Novel sinking and driving engineering freezing drill pipe

A drill pipe and engineering technology, which is applied in the field of frozen drill pipe in new-type shaft engineering, can solve problems such as difficulty in ensuring safety of shaft structure, long construction period, and large drilling deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

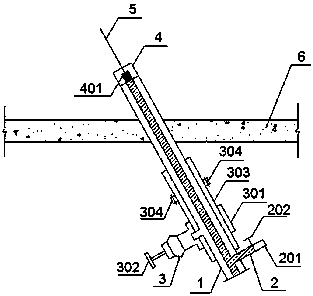

[0017] Such as figure 1 As shown, a new type of freezing drill pipe in roadway engineering includes a water supply pipe 2 and a freezing pipe 1. The water in the water supply pipe 2 is controlled by a water supply nozzle 201 and a water supply pipe gate valve 202. The end of the freezing pipe 1 is set Drill bit 4, the drill bit 4 is composed of high-strength drill core 401 and drill pipe 5, the frozen tube 1 is covered with the outer tube 301 of the check gate valve, and is connected by the fixing bolt 304 of the outer tube, and the inner tube of the check gate valve is clamped 303 is connected with the non-return gate valve 3, and the non-return gate valve 3 is connected with the non-return gate valve switch 302, and the opening of the non-return device is controlled by the non-return gate valve switch 302, and the drill bit 4 passes through the concrete formation 6 of the shaft.

[0018] The above embodiments are not limited to the protection scope of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com