Patents

Literature

32results about How to "Change the construction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

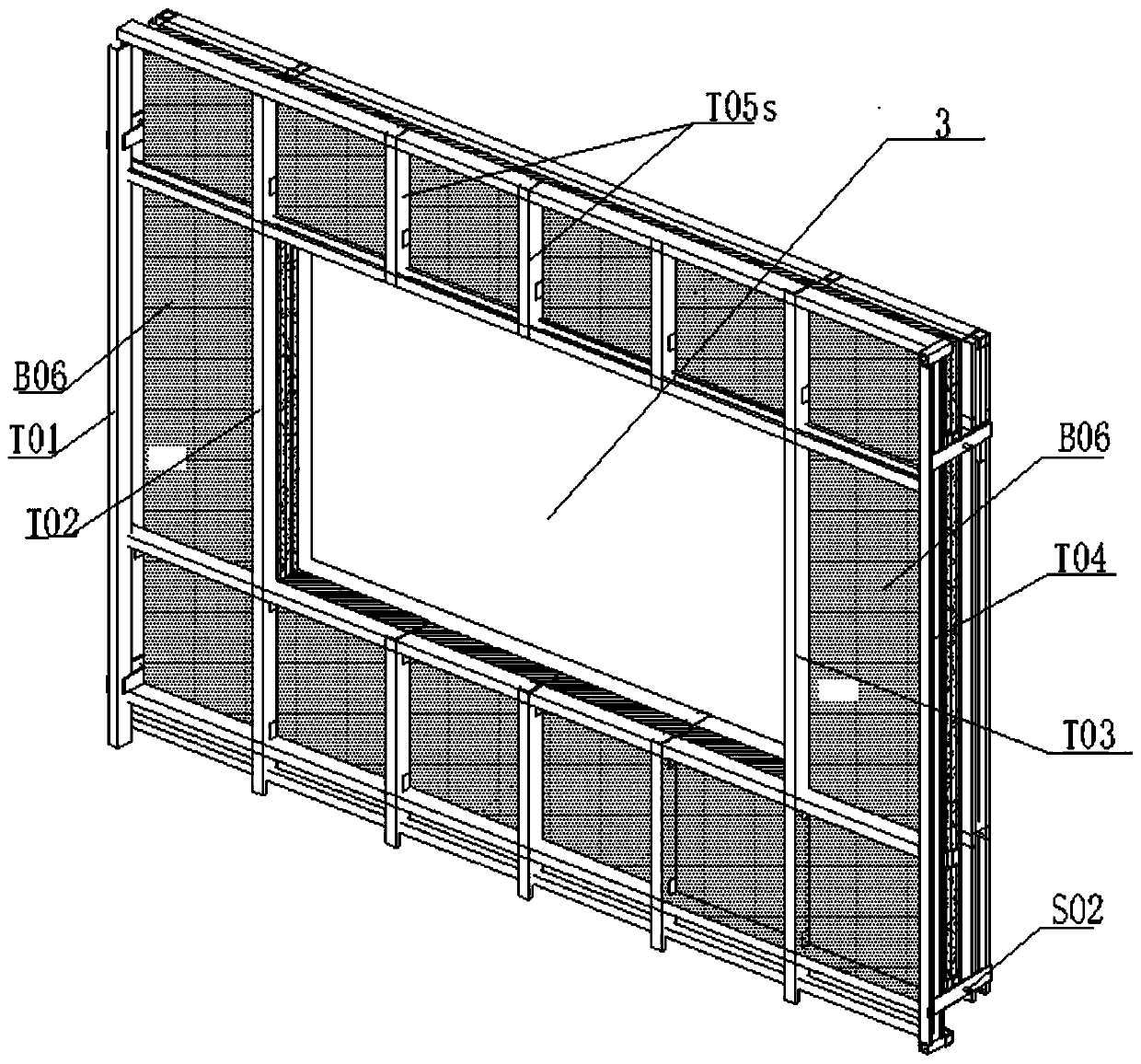

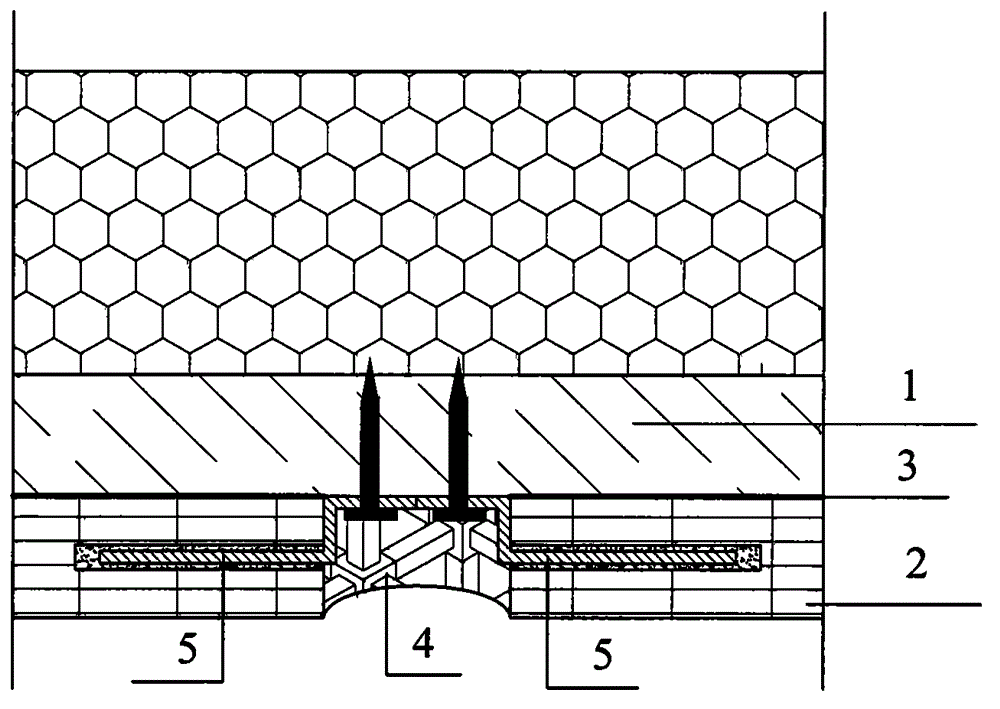

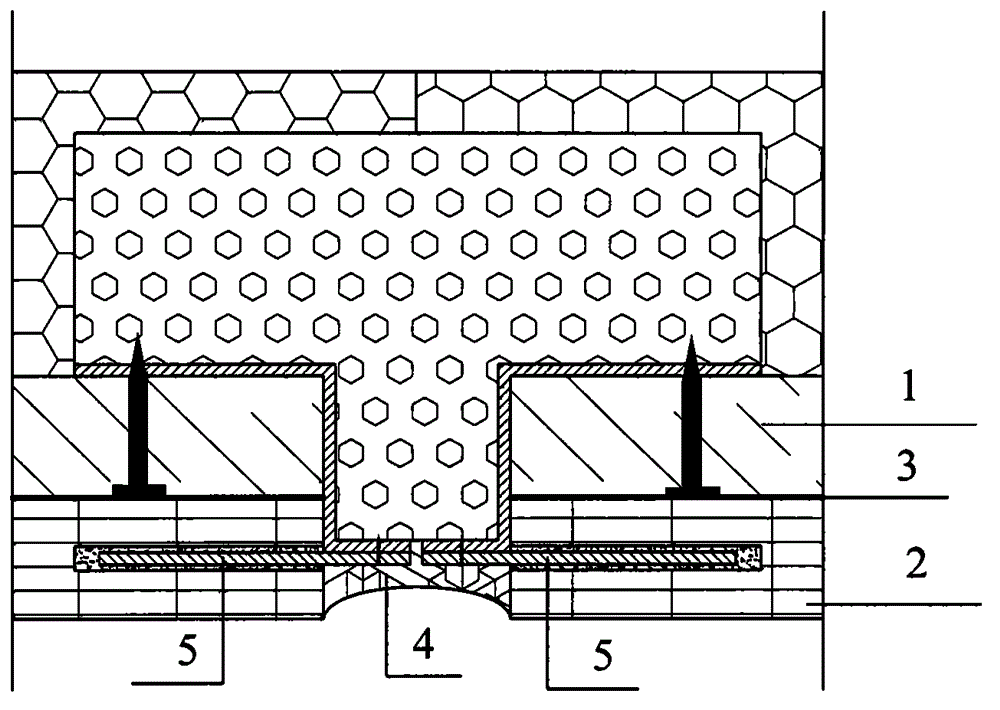

Light steel joist partition connecting structure and construction method thereof

InactiveCN102605883ASave rebar materialReduce investmentWallsBuilding material handlingRebarFloor slab

Disclosed are a light steel joist partition connecting structure and a construction method thereof. Ground joists of light steel joist partitions are directly fixed on a concrete floor via drive pins, after vertical joists are mounted, alley formworks are erected, and bottoms of the ground joists and bottoms of the vertical joists are totally poured in concrete. By the aid of the light steel joist partition connecting structure and the construction method thereof, construction period can be shorted by about 15 days, reinforcement materials can be saved, labor investment is reduced, construction quality of concrete alleys is improved, and rework probability is reduced.

Owner:CHINA CONSTR FIRST GRP THE SECOND CONSTR +1

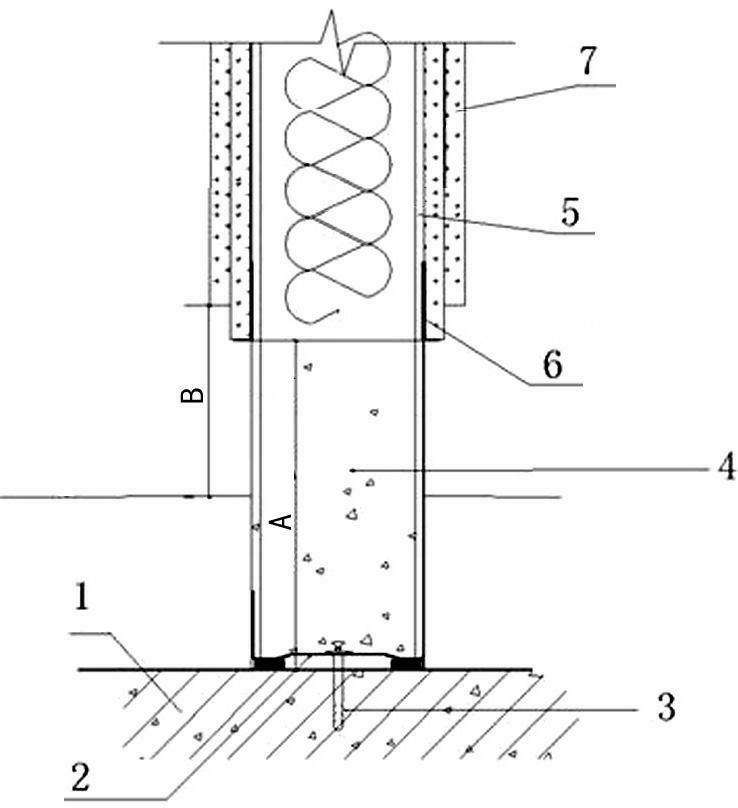

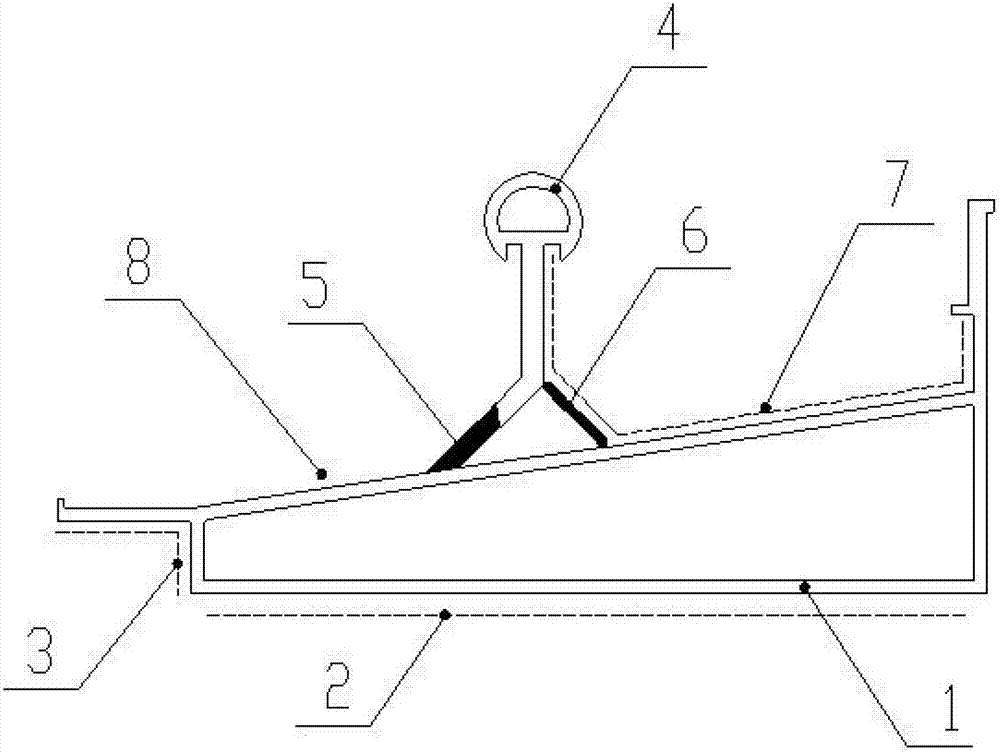

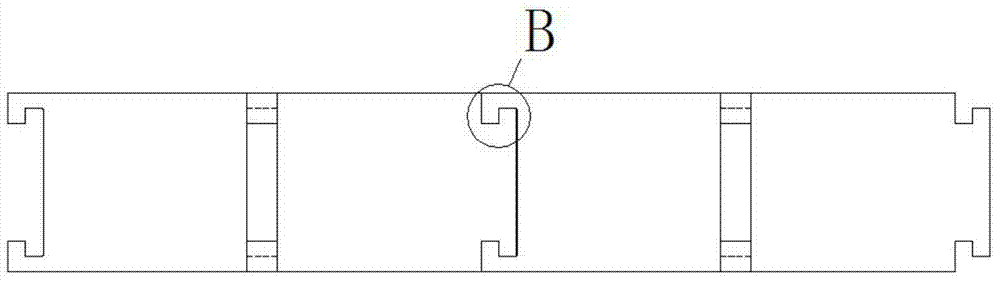

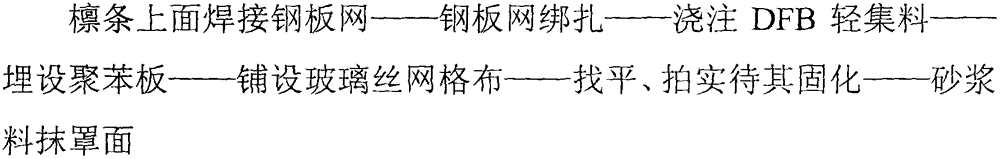

Method for producing cast-in-situ insulation roof

InactiveCN102787698AReduce dead loadChange the construction processRoof covering using sealantsRoof covering insulationsMesh gridFiberglass mesh

The invention discloses a method for producing a cast-in-situ insulation roof, which comprises the technological process that a steel screen is welded on a purline, the purline is bound with the steel screen, then DFB lightweight aggregates are poured, blocks of polyphenyl plates are embedded in the DFB lightweight aggregates side by side, fiberglass meshes are respectively laid between the DFB lightweight aggregates on the upper and lower surfaces of the polyphenyl plates, after the DFB lightweight aggregates are completely poured, a trowel for levelling up is used for beating the DFB lightweight aggregates to solidify, and finally, mortar is used for plastering an anti-cracking layer top facing. According to the method, an outer building envelop and energy-saving insulation engineering are integrated to be completed at one step, the technology is simple, the application scope is wide, and the construction progress is accelerated. The method can be used for manufacturing an insulation roof which is light, has high-strength and good integral fire proofing, and is low in comprehensive cost.

