Precise positioning and fixing device for embedded steel bars in cast-in-place bottom plate of fabricated channel side wall and construction method

A technology of precise positioning and fixing devices, which is applied in water conservancy projects, artificial waterways, and building materials processing, etc. It can solve problems such as large positioning deviation, loose binding, and weak fixation, so as to improve quality and accuracy, solve precise positioning, The effect of saving reinforcement materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

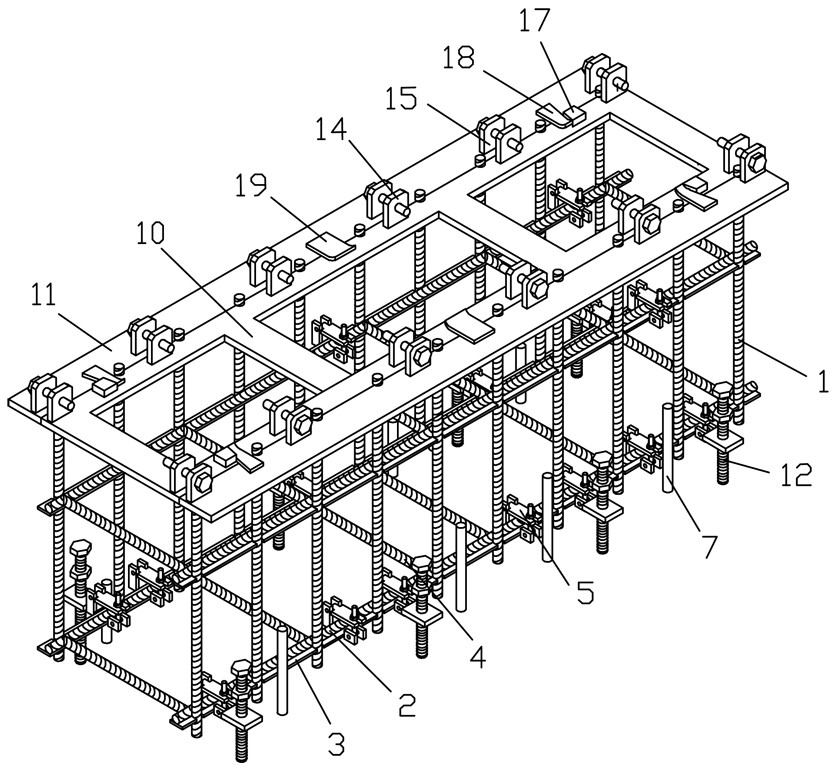

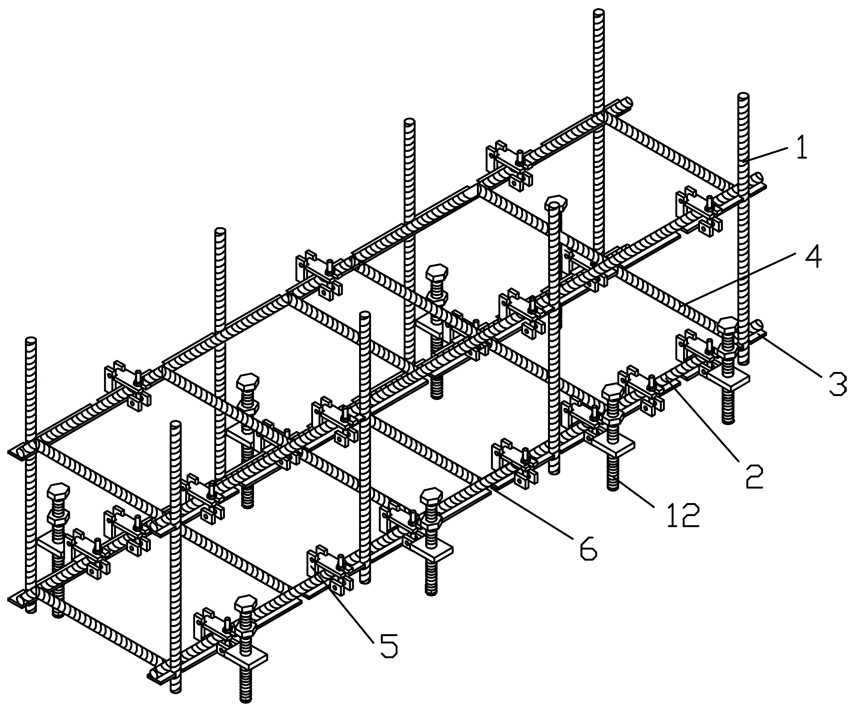

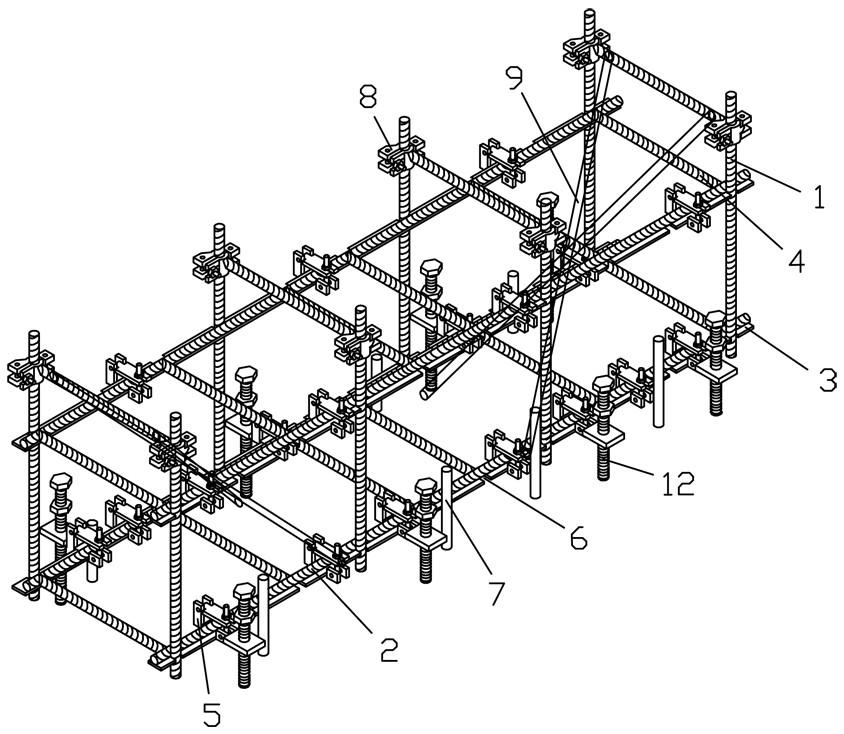

[0065] like Figure 1~Figure 10 As shown, the precision positioning and fixing device for pre-embedded steel bars in the cast-in-place bottom plate of the side wall of the prefabricated trench includes the lower horizontal positioning and fixing frame, the middle level horizontal positioning and fixing frame and the upper level horizontal positioning and fixing verification set that are arranged in sequence from bottom to top Board and eight uprights 1. The vertical rod 1 is used to connect the lower level horizontal positioning fixed frame, the middle level horizontal positioning fixed frame and the upper level horizontal positioning fixed verification cover plate in sequence, and after the connection, a rectangular three-dimensional frame structure device is formed together.

[0066] The precision positioning and fixing device is a rectangular thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com