Fabricated building and construction method thereof

A construction method and prefabricated technology, which can be used in infrastructure engineering, building components, building insulation materials, etc., can solve the problems of cumbersome procedures and slow progress, and achieve the effect of reducing overall weight, facilitating construction operations, and increasing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with specific embodiments.

[0061] In the present invention, when in use, the side close to the indoor space is defined as the inner side, and the side farther away from the indoor space is defined as the outer side, the distance between the inner and outer sides is defined as the thickness, and the laterally extending two end walls define the side walls.

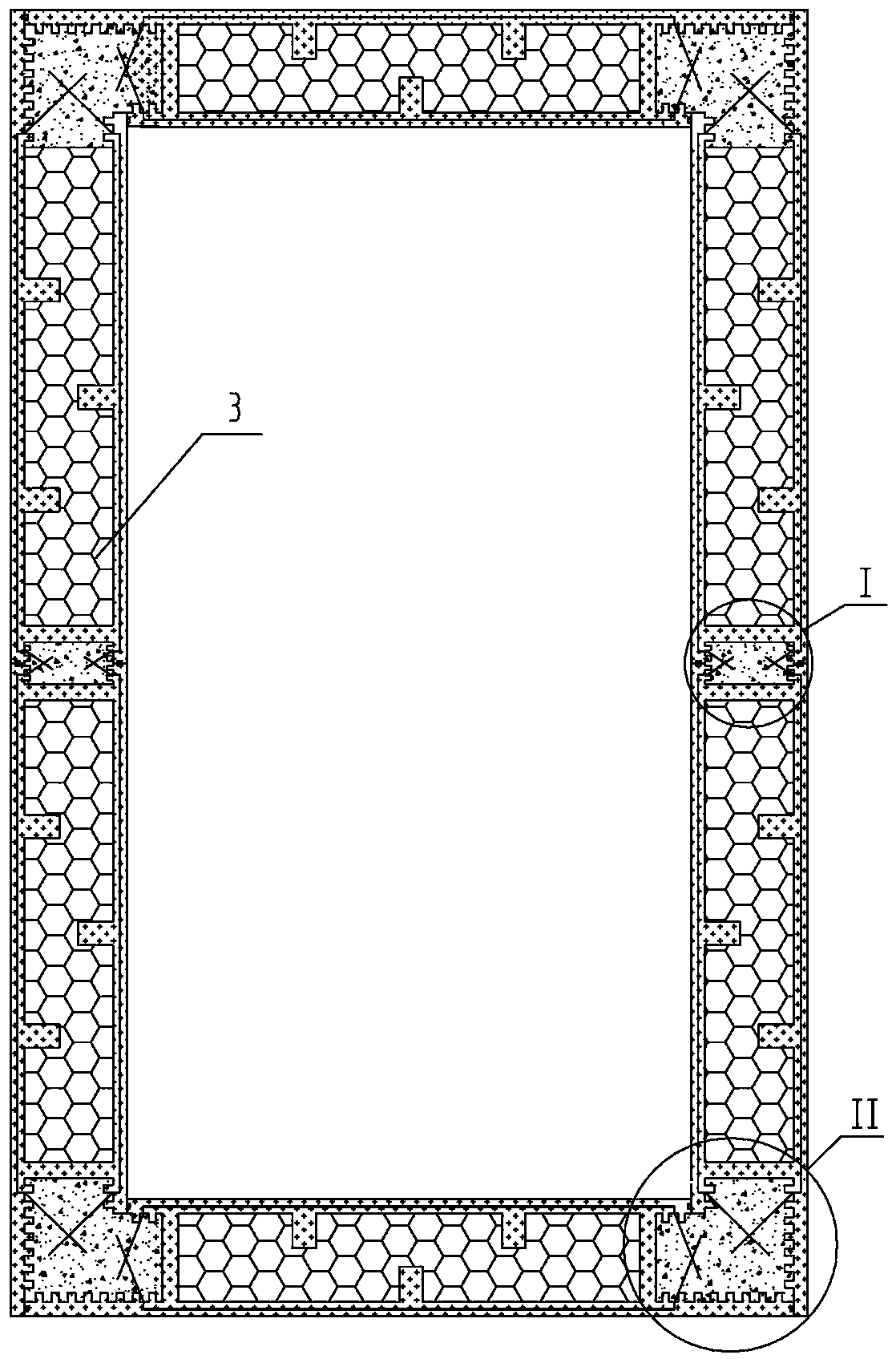

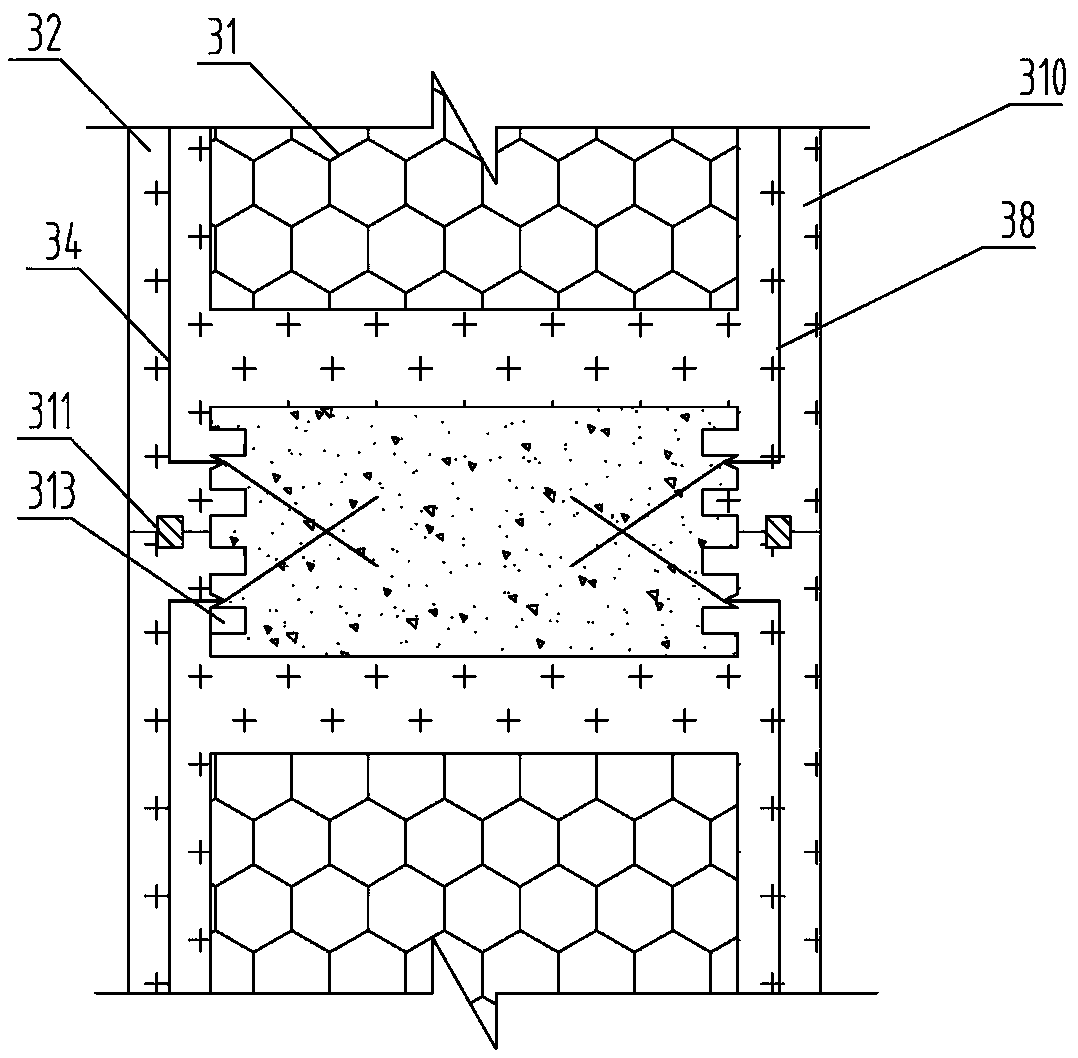

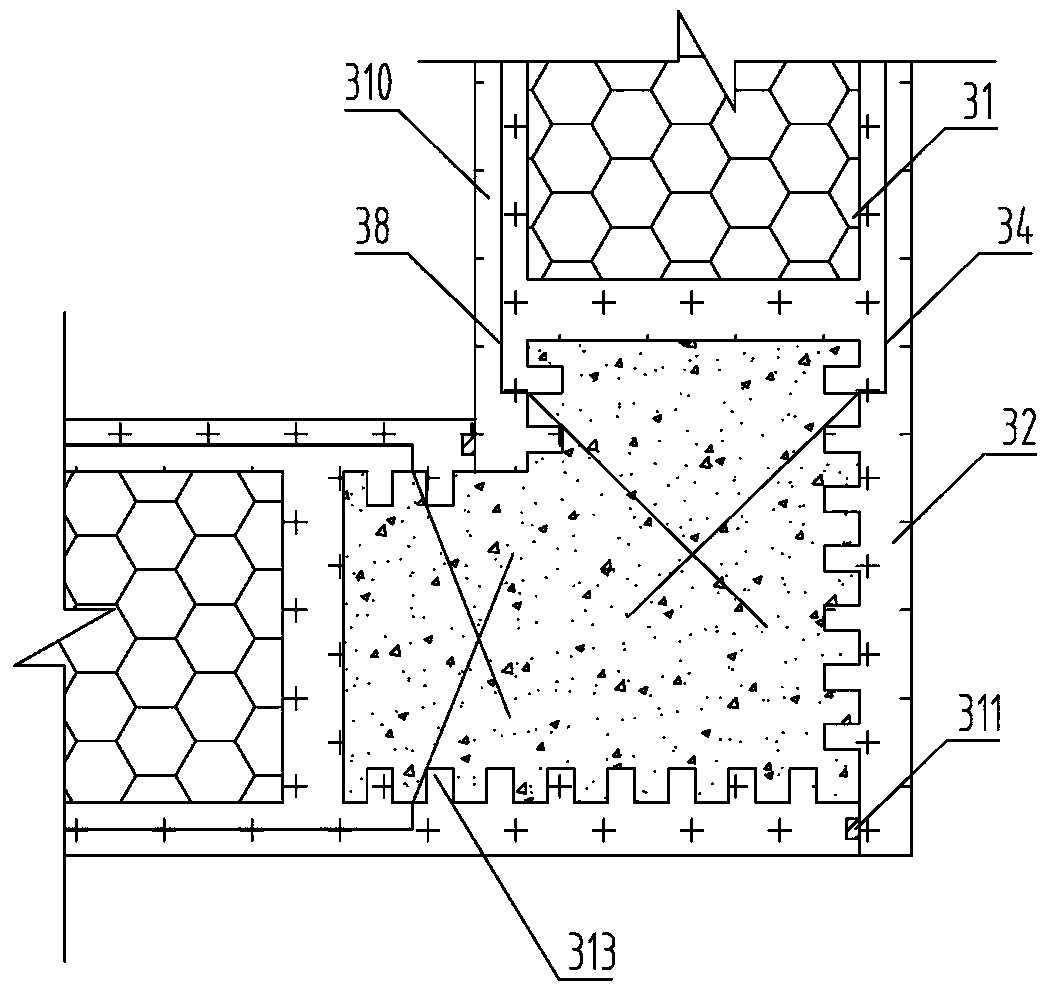

[0062] Such as Figure 7 As shown, the present invention has a ground groove 2 on the top wall of the basic body 1, the cross section of the ground groove 2 is a trapezoid with a large upper part and a smaller lower part, and the size of the bottom wall of the trapezoid is slightly larger than or just equal to the thickness of the wallboard 3 , so that the size of the bottom wall of the trapezoid adapts to the thickness of the wallboard 3 . A wall is installed in the trough 2, such as figure 1 , figure 2 and image 3 As shown, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com