Underwater construction method of steel tube

A construction method and technology for steel pipes, which are applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of underwater construction of steel pipes, long construction period and high risks, and save water transportation costs and construction costs. The effect of low cost and high construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

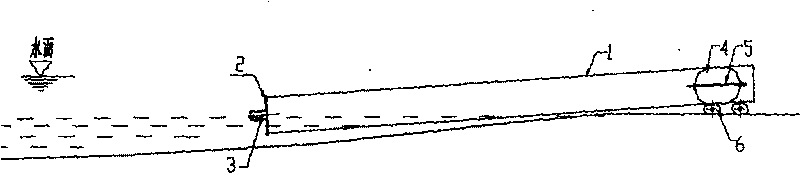

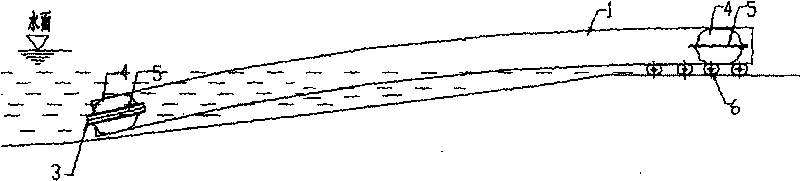

[0036] Example 1, such as figure 1 As shown, the construction method of the sewage pipe in water. Steel pipe 1 diameter is 2m, and total length is 1000m, and original design is that steel pipe 1 is divided into 20 joints, now changes construction by technical scheme of the present invention, method is as follows:

[0037] 1. The front end of the first steel pipe 1 is blocked with a blind plate 2, and the diameter of the inlet and outlet 3 is 200 mm on the blind plate 2, and a remote control valve is installed;

[0038] 2. Let the front section of the first steel pipe 1 enter the water, and the rear section is assembled and welded with other steel pipes on the shore;

[0039] 3. When launching into the water, block the mouth of the steel pipe 1 on the shore with an oval-shaped sealing air bag 4. The total length of the air bag 4 is 3m, its nominal diameter is 2m, and its aspect ratio is 1.5. , the perimeter of the airbag 4 is 5m, which is 80% of the inner perimeter of the ste...

Embodiment 2

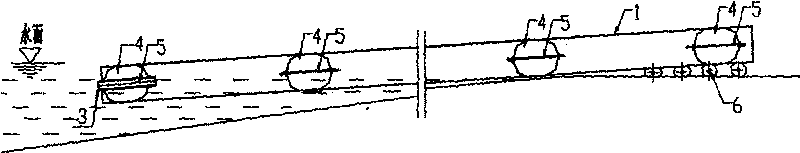

[0046] Example 2, such as image 3 As shown, the water intake steel pipe water construction method. The diameter of the steel pipe is 2.5m, and the total length is 4000m. The construction steps of the technical solution of the present invention are as follows:

[0047] 1. The front end of the first section of steel pipe 1 is blocked with a plugging air bag 4. The plugging air bag 4 has a piercing tube 5 with a diameter of 375mm. The inlet and outlet 3 on the piercing tube 5 are installed with remote Control the valve, if there is no emergency, the blocking air bag 4 at the front end generally cannot be exhausted;

[0048] 2. Let the front section of the first steel pipe 1 enter the water, and the rear section is assembled and welded with other steel pipes on the shore;

[0049] 3. When launching into the water, block the mouth of the steel pipe 1 on the shore with a sealing air bag 4;

[0050] The total length of the airbag 4 is 7.5m, with hemispherical heads at both ends, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com