Owner:张云麟 +1

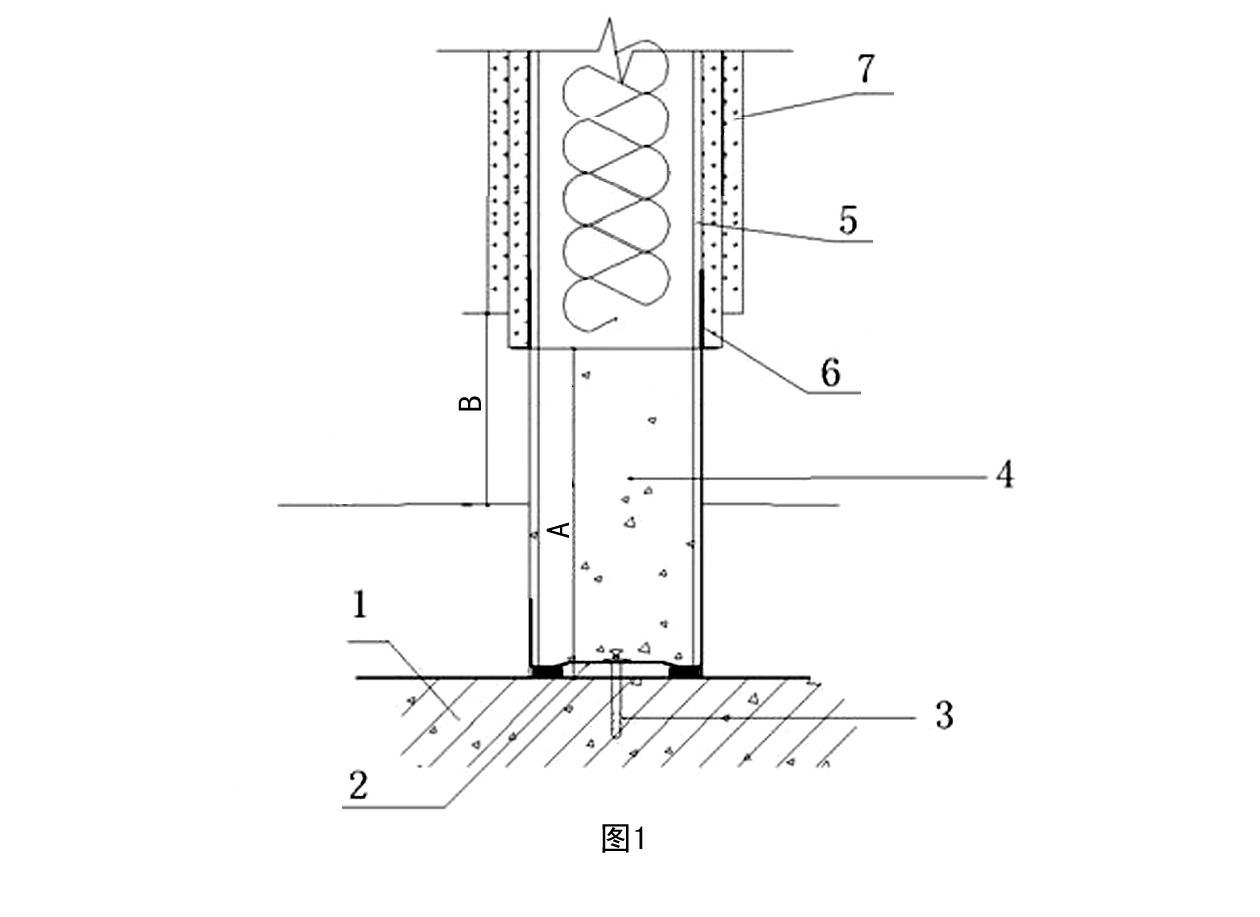

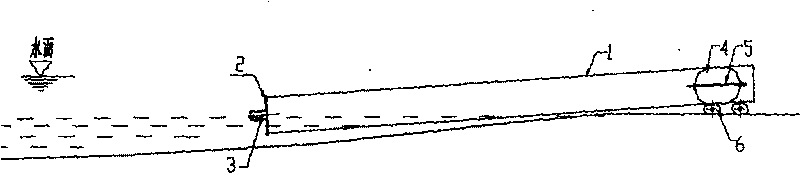

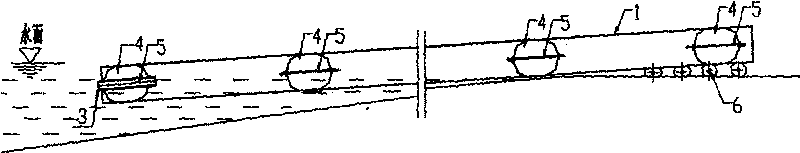

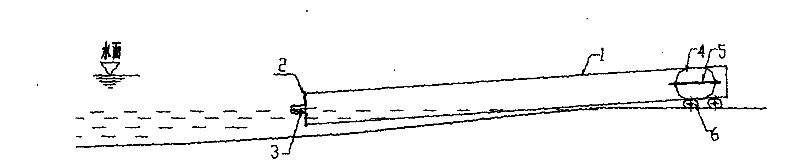

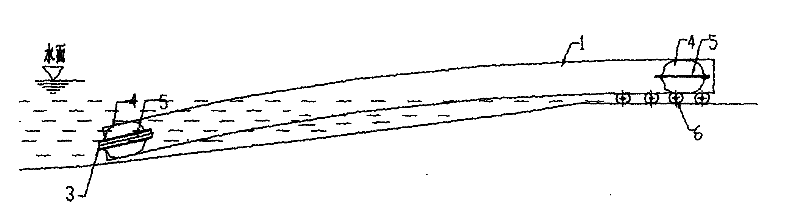

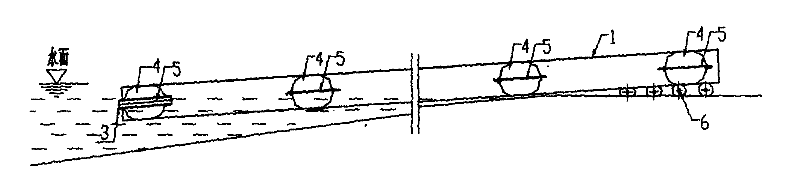

Underwater construction method of steel tube

InactiveCN101691893ASave shipping costImprove construction qualityPipe laying and repairSteel tubeShore

The invention is an underwater construction method of a steel tube, belonging to the technical field of underwater engineering and comprising the following steps: plugging steel tube openings at a front end and an on-shore segment of the first section of the steel tube by an air bag or a blind plate; enabling the steel tube to float on the water surface by inflating the steel tube, thus facilitating the steel tube to be fed into water; filling water in the steel tube to lead the steel tube to sink underwater, thus realizing continuous welding construction of the steel tube; changing underwater work to on-shore work, thus omitting water transportation of the steel tube; and welding and launching the steel tube section by section, thus needing no underwater work of divers and cooperation of a lot of large-scale ship engine equipment such as floating cranes, barges, tugboats and the like. The method in the invention is suitable for various water area constructions; the entire steel tube is integrated into a whole, and the construction quality is far higher than that in the prior art; and the construction risk and the construction cost are lower.

Owner:珠海澳新起重科技有限公司

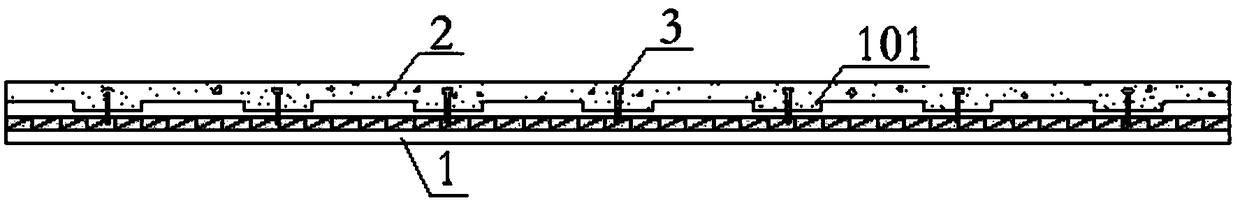

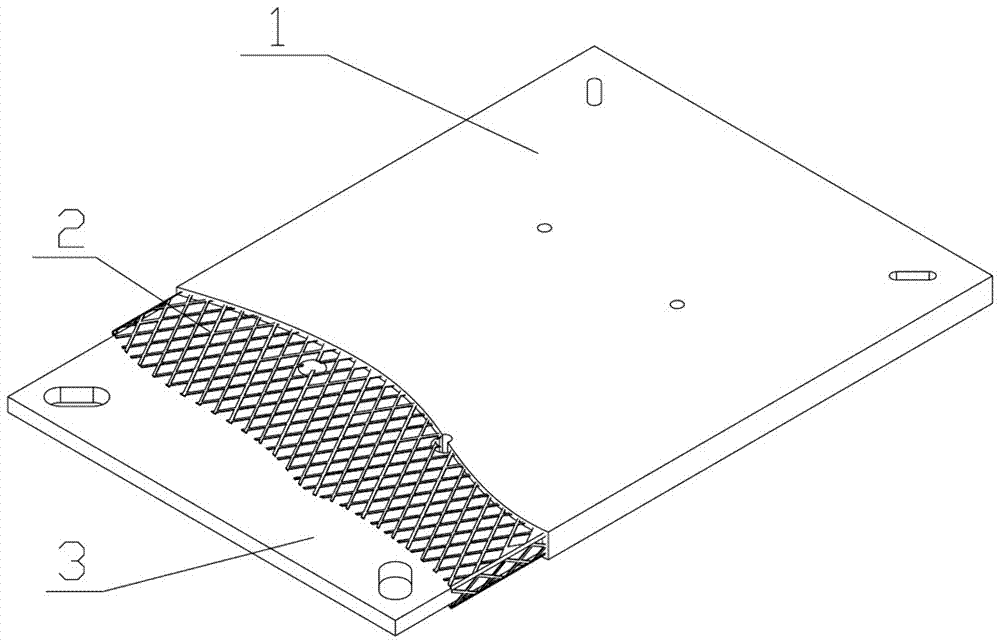

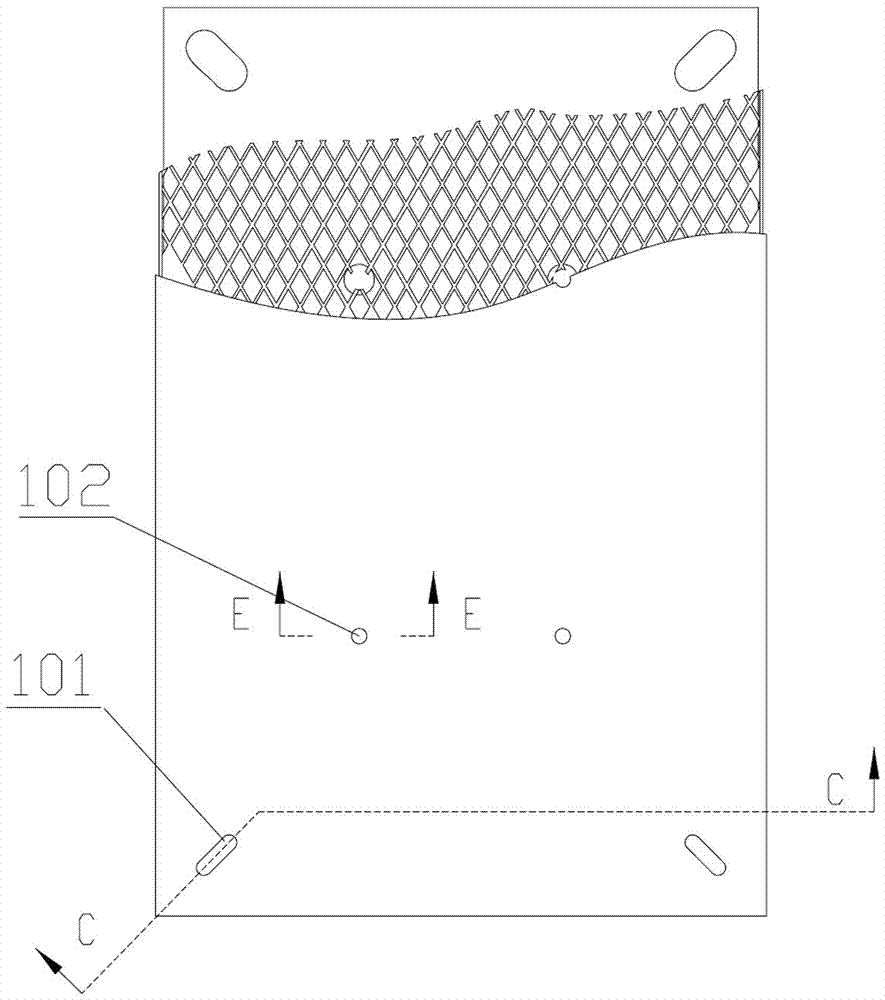

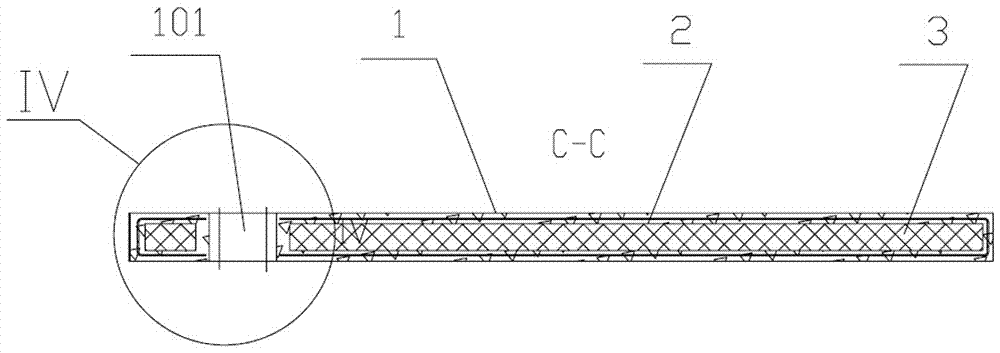

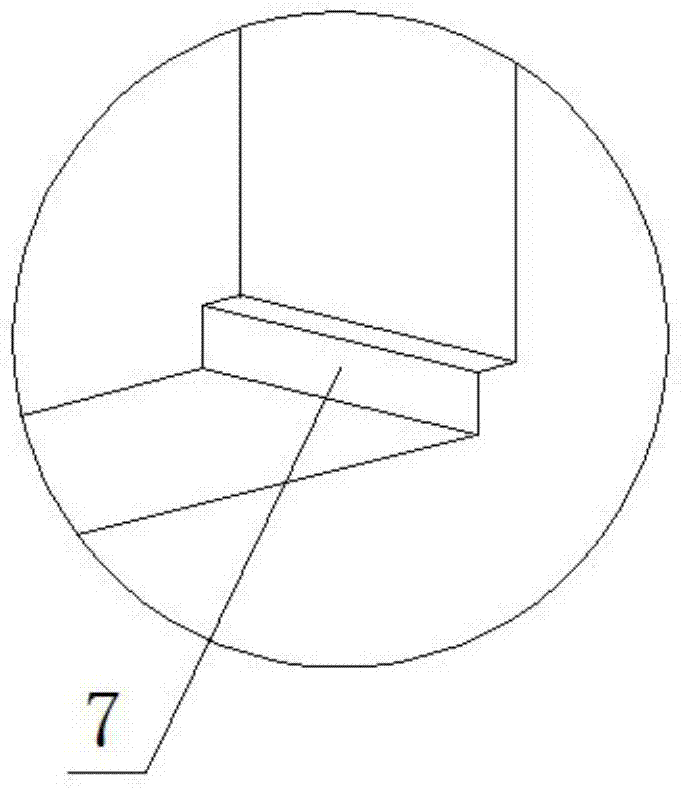

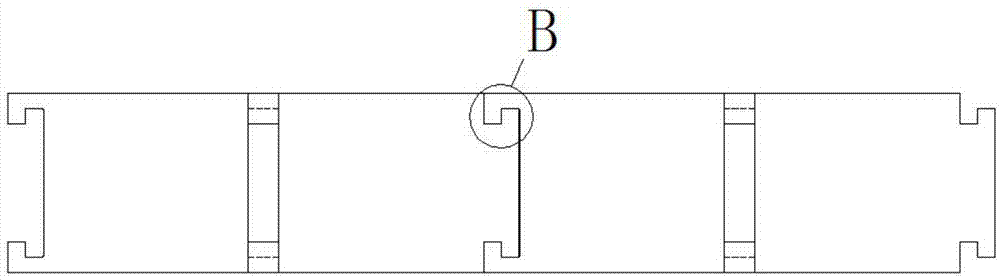

Novel combined type floor slab and construction method thereof

InactiveCN108505675AIncreased load carrying capacity and stiffnessImproved vibration and sound insulation and fire resistanceConstruction materialFloorsFloor slabCross laminated timber

The invention relates to a novel combined type floor slab and a construction method thereof. The novel combined type floor slab structurally comprises a CLT (Cross Laminated Timber) plate, a concreteplate and self-tapping screws, wherein a plurality of concave grooves are formed in the CLT plate at intervals; the tail parts of the self-tapping screws are fixedly connected into the concave grooves; the heads of the self-tapping screws are exposed out of the CLT plate; the concrete plate is poured onto the CLT plate and the self-tapping screws. According to the novel combined type floor slab provided by the invention, the concave grooves and the self-tapping screws are distributed on the interface of the CLT plate and the concrete plate, so that the CLT plate and the concrete plate have thecommon effect and the rigidity and the bearing capability of a wooden ceiling can be improved, the vibration absorption and sound insulation properties of the wooden ceiling are improved and the fireproof performance of the wooden ceiling is improved; a floor slab solution is provided for developing a wooden structure toward high-rise buildings.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

