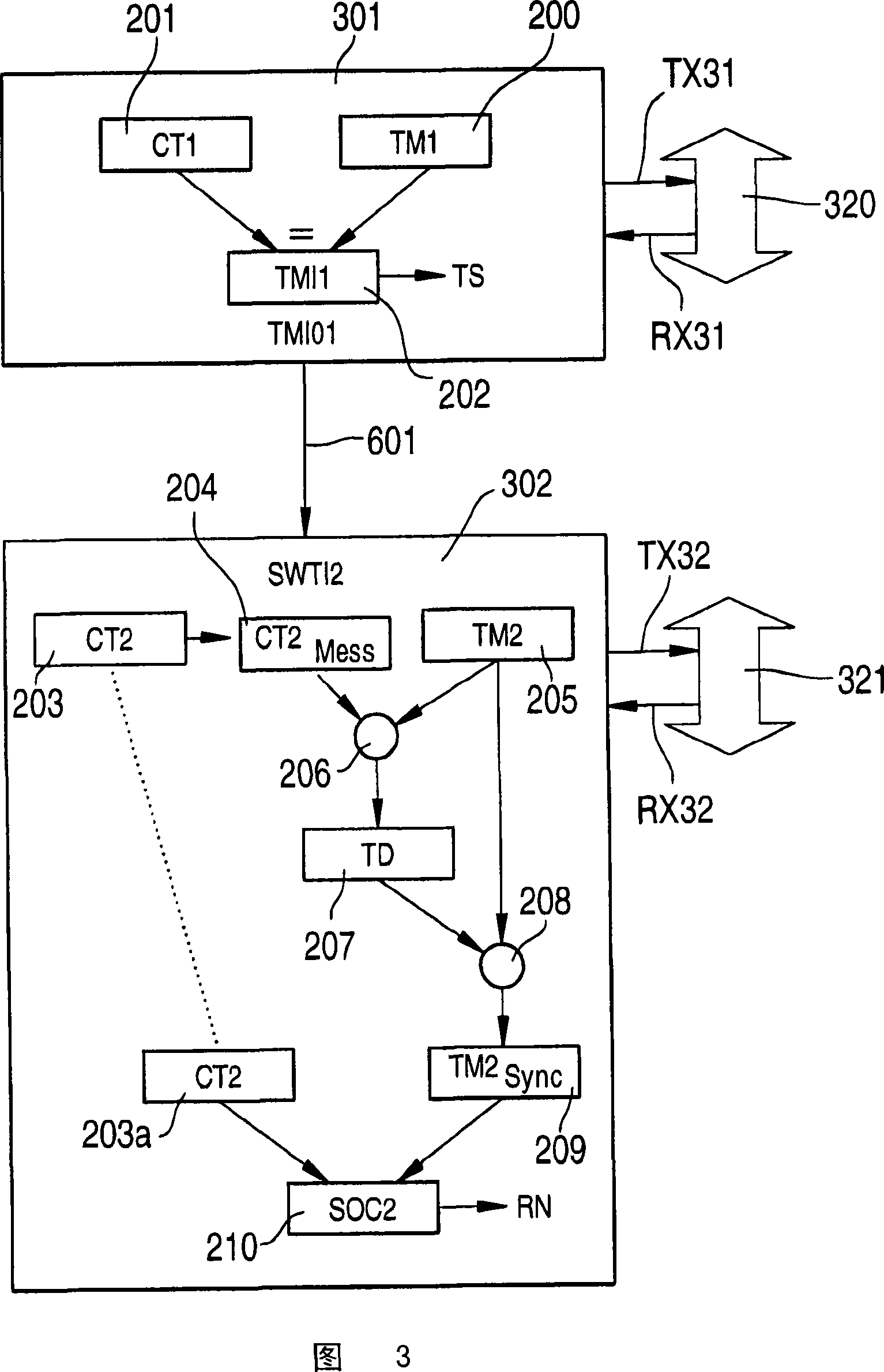

Method and device for synchronising two bus systems, and arrangement consisting of two bus systems

ActiveCN101164264AEasy to adjustAvoid inconsistenciesTime-division multiplexStar/tree networksComputer hardwareTime information

A device for synchronizing at least two bus systems, having a first communications module for a first bus system and a second communications module for a second bus system, wherein in the first communications module first trigger information is present by which a trigger signal is triggered in the first bus system, characterized in that the device is configured in such a manner that the first and second communications modules are connected to each other and the first trigger information is transmitted to the second communications module, and the second communications module is configured in such a manner that a time information value is determined from the first trigger information and that time information value is compared with a second time mark of the second bus system, a time difference being determined and the next reference message being triggered in the second bus system in dependence upon the second time mark and the time difference.

Owner:ROBERT BOSCH GMBH

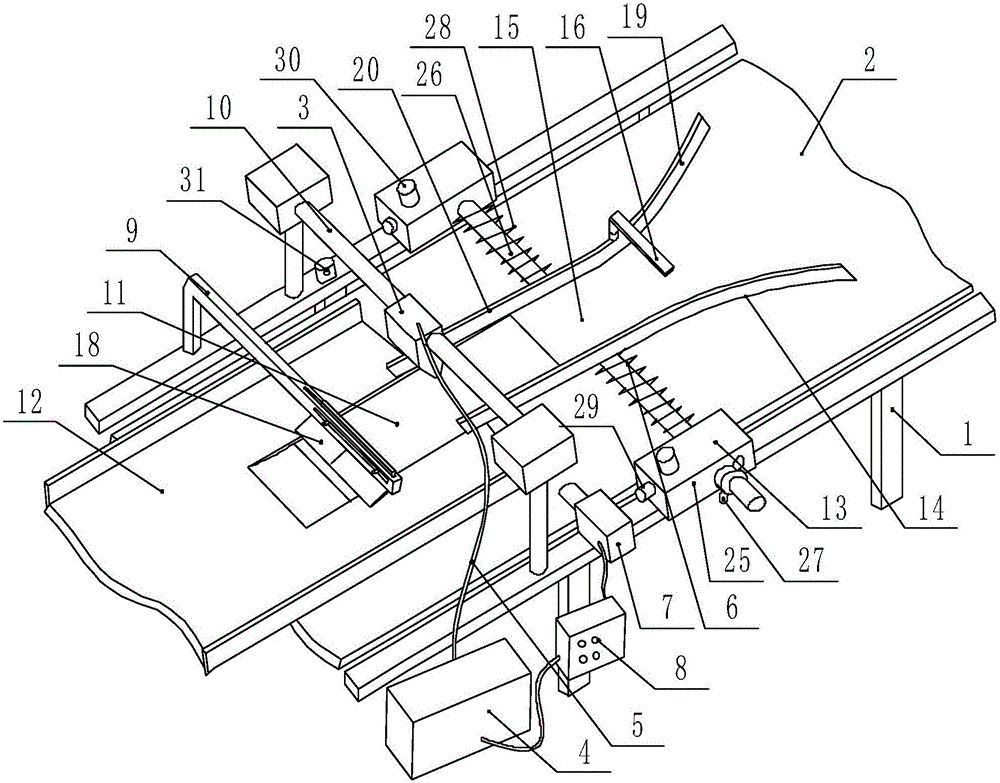

Multifunctional glue applying equipment

InactiveCN105149164AAvoid it happening againAvoid teleportationLiquid surface applicatorsCoatingsFixed frameDevice form

The invention provides multifunctional glue applying equipment which comprises a machine frame, a conveyor belt, a glue gun, a glue source and a glue discharging pipe communicated with the glue source. The multifunctional glue applying equipment further comprises a box arranging device, an induction device, a control box, a glue scraping device, a glue gun fixing frame arranged above the conveyor belt and a containing disc provided with a feeding groove. The box arranging device forms a box feeding channel. A blocking mechanism is arranged at the portion, corresponding to the box feeding channel, of the box arranging device. The feeding groove of the containing disc corresponds to the box feeding channel. The glue scraping device comprises a fixing frame and a scraper arranged at the portion, corresponding to the feeding groove, of the fixing frame. One end of the glue discharging pipe is connected with the glue source, and the other end of the glue discharging pipe is connected with the glue gun. The glue gun corresponding to the box feeding channel is installed on the glue gun fixing frame. The induction device is arranged at the position, close to the glue gun, of the machine frame. The glue gun and the induction device are connected with the control box. The multifunctional glue applying equipment can automatically correct the position of box bodies, can prevent the box bodies from being stacked, can automatically spray gun and scrape away excessive glue, and is multifunctional and high in integration degree.

