Concrete structure wall column corner wood formwork reinforcing method

A technology for reinforcement of concrete structures and formwork, applied in formwork/formwork/work frame, building structure, on-site preparation of building components, etc. Ensure construction quality, save later costs, and improve the effect of visual quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

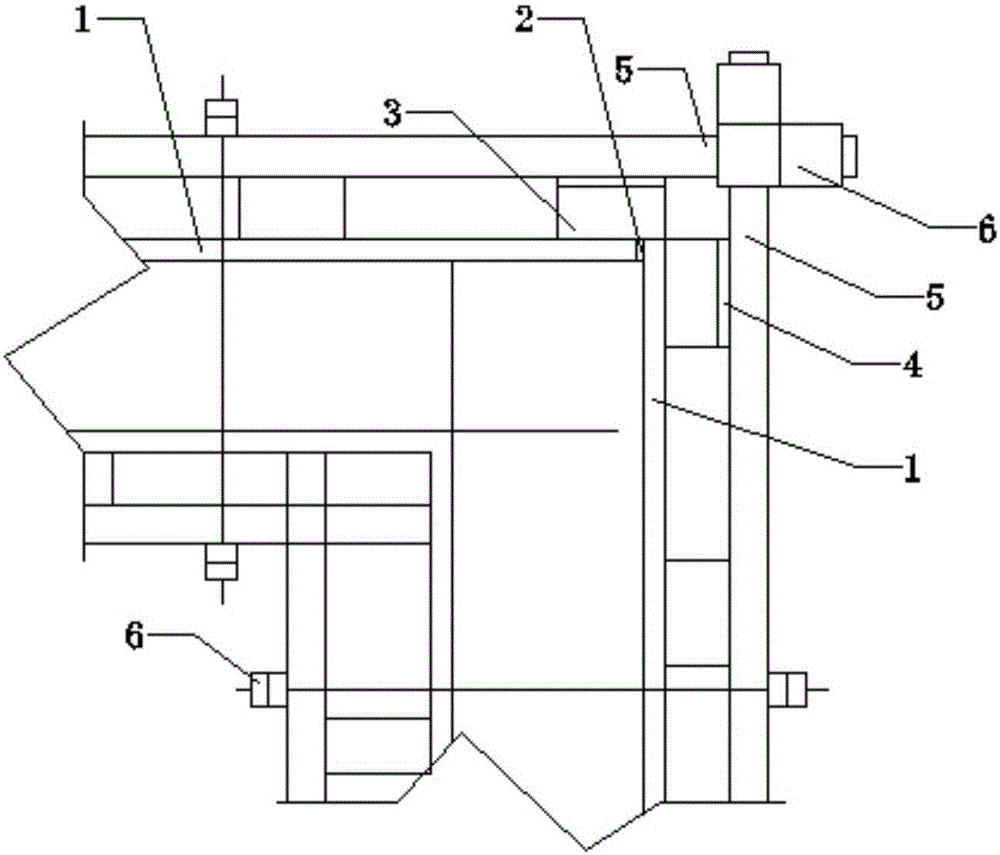

[0016] Such as figure 1 As shown, the present invention provides a concrete structure wall column angle wood formwork reinforcement method, comprising a template panel 1, double-sided adhesive tape 2, square wood 3, iron plate 4, reinforced double steel pipe 5 and double fittings 6, the reinforced double steel pipe 5 is provided with a double fitting 6 at one end, and the two reinforced double steel pipes 5 are connected to each other at the end provided with the double fitting 6. The inner side of the reinforced double steel pipe 5 is connected to the iron plate 4 and the square wood 3, and the square wood 3 is connected to the template When the panel is installed in the concrete structure wall column corner wood formwork, the double-sided adhesive 2 is used for bonding at the joint of the formwork panel 1, and the square wood 3 with a length of 2000 mm and a length of 50×100 is used to connect the joints. The joints are fully covered and uninterrupted along the floor height....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com