Basement bottom plate structure

A basement floor and slab technology, which is applied to underwater structures, infrastructure engineering, building components, etc., can solve problems such as large amount of reinforcement for foundation beams, and achieve the effects of reducing requirements, optimizing construction technology, and reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

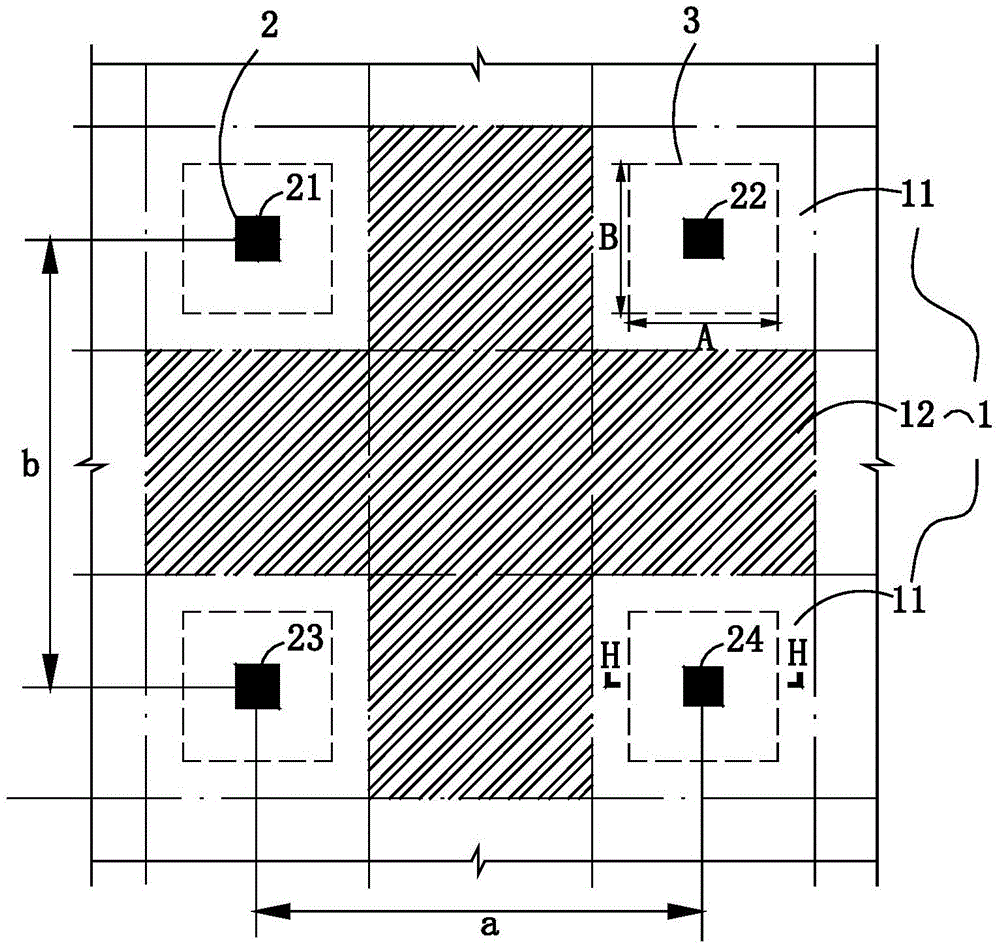

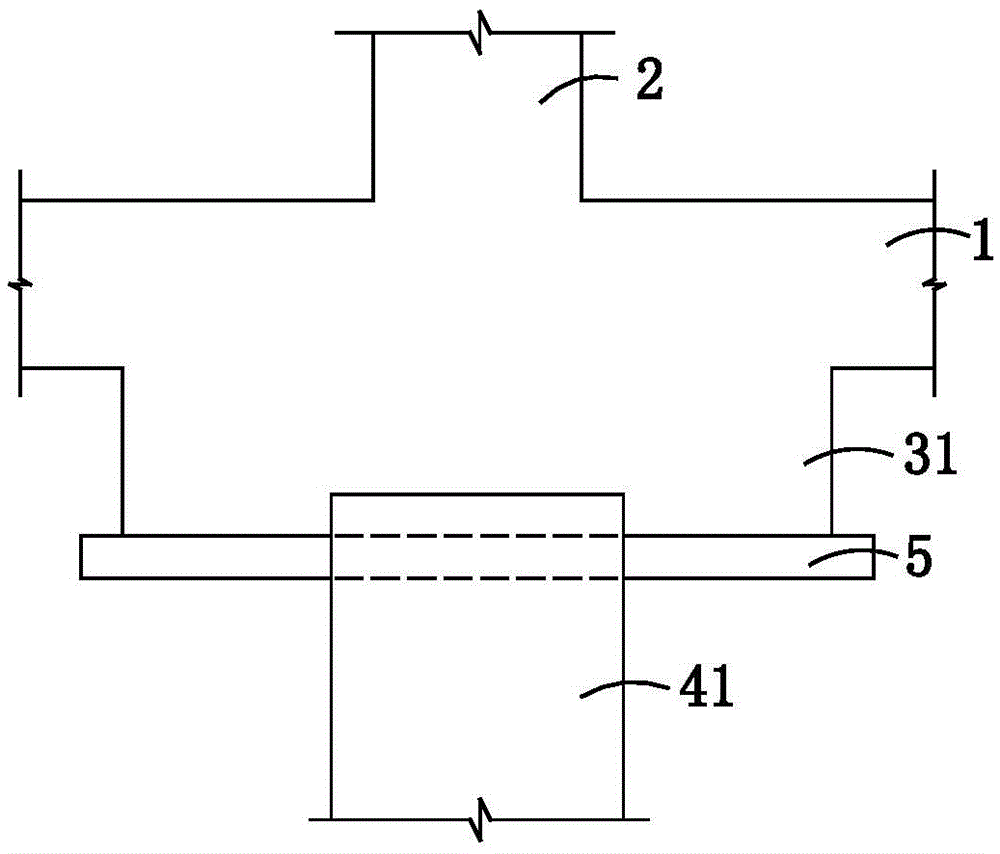

[0044] Such as figure 1 and figure 2 As shown, the basement floor structure of this embodiment includes a flat plate 1 and a support 3 supported below the flat plate 1, and columns 2 perpendicular to the flat plate 1 are respectively arranged on the top of the flat plate 1 at positions corresponding to each support. A support pile 41 is provided below the support. Wherein, the projections of the columns 2 on the plate 1 are distributed in a rectangular array, the horizontal column spacing is a, and the vertical column spacing is b.

[0045] Specifically, the column 2 of this embodiment includes four columns 21, 22, 23, 24, and the projections of the columns 21, 22, 23, 24 on the plate 1 are located at the upper left, upper right, lower left and lower right of the plate 1 respectively. , the four form a rectangular array distribution. Among them, the lateral direction of the projection of two adjacent columns on the plate 1 (ie figure 1 The left and right directions in the...

Embodiment 2

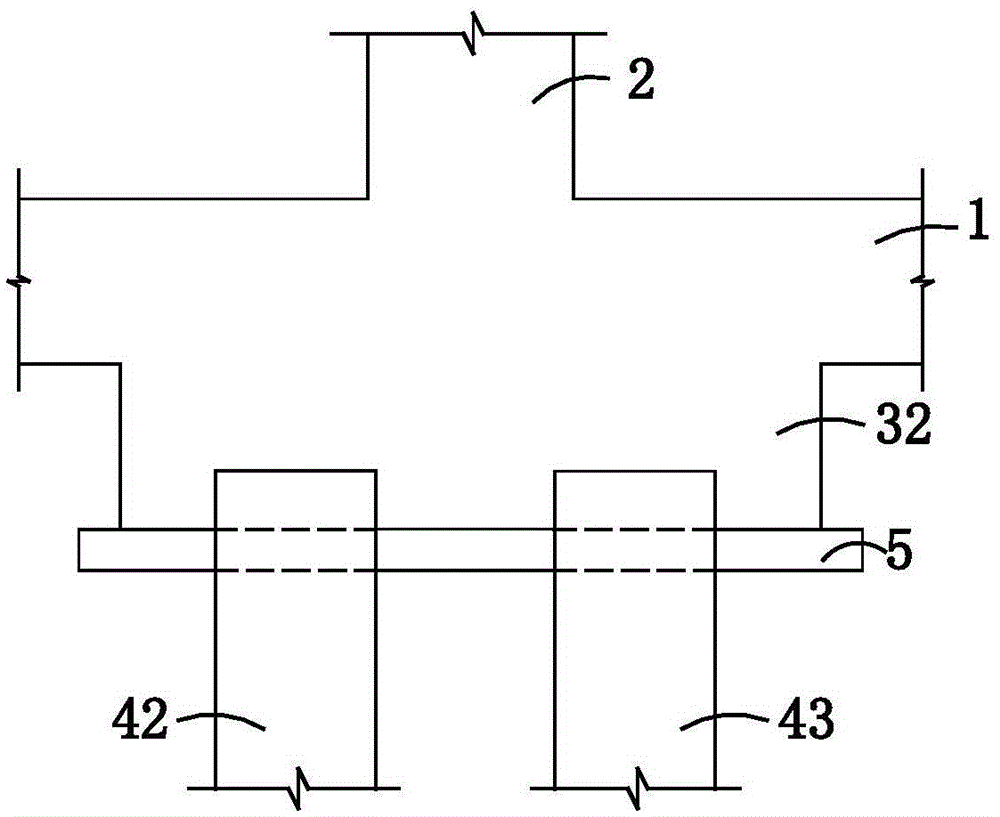

