Low-carbon low-shrinkage ultra-high strength concrete and preparation method and application thereof

An ultra-high-strength concrete, low-shrinkage technology, used in manufacturing tools, on-site coagulating pavement, roof insulation materials, etc. Natural resources, the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

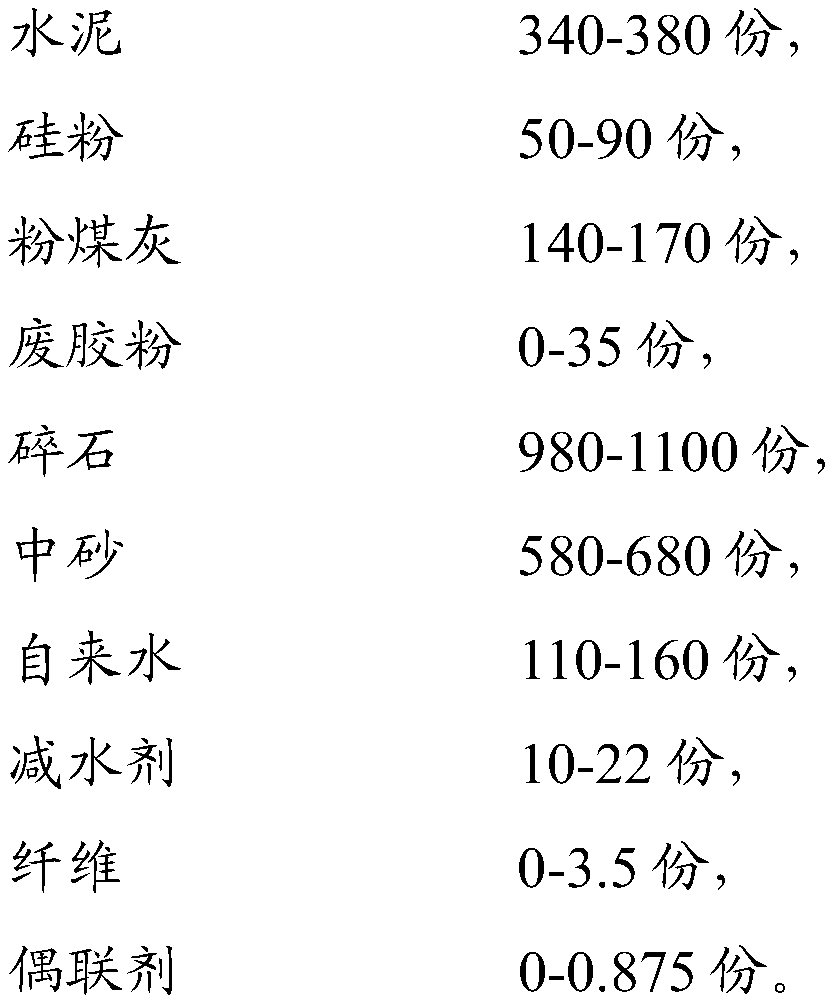

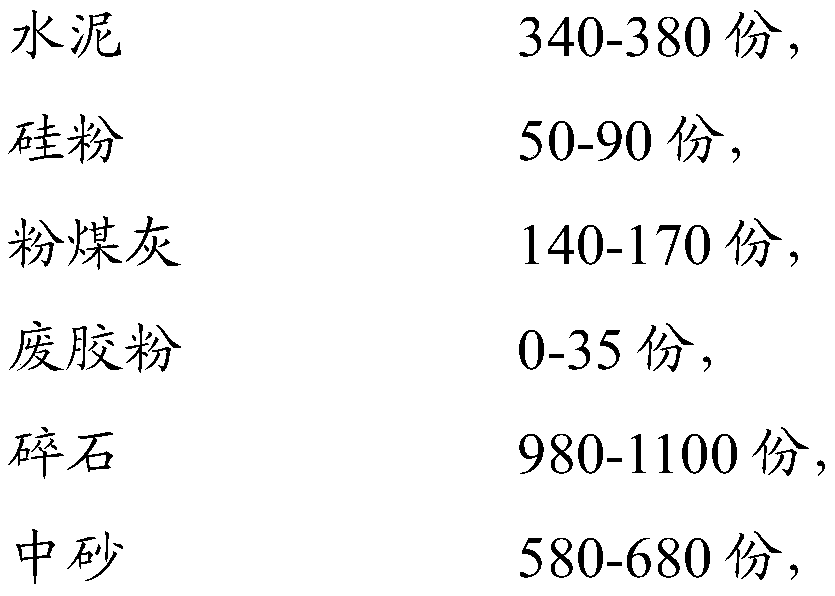

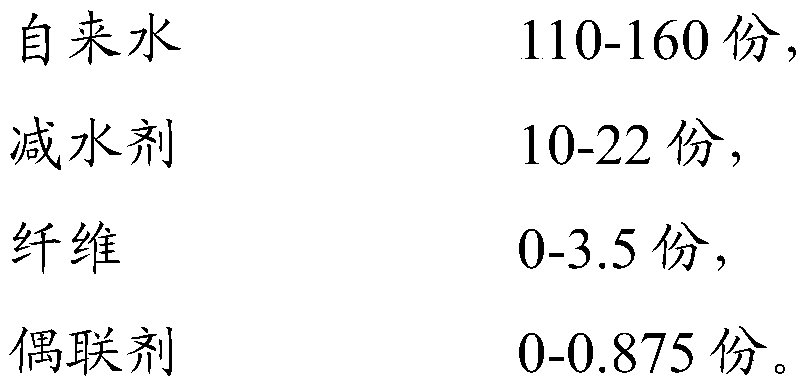

Method used

Image

Examples

Embodiment Construction

[0043] The applicant used 60 sets of specific examples to study the feasibility of the concrete forming process, and tested its compressive strength and split tensile strength. (It is unsuccessful to produce low-carbon, low-shrinkage and ultra-high-strength concrete with a mixing ratio of excessively high waste rubber powder, and it is excluded and not included). Tests have proved that the use of low water-to-binder ratio, low cement consumption, low water consumption per unit volume of concrete mix ratio technology route and conventional molding process, using cheap local raw materials can be used to prepare low-carbon waste rubber powder modification with better deformation properties Super high-strength concrete, its cubic compressive strength reaches 100Mpa, and the cement consumption of unilateral concrete is not higher than 342kg. The ratio of the splitting tensile strength of concrete to the cubic compressive strength is between 1 / 20.36 and 1 / 8.96.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com