Reinforced concrete retaining wall mold and mounting method thereof

An installation method and a technology of concrete retaining walls, which are applied to the joints of formwork/formwork/working frames, artificial islands, underwater structures, etc., can solve the cumbersome and complicated construction process of retaining walls, wasteful reinforcement materials, and retaining walls. The complex installation process of the wall and other problems can be achieved to save steel materials, improve convenience, and facilitate recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Attached to the following Figure 1-5 This application will be described in further detail.

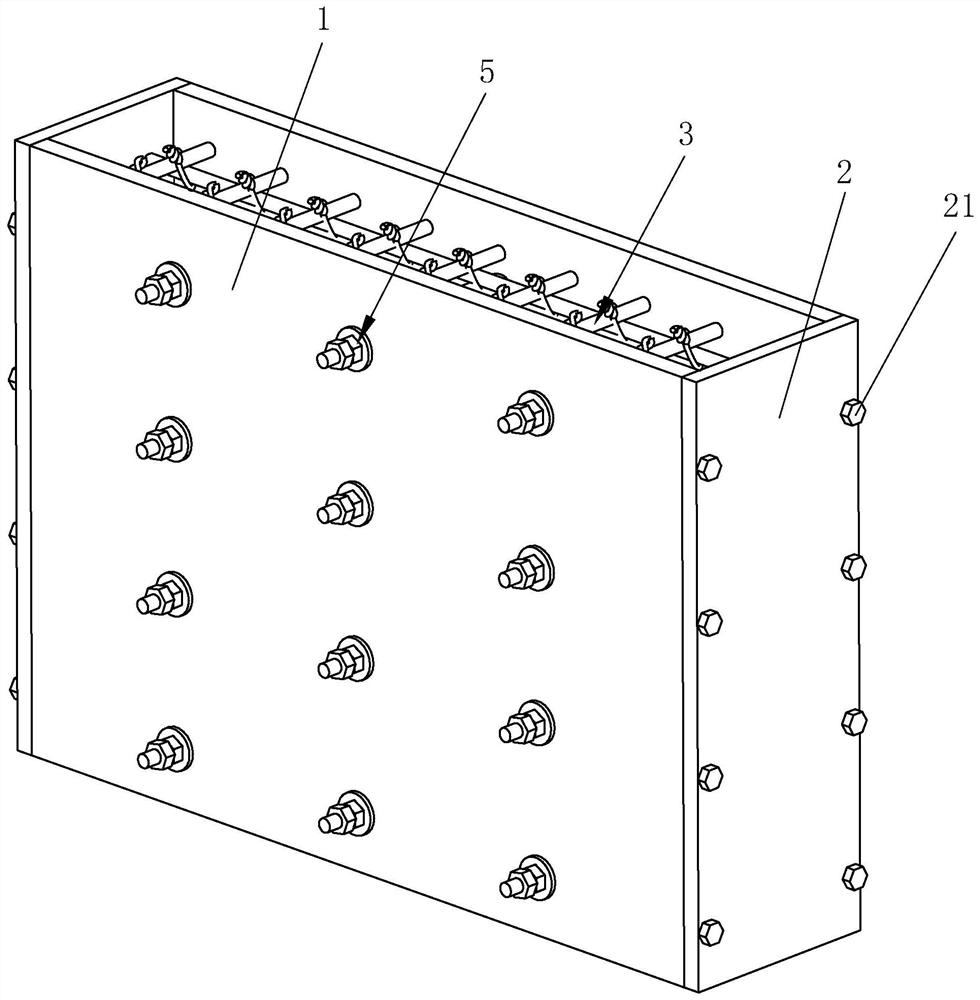

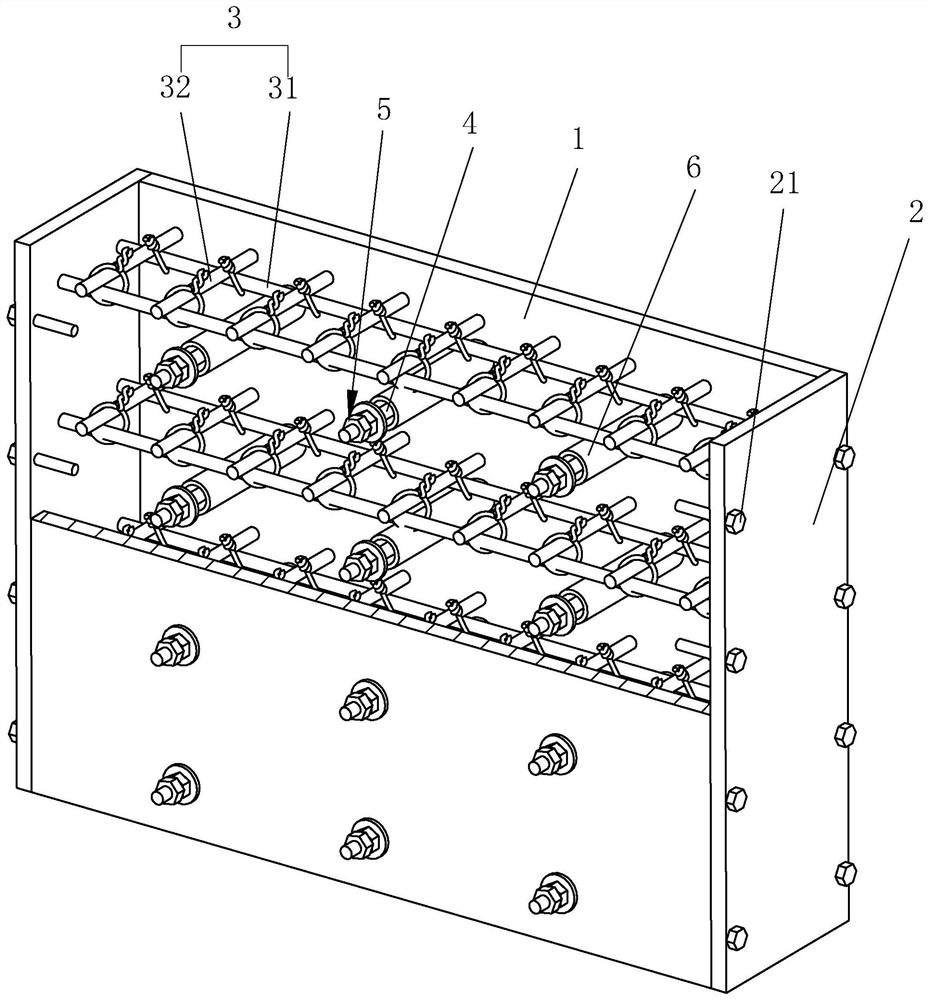