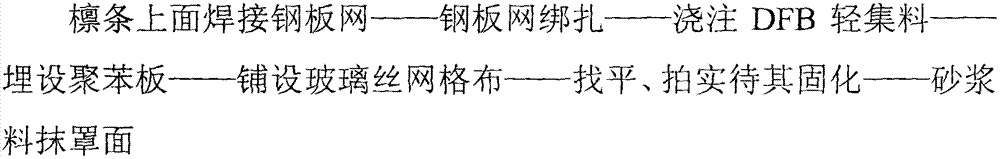

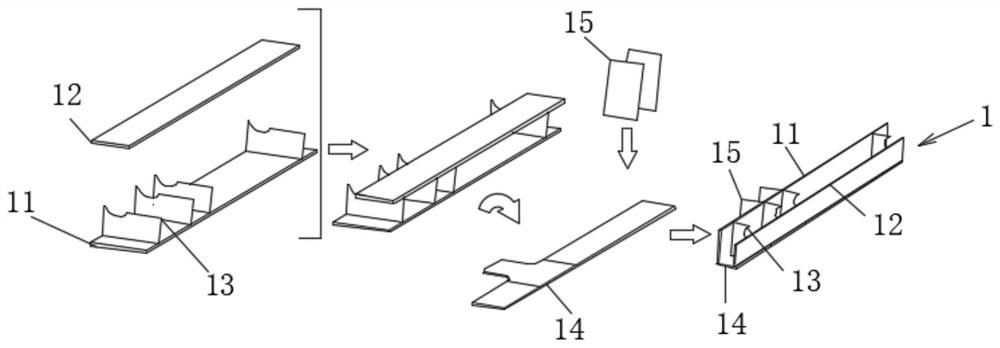

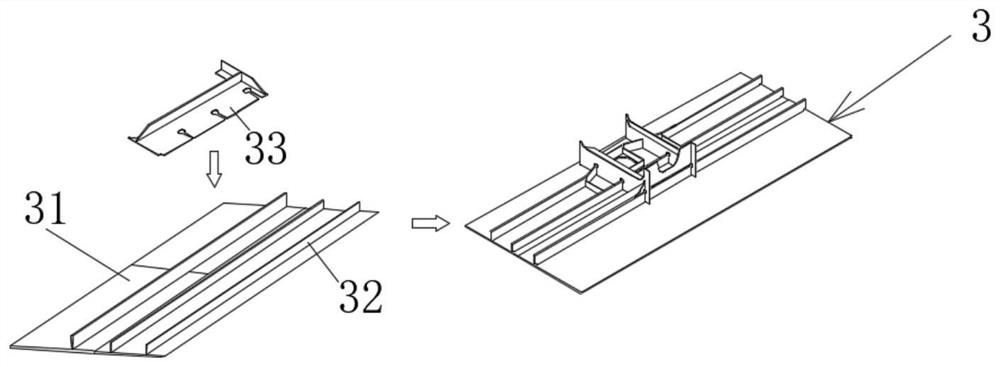

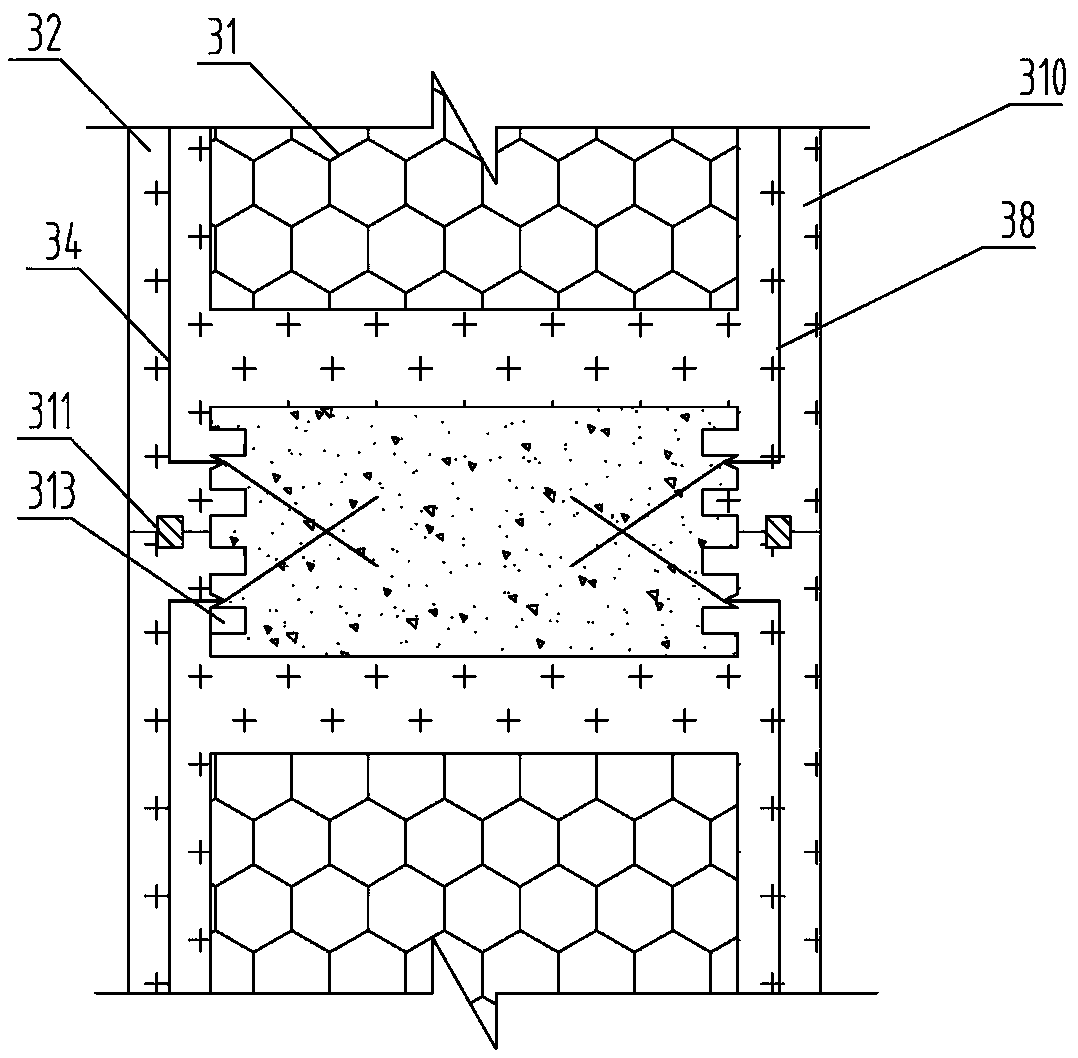

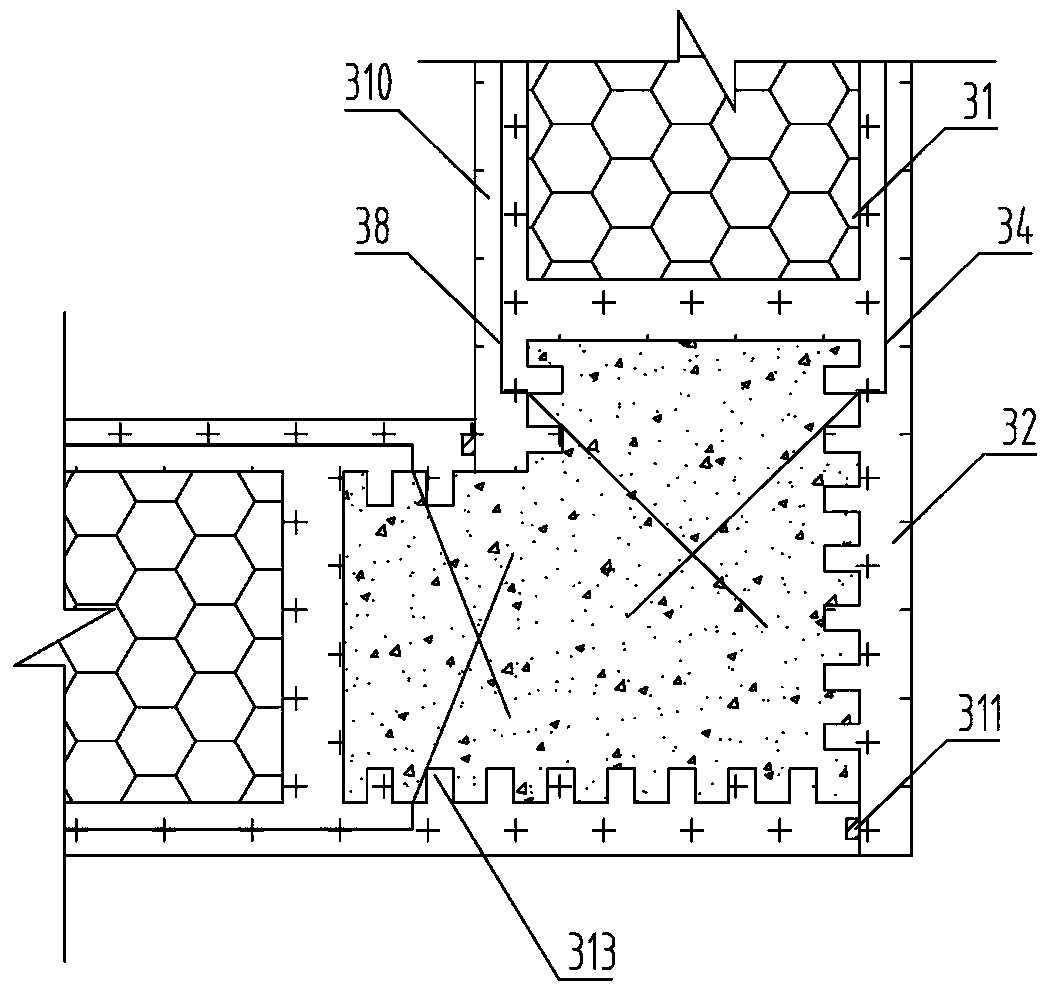

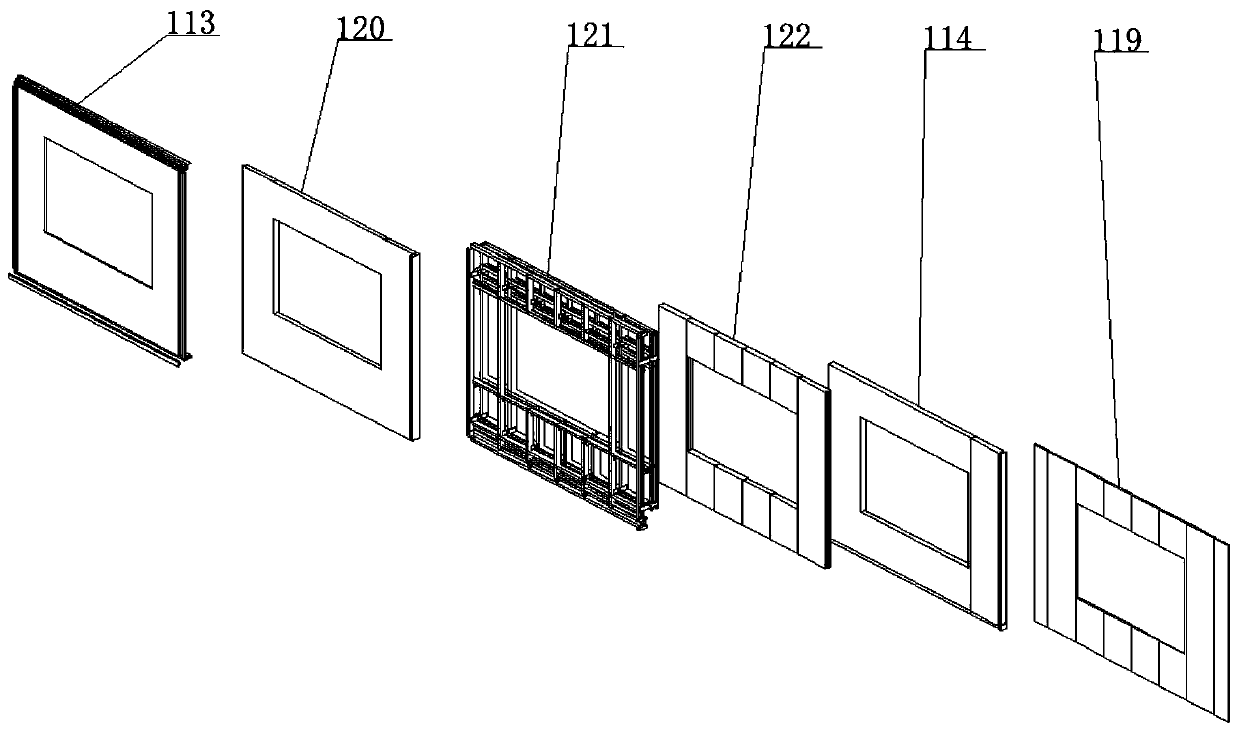

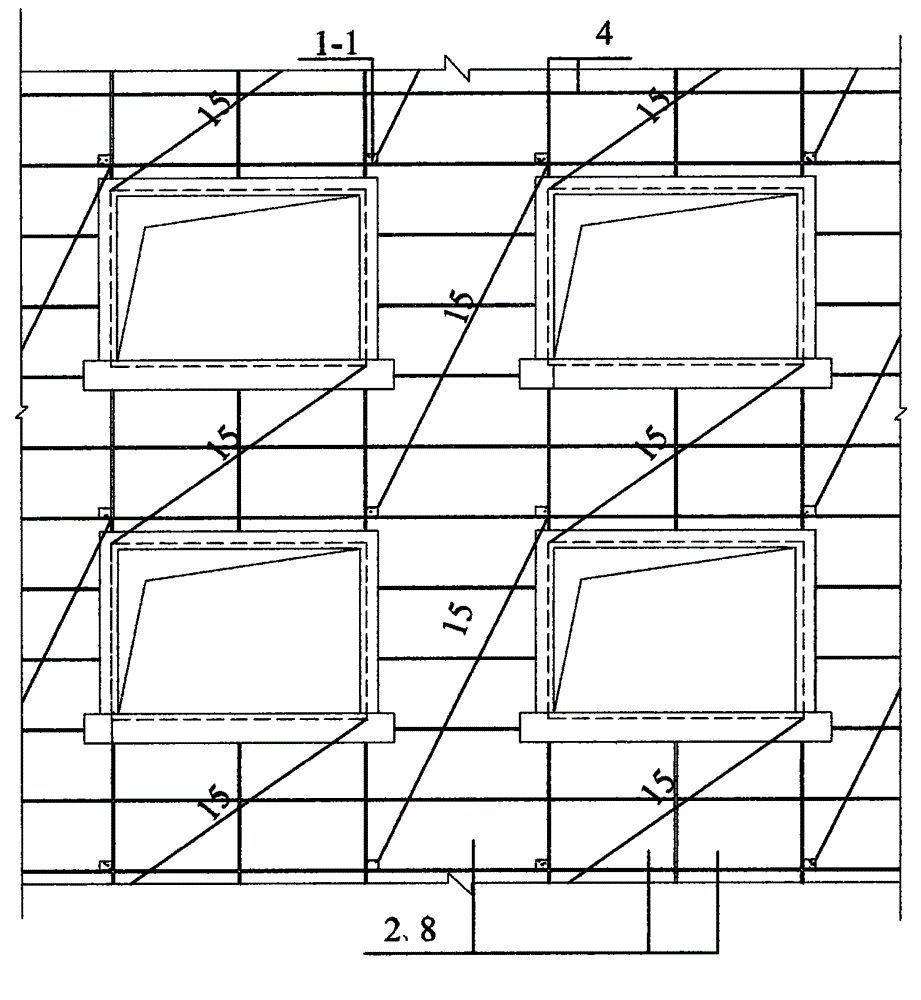

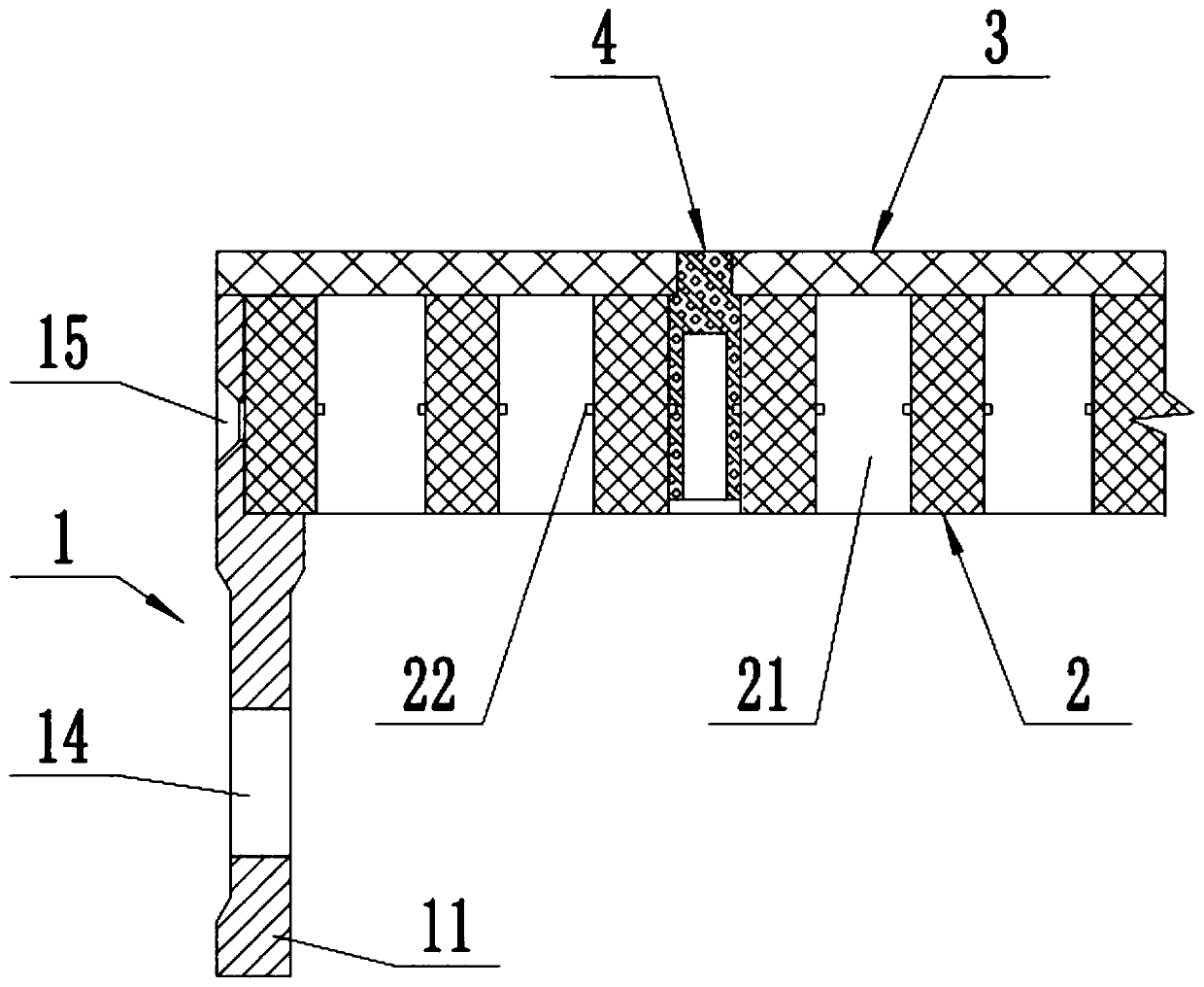

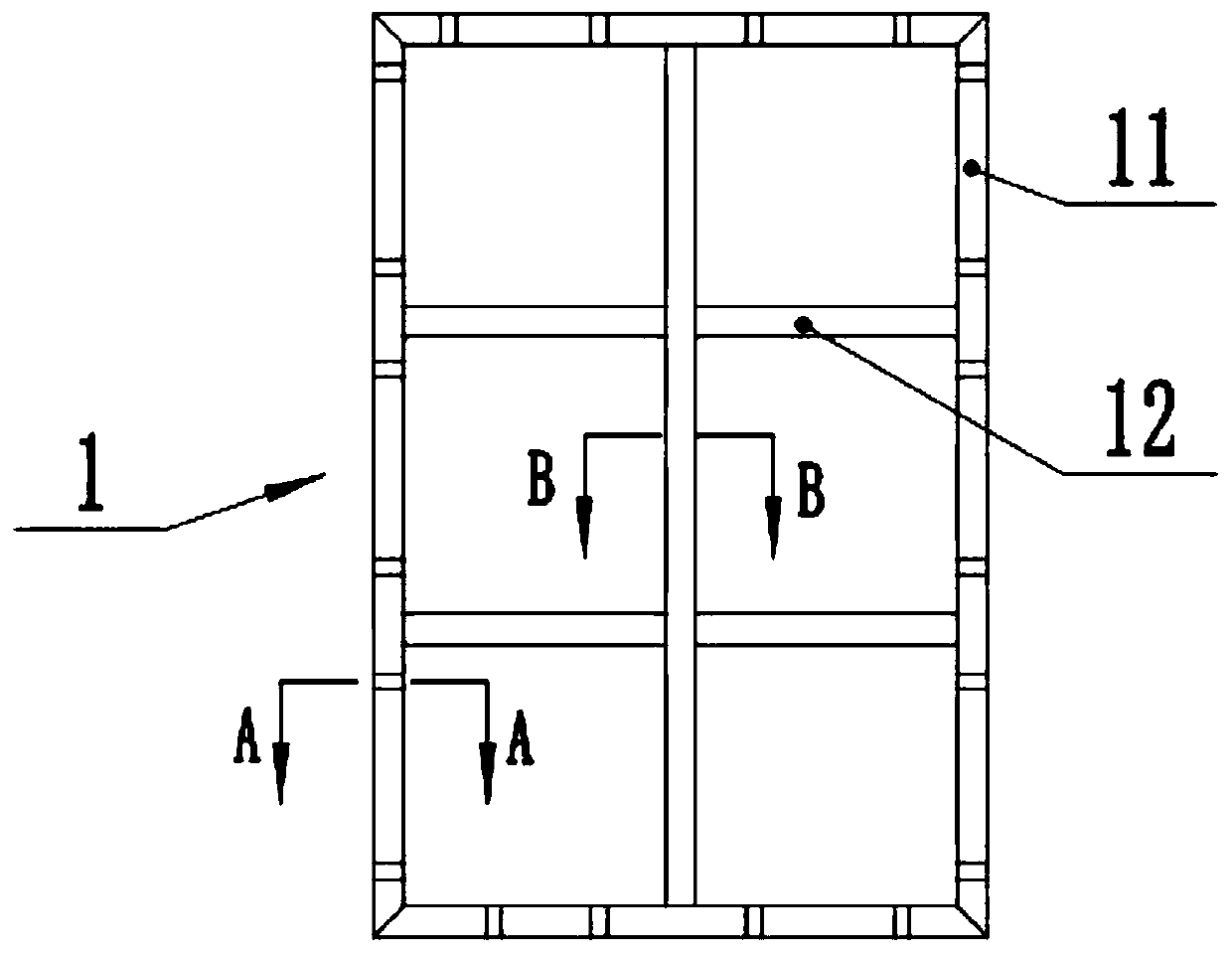

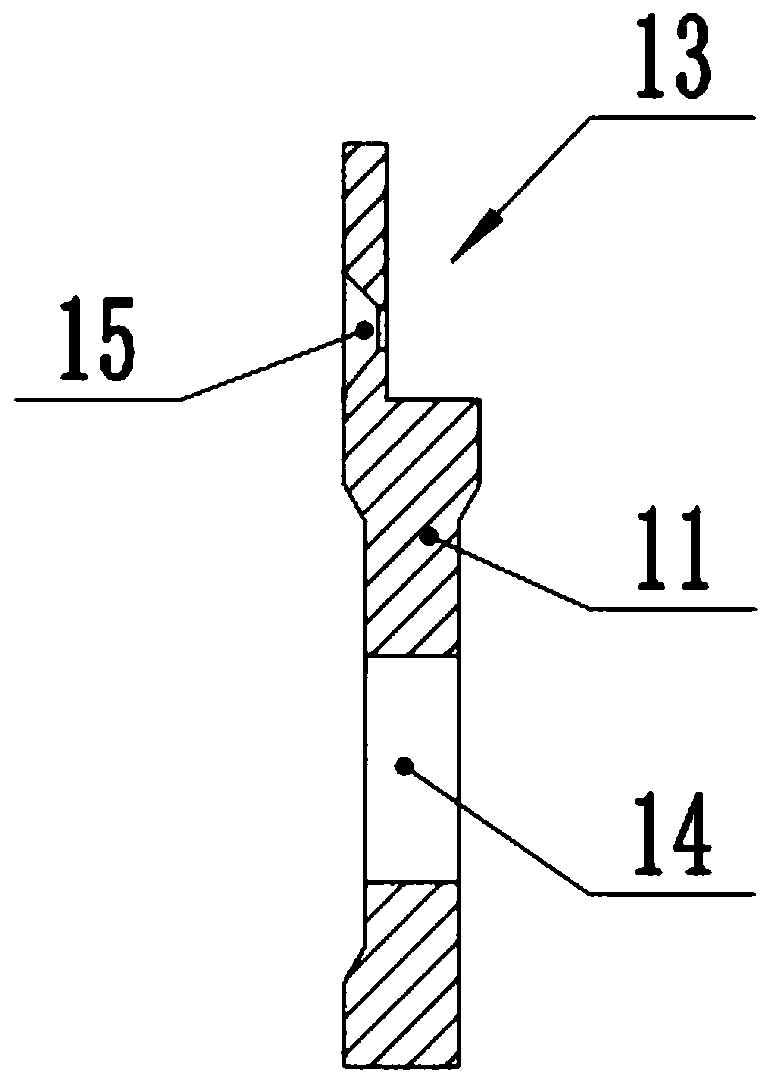

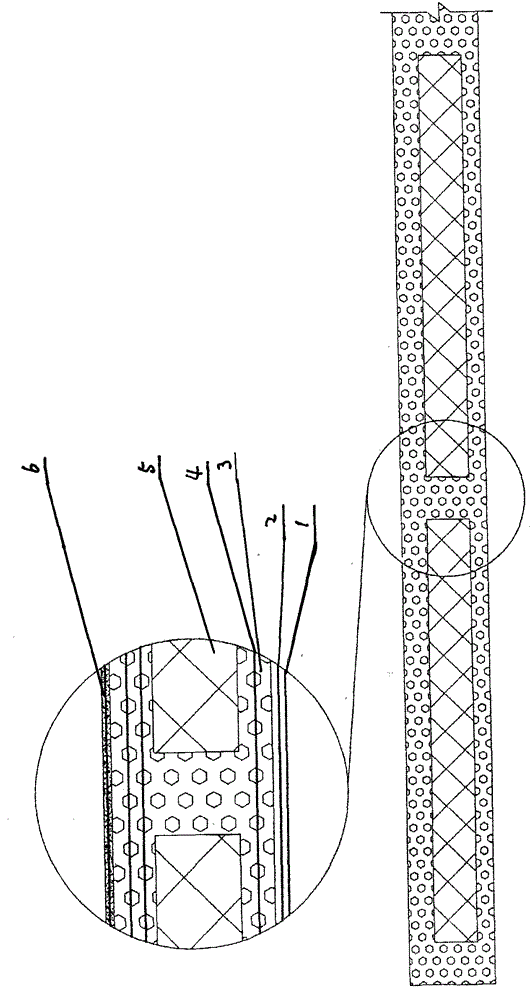

Packaged-type composite performance building dismantling-free formwork

PendingCN106948519AEasy to assembleAvoid situations where a large number of wooden keels are usedWallsFloor slabBuilding energy

The invention relates to a packaged-type composite performance building dismantling-free formwork and belongs to building materials and construction materials. The particularity of the formwork is that sandwich materials are sealed and packaged in a cement formwork shell made by a special mould. In a cast-in-place construction site, the formwork is subjected to assembling operation according to the configured sequence, the formwork is fixed on a formwork bracket, and after concrete pouring and tamping is completed, the formwork does not need to be dismantled. According to the packaged-type composite performance building dismantling-free formwork, the construction efficiency of a heat insulation outer wall and a heat insulation and sound insulation floor plate is improved, the safety and reliability of a heat insulation outer wall structure are strengthened, and important practical significance is achieved to meet the requirements of building energy saving and environmental protection, improve the building construction quality, change a traditional cast-in-place building formwork process, save timber resources and reduce the building and construction cost.

Owner:李美能

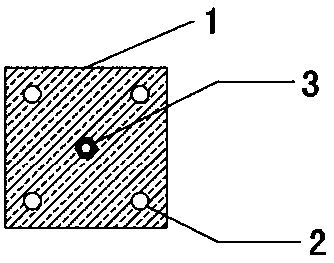

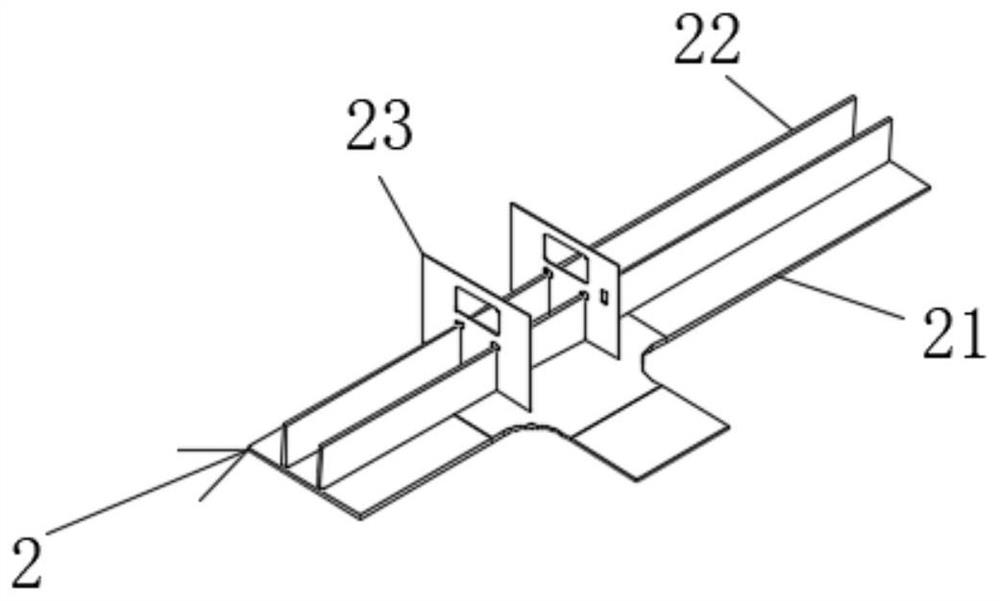

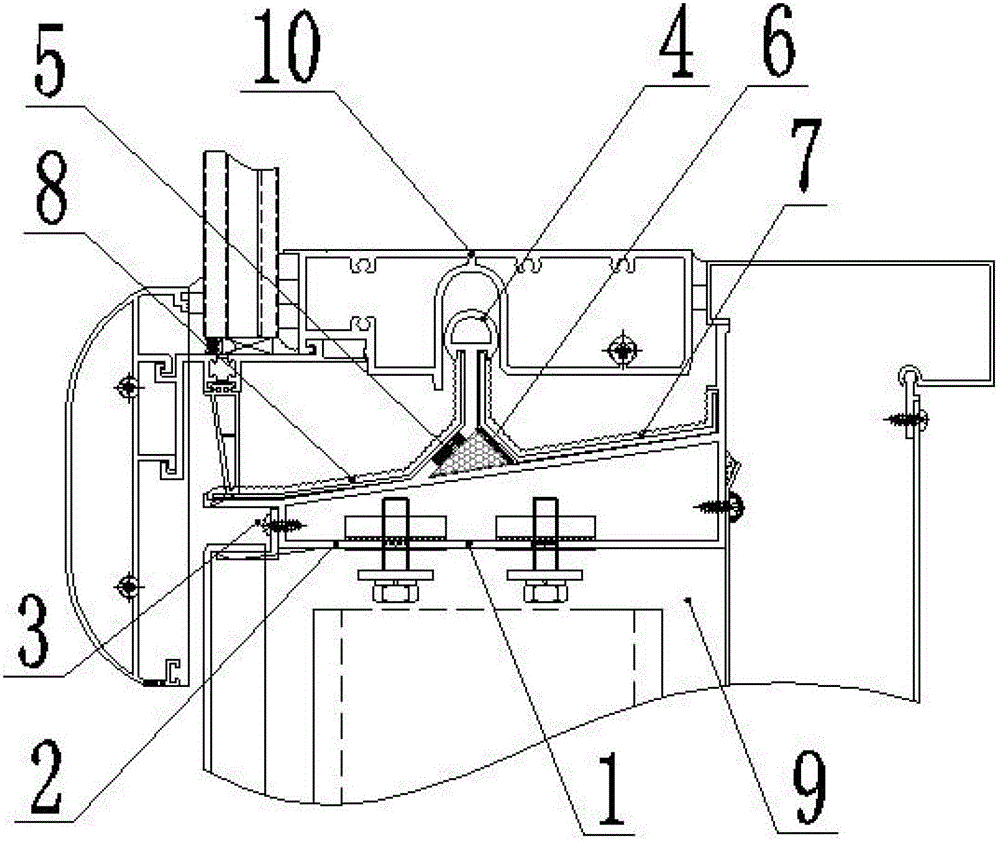

Non-welded flat plate fixed embedded piece and fixing method thereof

PendingCN110005073AReduce inputChange the construction processArtificial islandsBuilding constructionsWorking environmentArchitectural engineering