Owner:天津天美环保科技有限公司

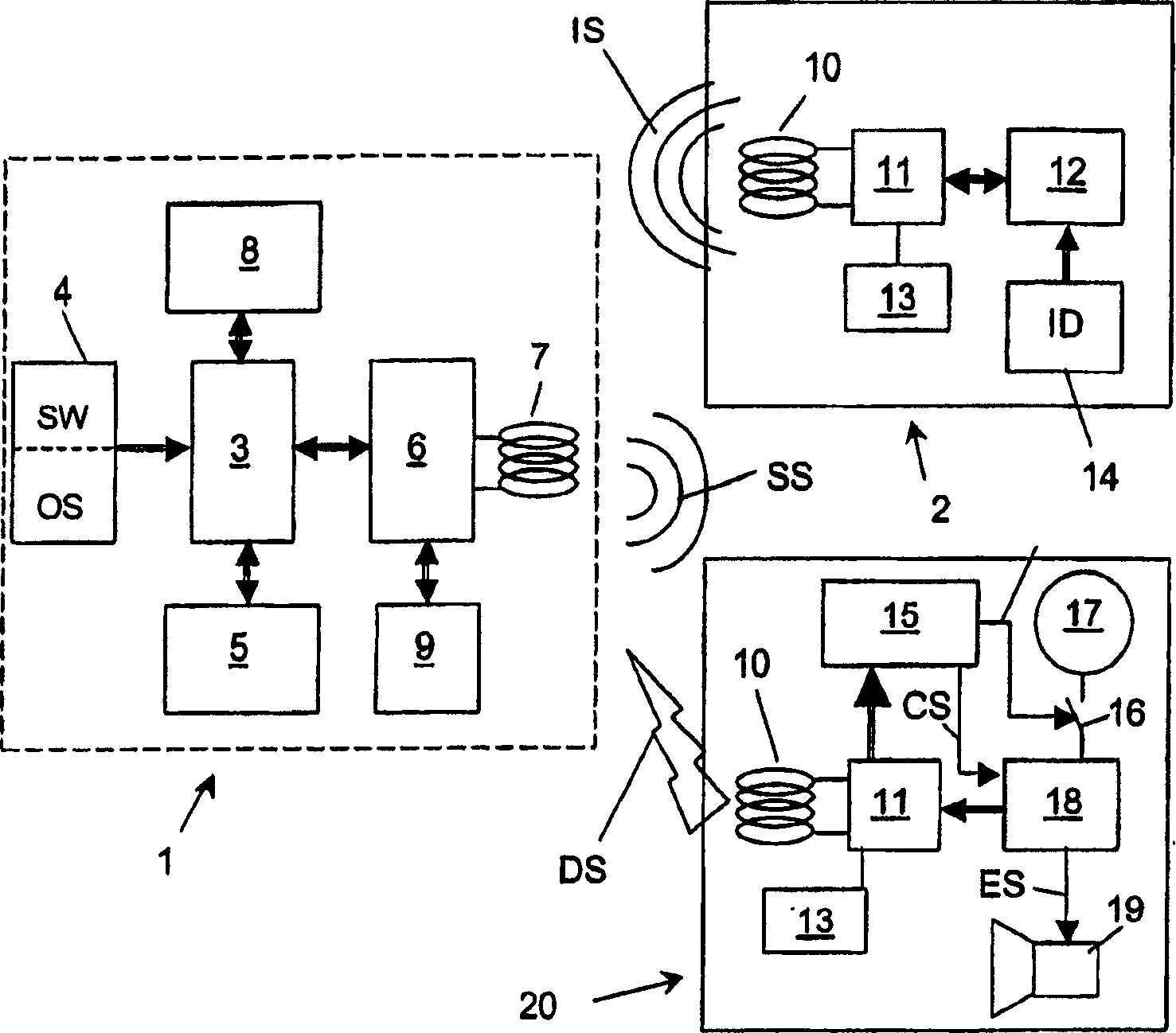

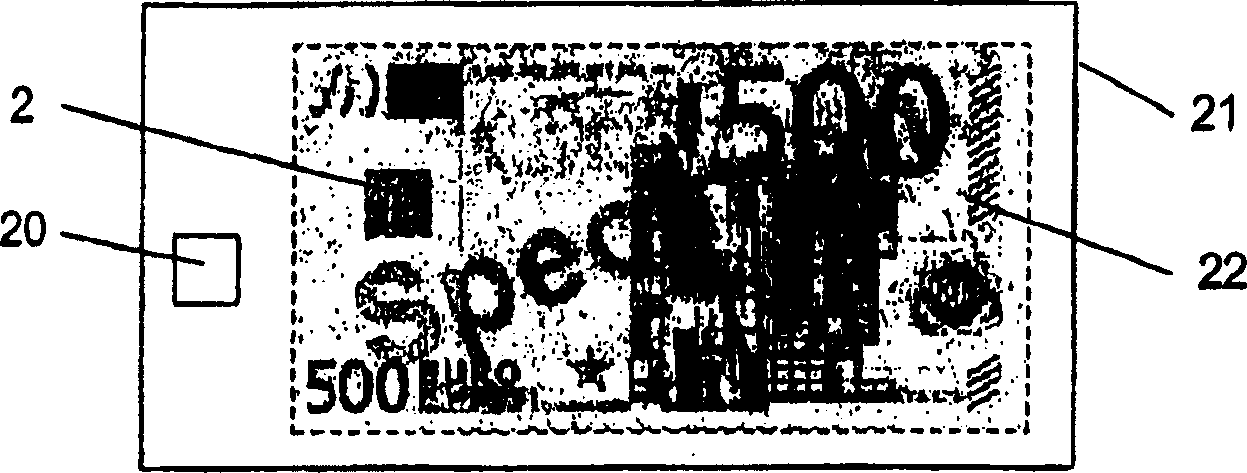

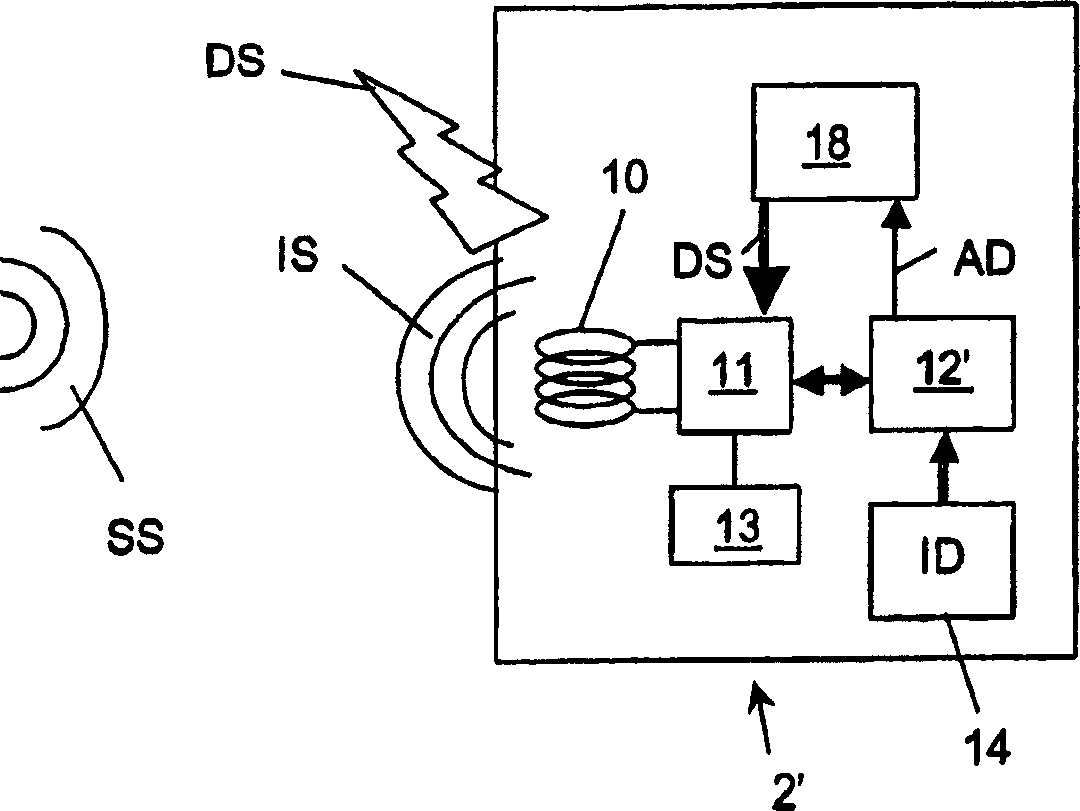

Jammer for tags and smart cards

InactiveCN1886750AIncreased private securityAvoid teleportationMemory record carrier reading problemsCo-operative working arrangementsReceiptAir interface

A jammer (20) for jamming the readout of contactless data carriers (2, 2') by a reader (1) emitting electromagnetic scanning signals (SS) has an air interface (11) for receiving electromagnetic signals, analyzing means (15) for analyzing the electromagnetic signals received by the air interface, and jamming-signal generating means (18) for generating a jamming signal (DS). The analyzing means (15) for analyzing the electromagnetic signals received are arranged to identify scanning signals (SS) from the reader (1) among the electromagnetic signals received and, when scanning signals (SS) are detected, to transmit a control signal (CS) to the jamming-signal generating means (18), which latter in turn generate the jamming signal (DS) and transmit it via the air interface (11) on receipt of the control signal (CS).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

