Backcut changeover cross beam of unitized curtain wall

A technology for unit curtain walls and beams, applied in the field of transfer beams, unit curtain walls and transfer beams at the entrance, can solve the problems of schedule and efficiency limitations, the nodes of cornice decorative panels are difficult to be sealed, and the system is not matched, so as to improve the construction effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

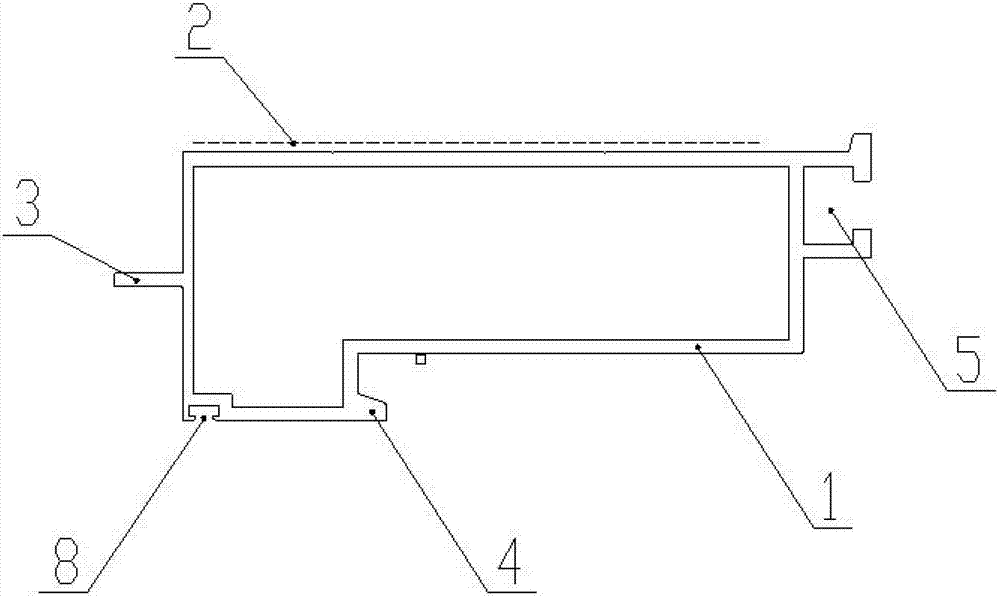

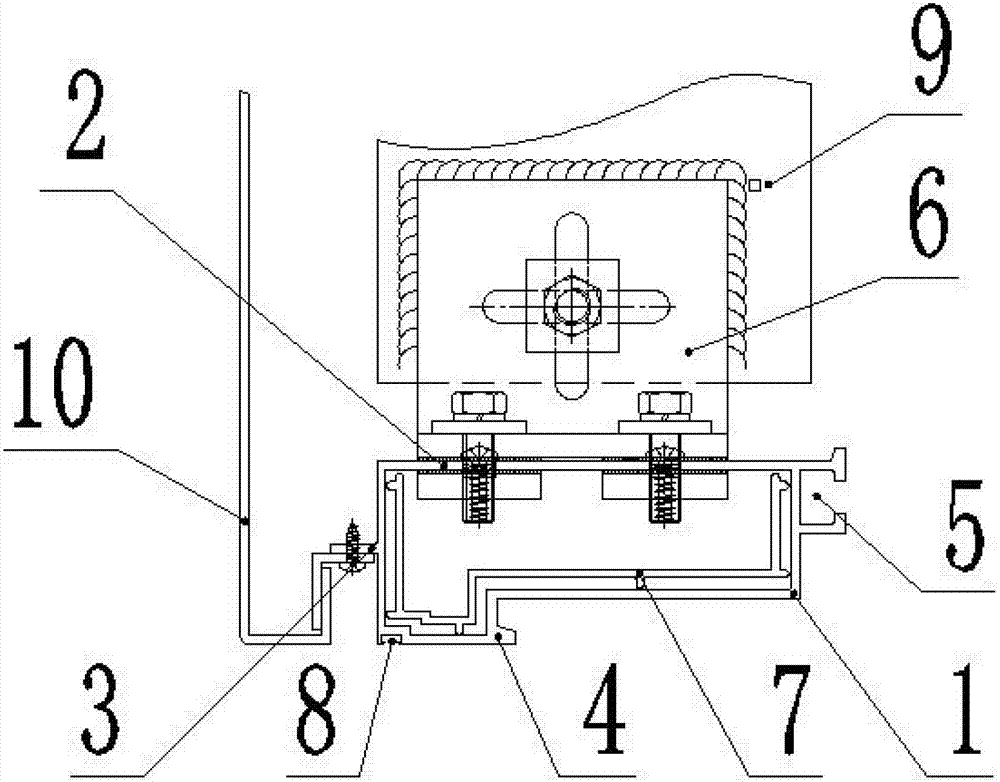

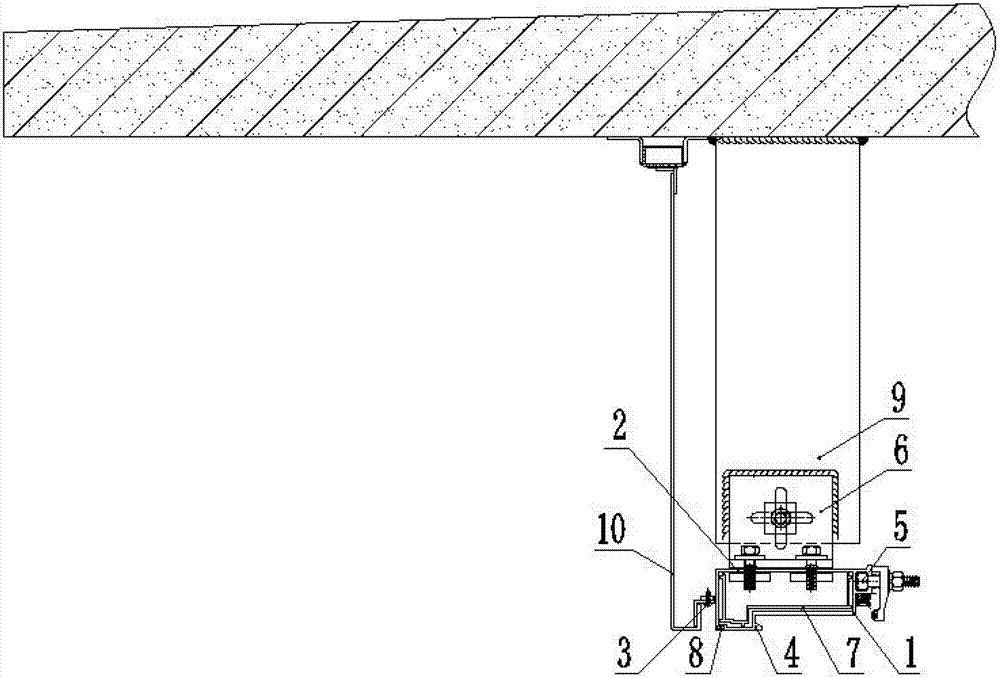

[0013] as attached Figure 1-3 As shown, a unit curtain wall opening transom beam of the present invention includes a beam frame 1, a corner bracket 6, a beam core sleeve 7, a channel steel 9, and an aluminum plate skeleton 10; the beam frame 1 includes a channel steel connection surface 2, The aluminum plate frame connection part 3, the transfer beam hook 4, the pressure plate assembly groove 5, and the glue strip groove 8; the channel steel connection surface 2 is the upper surface of the beam frame 1; the aluminum plate frame connection part 3 is arranged on the beam frame 1 on the middle position of the side near the left part; the beam frame 1 is installed and fixed under the channel steel 9 through the corner code 6; the corner code 6 is a right-angle corner code, and the vertical part of the corner code 6 is screwed The assembly is fixed on the channel steel 9, and the horizontal part is fixed on the channel steel connection surface 2 through the screw assembly. The rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com