Cold-formed thin-walled steel web combined PC box girder

A technology of cold-formed thin-walled steel and cold-formed steel, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of easy cracking of the web, complex construction, and self-heavyness, etc., to achieve a slim structure and improve the bending resistance of the section ability and torsion resistance, the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

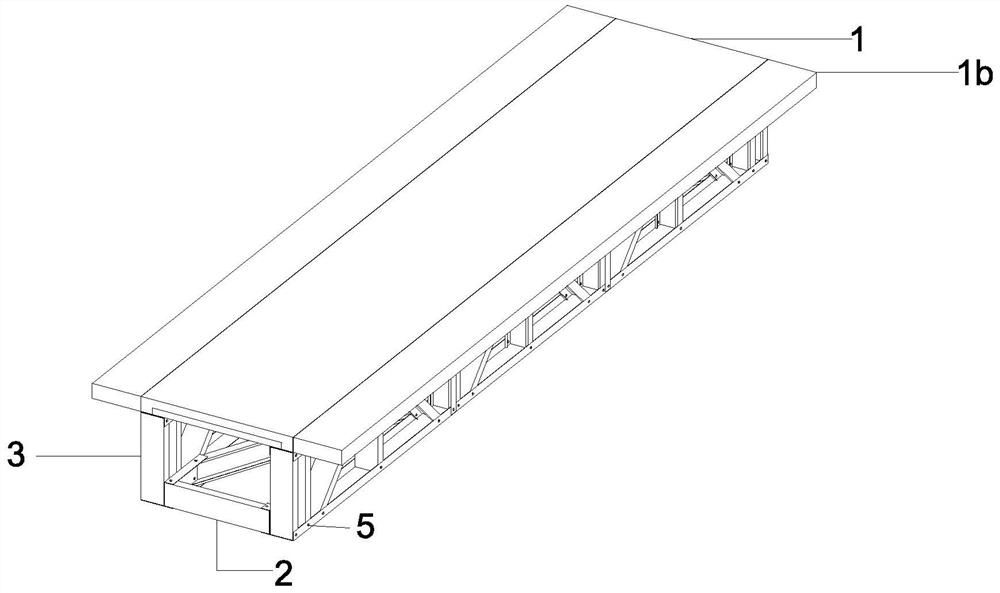

[0026] Such as figure 1 As shown, this example provides a cold-formed thin-walled steel web composite PC box girder for the main girder of bridge structure, including upper flange (1), truss-type cold-formed steel composite lower flange (2), truss Type cold-formed steel composite web (3), angle steel connectors (4), self-tapping self-drilling screws and other connectors (5) and C-type cold-formed thin-walled steel connectors (6).

