Outer wall decoration structure

A technology for exterior wall decoration and construction, applied in the field of exterior wall decoration of buildings, can solve problems such as shrinkage and deformation of cement fiber boards or calcium silicate boards, inability to quickly fix decorative boards or decorative blocks, unreliable pointing waterproofing, etc., to achieve change Construction technology, good waterproof effect, and the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

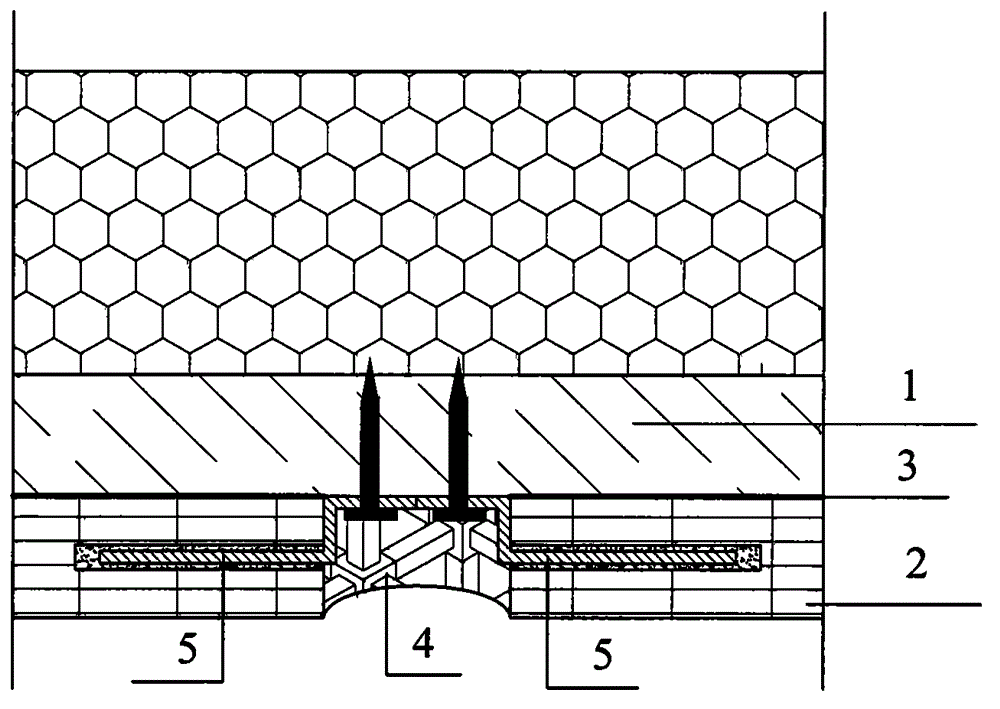

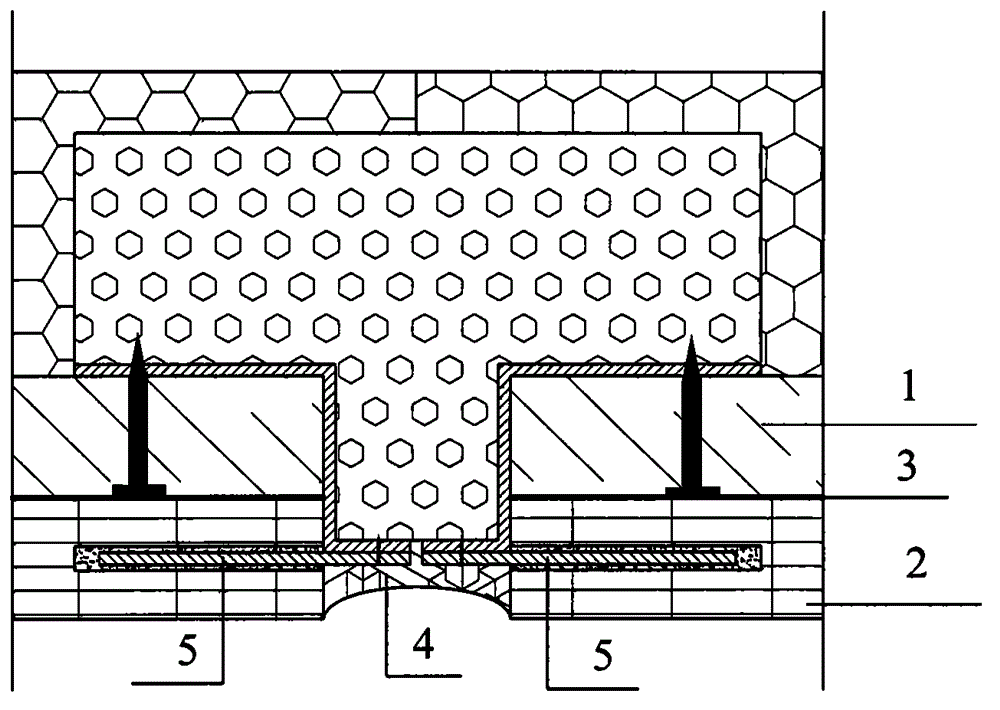

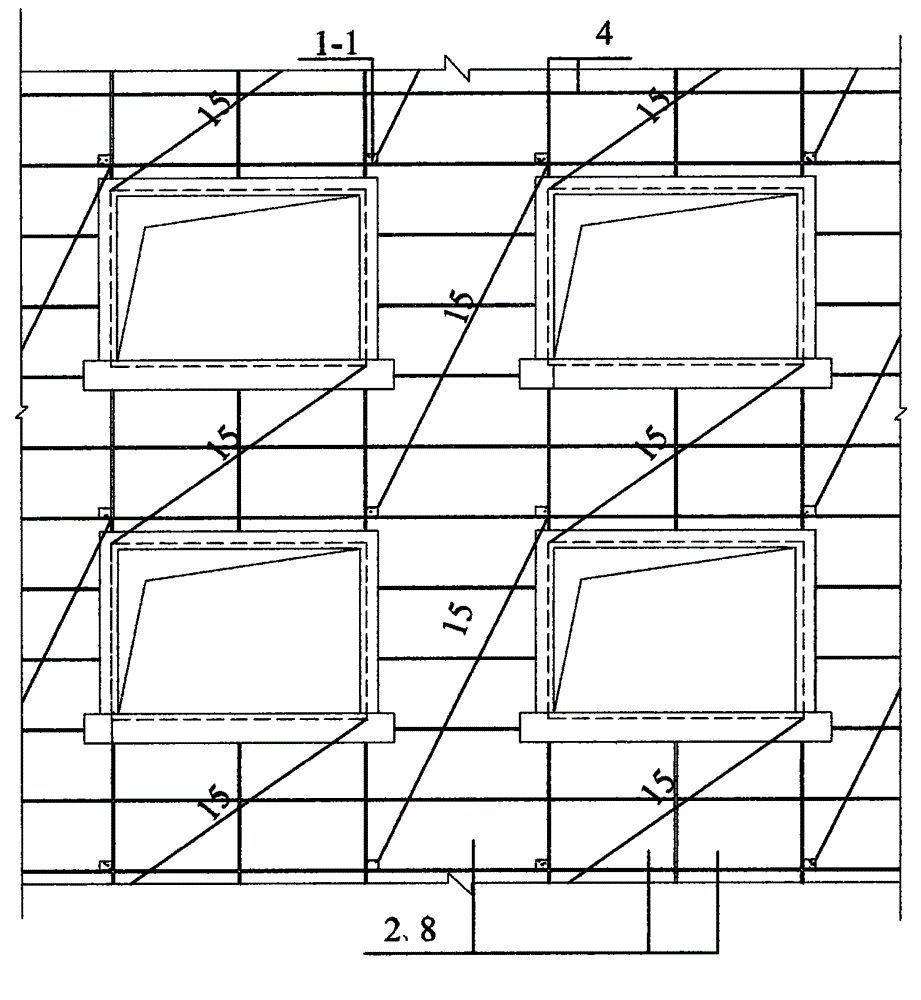

[0047] Implementation mode one: figure 1 , figure 2 , an exterior wall decoration structure of this embodiment, which is composed of a base layer 1, a decorative board or a decorative block 2, and a cementing material 3;

[0048] The base layer 1 is an exterior wall or a cement mortar plastering layer, a concrete layer, a cement fiber board or a calcium silicate board surface layer on an exterior wall, or an insulation layer of an energy-saving and heat-preserving wall, or the exterior of an energy-saving and heat-preserving wall The protective layer;

[0049] The cementing material 3 is a synthetic resin adhesive, and the synthetic resin adhesive should meet the waterproof performance and the elastic requirements for adapting to temperature changes or changes in dryness and humidity;

[0050] The decorative panels or blocks 2 are decorative panels or blocks of various materials, such as light decorative panels or blocks, ceramic decorative panels or blocks, stone decorativ...

Embodiment approach 2

[0072] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cementing material 3 of this embodiment is two different materials, which are bonded with structural glue (such as epoxy resin structural glue) in the middle of the decorative plate 2. The periphery of the decorative board 2 is bonded with a water-soluble adhesive.