The invention discloses a non-welded flat plate fixed embedded piece. The non-welded flat plate fixed embedded piece comprises a flat plate embedded piece body, steel bars with the equal length are perpendicularly arranged on four end parts of the same side surface of the flat plate embedded piece body, a fixed through hole is further formed in the middle of the flat plate embedded piece body, a fixing bolt penetrates through the fixed through hole and forms a fixed structure with a nut in a wire closing mode, and the fixed bolt is used for fixing with a template during embedding and used forfixing with a bracket when the bracket is mounted. According to the non-welded flat plate fixed embedded piece, the matched bolt is adopted to fix and change a fixing technology of traditional body steel bar welding for embedded mounting and bracket mounting, the construction efficiency is greatly improved, manpower is reduced, the construction procedure is changed, the construction quality is improved, the input quantity of consumable items are greatly saved, so that the construction work environment pollution is more environmentally friendly.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

Ultra-large container ship hatch coaming and torsion box integrated construction method

ActiveCN112758276AReduce weldingReduce dosageWaterborne vesselsMarine engineeringMechanical engineering

The invention discloses an ultra-large container ship hatch coaming and torsion box integrated construction method, which is applied to the field of ship construction and mainly comprises the following steps: S1, respectively constructing a hatch coaming assembly, a deck assembly, an inner shell plate assembly and an outer plate assembly; S2, the hatch coaming assemblage and the deck assemblage are spliced and then welded to form a hatch coaming deck assembly; S3, the hatch coaming deck assembly, the inner shell plate assemblage and the outer plate assemblage are spliced and welded; the integrated construction efficiency of the hatch coaming and the torsion box can be greatly improved.