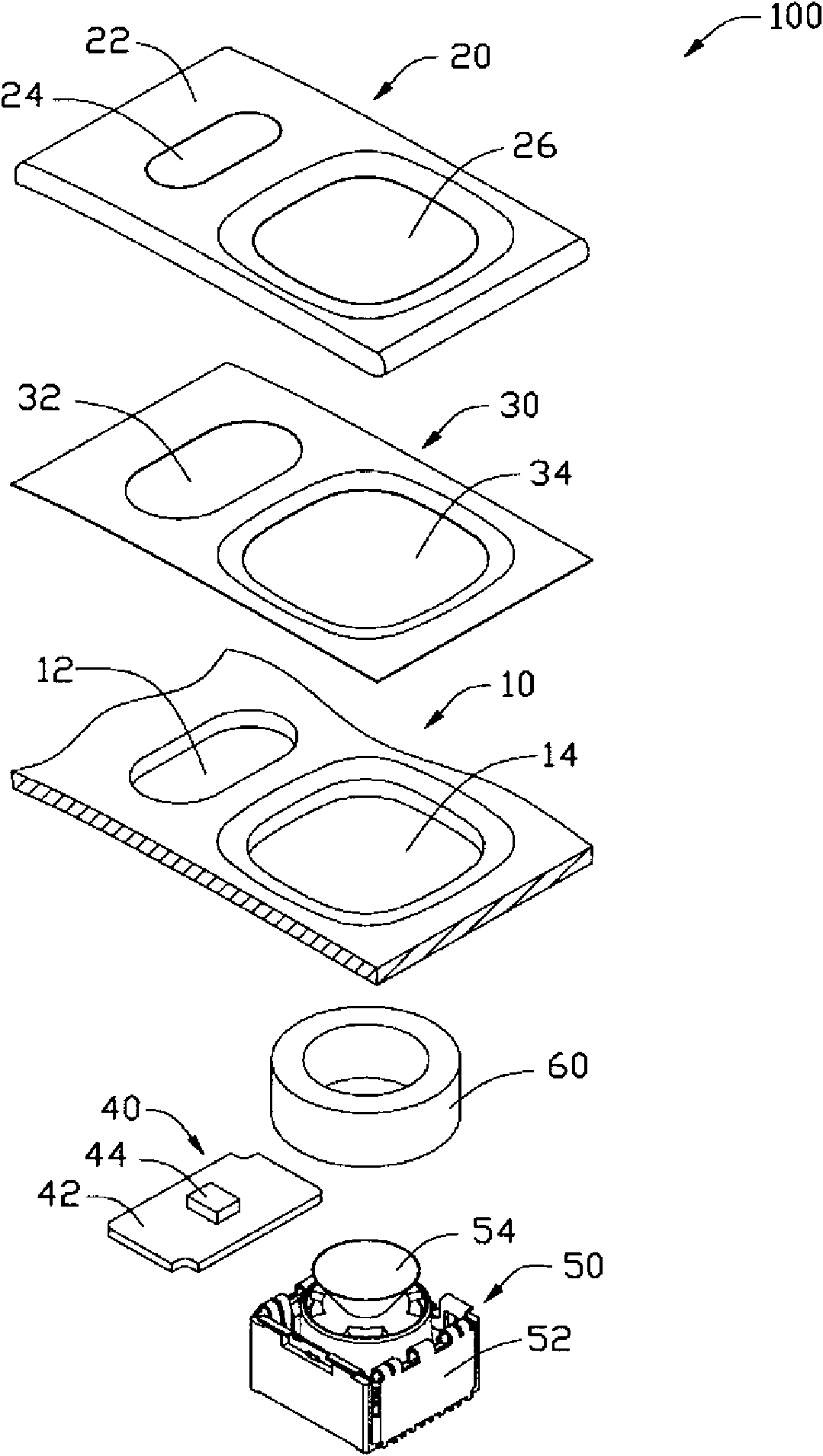

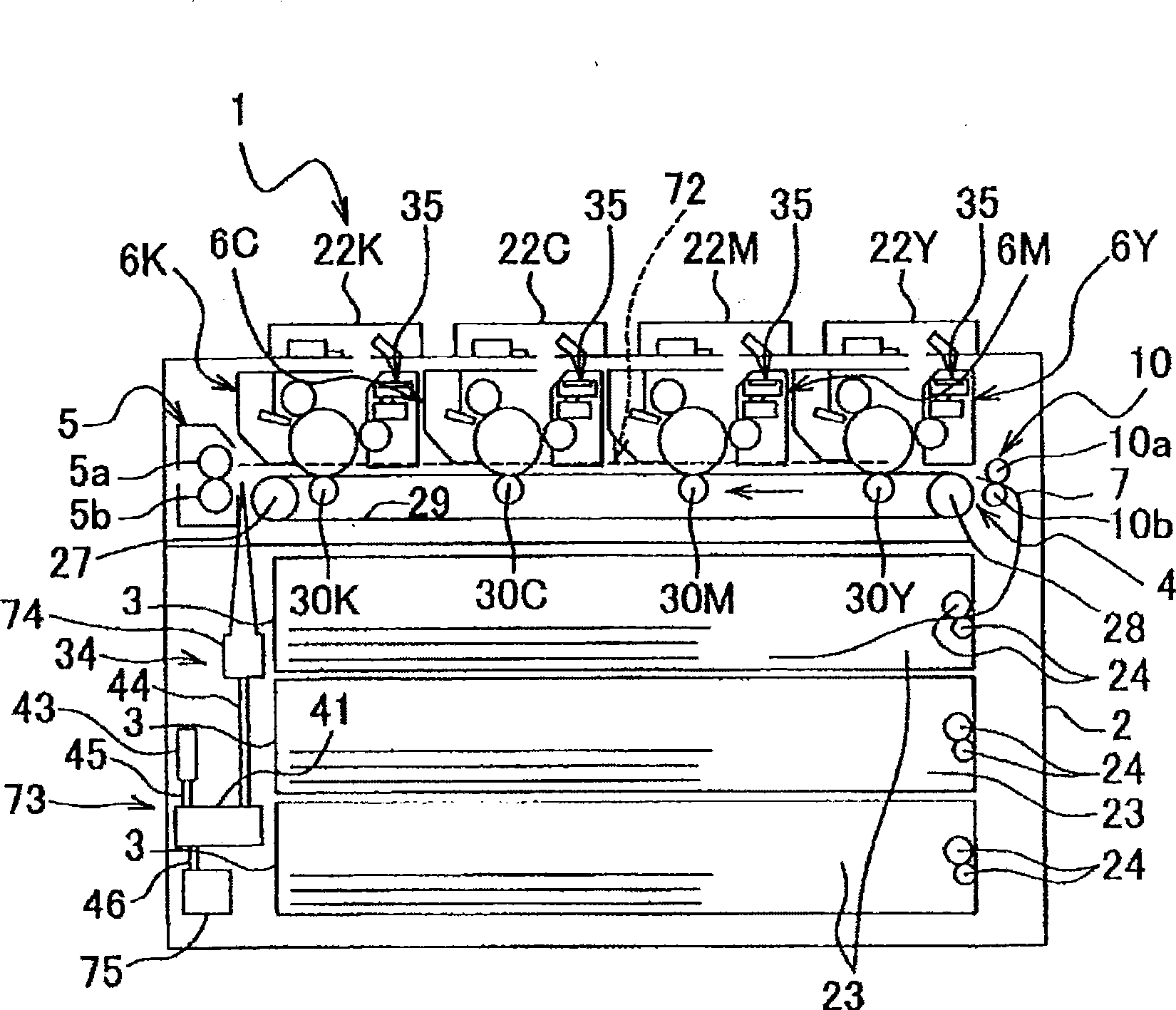

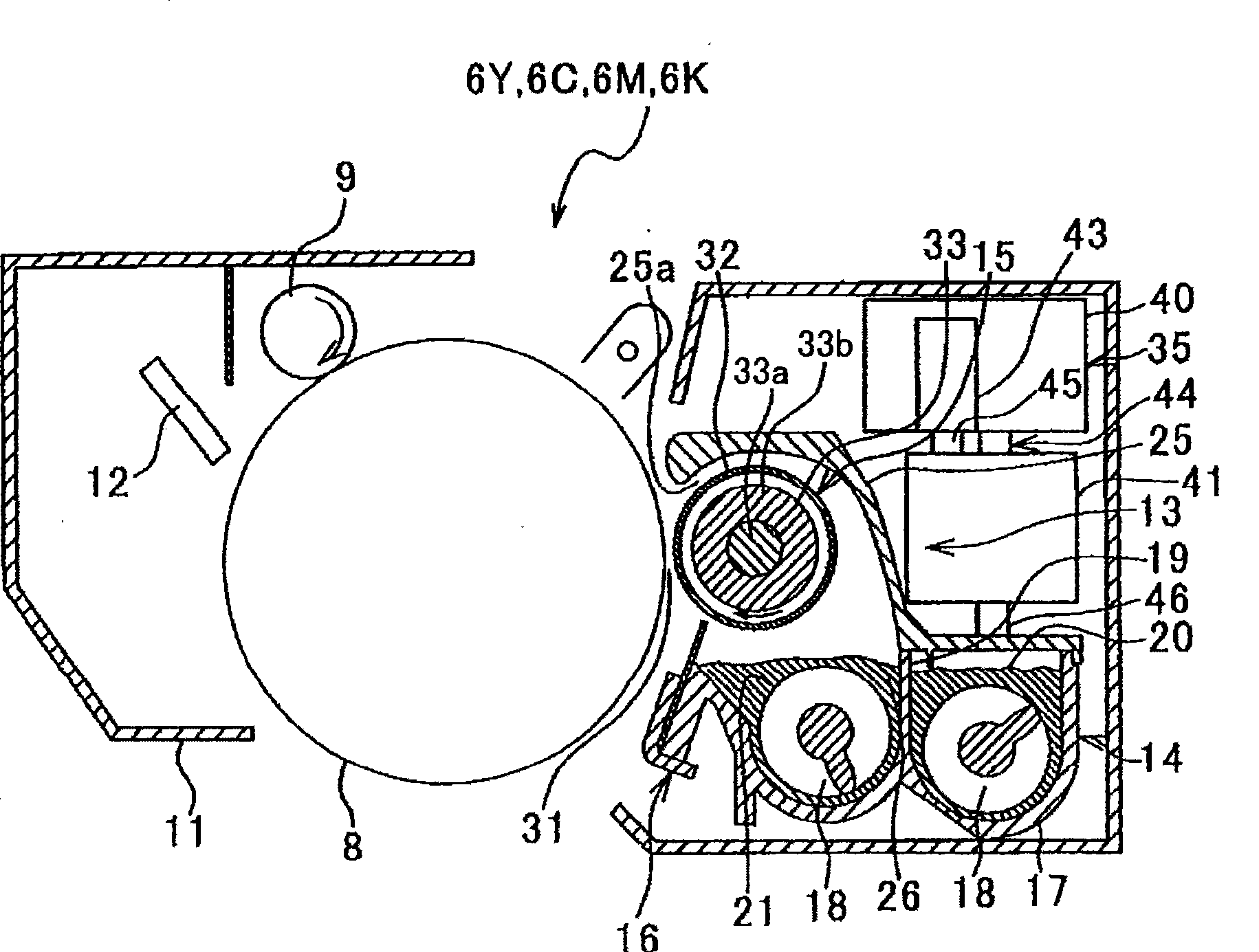

Powder transporting apparatus and image forming apparatus including the same

ActiveCN101470386AAvoid teleportationThermal stress minimizationElectrographic process apparatusMechanical engineering

A powder transporting apparatus is made up of: a powder container containing therein powder; a transportation tank having an inlet for supplying the powder from the powder container, and an outlet for discharging the powder to an outside; a conveying device disposed in the transportation tank and rotated about an axis to thereby transport the powder in the transportation tank from the inlet to the outlet; and a suction device disposed outside the transportation tank. The suction device sucks gas in the transportation tank through a suction port which is away from both the inlet and the outlet of the transportation tank. The powder in the powder container is thus sucked into the transportation tank.

Owner:RICOH KK

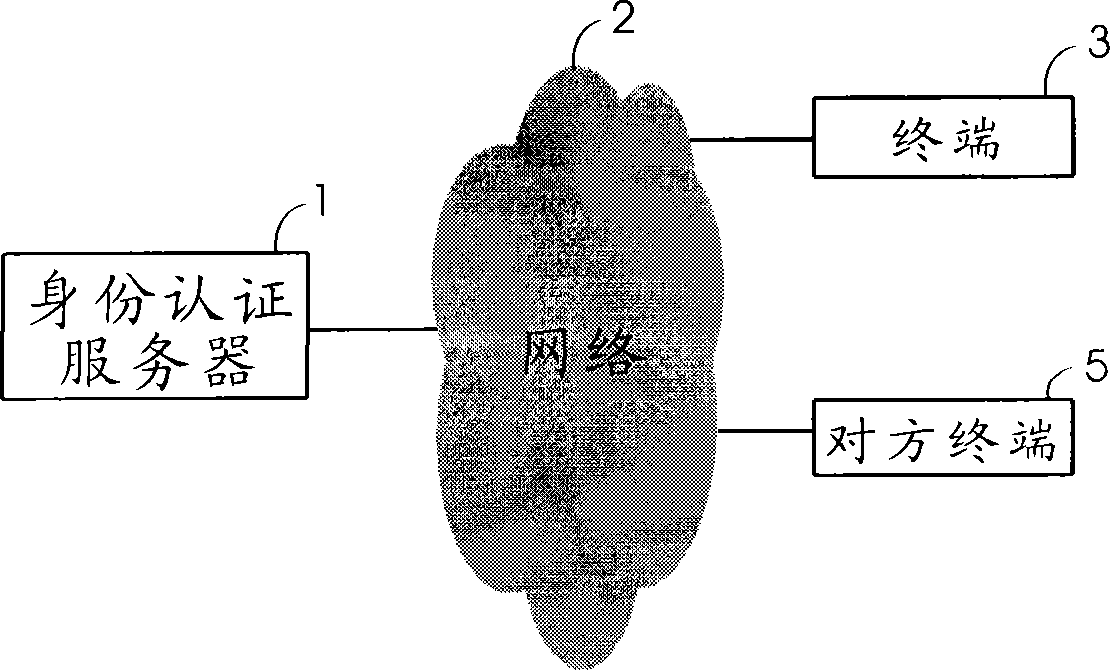

An identification mutual authentication system and method integrated net addresses

InactiveCN101217372AHigh transparencyImprove reliabilityUser identity/authority verificationNetwork terminationThird party

