Ultra-large container ship hatch coaming and torsion box integrated construction method

A construction method and hatch coaming technology, applied to ships and other directions, can solve the problems of steel plate thickness, long segmented construction period, unbalanced production load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0041] Such as Figure 1 to Figure 8 As shown, a kind of ultra-large container ship hatch enclosure and torsion box integrated construction method of the present invention comprises the following steps:

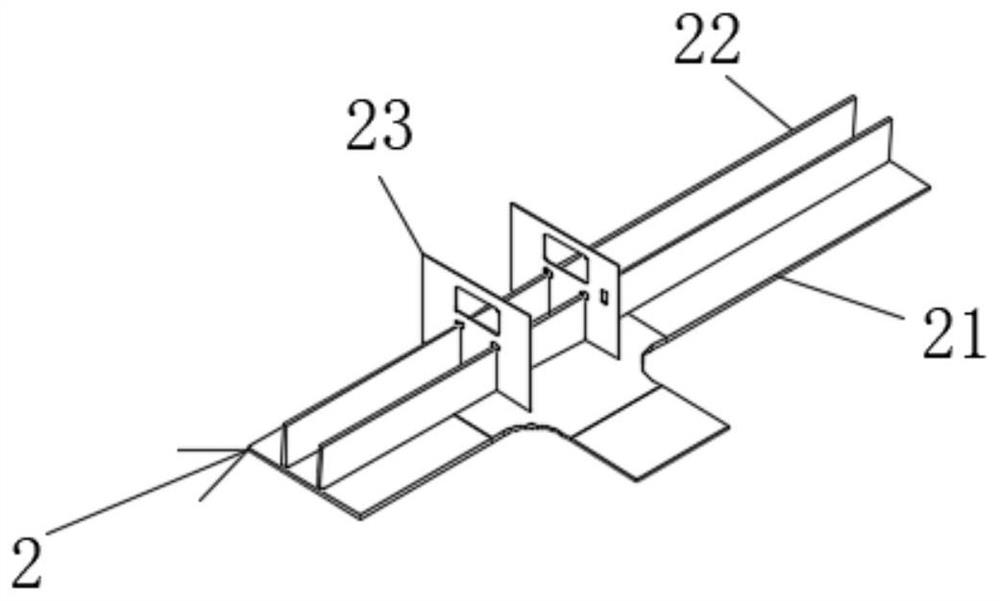

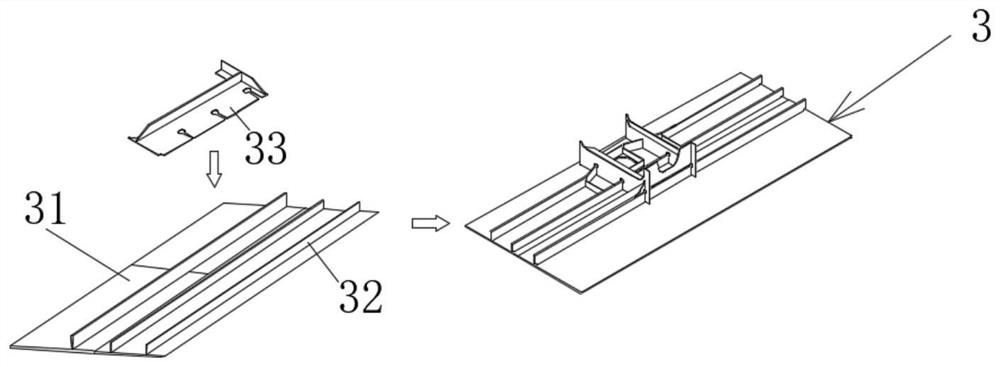

[0042] S1: Build hatch coaming assembly 1, deck assembly 2, inner shell assembly 3 and outer shell assembly 4 respectively;

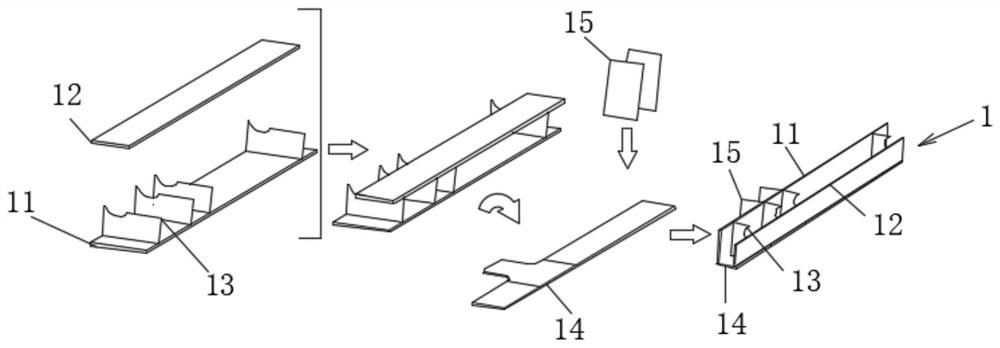

[0043] The process of constructing the hatch coaming assembly 1 is as follows:

[0044] Step 1: Place the hatch coaming web 11 horizontally on the ground, weld multiple first hatch coaming ribs 13 vertically to the hatch coaming web 11, and then lift the hatch coaming side vertical plate 12 by magnetic force Horizontally placed on the first rib 13 of the hatch coaming and welded; this step forms the first assembly of the hatch coaming;

[0045] Step 2: place the hatch coaming top plate 14 horizontally on the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com