Method for installing pipelines assisted by air bags

A pipeline and airbag technology, which is applied in the field of airbag-assisted installation of pipelines, can solve problems such as construction difficulties, underwater construction of pipelines, and long construction period, and achieve low construction risks and construction costs, easy floating or sinking operations, and saving water transportation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

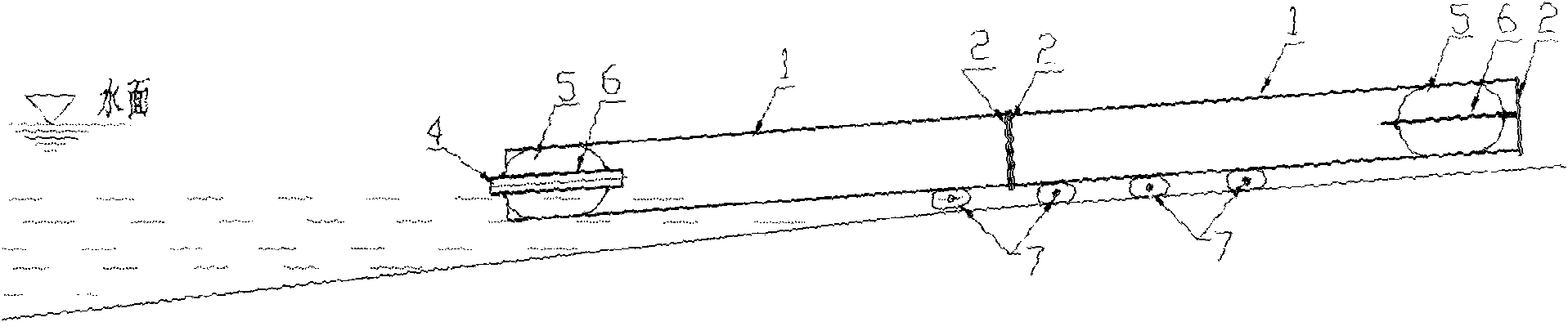

[0031] Example 1, such as figure 1 As shown, the water intake steel pipe water construction method. The diameter of steel pipe 1 is 2m, and total length is 1000m, is divided into 20 sections, adopts flange, bolt connection, construction scheme of the present invention:

[0032] 1. The front end of the first section of steel pipe 1 is blocked with a plugging air bag 5. The plugging air bag 5 has a piercing tube 6. Remote control valves are installed on the inlet and outlet ports 4 of the piercing tube 6. The plugging air bag at the front end 5 There is no emergency, generally can not exhaust;

[0033] 2. Let the front section of the first steel pipe 1 enter the water, and the rear section is assembled and connected with other steel pipes 1 on the shore;

[0034] 3. When launching into the water, seal the nozzle of the steel pipe 1 on the shore with a sealing air bag 5 and inflate it to 0.5 MPa;

[0035] 4. Inflate the steel pipe by blocking the piercing pipe 6 of the air bag...