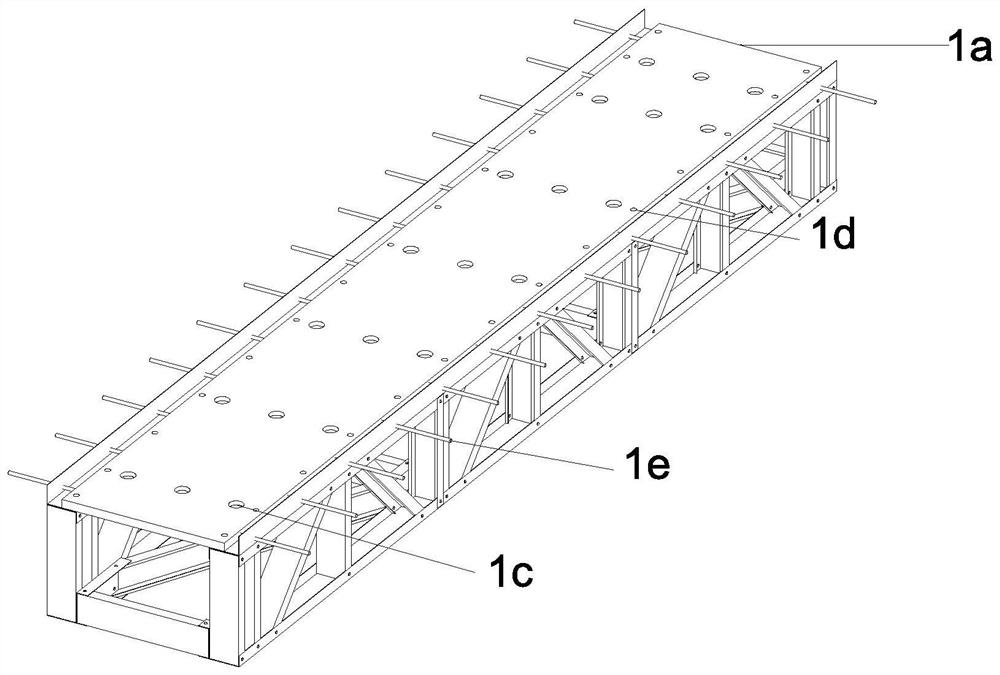

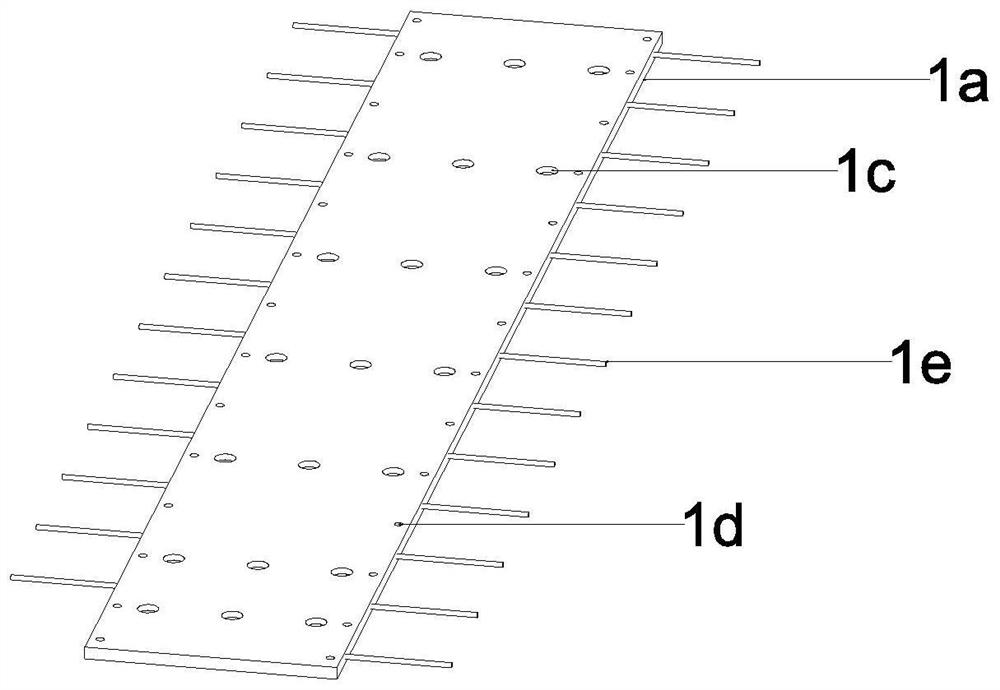

[0027] Such as Figure 2-3 As shown, the upper flange (1) is composed of a prefabricated concrete composite panel (1a) and a cast-in-place concrete section (1b), and the precast concrete composite panel (1a) is a UHPC-reinforced concrete panel with a thickness of 300mm. The cast-in-place concrete section (1b) is UHPC material. The prefabricated concrete composite slab (1a) is provided with a circular post-casting hole (1c) penetrating through the thickness of the slab. The post-cast hole (1c) is also filled with UHPC during the construction of th...

example 2

[0033] This example provides a cold-formed thin-walled steel web composite PC box girder used for primary and secondary beams of building structures.

[0034] The upper flange (1) is composed of a precast concrete composite slab (1a) and a cast-in-place concrete section (1b), and the precast concrete composite slab (1a) is a recycled concrete-reinforced concrete slab with a thickness of 70 mm. The cast-in-place concrete section (1b) is recycled concrete material. The prefabricated concrete composite slab (1a) is provided with a square post-casting hole (1c) penetrating through the thickness of the slab. The post-cast hole (1c) is filled with recycled concrete during the construction of the cast-in-place concrete section (1b). The two longitudinal sides of the prefabricated concrete composite slab (1c) are provided with installation holes (1d) with a spacing of 100mm, and are connected with the truss-type cold-formed steel web (3) and the angle steel connector (4) through cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com