[0052] Such as Figure 5 and Figure 6 As shown, the basement floor structure of this embodiment includes a flat plate 1 and a support 3 supported below the flat plate 1, and columns 2 perpendicular to the flat plate 1 are respectively arranged on the top of the flat plate 1 at positions corresponding to each support. A support pile 41 is provided below the support. Wherein, the projections of the columns 2 on the plate 1 are distributed in a rectangular array, the horizontal column spacing is a, and the vertical column spacing is b.

[0053] Specifically, the column 2 of this embodiment includes four columns 21, 22, 23, 24, and the projections of the columns 21, 22, 23, 24 on the plate 1 are located at the upper left, upper right, lower left and lower right of the plate 1 respectively. , the four form a rectangular array distribution. Among them, the lateral direction of the projection of two adjacent columns on the plate 1 (ie figure 1 The left and right directions in th...

Embodiment 3

[0059] Such as Figure 8 and Figure 9 As shown, the basement floor structure of this embodiment includes a flat plate 1 and a support 3 supported below the flat plate 1, and columns 2 perpendicular to the flat plate 1 are respectively arranged on the top of the flat plate 1 at positions corresponding to each support. Support piles 41 are arranged inside or below the support. Wherein, the projections of the columns 2 on the plate 1 are distributed in a rectangular array, the horizontal column spacing is a, and the vertical column spacing is b.

[0060] Specifically, the column 2 of this embodiment includes four columns 21, 22, 23, 24, and the projections of the columns 21, 22, 23, 24 on the plate 1 are located at the upper left, upper right, lower left and lower right of the plate 1 respectively. , the four form a rectangular array distribution. Among them, the lateral direction of the projection of two adjacent columns on the plate 1 (ie figure 1 The left and right direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com