Transparent building template

A building formwork and transparent technology, applied in construction, building structure, formwork/formwork components, etc., can solve problems such as concrete quality defects, improve the visual quality and physical quality, realize mechanized operations, and save engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

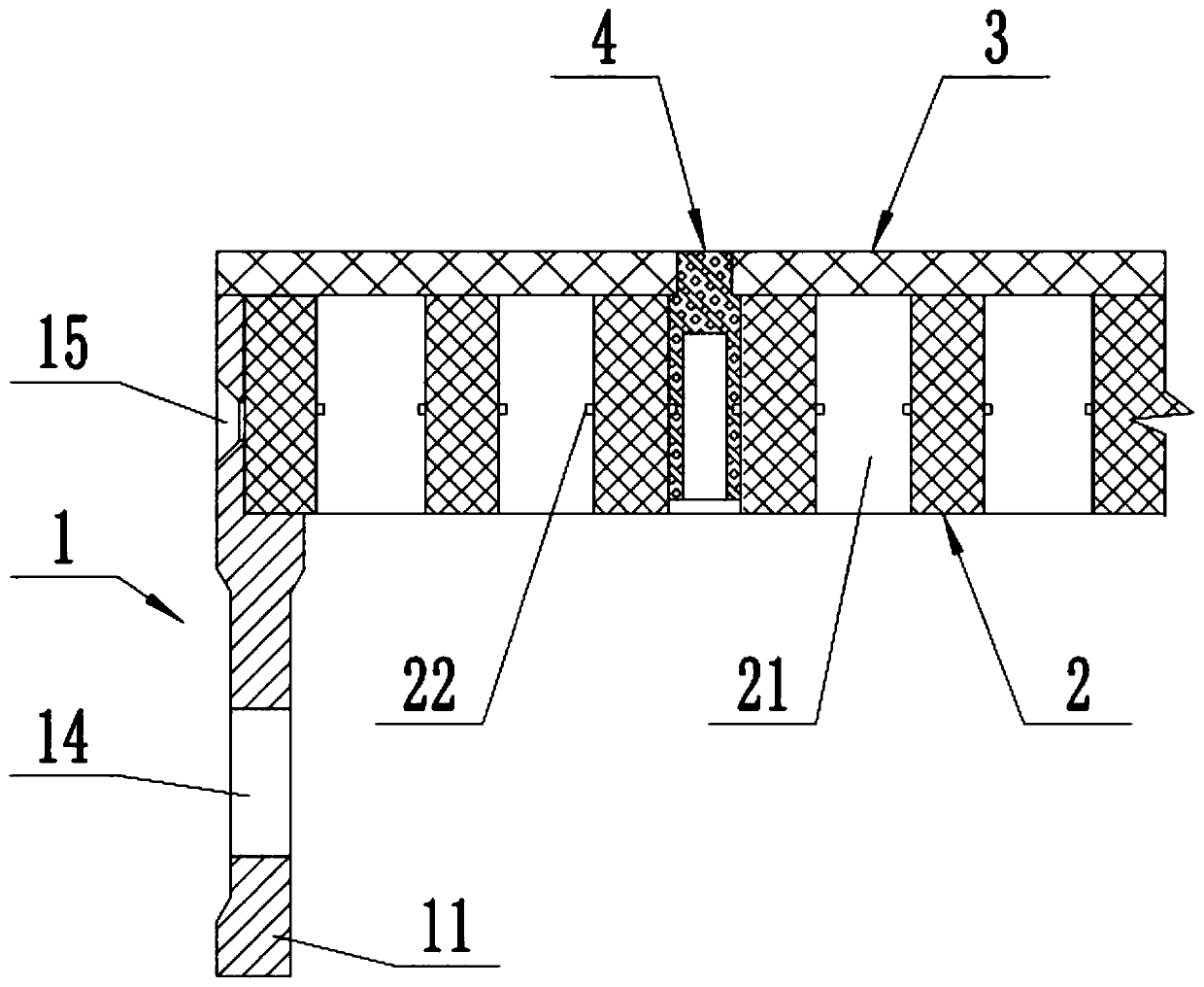

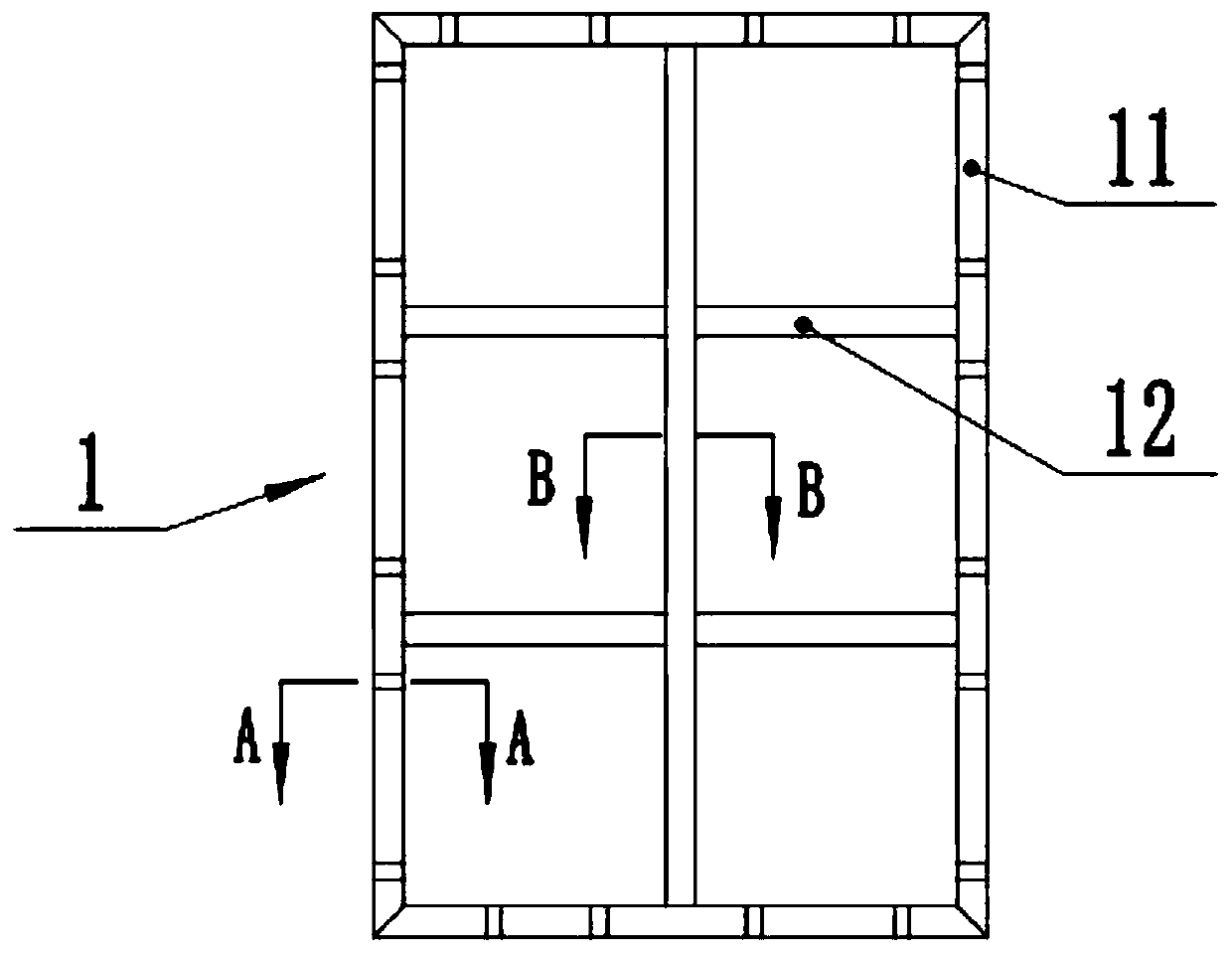

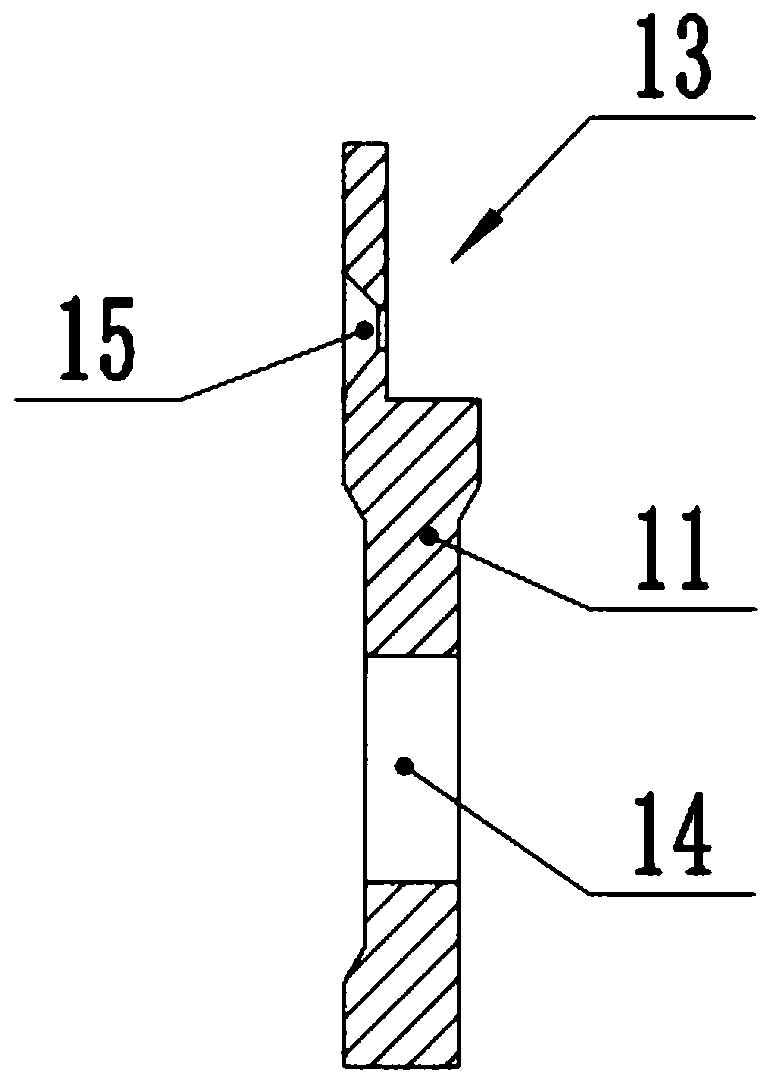

[0041] Such as Figure 1-7 As shown, Embodiment 1 provides a transparent building template, which includes a template structure layer and a film layer 3, wherein the template structure layer includes a skeleton 1 and a panel 2. Wherein, the template structure layer is a stressed structure, and the film layer 3 is a protective layer.

[0042] The thickness of the panel 2 is greater than that of the film layer 3 . The thickness of the panel 2 is 15 mm, and the thickness of the film layer 3 is 3 mm. Both the panel 2 and the film layer 3 are transparent plastic boards, such as PC boards, PS boards or PMMA boards, preferably polycarbonate boards (PC boards). Polycarbonate, referred to as PC, is an amorphous, odorless, odorless Toxic, highly transparent thermoplastic engineering plastics. Has excellent physical and mechanical properties. In particular, impact resistance, tensile strength, bending strength, and compressive strength are high. Good heat resistance, low temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com