The invention discloses a system and a method for identity mutual authentication in combination with network addresses; wherein, the invention carries out one-to-one correspondence and binding of identity information, attribute information, application information and network terminals and terminal addresses of the network terminals of objects; the identity information, the network addresses and the application information of counterparts is mutually provided through network terminals of both parties, in particular to mobile terminals, the identity can be authenticated mutually without certificates, identity codes and the inspection of counterpart personnel and the application information can be provided; the reliability of the identity information and the fake difficulty are increased by registering the identity information at a third party, making one-to-one correspondence of the identity information with the terminal addresses, the identity passwords and / or biological features and making identity mutual authentication through the network terminals and an identity authentication server; the reliability of service information is improved by the interaction of the application information at the same time when the identity authentication is carried out.

Owner:刘小鹏

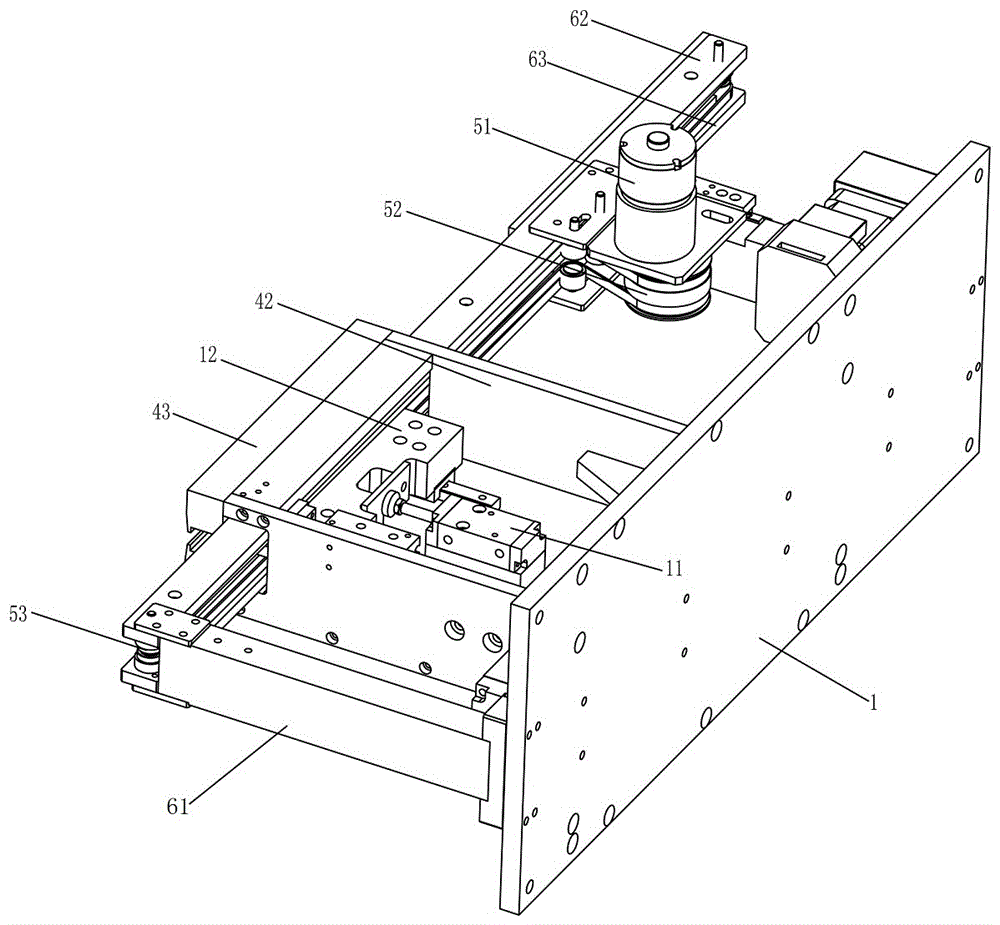

Synchronous feeding assembly line

ActiveCN112249677APurchase Fee WaiverLow costStacking articlesDe-stacking articlesAssembly lineElectrical and Electronics engineering