Owner:DALIAN SHIPBUILDING IND

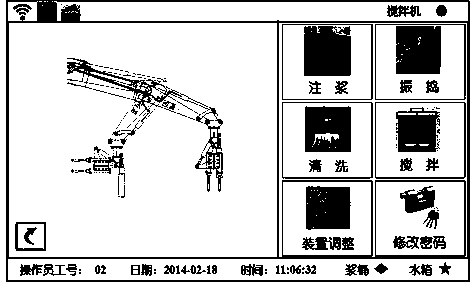

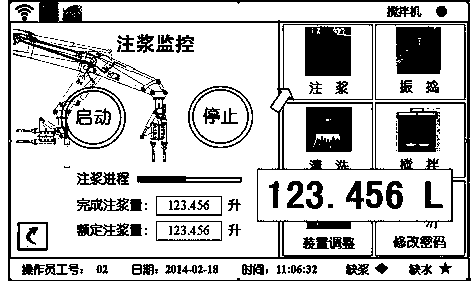

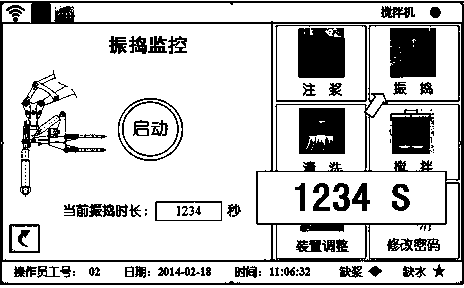

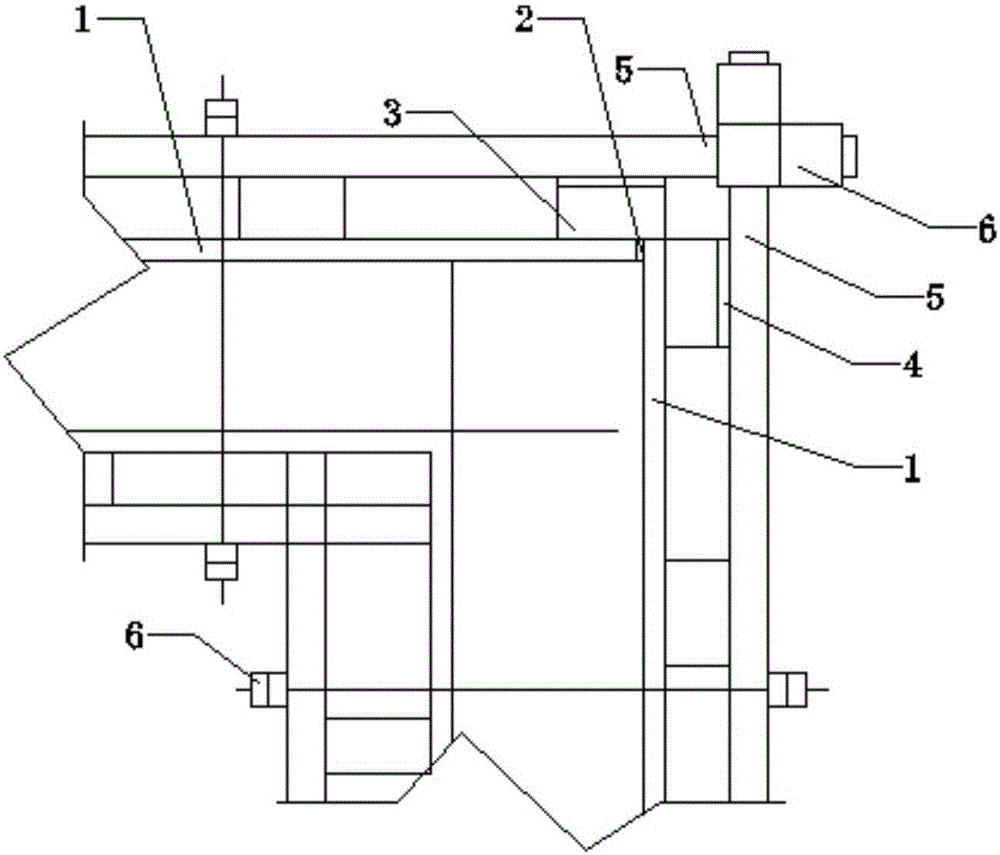

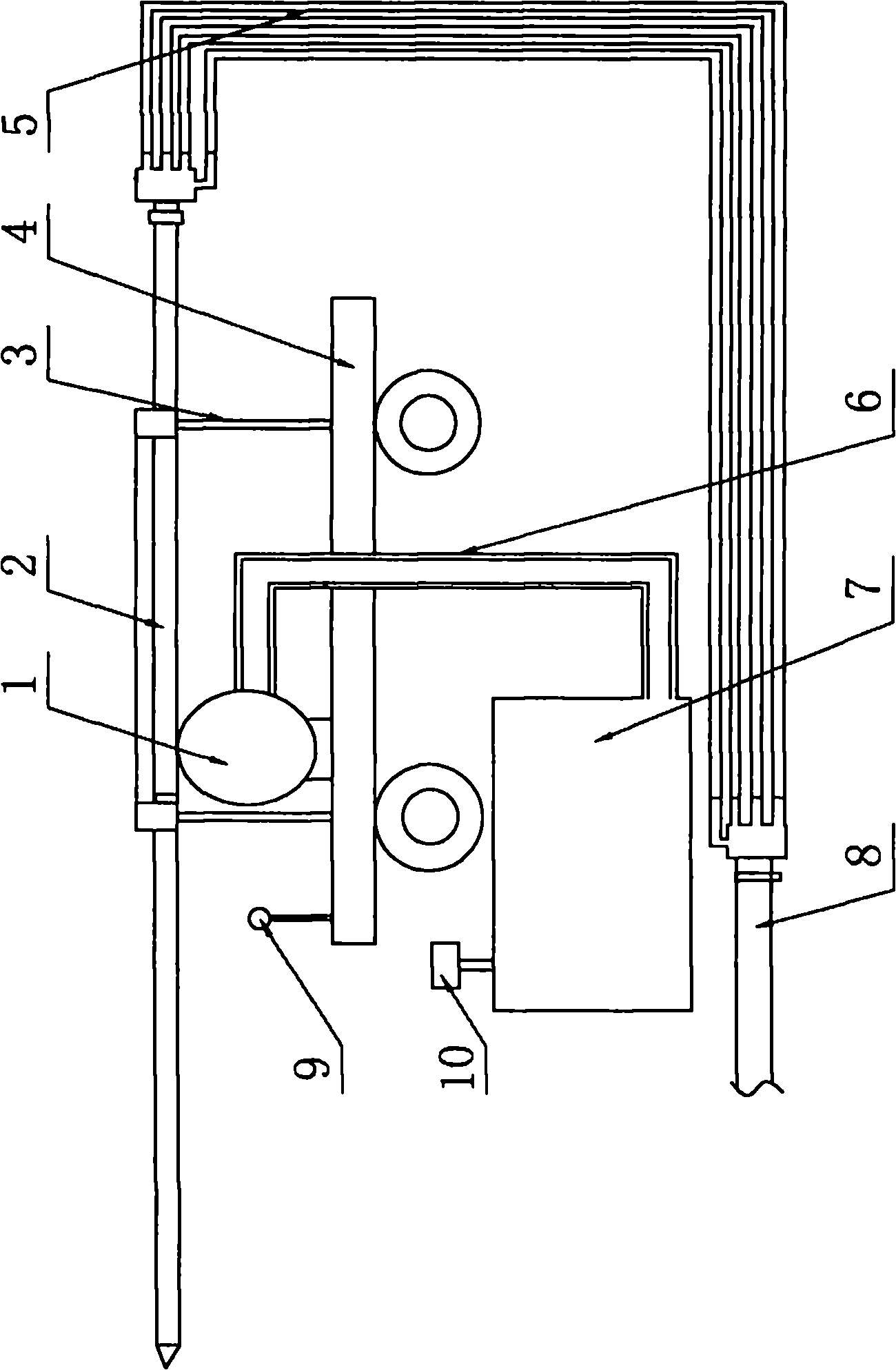

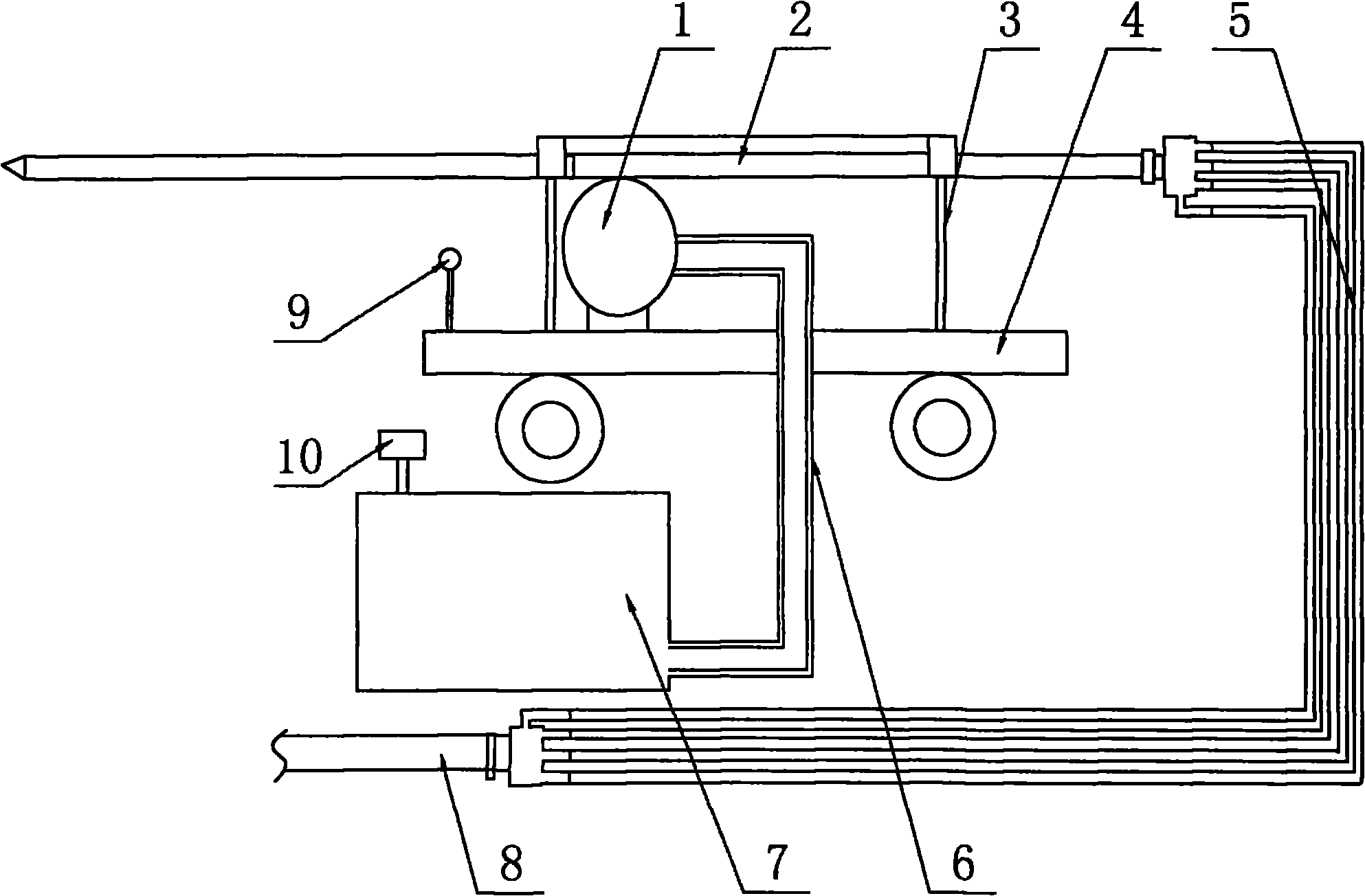

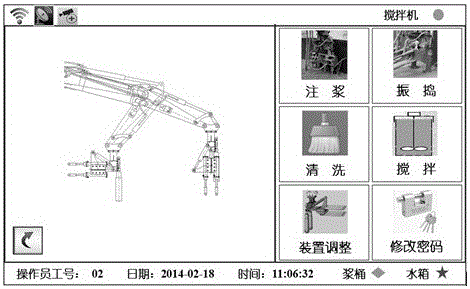

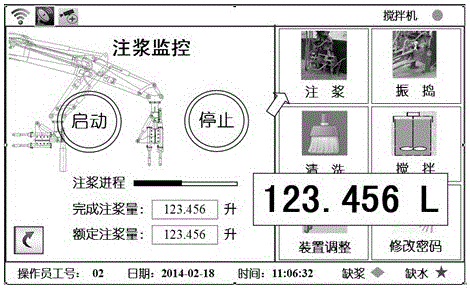

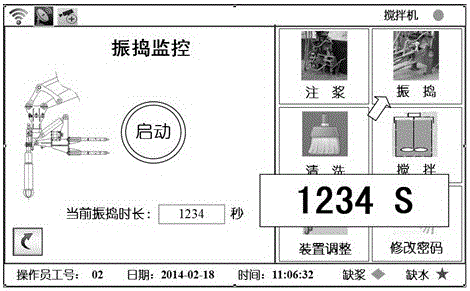

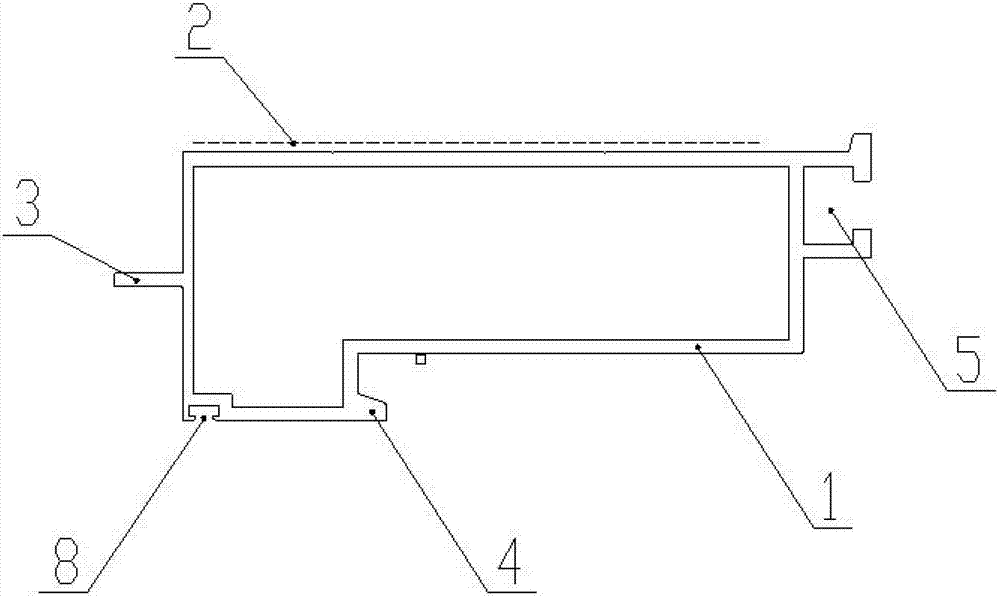

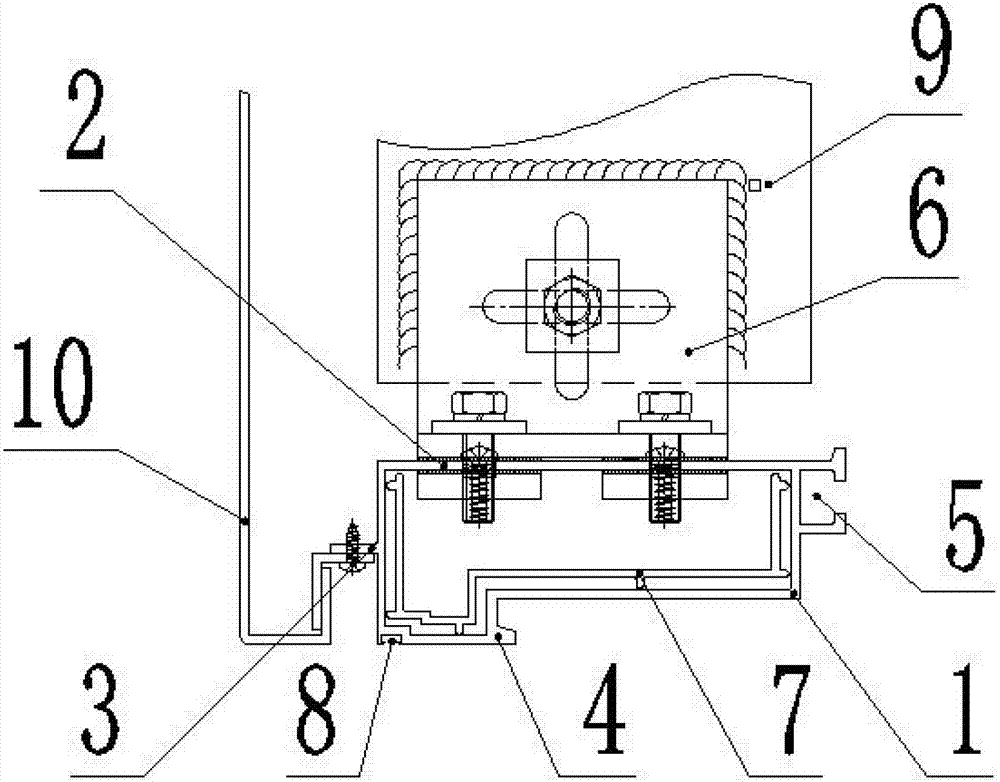

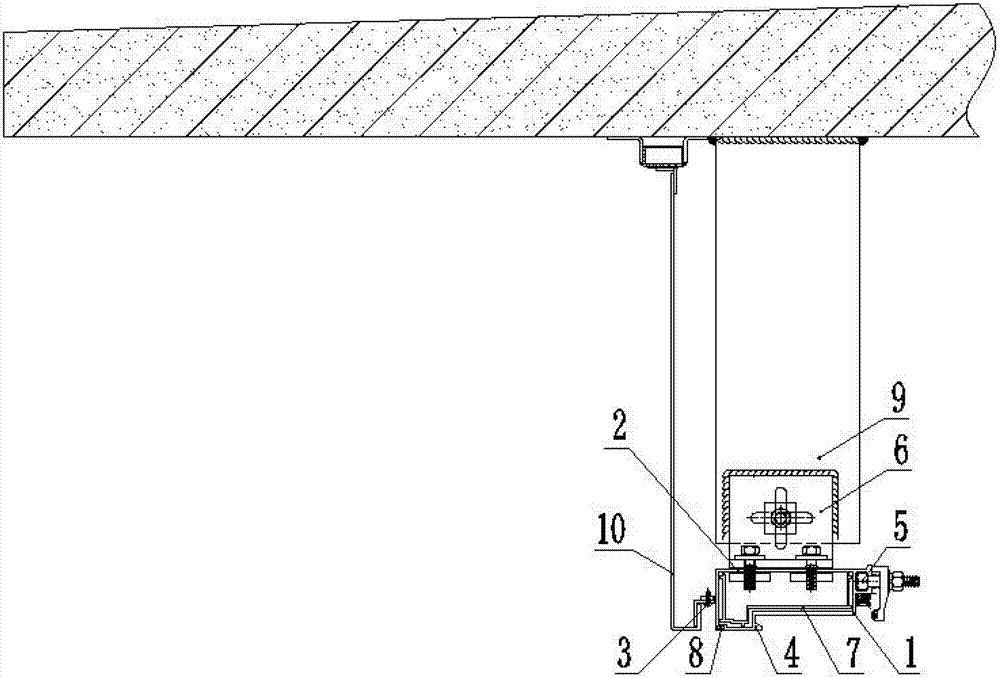

Automatic control system for distorted concrete grouting and vibrating device

InactiveCN104007737AEasy to operateReduce work intensityFoundation engineeringTotal factory controlAutomatic controlDynamic display

The invention discloses an automatic control system for a distorted concrete grouting and vibrating device. A grout barrel, a water tank, a grouting device, a vibrating device and a mixing device are mainly arranged in the distorted concrete grouting and vibrating device. The automatic control system is characterized by comprising a grouting control module, a vibrating control module, a cleaning control module, a mixing control module, a device adjusting control module, a password change control module, an input control module and an output display module. The automatic control device is convenient to operate. Work intensity of operators is relieved, work efficiency is improved, and energy is saved. In the grouting period, the single-point required grouting amount and the finished grouting amount can be dynamically displayed, and the operators can conveniently grasp grouting related information in real time. Distorted concrete grouting errors can be controlled within an allowance range, and distorted concrete construction metering and monitoring requirements are met. Grout waste caused by manual construction can be reduced, construction cost is saved, and the automatic control system is of great practical significance in changing the concrete construction process and the like.

Owner:WUHAN UNIV

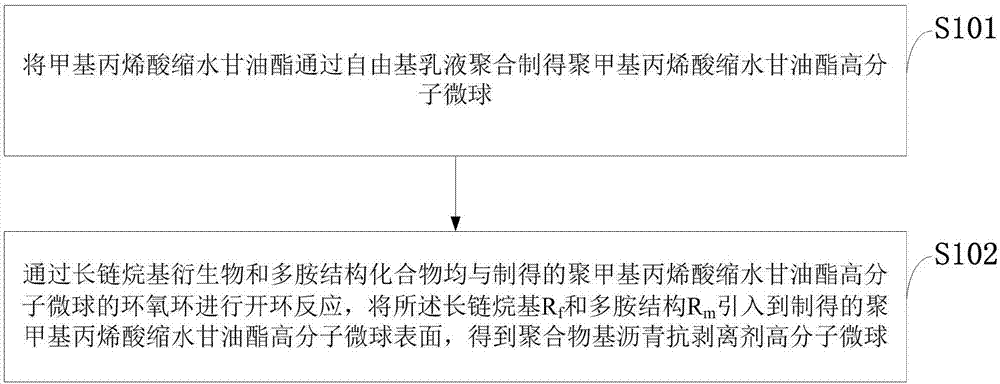

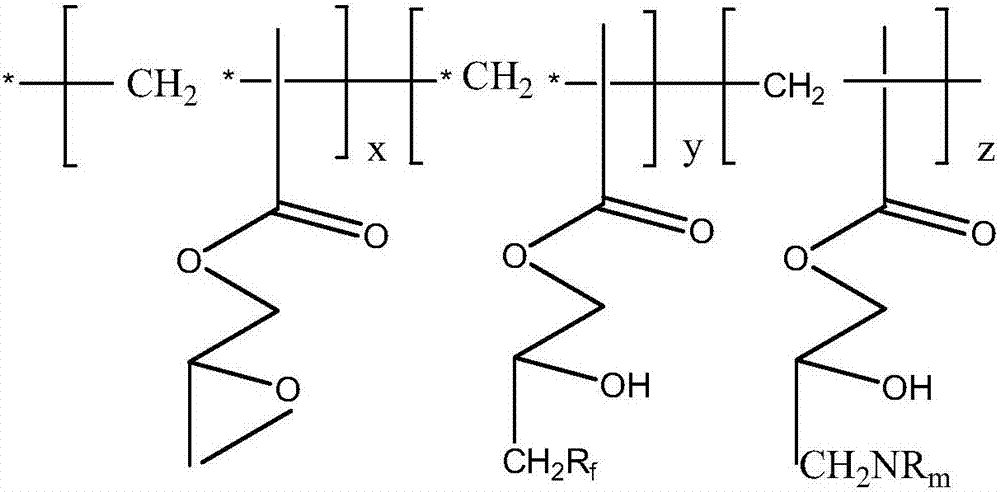

Polymer-based asphalt anti stripping agent and preparation method and application thereof

The invention belongs to the technical field of new materials, and discloses a polymer-based asphalt anti stripping agent and a preparation method and application thereof; by winding of long chain alkyl groups and asphalt molecular chains, compatibility between asphalt and coarse and fine aggregates can be increased, polyamine structures and epoxy rings in the asphalt anti stripping agent can be firmly attached on the surface of the coarse and fine aggregates so as to bridge the asphalt and aggregate components with high polarity and weak acidity to increase the strong interaction between the asphalt and aggregates, the dosage of the polymer-based asphalt anti stripping agent is less (0.3-5wt.%), a construction process is not changed, difficulty in construction is not increased; the polymer-based asphalt anti stripping agent is in an emulsion form, a separation link in the preparation process is reduced, preparation cost is greatly reduced, and the polymer-based asphalt anti stripping agent is practical and efficient.

Owner:沐联环境科技(重庆)股份有限公司 +1

Concrete structure wall column corner wood formwork reinforcing method

InactiveCN105937303AChange the construction processEasy constructionForms/shuttering/falseworksSteel tubeSurface plate

The invention discloses a concrete structure wall column corner wood formwork reinforcing method. According to the method, a formwork panel, double-faced adhesive tape, wood lumps, an iron plate, reinforcing double steel pipes and double accessories are included; one end of each reinforcing double steel pipe is provided with one accessory, the ends, provided with the double accessories, of the two reinforcing double steel pipes are connected, the inner sides of the reinforcing double steel pipes are connected with the iron plate and the wood lumps, and the wood lumps are connected with the formwork panel. During installation of a concrete structure wall column corner wood formwork, closing joints of the formwork panel 1 are bonded through the double-faced adhesive tape, and the 50*100 wood lumps which are 2,000-mm long are used for covering the joints completely and ceaselessly along the floor height; after the wall column corner formwork is corrected and reinforced, an accessory is added to the accessory of each reinforcing double steel pipe to form double accessories, the situation that formwork expansion is caused by quality problems of the accessories is prevented, the construction level is increased, construction quality is ensured, a construction method is simplified, the later cost is reduced, and the concrete appearance quality is improved.

Owner:CHINA MCC17 GRP

Low-carbon low-shrinkage ultra-high strength concrete and preparation method and application thereof

PendingCN110128072ASolve technical problems such as large self-shrinkageImprove brittlenessIn situ pavingsCovering/liningsHigh strength concreteFiber

The invention relates to low-carbon low-shrinkage ultra-high strength concrete and a preparation method and application thereof. The low-carbon low-shrinkage ultra-high strength concrete comprises 340-380 parts of cement, 50-90 parts of silicon powder, 140-170 parts of fly ash, 0-35 parts of waste rubber powder, 980-1100 parts of crushed stone, 580-680 parts of medium sand, 110-160 parts of tap water, 10-22 parts of a water reducing agent, 0-3.5 parts of fiber and 0-0.875 part of a coupling agent. According to the method, during preparation, first drying the medium sand in the sun; measuring various components in proportion, manually kneading the waste rubber powder, pouring the waste rubber powder into a stirring barrel, then uniformly stirring the water reducing agent, the coupling agentand water, pouring the water reducing agent, the coupling agent and the water into the stirring barrel, and stirring; pouring the cement, the silicon powder and the fly ash into the stirring barrel,and stirring; adding the crushed stone, and stirring; finally, adding the medium sand and the fiber, stirring and discharging. The low-carbon low-shrinkage ultra-high strength concrete is configured with lower single cement consumption, and effectively solves the problems of high-efficiency utilization of waste rubber powder resources, excessively high viscosity, excessively high self-constrictionand high brittleness of ultra-high strength concrete mixtures, thus achieving multiple benefits at one stroke.

