Non-welded flat plate fixed embedded piece and fixing method thereof

An embedded, non-welding technology, applied in water conservancy projects, artificial islands, infrastructure projects, etc., can solve problems such as polluting the environment and human harmful gases, saving investment, improving construction quality, and changing construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

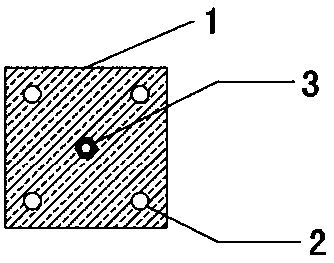

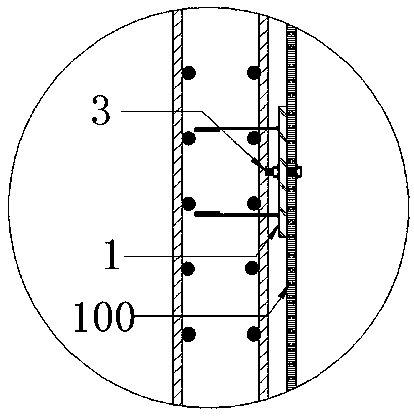

[0030] see Figure 1-4 As shown, a non-welded plate fixed embedded part includes a main body 1 of the plate embedded part.

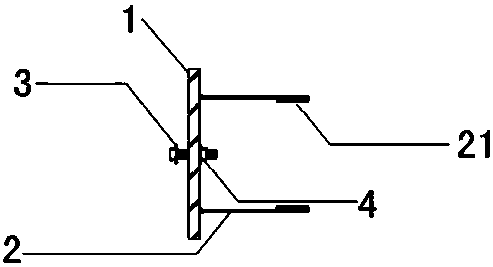

[0031] Specifically, the four ends of the same side of the main body of the plate embedded part 1 are vertically provided with steel bars 2 of equal length, and the ends of the steel bars 2 are provided with superimposed reinforcing sections 21 .

[0032] The middle part of the main body 1 of the plate embedded part is also provided with a fixing through hole, and the fixing bolt 3 passes through the fixing through hole and fits with the nut 4 to form a fixing structure, which is used for fixing with the formwork and the bracket.

[0033] Specifically, the nut is arranged on the inner side of the main body of the plate embedded part, and the fixing bolt is arranged on the other side. The two are combined to fix the main body of the plate embedded part 1 on the inner side of the formwork, and, after being fixed with the formwork, the fixing screw 3 The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com