The invention discloses a synchronous feeding assembly line. A carrier feeding and conveying line comprises a stock bin, a carrier lifting assembly, a carrier carrying assembly, and at least one carrier conveying belt, wherein the stock bin comprises at least two storage boxes which are arranged in parallel; the carrier lifting assembly is arranged beside the stock bin; the carrier carrying assembly is arranged beside the carrier lifting assembly; and the at least one carrier conveying belt is arranged beside the carrier carrying assembly. A loading and conveying line comprises a product feeding device, a carrier feeding device, and a product carrying mechanism, wherein a plurality of trays used for containing products are stacked in the product feeding device; the carrier feeding device is arranged beside the product feeding device; and the product carrying mechanism comprises a carrying cross beam erected between the carrier feeding device and the product feeding device, a grabbing assembly connected with the carrying cross beam in a sliding manner, and a carrying driver connected with the grabbing assembly in a drive manner. By using the synchronous feeding assembly line, the integration level of equipment is improved; the cost of the equipment and the floor area of the equipment are greatly reduced; and the production efficiency and the yield are improved.

Owner:SUZHOU RS TECH

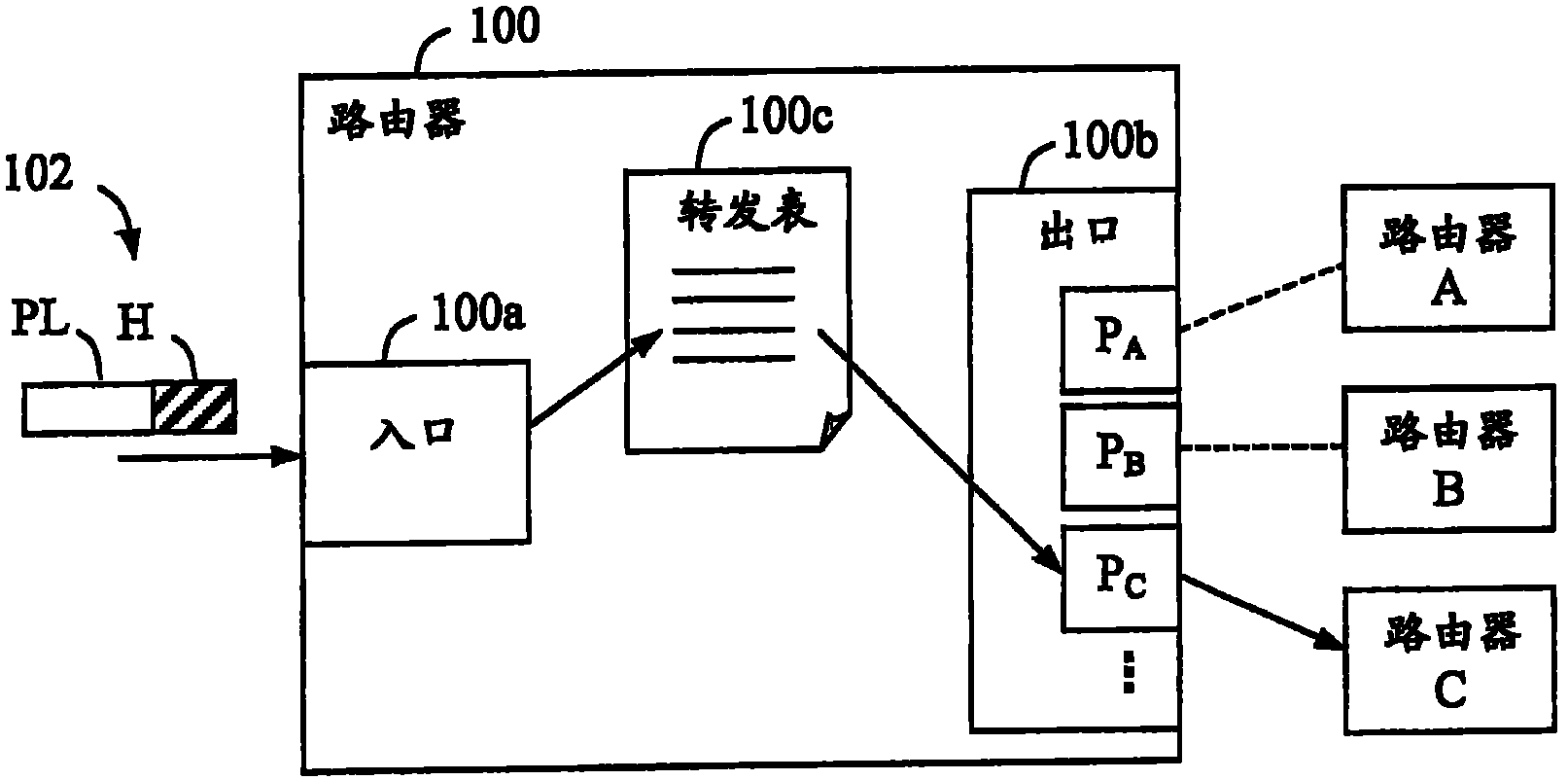

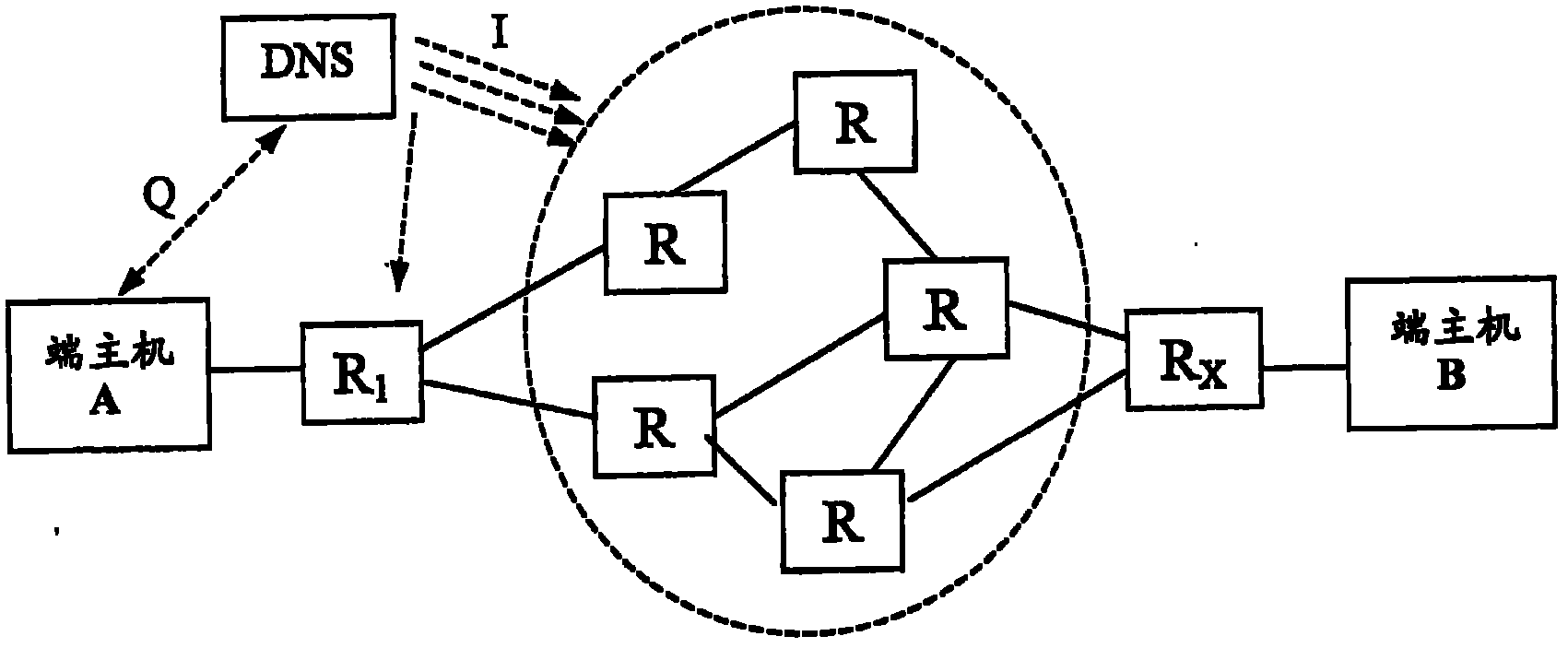

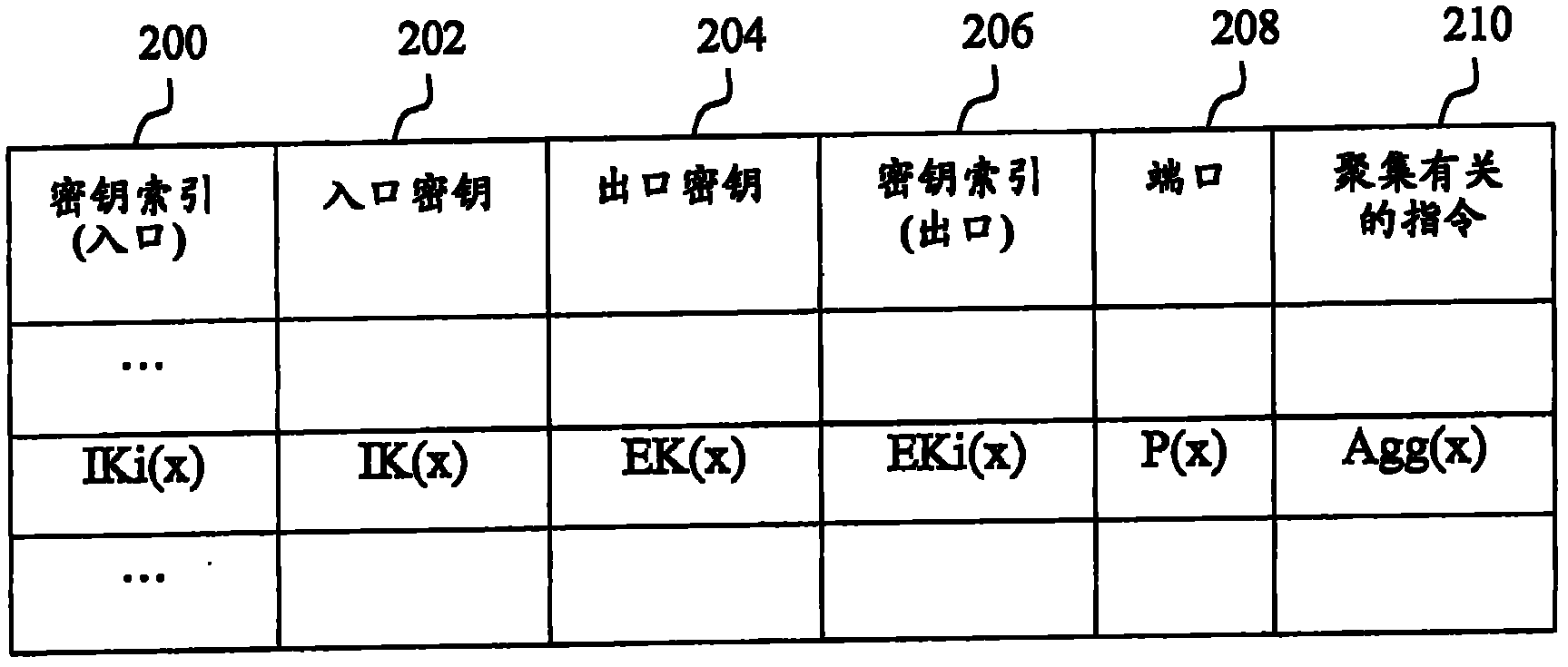

Method and apparatus for forwarding data packets using aggregating router keys

InactiveCN102210126AAvoid packet switchingAvoid teleportationData switching networksComputer networkKey management

Method and apparatus for supporting the forwarding of received data packets in a router (402,702) of a packet- switched network. A forwarding table (706a) is configured in the router based on aggregating router keys and associated aggregation related instructions received from a key manager (400,700). Each aggregating router key represents a set of destinations. When a data packet (P) is received comprising an ingress tag derived from a sender key or router key, the ingress tag is matched with entries in the forwarding table. An outgoing port is selected for the packet according to a found matching table entry that further comprises an associated aggregation related instruction. An egress tag is then created according to the aggregation related instruction, and the packet with the created egress tag attached is sent from the selected outgoing port to a next hop router.

Owner:TELEFON AB LM ERICSSON (PUBL)

