Precast ultra-high-performance concrete steel bridge deck pavement structure and preparation method

An ultra-high performance, concrete technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as difficult flatness control, rivet welding damage, etc., to achieve reliable pavement quality, improve toughness, and delay fatigue damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

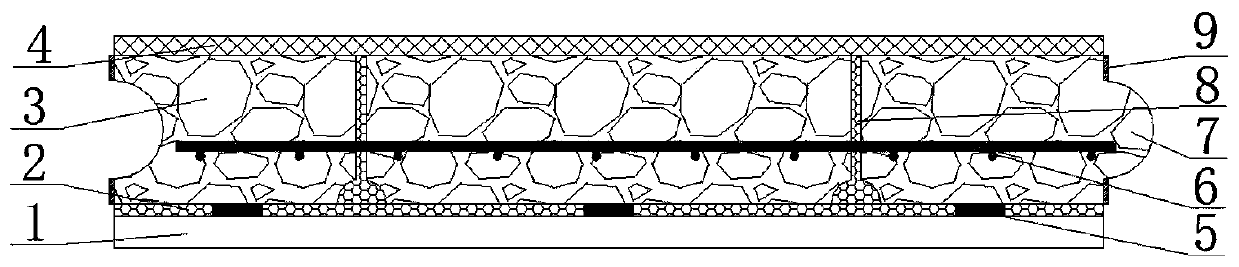

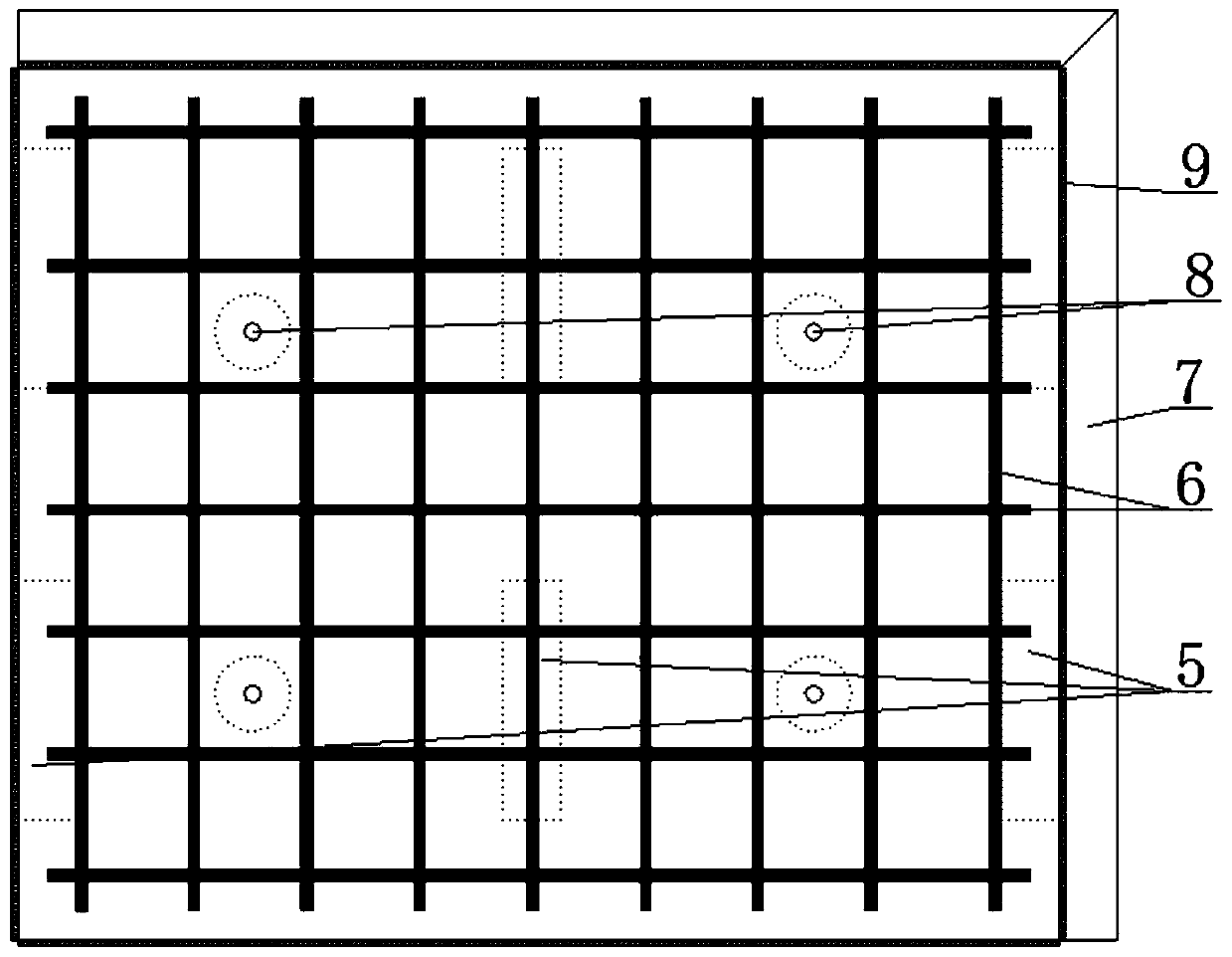

[0059] The prefabricated ultra-high performance concrete steel bridge deck pavement structure and preparation method in the embodiment of the present invention include the following steps:

[0060] S1. Use threaded ribbed steel bars with a diameter of 8-10mm to make steel mesh sheets, set the horizontal and vertical steel bar spacing to 50-100mm, place them in a fixed mold to form high-density fiber concrete prefabricated panels, and control the thickness of the steel mesh protective layer by welding trapezoidal steel bars. ~20mm;

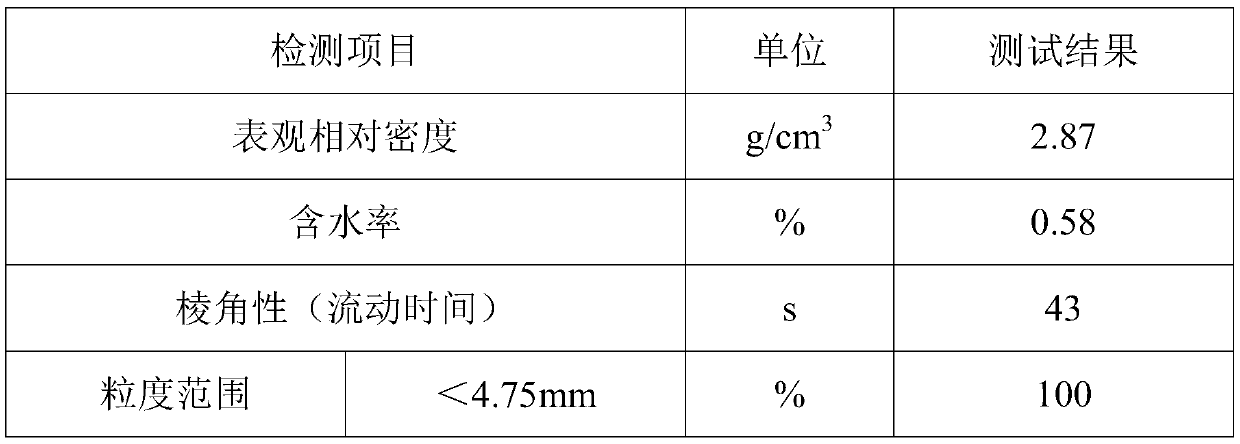

[0061] S2. Weigh 25-30 parts of Portland cement, 6-10 parts of silica fume, 8-12 parts of quartz powder, 30-35 parts of quartz sand with particle size ≤ 1mm, 2-4 parts of composite chopped steel fiber and 4-8 parts of basalt fiber, 8-12 parts of water, 1-2 parts of polycarboxylate high-efficiency water reducer, use a horizontal mixer to stir the dry mixture at a rate of 25-35 rpm for 1 min, and then add basalt fiber and steel fiber, then add water...

Embodiment 1

[0072] A prefabricated ultra-high performance concrete steel bridge deck pavement structure and a preparation method thereof, comprising the following steps:

[0073] S1. Use threaded ribbed steel bars with a diameter of 8mm to make steel mesh sheets, set the horizontal and vertical steel bar spacing to 50mm, place them in a fixed mold to form high-density fiber concrete prefabricated panels, and control the thickness of the steel mesh protective layer by welding trapezoidal steel bars to 20mm;

[0074] S2. Weigh 25 parts of Portland cement, 8 parts of silica fume, 12 parts of quartz powder, 35 parts of quartz sand with particle size ≤ 1mm, 4 parts of composite chopped steel fiber, 6 parts of basalt fiber, 8 parts of water, Carboxylic acid high-efficiency water reducer 2 parts, use a horizontal mixer to stir the dry mixture at a rate of 35 rpm for 1 minute, add basalt fiber and steel fiber in turn, then add water reducer and mixing water, and wet mix for 8 minutes to prepare ne...

Embodiment 2

[0090] A prefabricated ultra-high performance concrete steel bridge deck pavement structure and a preparation method thereof, comprising the following steps:

[0091] S1. Use threaded ribbed steel bars with a diameter of 10mm to make steel mesh sheets, set the horizontal and vertical steel bar spacing to 75mm, place them in a fixed mold to form high-density fiber concrete prefabricated panels, and control the thickness of the steel mesh protective layer by welding trapezoidal steel bars to 15mm;

[0092] S2. Weigh 27 parts of Portland cement, 10 parts of silica fume, 10 parts of quartz powder, 33 parts of quartz sand with particle size ≤ 1mm, 3 parts of composite chopped steel fiber, 5 parts of basalt fiber, 10 parts of water, and Carboxylic acid high-efficiency water reducer 2 parts, use a horizontal mixer to stir the dry mixture at a rate of 35 rpm for 1 minute, add basalt fiber and steel fiber in turn, then add water reducer and mixing water, and wet mix for 6 minutes to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com