Light steel joist partition connecting structure and construction method thereof

A technology for connecting structures and light steel keels, applied in the direction of walls, building components, building structures, etc., can solve the problems of wall stability and safety impact, lag, etc., to save steel materials, reduce investment, and improve construction. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

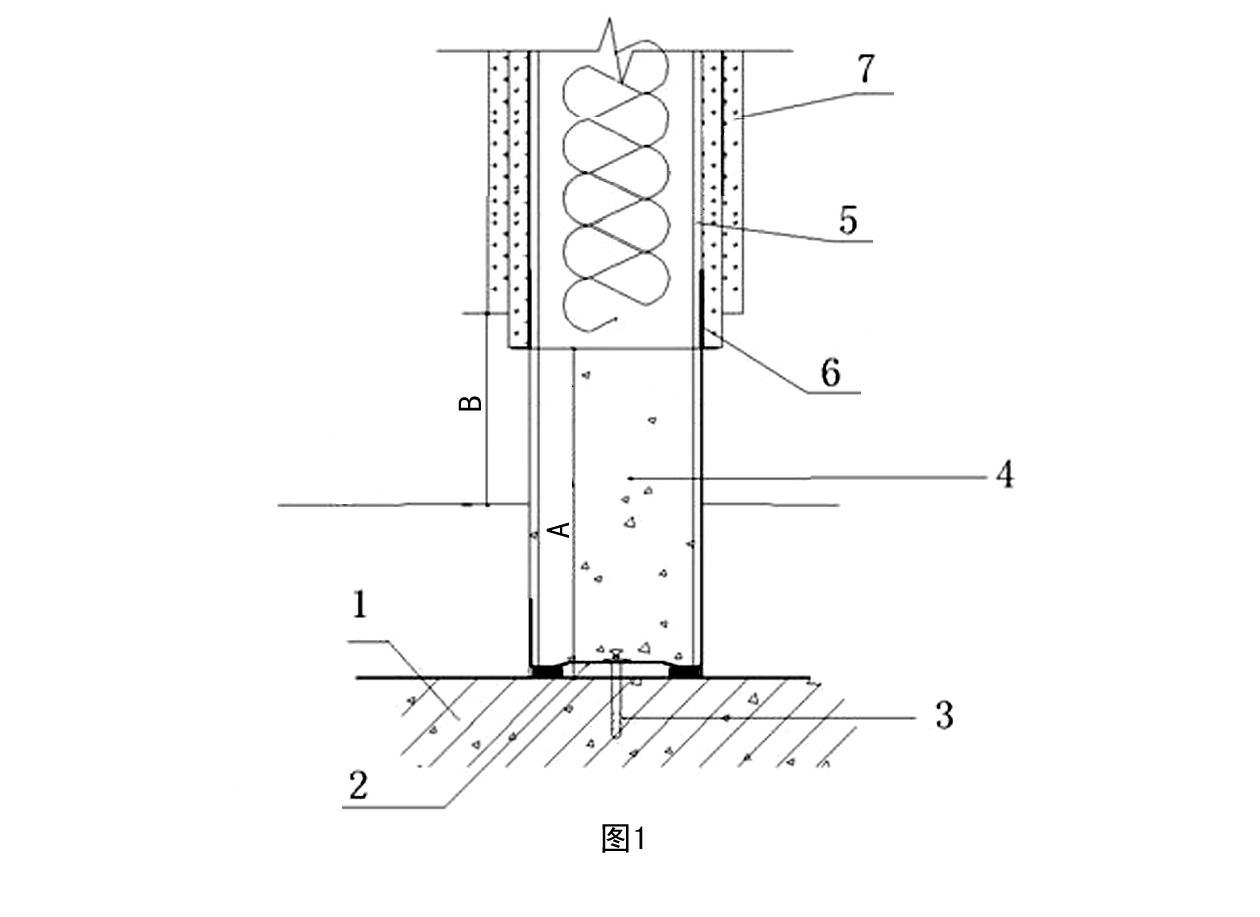

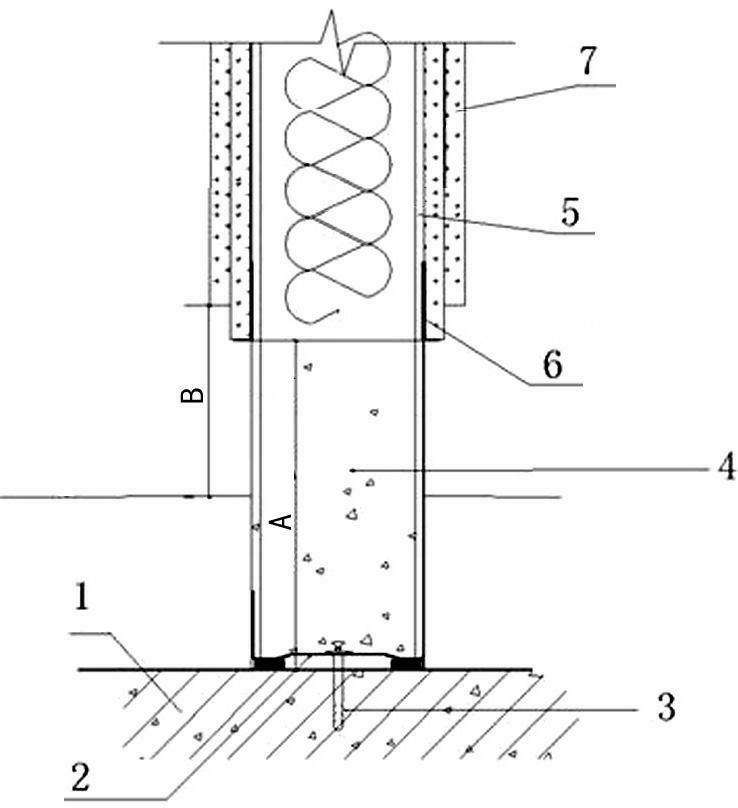

[0017] Below in conjunction with specific embodiment, the present invention is specifically described as follows: As the light steel keel partition wall bottom structure of an embodiment of the present invention, its schematic diagram is as follows figure 1 As shown, the light steel keel partition wall connection structure includes structural concrete floor 1, along the ground keel 2, expansion bolt 3, ground ridge 4, light steel vertical keel 5, wide light steel parallel joint 6, paper-faced gypsum board 7, along the ground The keel 2 is directly fixedly connected with the structural concrete floor 1 through the expansion bolt 3, the light steel vertical keel 5 is connected with the keel 2 along the ground, and the lower ends of the keel 2 and the vertical keel 5 of the light steel are all fixed in the ridge 4 by pouring concrete. On the light steel vertical keel 5, rivets are used to fix the full-length wide light steel parallel joint 6 at the top of the skirting, and the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com