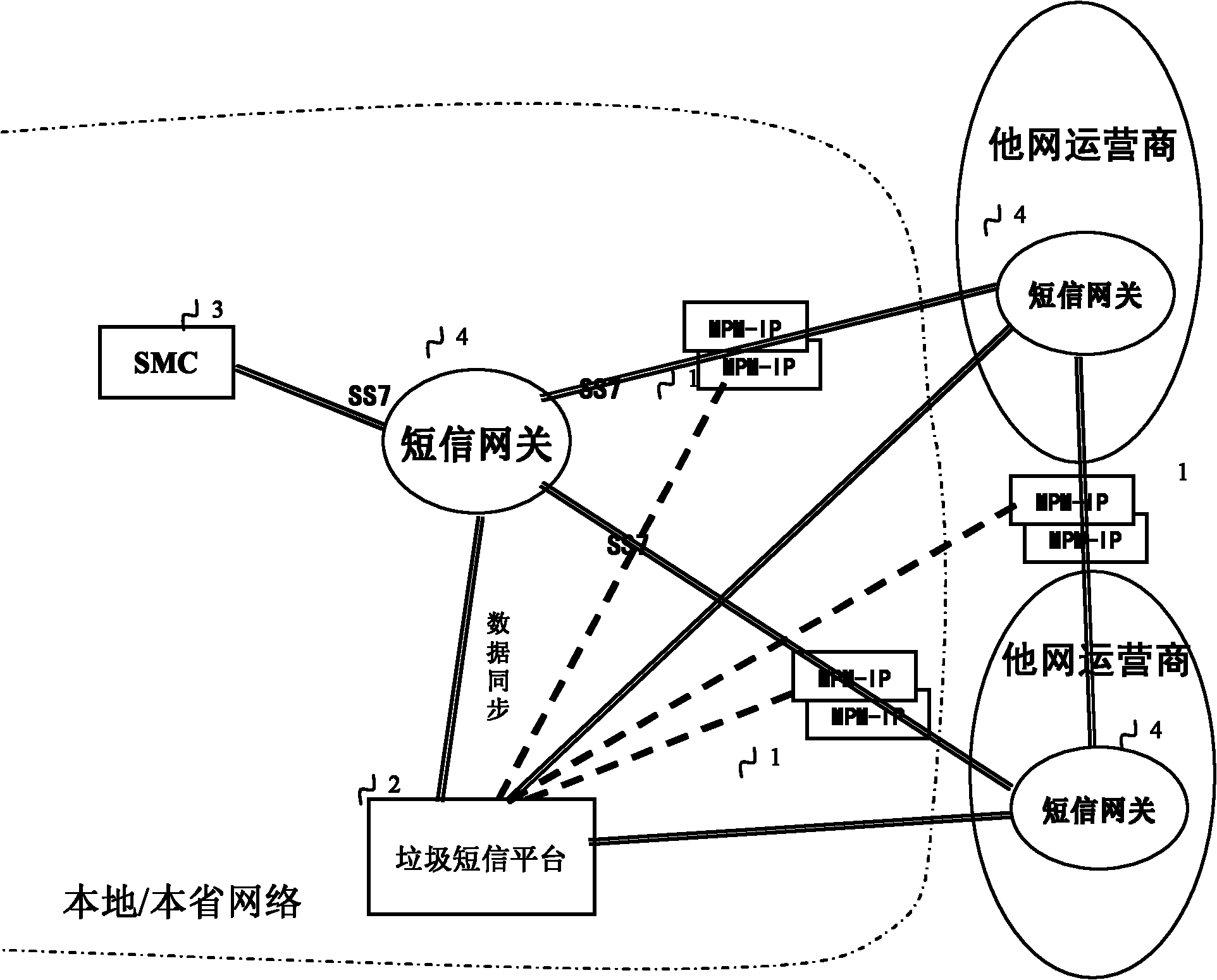

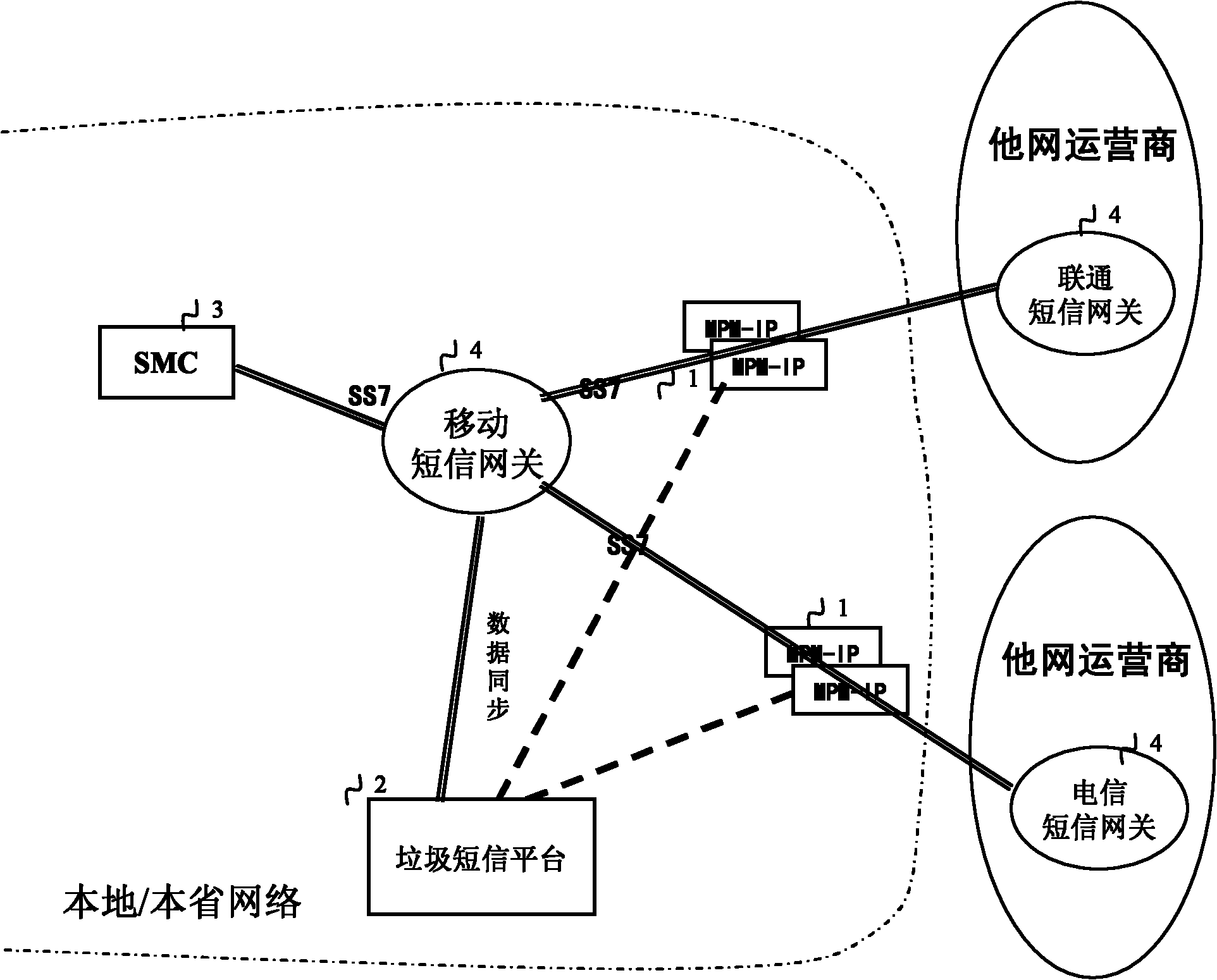

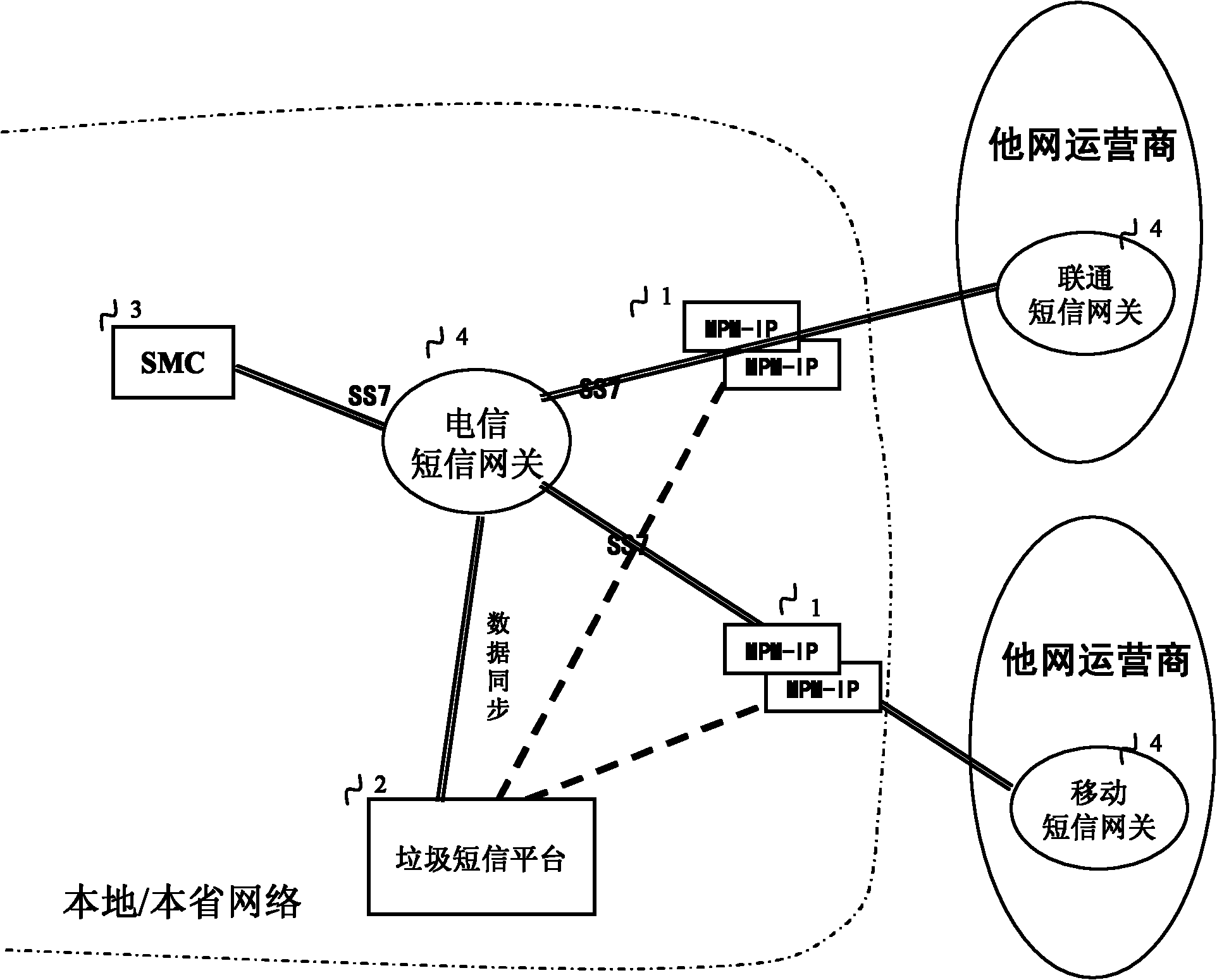

System and method for monitoring internetwork junk short messages

InactiveCN102638778AAvoid teleportationDoes not require additional processing powerMessaging/mailboxes/announcementsSecurity arrangementData managementNetwork service

The invention discloses a system and a method for monitoring internetwork junk short messages. The system comprises a plurality of IP (Internet Protocol) signaling message detecting processing devices (MPM-IP) which are connected with an internetwork short message transmission link and a junk short message platform. The MPM-IP is used for analyzing the flowing-through internetwork short message as well as realizing the gate of the short message and rerouting to the junk short message platform for processing according to a service rule and a black and white list. The junk short message platform is used for processing the junk short message, replying message response, managing and synchronizing the service rule and the use data, and the like. The problems that the traditional mode is difficult to implement, the maintenance is complex, and the like, are solved by the system and method provided by the invention; the reformation for a short message center and a short message gateway is avoided; the extra processing capacity of the existing network equipment is not needed to be increased; with less investment, a comprehensive effective short message purifying method is independently supplied from point to plane among operator networks; the spreading of internetwork junk short messages is effectively restrained; high quality of network service is supplied; and network resources are saved.

Owner:SHANGHAI LIANGJIANG COMM SYST

Automatic transportation production line for electronic product materials

The invention discloses an automatic transportation production line for electronic product materials, which comprises a support plate, connecting plates, a support, a material push transportation mechanism and a material adsorption hauling mechanism, wherein the support plate is vertically fixed on a peripheral stand, the number of the connecting plates is two, corresponding ends of the two connecting plates are respectively connected with the left side and the right side of the support plate, an U-shaped empty groove is arranged in the wall of each connecting plate; the support is connected with the other end of each connecting plate; the material push transportation mechanism is arranged on one side of the support plate; the material push transportation mechanism comprises a guide component and a material push component, the guide component extends along the side of the support plate, the material push component is arranged on one side of the guide component and slides on the guide component along with products to push the products out of the guide component; and the material adsorption hauling mechanism is arranged on a sliding seat which is connected with the left side wall and the right side wall of the support. The automatic transportation production line for the electronic product materials can realize automatic material obstructing, rectilinear moving, material blocking, pushing, transferring, adsorbing, and hauling for the electronic products.