Owner:PUTIAN UNIV

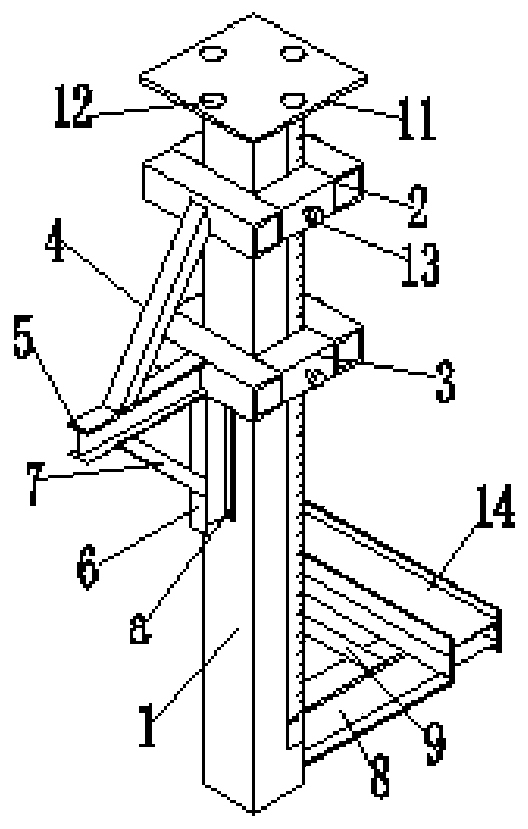

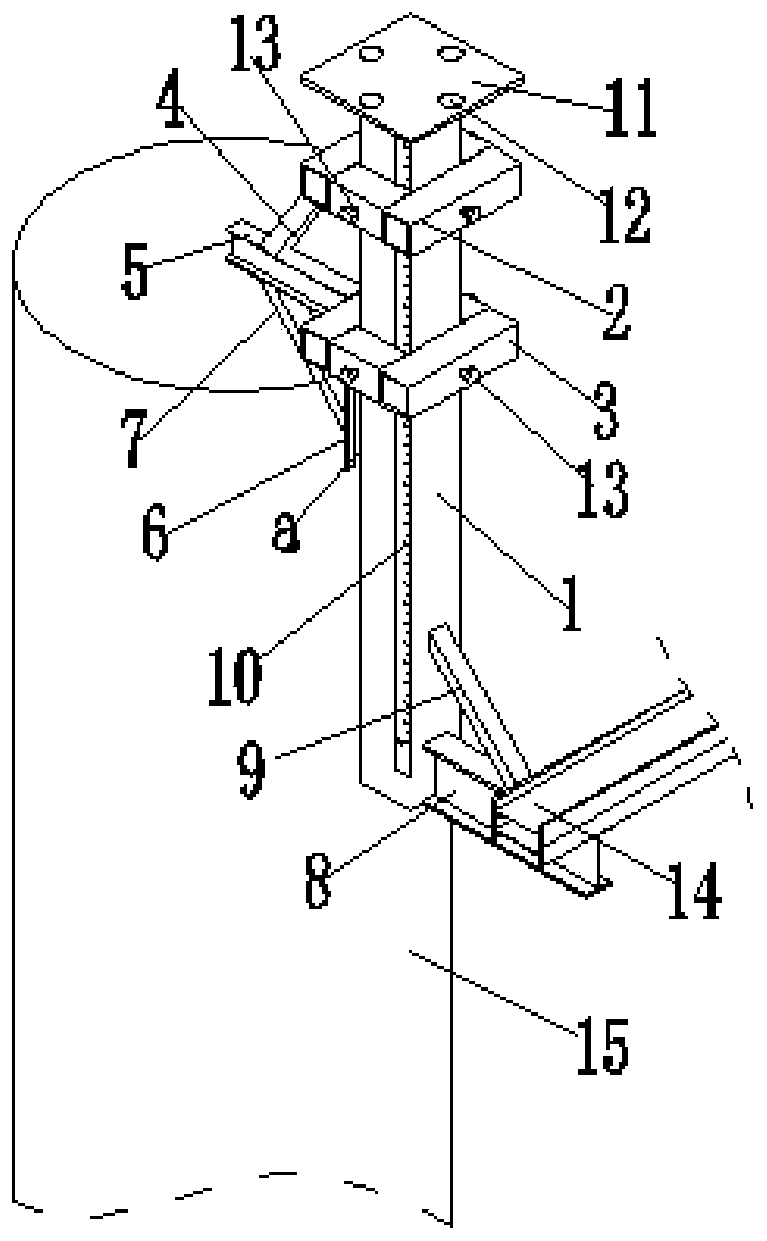

Recyclable temporary bracket for installing steel sheet pile cofferdam purlin

PendingCN110318408ADetermine the sizeChange the construction processFoundation engineeringPurlinArchitectural engineering

Disclosed is a recyclable temporary bracket for installing a steel sheet pile cofferdam purlin. The recyclable temporary bracket for installing the steel sheet pile cofferdam purlin is characterized in that a bolt is used for installing an upper ring and a lower ring on a stand column provided with a graduated scale; a first transverse rod is welded to the side wall of the lower ring, and the twoends of a first inclined rod are welded to the top surface of the left end of a first transverse rod and one lateral side of the upper ring correspondingly, so that the upper ring and the lower ring constitute a triangular bracket structure; the upper end of a baffle block is welded to the lower bottom surface of the first transverse rod, the two ends of a second inclined rod are welded to the left end of the first transverse rod and the bottom end of the baffle block correspondingly, and a groove is formed between the baffle block and the stand column; the two ends of a third inclined rod arewelded to the right end portion of the second transverse rod and the stand column correspondingly, and a third triangular supporting seat structure is formed; one end of the purlin is welded to the top surface of the right end of the second transverse rod; the groove between the baffle block and the stand column in the temporary bracket is clamped on the cylinder wall of a steel protective cylinder; and the recyclable temporary bracket for installing the steel sheet pile cofferdam purlin is formed through the structure.

Owner:NO 1 ENG CO LTD OF CR11BG +1

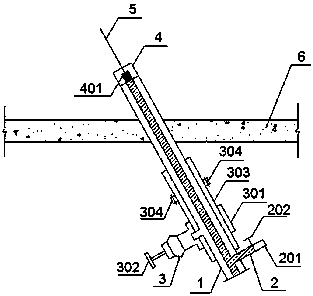

High-pressure small jet coal and gas outburst control device

InactiveCN102061932AIncreased propulsion speedImprove securityMining devicesGas removalHydraulic motorRemote control

The invention discloses a high-pressure small jet coal and gas outburst control device which comprises a high-pressure water gun, a high-pressure water pipeline, a hydraulic motor, a walking vehicle, a high-pressure hose, a hydraulic remote control pump station and an explosion-proof monitor device, wherein the high-pressure water gun is connected with the high-pressure water pipeline through the high-pressure hose, the hydraulic motor and the high-pressure water gun are both installed on the walking vehicle, a gear installed at the output shaft end of the hydraulic motor is in meshing transmission with a rack arranged at the bottom of a gun barrel of the high-pressure water gun, the hydraulic motor is connected with the hydraulic remote control pump station through a high-pressure oil pipe, and the explosion-proof monitor device comprises an explosion-proof camera and an explosion-proof display. The device fulfills the function of protecting a tunneling constructer and also has the functions of accelerating the tunneling working face advance, reasonably arranging a cohesion sequence of a working face, lowering the investment on gas control and enhancing the production efficiency. The use of the device can change the construction technology in the outburst coal seam tunneling operation process, accelerate the tunneling and also enhance the safety coefficient of the tunneling work.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

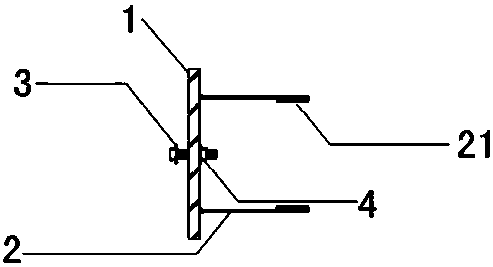

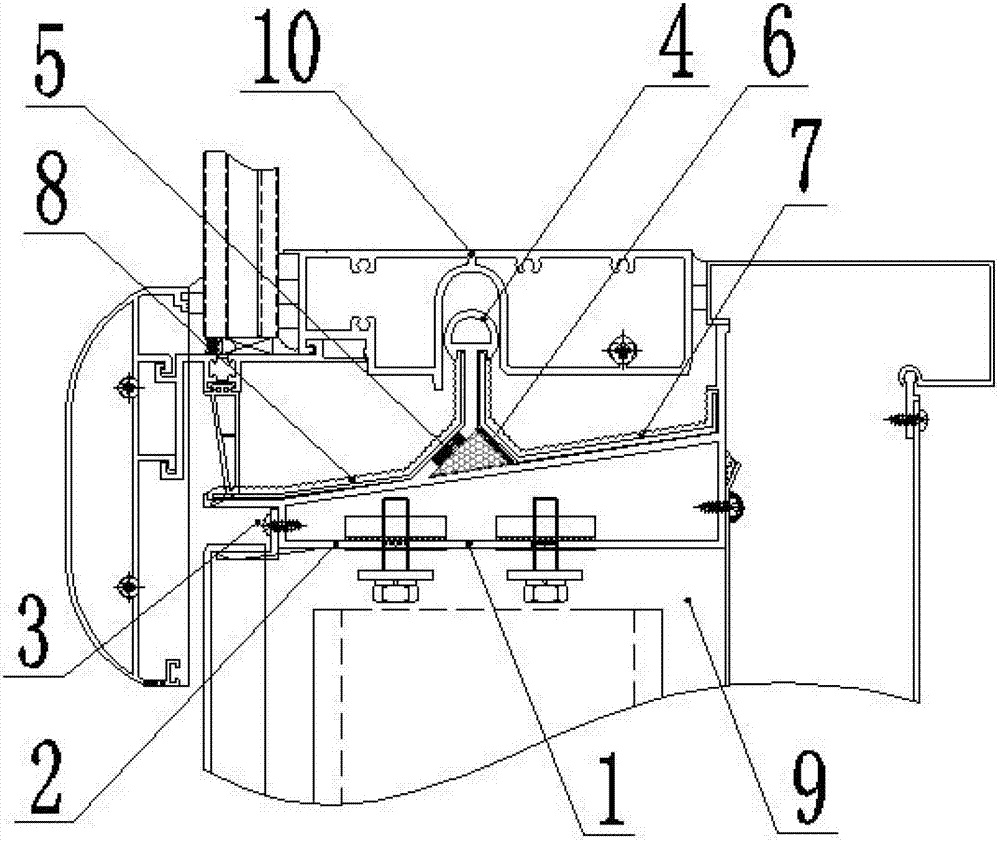

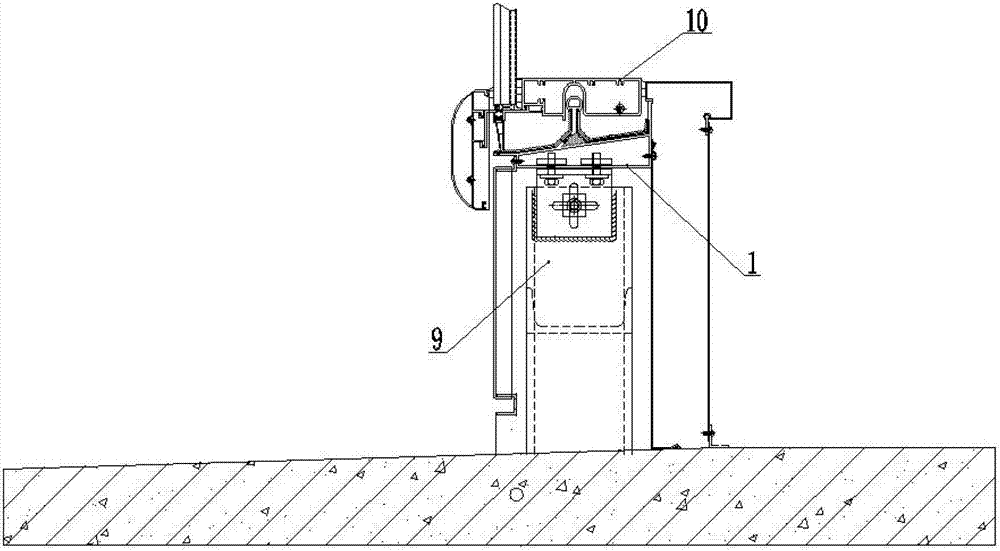

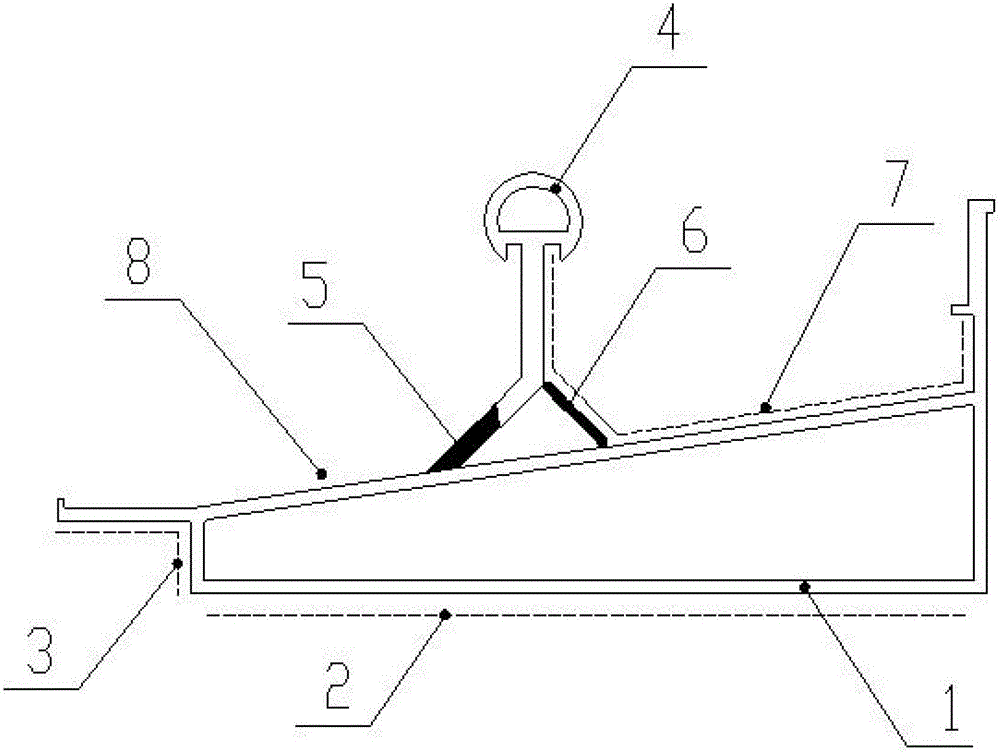

Transferring cross beam of lower openings of unitized curtain walls

ActiveCN102733514AMeet functional requirementsChange the construction processWallsArchitectural engineeringCornice

The invention discloses a transferring cross beam of lower openings of unitized curtain walls. The transferring cross beam comprises a lower transferring cross beam frame. The lower surface of the lower transferring cross beam frame is a grounding U-steel joint face; an aluminium plate framework connecting part is arranged at the left side of the lower transferring cross beam frame; a guide positioning boss is arranged at the upper surface of the lower transferring cross beam frame; the connecting part of the guide positioning boss and the upper surface of the lower transferring cross beam frame is a left hollow stand bar and a right hollow stand bar; and an outer layer drainage channel and an inner layer drainage channel are arranged inside respectively. According to the transferring cross beam of lower openings of the unitized curtain walls, the common construction process of the curtain walls is changed, and the decorative face plate with the cornice is installed firstly. Working plane can be developed entirely to realize cross working and parallel construction can be carried out without the limitation of construction sequence, thus the construction progress is greatly accelerated. The transferring cross beam is combined with the cornice aluminium plate framework by virtue of the lower transferring cross beam frame to form a complete closed opening, so that the function requirement of the cornice aluminium plate framework is satisfied and the function of combination with lower cross beams of interlayered unitized curtain walls is satisfied.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Heap foam concrete and construction method thereof

PendingCN109987964ALess quantityShorten the construction periodArtificial islandsEmbankmentsFoam concreteCarboxymethyl cellulose

The invention discloses heap foam concrete and a construction method thereof. The heap foam concrete is characterized by being prepared from 38-56 parts by weight of self-leveling foam concrete slurryand 44-62 parts by weight of a prefabricated block, wherein the self-leveling foam concrete slurry is formed by mixing and stirring cement, fly ash, a polycarboxylic acid water reducing agent, carboxymethyl cellulose ether, water and foam, and the prefabricated block is a foam concrete block with the particle size not smaller than 40 mm in a dry state and is in the shape of any one or a combination of two of spheres and sphere-like bodies; when the heap foam concrete is constructed, blocks prefabricated in advance are naturally stacked and fully filled in a site where a template or a templatesubstitute is arranged or a site with a natural barrier to form a heap; and then, the self-leveling foam concrete slurry meeting the requirements is directly poured on the surface of the heap, and heap gaps are automatically filled without vibration to form the heap foam concrete, so that the method has the advantages of reducing the manual labor cost, improving the construction efficiency, improving the construction environment and improving the pouring body quality.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Fabricated building and construction method thereof

PendingCN111155792AReduce weightImprove connection strengthWallsFoundation engineeringArchitectural engineeringSlurry

The invention discloses a fabricated building and a construction method thereof, and belongs to the technical field of buildings. The fabricated building comprises a foundation body, and is characterized in that a ground groove is formed in the top wall of the foundation body, a wall is assembled in the ground groove, and the wall is formed by splicing more than two wallboards; the wallboards comprise light core blocks, first protective layers are arranged on the inner walls of the light core blocks, second protective layers are arranged on the outer walls of the light core blocks, two or morereinforcing ribs are arranged on the second protective layers, the other ends of the reinforcing ribs are connected with the first protective layers, and the reinforcing ribs, the first protective layers and the second protective layers jointly define groove cavities located in the side walls of the wallboards; and the groove cavities in two adjacent wallboards are connected to define cavities, and the cavities are filled with bonding slurry. According to the building, the wall formed by splicing the wallboards is assembled in the ground groove in the foundation body, so that on one hand, theconnection strength between the wall and the foundation body is increased, and the wall and the foundation body are connected into a whole; on the other hand, the traditional construction process isthoroughly changed, and the construction progress is accelerated; and the overall weight of the wallboards is reduced.

