Modified polyurethane waterproof paint as well as preparation method and construction method thereof

A polyurethane waterproof and polyurethane acrylate technology is applied in the field of modified polyurethane waterproof coatings and preparation methods and construction fields, and can solve the problems of affecting the aging resistance of products, easy yellowing of aromatic polyurethanes, and inability to meet waterproof requirements, etc. Short curing time, fast curing speed, less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

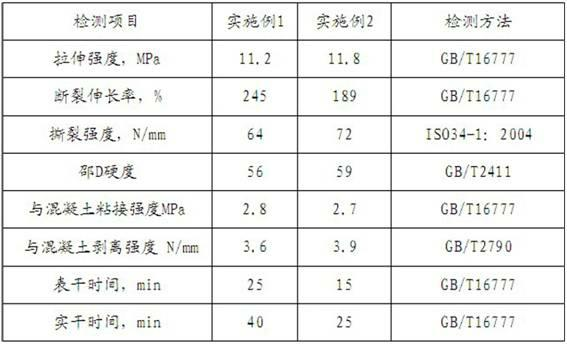

Examples

Embodiment 1

[0029] The modified polyurethane waterproof coating according to the present embodiment includes three components A, B and C. Preparation of component A: add 18 parts by weight of methyl methacrylate, 2 parts of styrene, 20 parts of methyl acrylate and 35 parts of aliphatic urethane acrylate prepolymer into a high-speed disperser and disperse until the resin Dissolve completely, then add 10 parts of Shuangfei powder, 10 parts of talc powder, 1 part of N,N-dimethylaniline, 1 part of N,N-diethylaniline, and 3 parts of fumed silica into the high-speed disperser, The stirring speed is 800 rev / min, the dispersion time is 30min, and it is ground to a fineness below 40μm with a horizontal sand mill.

[0030] Preparation of component B: Add 25 parts of methyl methacrylate, 15 parts of methyl acrylate and 30 parts of aliphatic urethane acrylate prepolymer into a high-speed disperser and disperse until the resin is completely dissolved, and then 15 parts by weight Add 1 part of mica po...

Embodiment 2

[0034] The three-component spray-coated modified polyurethane waterproof coating according to this embodiment includes three components A, B and C. Preparation of component A: Add 18 parts of methyl methacrylate, 22 parts of methyl acrylate and 35 parts of aliphatic urethane acrylate prepolymer in parts by weight to disperse in a high-speed disperser until the resin is completely dissolved, and then 10 parts Add 1 part of silicon micropowder, 10 parts of talc powder, 1.5 parts of N,N-dimethylaniline, 0.5 part of cobalt isooctanoate, and 3 parts of bentonite into a high-speed disperser with a stirring speed of 600 rpm and a dispersion time of 45 minutes. The mill grinds to a fineness of 40 μm or less.

[0035] Preparation of component B: In parts by weight, add 25 parts of methyl methacrylate, 20 parts of butyl methacrylate and 30 parts of aliphatic urethane acrylate prepolymer into a high-speed disperser and disperse until the resin is completely dissolved , and then add 10 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com