[0073] It is inconvenient to use structural glue for large-scale pasting. It is not easy to construct, the cost is high, and it has no elasticity. However, if you only use structural glue in the middle of the decorative panel, it is still convenient for construction. The amount of structural glue used is small, which will affect the cost. It is very small and does not affect the free shrinkage and deformation around the decorative panel.

[0074] This implementation mode can utilize the advantages of different adhesives to ensure reliable bonding and durability.

[0075] The difference between this embodiment and the disclose...

Embodiment approach 3

[0077] Implementation mode three: figure 1 , figure 2 , the difference between this embodiment and one or two of the embodiments is that the present embodiment increases the iron parts 5; the iron parts 5 are installed on the side of the decorative board and the decorative block 2; The side of 2 is fixed to the base layer 1, and the connection between the iron piece 5 and the base layer 1 is an elastic connection.

[0078] figure 2 Indicates that the base layer 1 is equipped with a thin steel plate at the seam, and the connection between the iron piece 5 and the thin steel plate is to be connected with the base layer 1, or other iron pieces and connection methods can also be used to connect. Because the thin steel plate installed on the base layer 1 is stretchable, the connection between the iron piece 5 and the base layer 1 meets the requirements of elastic connection.

[0079]The purpose of this embodiment is to prevent the decorative board and the decorative block 2 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com