Hollow shear wall vertical reserved steel bar fixing device and construction method thereof

A technology for reserving steel bars and fixing devices, which is applied in the processing of walls and building materials, construction, etc., can solve the problems of structural system damage, structural strength reduction, low positioning effect, etc., and achieve quality improvement, construction efficiency, and no construction Garbage and Pollution Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

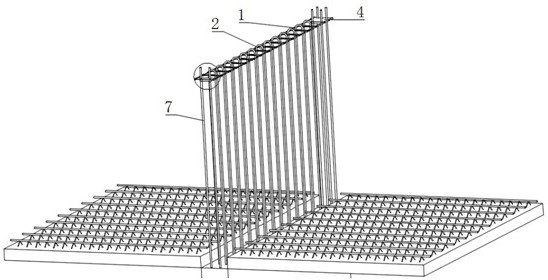

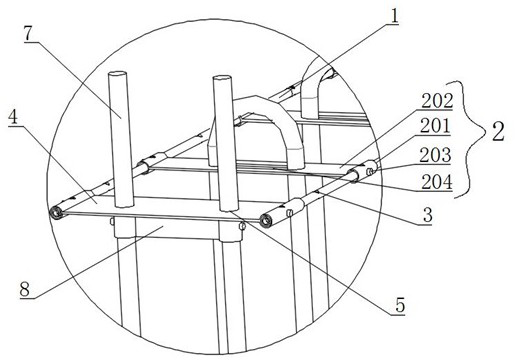

[0036] The present invention will be further described in detail below with reference to the accompanying drawings.

[0037] The embodiment of the invention discloses a fixing device for vertically reserved steel bars for a hollow shear wall and a construction method thereof.

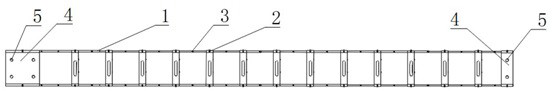

[0038] refer to figure 1 , including two mutually parallel telescopic rods 1 and a plurality of sliding assemblies 2 sliding on the two telescopic rods 1, the upper side of the telescopic rods 1 is evenly provided with scale holes 3, and the two telescopic rods 1 are The distance between adjacent scale holes 3 is 10 cm. The telescopic rod 1 includes a plurality of steel pipes whose diameters are adapted to each other. The rear scale holes 3 of each section of the steel pipe except the steel pipes at the rear end are provided at the rear scale holes 3 There is a steel ball spring 6, and the steel ball spring 6 is used to fix and connect two adjacent sections of the steel pipe in sequence.

[0039] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com