Packaged-type composite performance building dismantling-free formwork

A formwork-free, wrapping technology, applied in construction, building components, building structures, etc., can solve the problems of increasing the construction area of the exterior wall, the failure of the adhesive glue, and the long construction period, so as to reduce the construction cost and construction cost. The effect of reducing the use of wood and changing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments will be described below in conjunction with the accompanying drawings, but the embodiments do not constitute a limitation to the present invention.

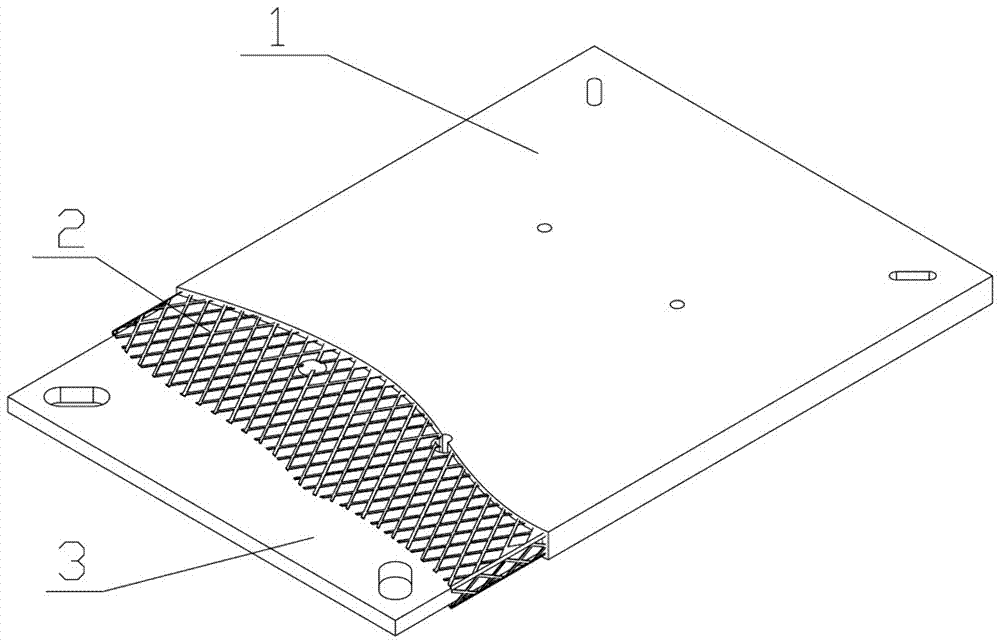

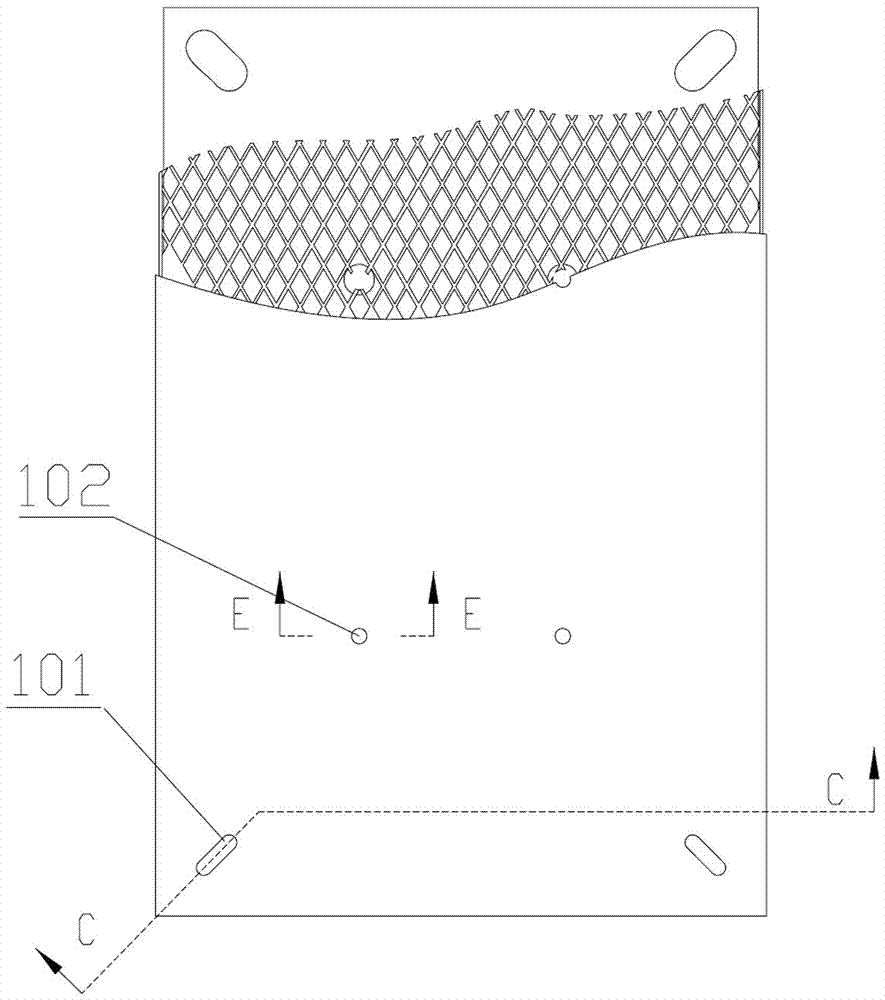

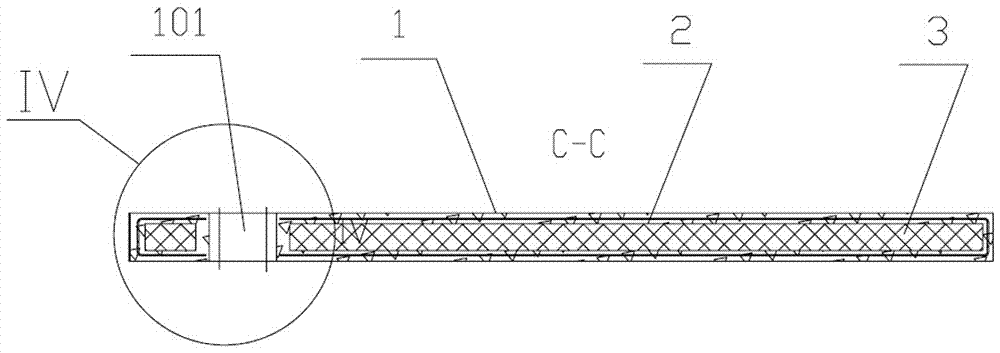

[0024] figure 1 It is the structural diagram of the package-type composite performance building non-dismantling formwork of the present invention. The non-dismantling formwork uses high-performance cement as the base material, and the high-performance cement slurry is poured into the special mold to form a cement formwork after the cement is solidified and formed. , the cement formwork 1 is sealed and wrapped with a sandwich material 3 . In this embodiment, the sandwich material 3 sealed and wrapped by the cement formwork 1 is an extruded polystyrene board, or other heat-insulating materials, so as to make a building formwork with heat-retaining property without dismantling. The cement formwork 1 seals and wraps the sandwich material 3 to isolate it from the air, which conforms to the principle of insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com