Owner:滨州市宏基建材有限公司

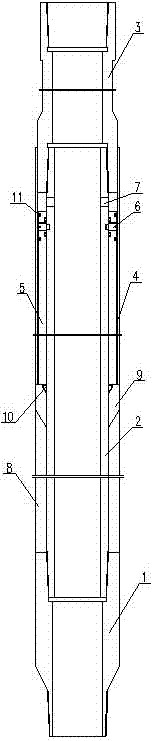

Packer

The invention relates to a packer. The packer comprises a lower joint, a central pipe and a lifting joint, wherein the lower joint and the lifting joint are arranged at both ends of the central pipe in a sleeve mode; the lower outer circumference of the lifting joint is provided with an external pipe in a sleeve mode; a piston casing pipe is arranged between the external pipe and the central pipe, the upper end of the piston casing pipe is fixedly connected with the outer wall of the central pipe through a shear pin; the side wall of the central pipe is provided with a plurality of inlet holes between the piston casing pipe and the lifting joint; a rubber barrel, a slope short joint and a retaining ring are sequentially arranged between the lower joint and the piston casing pipe from top to bottom, the lower end of the slop short joint is welded inside the upper end of the rubber barrel, and the retaining ring is wedged inside the upper end of the slope short joint; the outer surface of the central pipe is provided with hangnails for snapping the retaining ring and preventing the slope short joint from moving upwards. The packer is simple in structure, convenient, safe and reliable to operate, high in packing effects without changing original well cementing operation processes, and wide in application range. The packer can be applied to oil-gas wells in different conditions as well as can be matched with other well cementing tools to achieve multi-tool construction of the same well.

Owner:扬州市油田金达实业有限公司

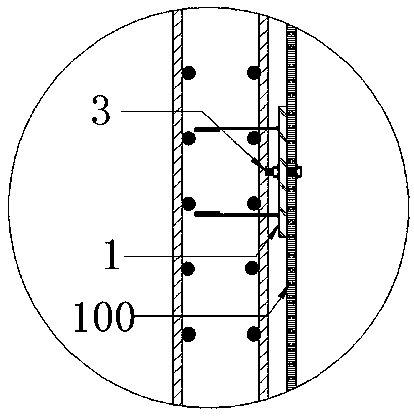

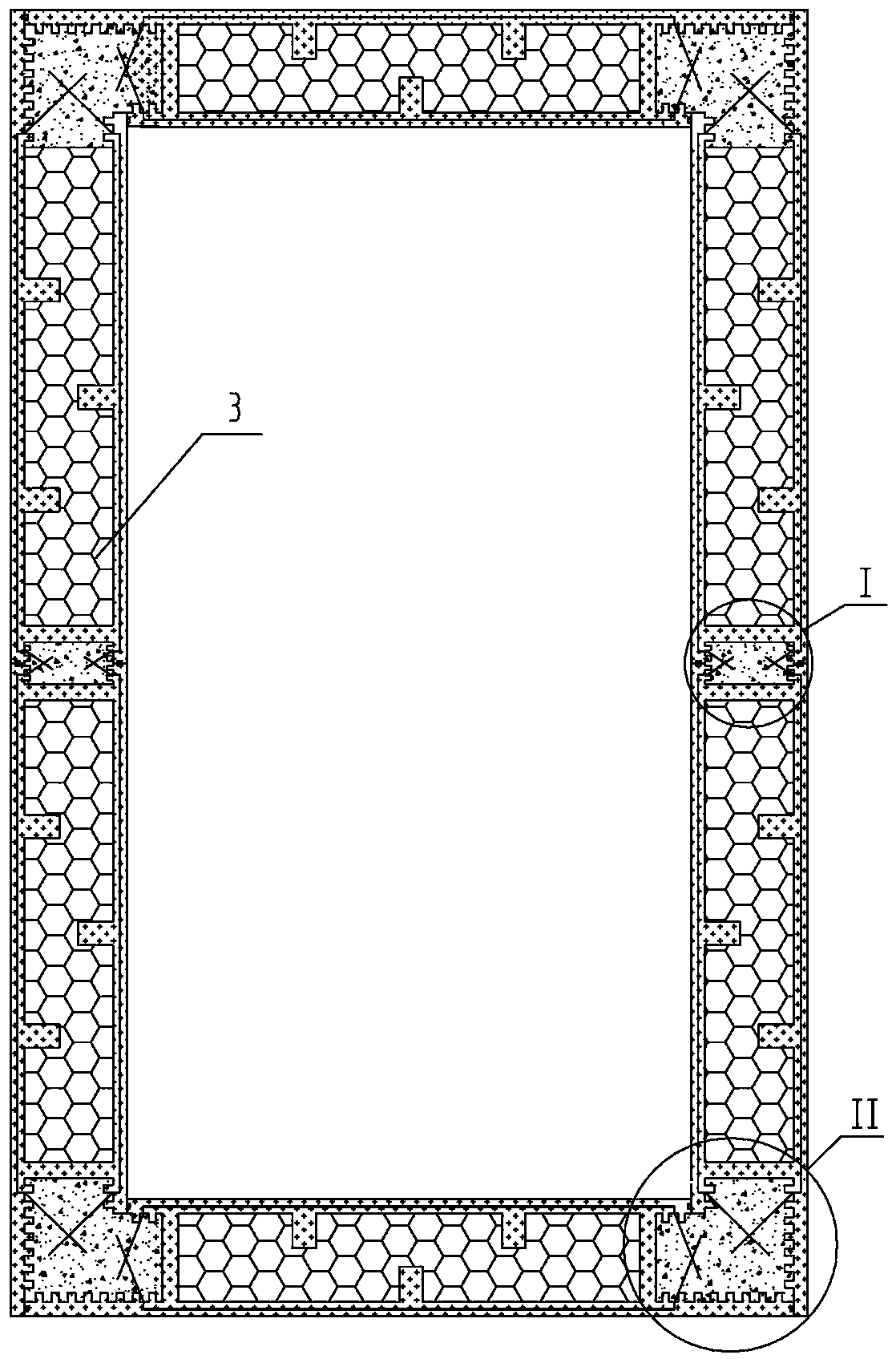

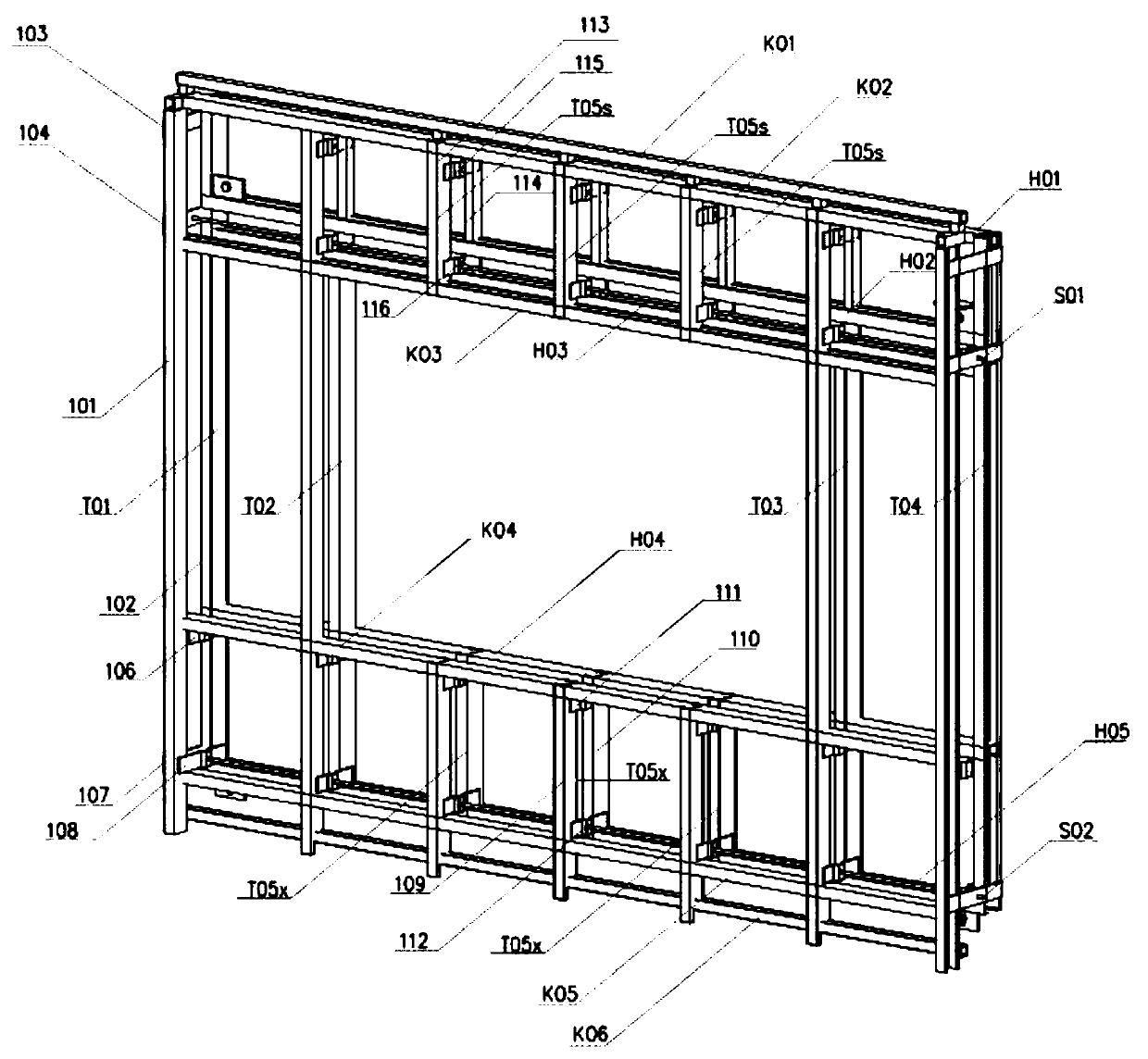

An outer protection system for prefabricated steel structure residences suitable for severe cold regions

ActiveCN110778016BReduce construction proceduresSimplified operational requirementsWallsInsulation layerTube (structure)

The invention belongs to the technical field of buildings, and particularly relates to an external enclosure system of a fabricated steel structure house suitable for severe cold areas. The system comprises a standard unit wallboard, a convex column unit wall plate and accessories, wherein the standard unit wallboard is composed of a truss type wall frame structure, an ALC strip plate core wall, an inner side filling wall body, a heat insulation layer and an outer wall decorative plate, and the convex column unit wall plate is composed of a cold-formed square tube framework, a heat insulationboard and an outer decoration panel. According to the system, the standardized wallboard and the convex column unit wall plate are adopted, so that standardized product design and industrial continuous production can be realized, technical requirements of site construction are reduced, production efficiency and assembly efficiency are greatly improved, assembly operation and construction difficulty are greatly simplified, the common problem that an existing external enclosure system of the fabricated steel structure building restricts the development of fabricated buildings is solved, a help force is provided for popularization and development of the fabricated buildings, and site construction become fabricated construction worthy of the name.

Owner:曲圣玉

Outer wall decoration structure

InactiveCN105888178ANo consumptionLow costCovering/liningsClimate change adaptationInsulation layerBody joints

The invention provides an outer wall decoration structure, relates to building exterior decoration and solves problems that high-grade curtain wall decoration uses multiple steel products and has high costs, adhered face tiles are easy to remove, and an assembly type heat-insulation wall body joint is cracked. The structure I comprises a base, a decoration plate or block, and an adhesion material, wherein the adhesion material is a synthetic resin adhesive; the adhesion material is coated on the base or / and the decoration plate or block, so that the decoration plate or block and the base are adhered in a dry manner. The structure II comprises a base wall body, a heat-insulation layer, outer protection layers and an elastic waterproof sealant, wherein the heat-insulation layer is arranged at the joints among the outer protection layers, and the elastic waterproof sealant is filled with the joints among the outer protection layers so as to form elastic waterproof heat-insulation decoration separation joints; the positions of the elastic waterproof heat-insulation decoration separation joints are sequential. The outer wall decoration structure has the advantages of steel product saving, low costs and good durability; assembled energy-saving heat-insulation wall body joints can be coordinated with the outer wall decoration; besides, elastic, waterproof and heat-insulation requirements are met.

Owner:吴淑环

Transparent building template

PendingCN110259111AImproved physical and perceived qualityImprove safety and reliabilityAuxillary members of forms/shuttering/falseworksForming/stuttering elementsBisphenol-A-polycarbonateSurface plate

The embodiment of the invention discloses a transparent building template, and relates to the technical field of building templates. The transparent building template includes a skeleton, a panel and a pad pasting layer, the skeleton is provided with an installation groove used for installing the panel, the panel is fixed to the installation groove, the pad pasting layer is detachably fixed on the side, away from the skeleton, of the panel, wherein the panel and the pad pasting layer are both transparent plastic plates, the thickness of the panel is larger than that of the pad pasting layer. A polycarbonate board is a transparent board, and has the transparent performance, the skeleton is the structure of a frame, and has a certain transparency, the skeleton is combined with the panel and the pad pasting layer, and has the transparent performance, in the process of concrete casting and pouring and vibrating, the pouring quality of concrete can be visualized, the quality result can be controlled in real time, and the forming quality defect of concrete components can be completely eliminated.

Owner:刘先跃

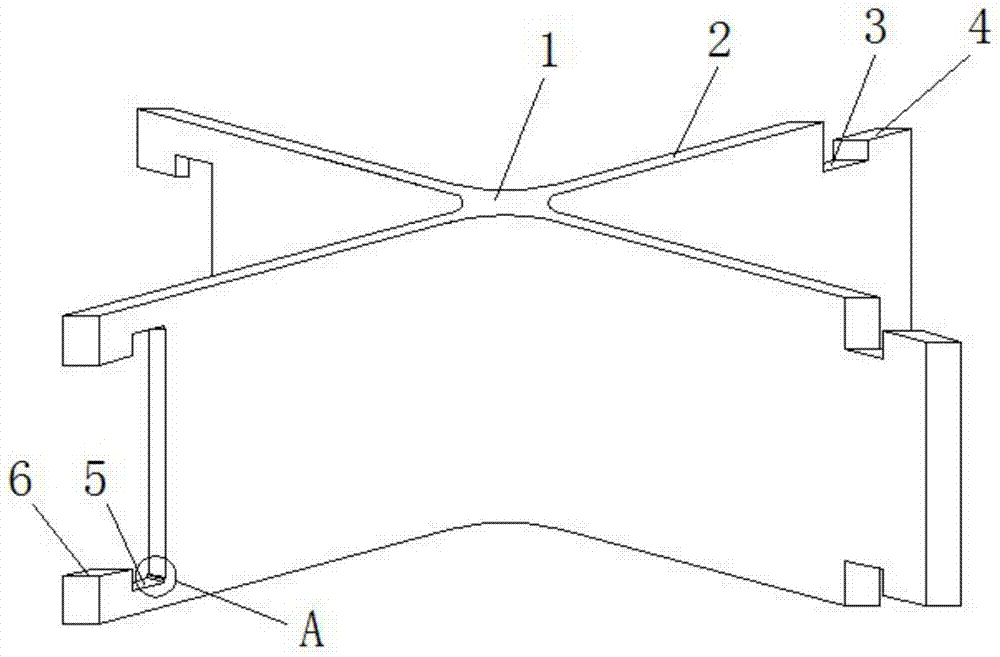

Prefabricated skeleton structure and construction method for vegetation protection of slope of hydropower station

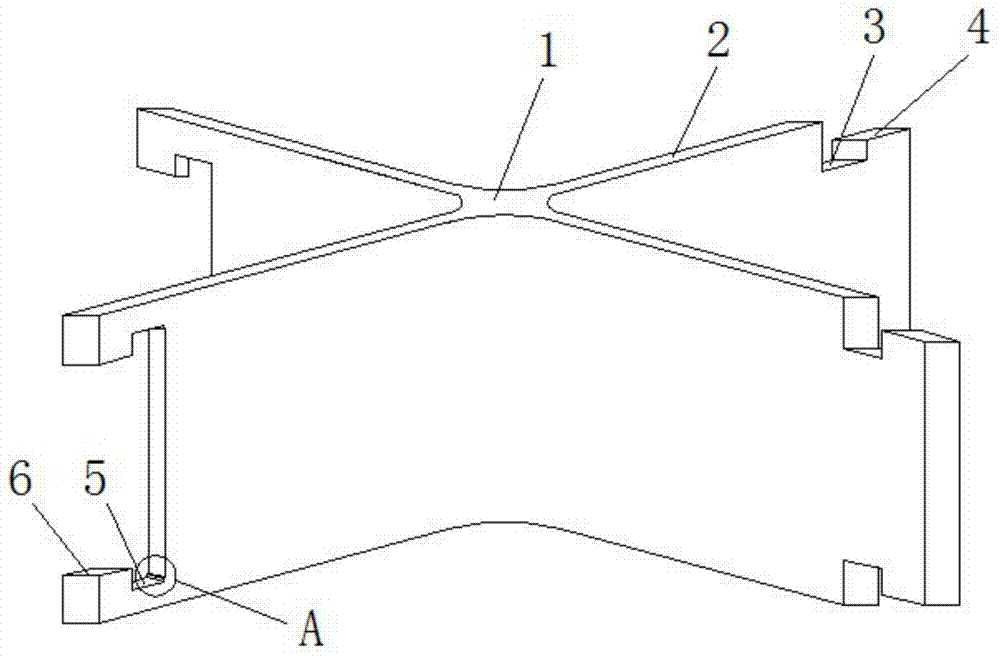

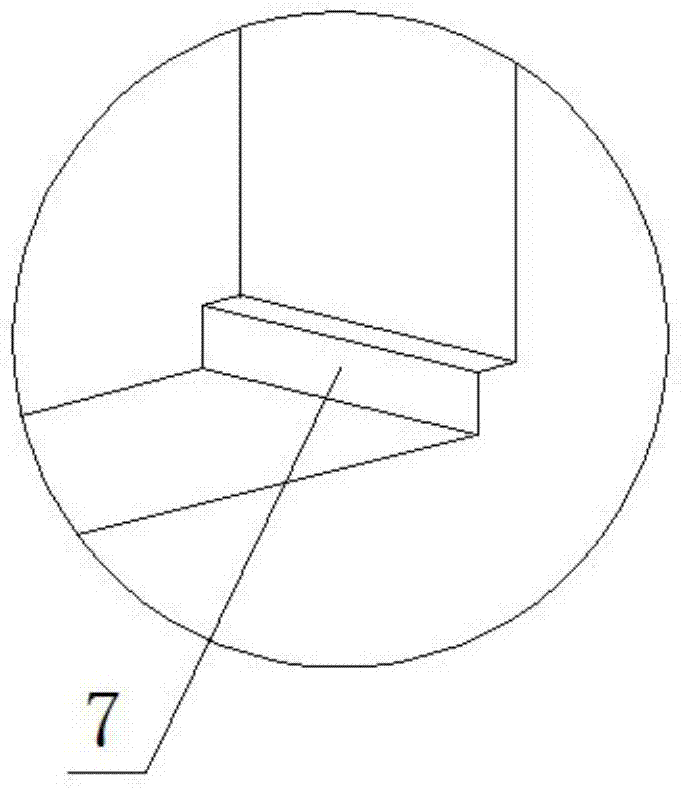

ActiveCN104846834BRealize splicingChange the construction processBreakwatersQuaysVegetationArchitectural engineering

The invention discloses a prefabricated skeleton structure for protection of slope vegetation in a hydropower station and a construction method thereof, which belongs to the technical field of slope protection and includes a main body, the main body includes two symmetrically intersecting cross sides, and one end of the cross side is provided with an outer groove and the outer boss, the other end is provided with an inner groove and an inner boss, and the outer groove is matched with the inner boss, and the inner groove is matched with the outer boss, so as to facilitate the connection and fixation between the two skeleton structures . By modularizing and standardizing the slope protection framework, this technical solution can realize batch prefabrication and standard installation. It can be produced on site or in factory batch production. The skeleton structure can be assembled directly, changing the traditional slope protection. The construction process of the project reduces the construction process and simplifies the construction process, which can reduce the cost and speed up the construction progress, so that the project can be put into use faster and achieve the protection effect.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

How to make cast-in-place thermal insulation roof

InactiveCN102787698BReduce dead loadChange the construction processRoof covering using sealantsRoof covering insulationsFiberglass meshUltimate tensile strength

The invention discloses a method for producing a cast-in-situ insulation roof, which comprises the technological process that a steel screen is welded on a purline, the purline is bound with the steel screen, then DFB lightweight aggregates are poured, blocks of polyphenyl plates are embedded in the DFB lightweight aggregates side by side, fiberglass meshes are respectively laid between the DFB lightweight aggregates on the upper and lower surfaces of the polyphenyl plates, after the DFB lightweight aggregates are completely poured, a trowel for levelling up is used for beating the DFB lightweight aggregates to solidify, and finally, mortar is used for plastering an anti-cracking layer top facing. According to the method, an outer building envelop and energy-saving insulation engineering are integrated to be completed at one step, the technology is simple, the application scope is wide, and the construction progress is accelerated. The method can be used for manufacturing an insulation roof which is light, has high-strength and good integral fire proofing, and is low in comprehensive cost.