Owner:东莞市高东电子科技有限公司

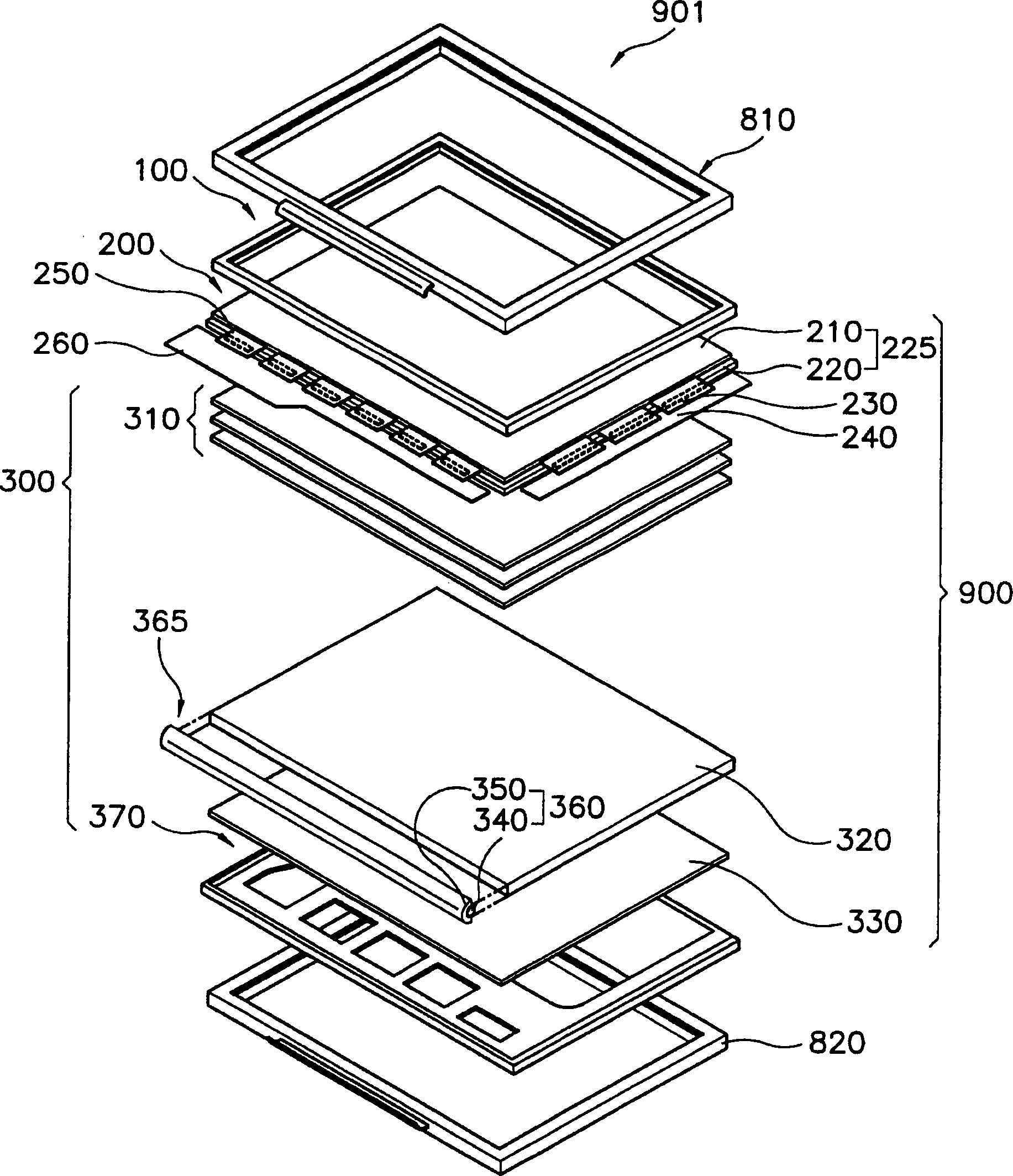

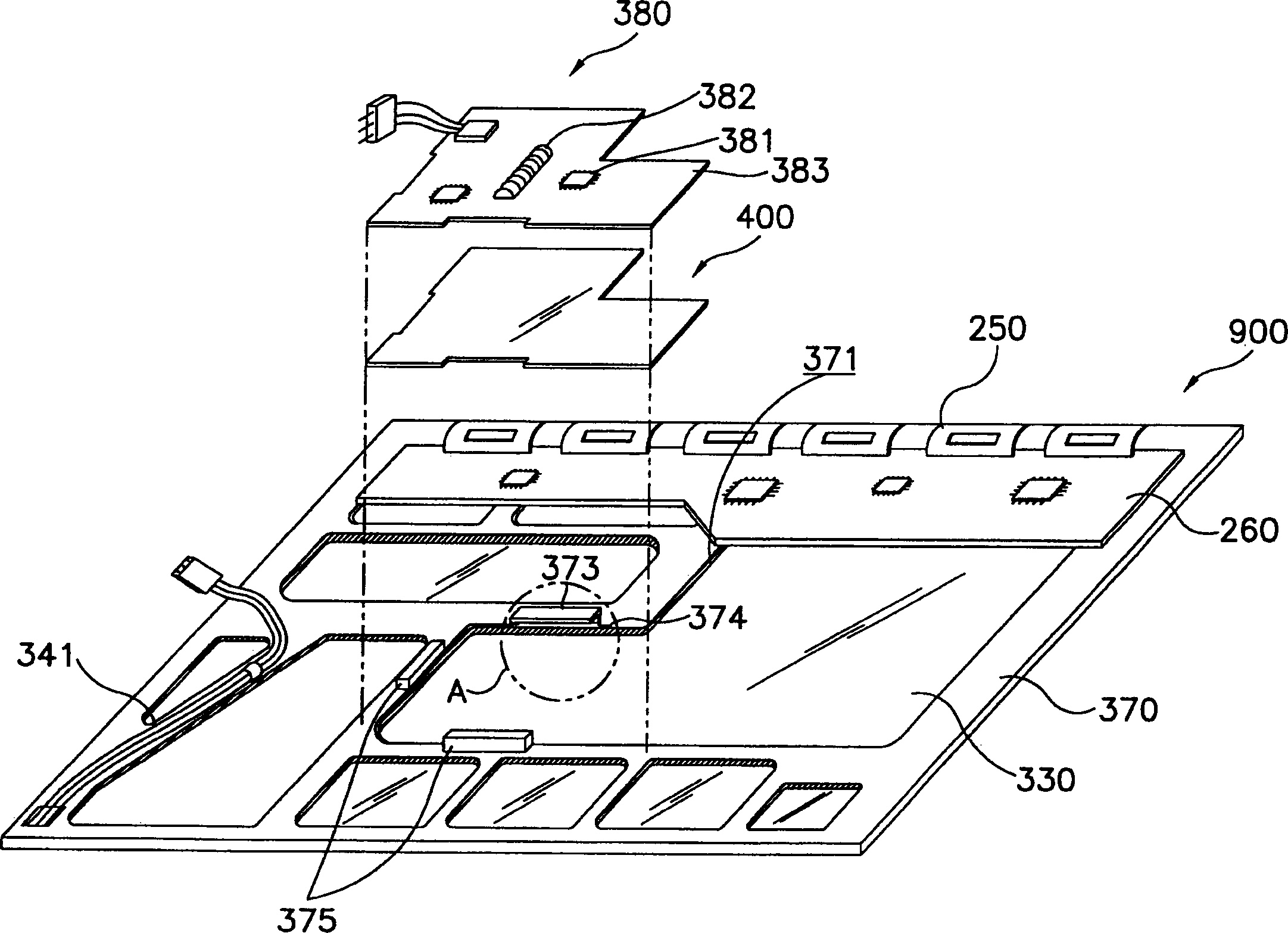

Liquid crystal display

InactiveCN1387072AImprove uniformityAvoid teleportationTelevision system detailsStatic indicating devicesLiquid-crystal displayComputer module

The present invention discloses a liquid crystal display (LCD), which prevents the degradation of display performance due to heat generated in the LCD. The heat-shielding film of aluminum-containing material arranged in the installation container shields the extra heat generated in the conversion process of the power used to drive the lamp in the inverter module, thereby minimizing the heat transmitted to the reflector. Thus, the heat generated in the process of generating light is effectively blocked and released, thereby minimizing the degradation of display characteristics.

Owner:SAMSUNG DISPLAY CO LTD

Pile-forming process dynamic testing device for underwater sand compaction pile

The invention provides a pile-forming process dynamic testing device for an underwater sand compaction pile. The testing device is connected with a pile pipe and comprises a fiber bragg grating soil pressure sensor, multiple sets of fiber bragg grating strain meters and two sets of acceleration sensors, wherein the fiber bragg grating soil pressure sensor and the multiple sets of fiber bragg grating strain meters are connected with a dynamic fiber bragg grating demodulation instrument, the two sets of acceleration sensors are connected with a vibration and dynamic signal acquisition analyzer, cable protection structures are arranged outside the cable of the fiber bragg grating soil pressure sensor, the cables of the fiber bragg grating strain meters and the cables of the acceleration sensors, and the fiber bragg grating soil pressure sensor is fixedly arranged on an end plate of the pile pipe; the fiber bragg grating strain meters are distributed along the pile pipe from top to bottom and fixedly arranged on the outer side wall of the pile pipe; the two sets of acceleration sensors are arranged on the outer side faces, close to the pile top and the pile bottom, of the pile pipe respectively. The pile-forming process dynamic testing device for the underwater sand compaction pile is not prone to being influenced and limited by environmental conditions and structure conditions, can guarantee test precision and is more suitable for pile-forming process dynamic testing for the underwater sand compaction pile.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com