[0054] The embodiment of the present application discloses a reinforced concrete retaining wall mold. refer to figure 1, the mold includes two main formwork 1 and two side formwork 2, the main formwork 1 is arranged vertically, the two main formwork 1 are arranged parallel to each other and spaced apart, and the two side formwork 2 are respectively arranged on both sides of the two main formwork 1, And the two ends of the side formwork 2 are detachably connected with the two main formwork 1 respectively, so that the two main formwork 1 and the two side formwork 2 are spliced together to form a pouring space that is compatible with the retaining wall, and a steel skeleton is provided in the pouring space. 3.

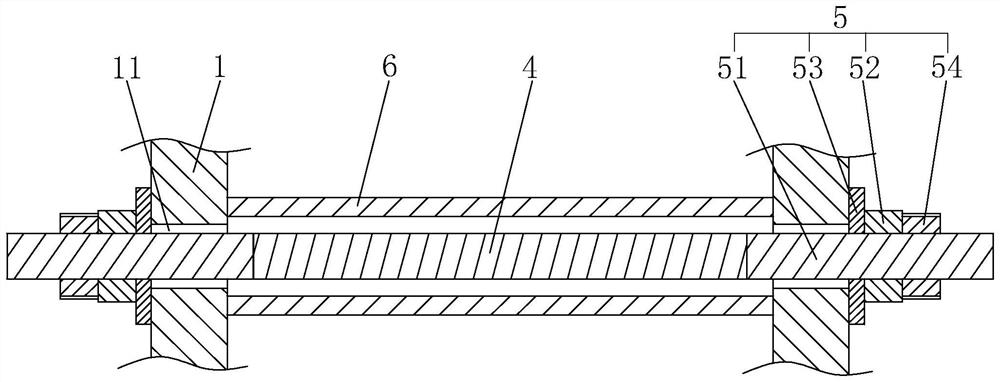

[0055] refer to figure 2 and image 3 , a plurality of connecting rods 4 are arranged between the two main formwork 1, the connecting rod 4 is located between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com