Packer

A technology of packer and center pipe, which is applied in the field of packers, can solve problems such as the difficulty of sealing the rubber sleeve, irregular well walls, and rupture of the rubber sleeve, and achieve good sealing effect, convenient operation, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

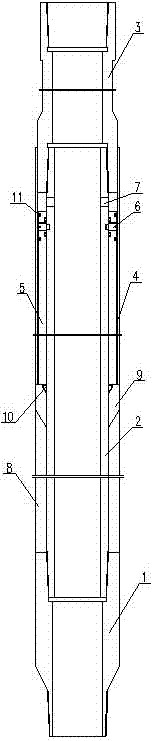

[0012] A packer, comprising a lower joint 1, a central pipe 2 and a lifting joint 3, the lower joint 1 and the lifting joint 3 are respectively sleeved on both ends of the central pipe 2, the lower end of the lifting joint 3 is sleeved with an outer tube 4, the outer tube 4 and the central tube 2 are provided with a piston sleeve 5, the upper end of the piston sleeve 5 is fixedly connected with the outer wall of the central tube 2 through a shear pin 6, and a number of liquid inlet holes 7 are arranged on the side wall of the central tube 2 and are located between the piston sleeve 5 and the outer wall of the central tube 2. Between the lifting joint 3, between the lower joint 1 and the piston sleeve 5, there are sequentially provided a rubber cylinder 8, a slope nipple 9 and a stop ring 10 from bottom to top, and the lower end of the slope nipple 9 is wedged into the inner side of the upper end of the rubber cylinder 8, The anti-retraction ring 10 is wedged into the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com