Owner:张云麟 +1

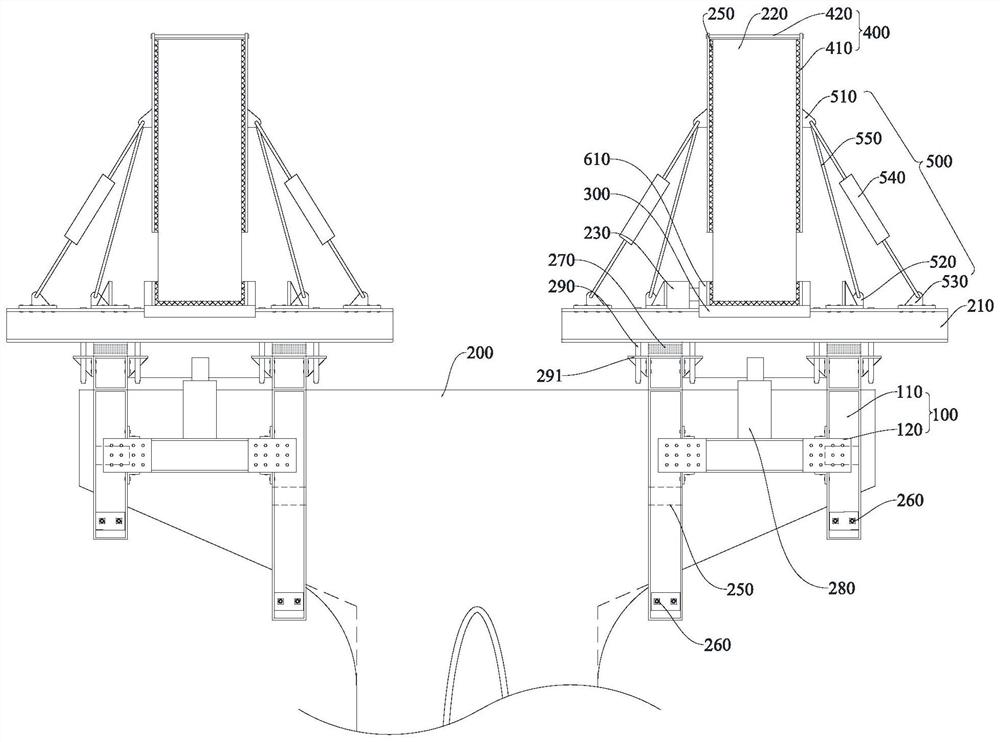

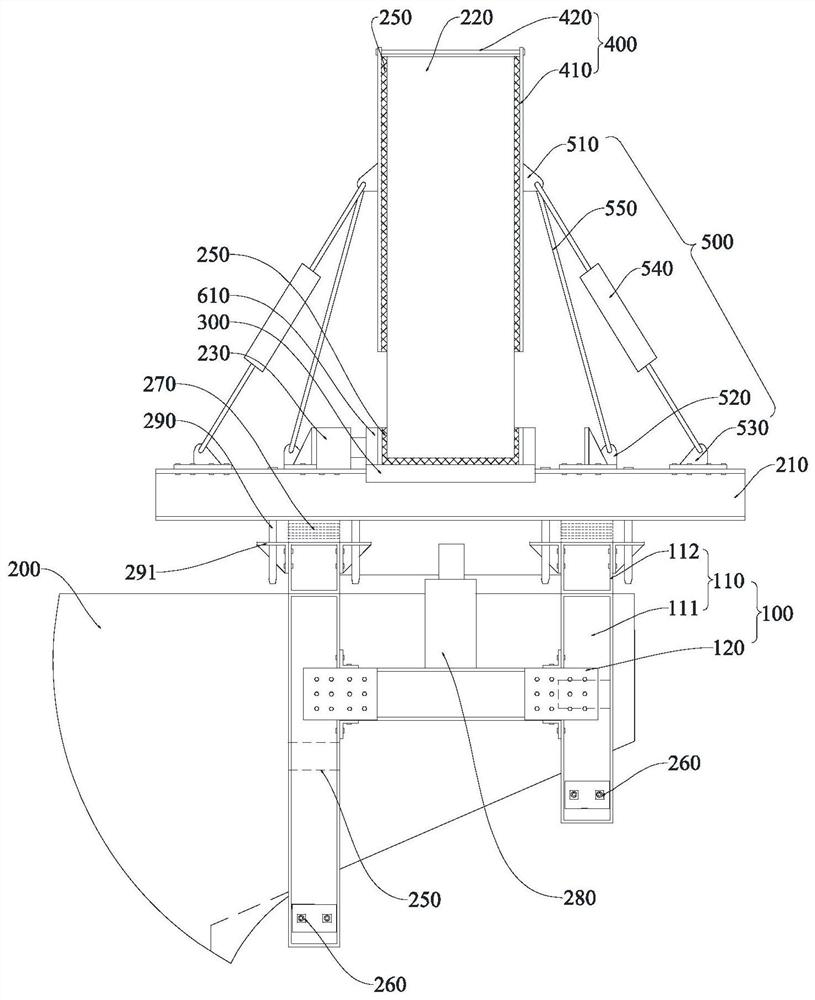

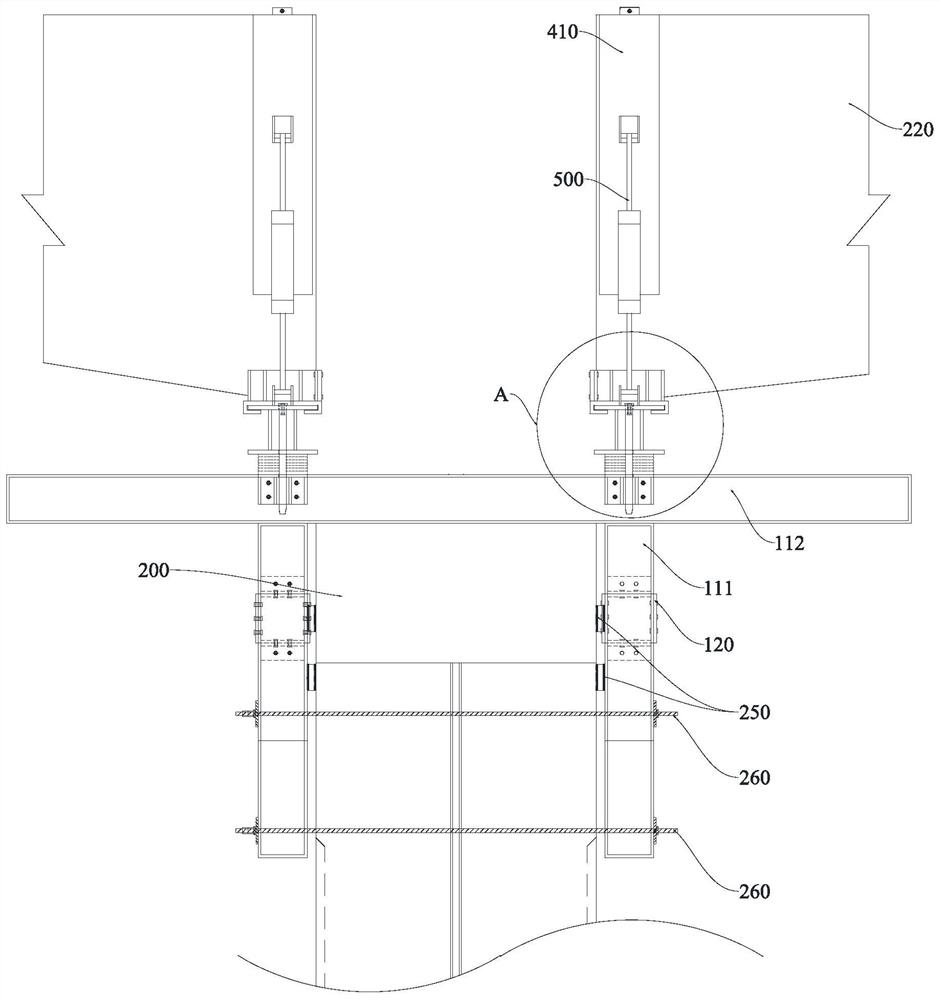

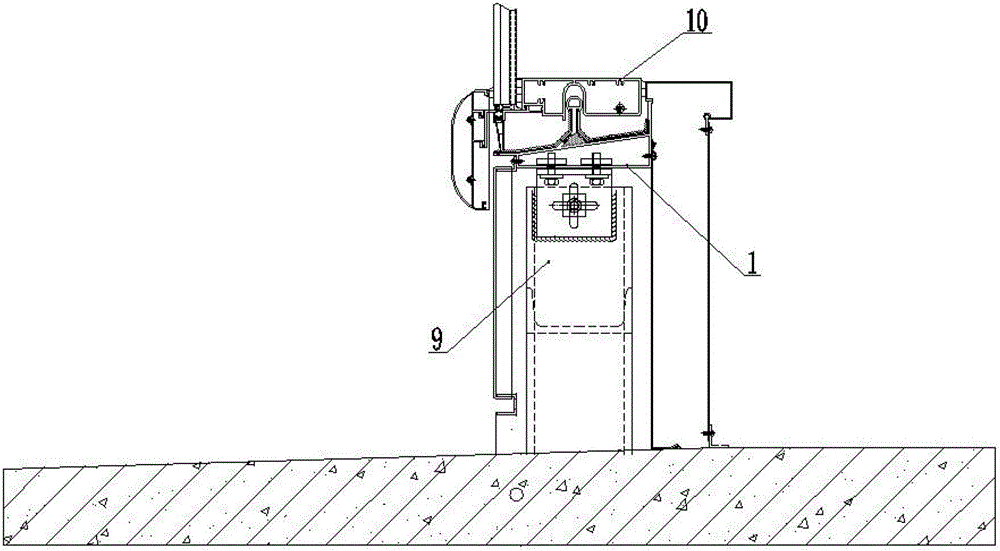

Riding-hung bearing structure and construction method of simply supported first and then continuous bridge

ActiveCN111206507BAdjust verticalityAchieve fixationBridge erection/assemblyArchitectural engineeringStructure support

The invention provides a riding-hanging support structure and a construction method for a simply-supported and then continuous bridge, belonging to the technical field of bridge construction. The ride-on support structure includes a ride-on bracket, a first assembled beam arranged on the top of the ride-on bracket, a sliding support, a lateral pushing device arranged on the first assembled beam, a clamp positioned above the slide bearing, and The deviation correcting device arranged on the first assembled beam and connected with the fixture; the riding bracket is used to be placed on the end of the cover beam; the horizontal pushing device is used to drive the sliding support to reciprocate and slide along the length direction of the first assembled beam; The clamp is used to clamp the middle and / or upper part of the simply supported beam; the deviation correction device is used to adjust and fix the perpendicularity between the simply supported beam and the cover beam. The invention also provides a construction method of a simple-supported bridge and then a continuous bridge. The riding-hanging support structure and the construction method of the simply-supported and then continuous bridge provided by the invention reduce the bridge construction cost, equipment purchase cost and turnover cost.

Owner:SHIJIAZHUANG TIEDAO UNIV

Novel sinking and driving engineering freezing drill pipe

PendingCN108412432AChange the construction processImprove work efficiencyDrill bitsDrilling rodsGate valveStructural safety

The invention provides a novel sinking and driving engineering freezing drill pipe. The novel sinking and driving engineering freezing drill pipe comprises a water supply pipe and a freezing pipe, andwater in the water supply pipe is controlled by a water supply pipe opening and a water supply pipe gate valve. A dill bit is arranged on the end portion of the freezing pipe, and the drill bit is composed of a high-strength drilled core and a drill pipe body. A non-return gate valve outer pipe clamp covers the freezing pipe, a non-return gate valve inner pipe clamp is connected with a non-returngate valve through the connection of an outer pipe fixing bolt, and the non-return gate valve is connected with a non-return gate valve switch. The opening of a non-return device is controlled by thenon-return gate valve switch, and the drill bit passes through a roadway concrete formation. The novel sinking and driving engineering freezing drill pipe combines the freezing pipe and the drill pipe body into one, the process of completing the installation of a drill hole and the freezing pipe is formed, the purpose that freezing pipe can be frozen while drilling the drill pipe body is realizedin the construction process of a freezing method, a traditional construction technology is changed, the work efficiency is improved, and the structural safety of a well wall of a roadway is ensured.

Owner:吕琳

Transition beam for lower opening of unit curtain wall

ActiveCN102733514BMeet functional requirementsChange the construction processWallsCorniceBuilding construction

The invention discloses a transferring cross beam of lower openings of unitized curtain walls. The transferring cross beam comprises a lower transferring cross beam frame. The lower surface of the lower transferring cross beam frame is a grounding U-steel joint face; an aluminium plate framework connecting part is arranged at the left side of the lower transferring cross beam frame; a guide positioning boss is arranged at the upper surface of the lower transferring cross beam frame; the connecting part of the guide positioning boss and the upper surface of the lower transferring cross beam frame is a left hollow stand bar and a right hollow stand bar; and an outer layer drainage channel and an inner layer drainage channel are arranged inside respectively. According to the transferring cross beam of lower openings of the unitized curtain walls, the common construction process of the curtain walls is changed, and the decorative face plate with the cornice is installed firstly. Working plane can be developed entirely to realize cross working and parallel construction can be carried out without the limitation of construction sequence, thus the construction progress is greatly accelerated. The transferring cross beam is combined with the cornice aluminium plate framework by virtue of the lower transferring cross beam frame to form a complete closed opening, so that the function requirement of the cornice aluminium plate framework is satisfied and the function of combination with lower cross beams of interlayered unitized curtain walls is satisfied.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Underwater construction method of steel tube

InactiveCN101691893BEliminate water transportImprove construction qualityPipe laying and repairState of artUnderwater

The invention is an underwater construction method of a steel tube, belonging to the technical field of underwater engineering and comprising the following steps: plugging steel tube openings at a front end and an on-shore segment of the first section of the steel tube by an air bag or a blind plate; enabling the steel tube to float on the water surface by inflating the steel tube, thus facilitating the steel tube to be fed into water; filling water in the steel tube to lead the steel tube to sink underwater, thus realizing continuous welding construction of the steel tube; changing underwater work to on-shore work, thus omitting water transportation of the steel tube; and welding and launching the steel tube section by section, thus needing no underwater work of divers and cooperation ofa lot of large-scale ship engine equipment such as floating cranes, barges, tugboats and the like. The method in the invention is suitable for various water area constructions; the entire steel tube is integrated into a whole, and the construction quality is far higher than that in the prior art; and the construction risk and the construction cost are lower.

Owner:珠海澳新起重科技有限公司

Hydropower station side slope vegetation protecting prefabricated-framework structure and construction method thereof

ActiveCN104846834ARealize splicingChange the construction processBreakwatersQuaysVegetationPower station

The invention discloses a hydropower station side slope vegetation protecting prefabricated-framework structure and a construction method thereof and belongs to the technical field of side slope protection. The hydropower station side slope vegetation protecting prefabricated-framework structure comprises a main body, wherein the main body comprises two symmetrically-crossed cross edges, wherein an outer groove and an outer boss are arranged at one end of each cross edge, an inner groove and an inner boss are arranged at the other end of each cross edge, the outer grooves are correspondingly matched with the inner bosses, the inner grooves are correspondingly matched with the outer bosses to facilitate connection and fixing of two framework structures. By means of the technical scheme, the side slope protection framework are modular and standard, batch prefabrication and standard installation can be achieved, field manufacture can be performed, industrial batch production can be achieved, the framework structure is directly spliced, a construction process of a traditional side slope protection project is changed, construction work procedures are decreased, a construction process is simplified, cost can be reduced, construction progress can be accelerated to enable the project to more quickly come into service, and protection effect is achieved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Material on tunnel drainage layer

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

An automatic control system for abnormal concrete grouting and vibrating equipment

InactiveCN104007737BReduce work intensityEasy to operateFoundation engineeringTotal factory controlTime informationVibration control

The invention discloses an automatic control system for metamorphic concrete grouting and vibrating equipment. The metamorphic concrete grouting and vibrating equipment is mainly equipped with a grout bucket, a water tank, a grouting device, a vibrating device and a stirring device. It is characterized in that it includes a grouting control module, a vibrating control module, a cleaning control module, a stirring control module, a device adjustment control module, a password modification control module, an input control module and an output display module; the invention is easy to operate and reduces the workload of the operator strength, improve work efficiency, and save energy; during the grouting period of the present invention, the required grouting amount of a single point and the completed grouting amount can be dynamically displayed, which is convenient for operators to grasp grouting related information in real time; the present invention can add grouting to metamorphic concrete The error is controlled within the allowable range, which meets the requirements of measurement and monitoring of metamorphic concrete construction; the invention can reduce the waste of grout caused by manual construction, save construction cost, and has important practical significance for changing the concrete construction technology and the like.

Owner:WUHAN UNIV

Backcut changeover cross beam of unitized curtain wall

ActiveCN102733519BMeet functional requirementsChange the construction processWallsArchitectural engineeringCornice

The invention discloses a backcut changeover cross beam of a unitized curtain wall. The backcut changeover cross beam of the unitized curtain wall comprises a cross beam framework. The upper surface of the cross beam framework is a channel steel junction surface; the left side of the cross beam framework is provided with an aluminum plate skeleton connecting part; the lower surface of the cross beam framework is provided with a changeover cross beam hook; the hooking part of the changeover cross beam hook forms an inclination towards the inner side and along the horizontal direction; and the right side of the cross beam framework is provided with a pressing plate assembly slot. According to the backcut changeover cross beam of the unitized curtain wall, the construction flow of a general curtain wall is changed, i.e. a decoration panel of a cornice is firstly installed, and a working face can be totally spread to engineering to realize cross operation; the cross operation is not limited by the construction sequence, and parallel construction can be performed, therefore, the construction progress is greatly increased. An interlayer backcut changeover cross beam of the unitized curtain wall and a cornice aluminum plate skeleton are combined to form an integral seal, therefore, not only can the functional requirement of the cornice aluminum plate skeleton be met but also the functional requirement that the cornice aluminum plate skeleton is combined with the interlayer backcut changeover cross beam of the unitized curtain wall can be met.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com