Embodiment 2

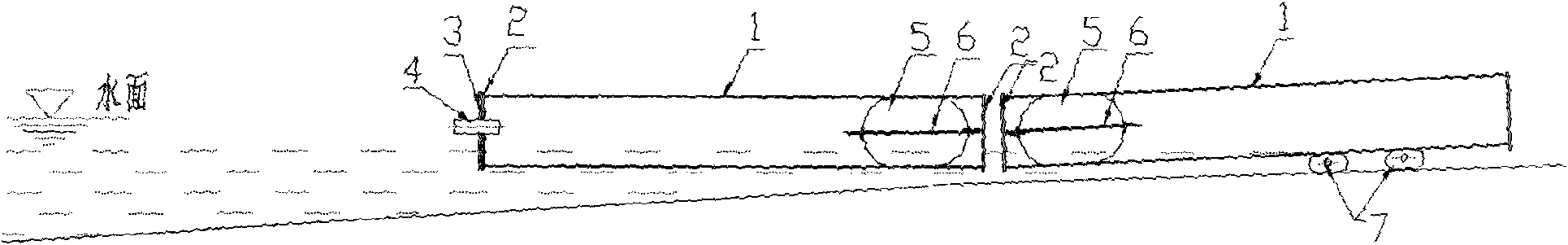

[0040] Example 2, such as figure 2 As shown, the construction method of the drainage steel pipe in water. The diameter of the steel pipe is 1.8m, the total length is 2000m, and it is divided into 40 sections, which are connected by Haval. The construction scheme of the present invention:

[0041] 1. The flange 2 at the front end of the first steel pipe 1 is blocked with a blind plate 3, and the inlet and outlet ports 4 are arranged on the blind plate 3, and a remote control valve is installed, and the rear end of the steel pipe 1 is blocked with a The air bag 5 is blocked, and the blocked air bag 5 has a through-core pipe 6 that can be inflated into the steel pipe 1, so that the first section of the steel pipe 1 enters the water and floats on the water surface;

[0042] 2. The water inlet end of the steel pipe 1 to be connected is blocked with a plugging air bag 5, so that the steel pipe 1 enters the water longitudinally, and the steel pipe 1 on the bank is supported by two ...

Embodiment 3

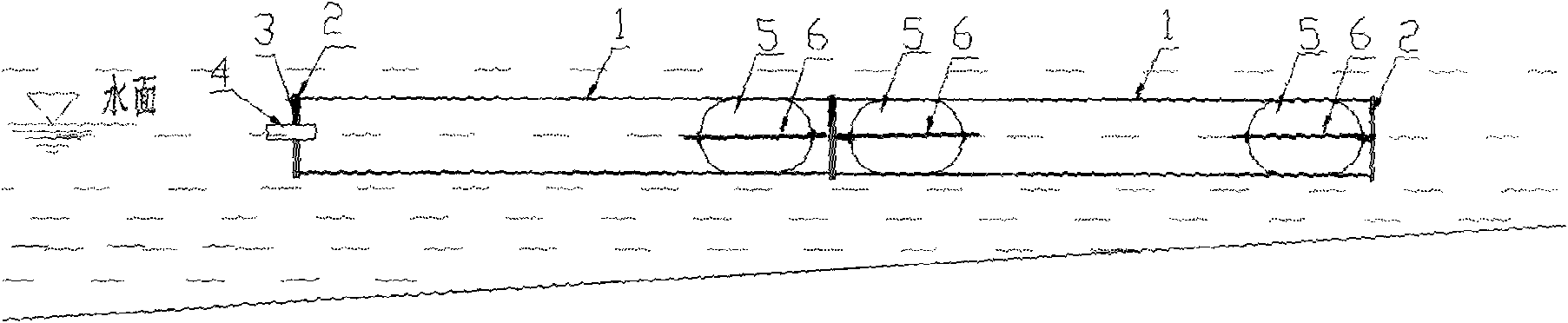

[0049] Example 3, such as image 3 Shown, cast iron blowdown pipeline diameter is 3m, and total length is 4000m, and every joint length 20m, construction scheme of the present invention:

[0050] 1. The flange 2 at the front end of the first section of the pipeline 1 is blocked with a blind plate 3, and an inlet and outlet 4 are provided on the blind plate 3, and a remote control valve is installed;

[0051] 2. Both ends of the other pipelines 1 to be connected are blocked with the sealing air bag 5, so that the pipeline 1 rolls horizontally and launches into the water;

[0052] 3. The pipeline 1 is connected in a floating state, the construction personnel can operate on the pipeline and the ship, and the pipeline 1 can be turned over with the help of the ship in the water;

[0053] 4. When the pipe 1 is connected and needs to sink, open the valves of the inlet and outlet 4, and the pipe can be exhausted through the through-pipe 6, and the water will enter the pipe 1, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com