Omni-directional mobile wall-climbing robot for ship

A wall-climbing robot and omnidirectional moving technology, applied in the field of wall-climbing robots, can solve the problems of difficulty in crossing hull welds or small structural parts, inflexible movement, powerlessness, etc., so as to reduce invalid load, avoid falling, and increase friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

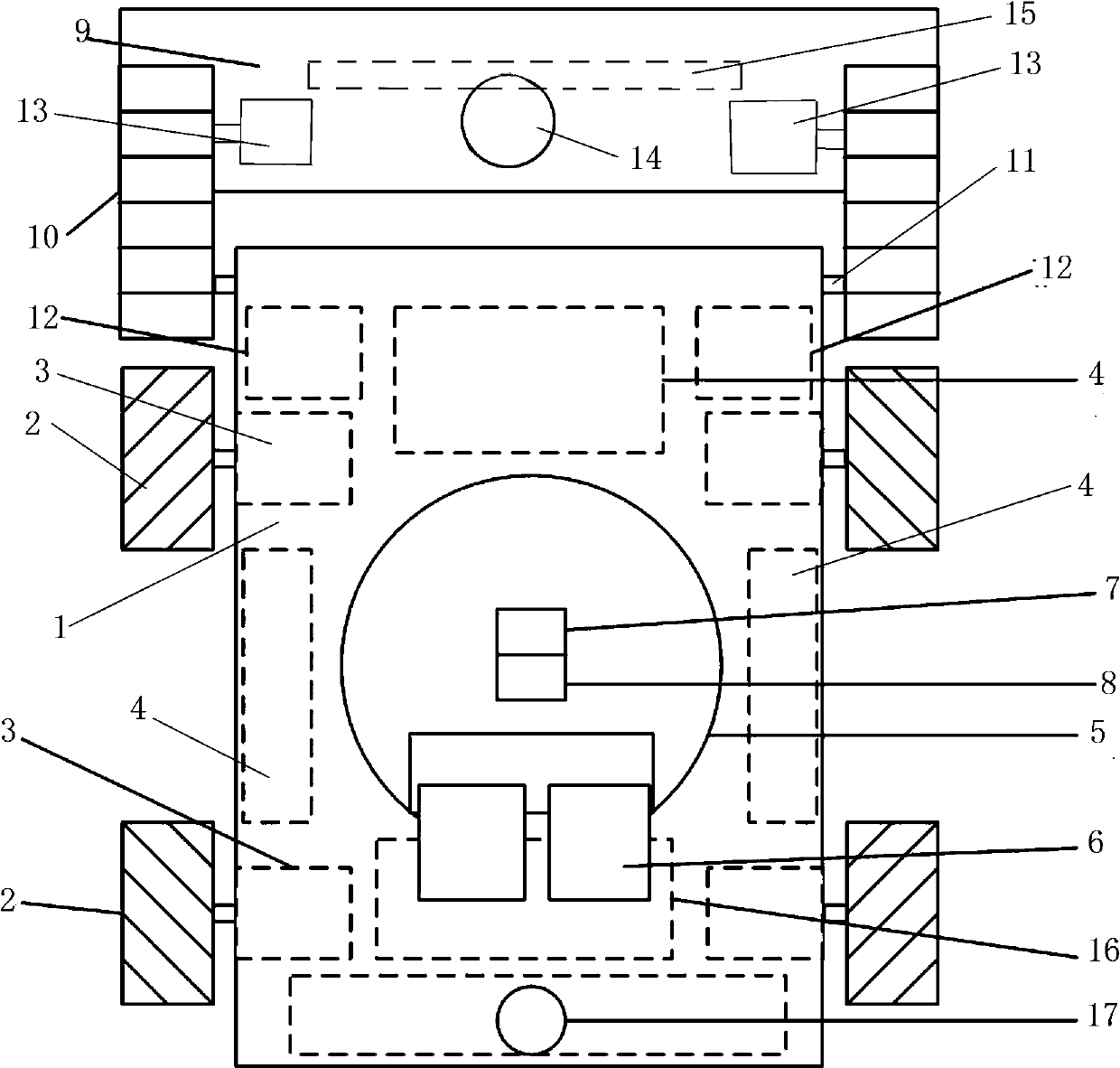

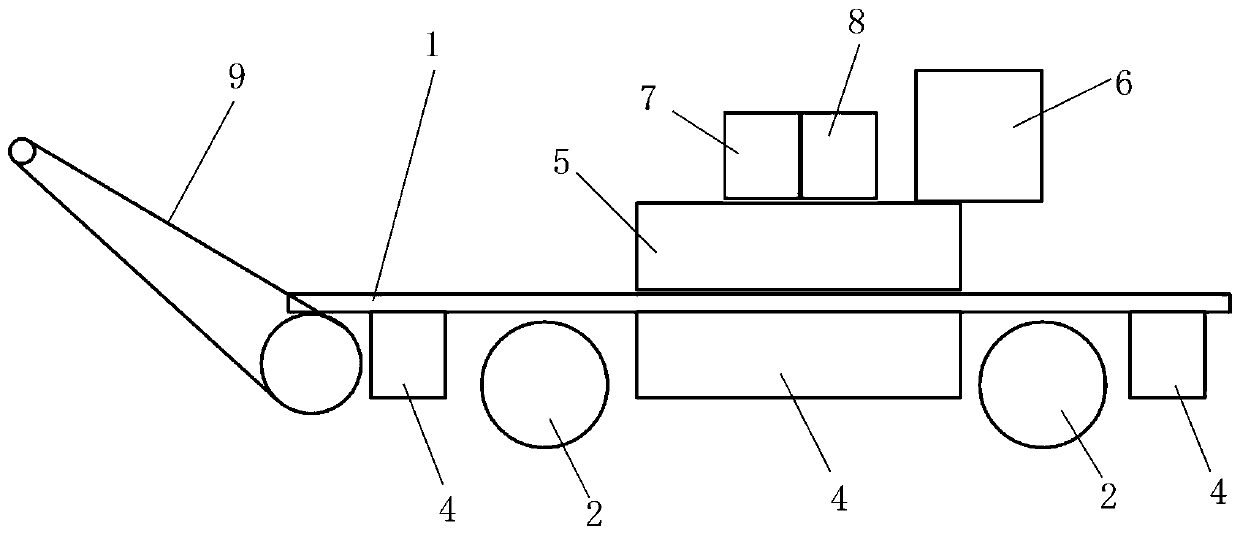

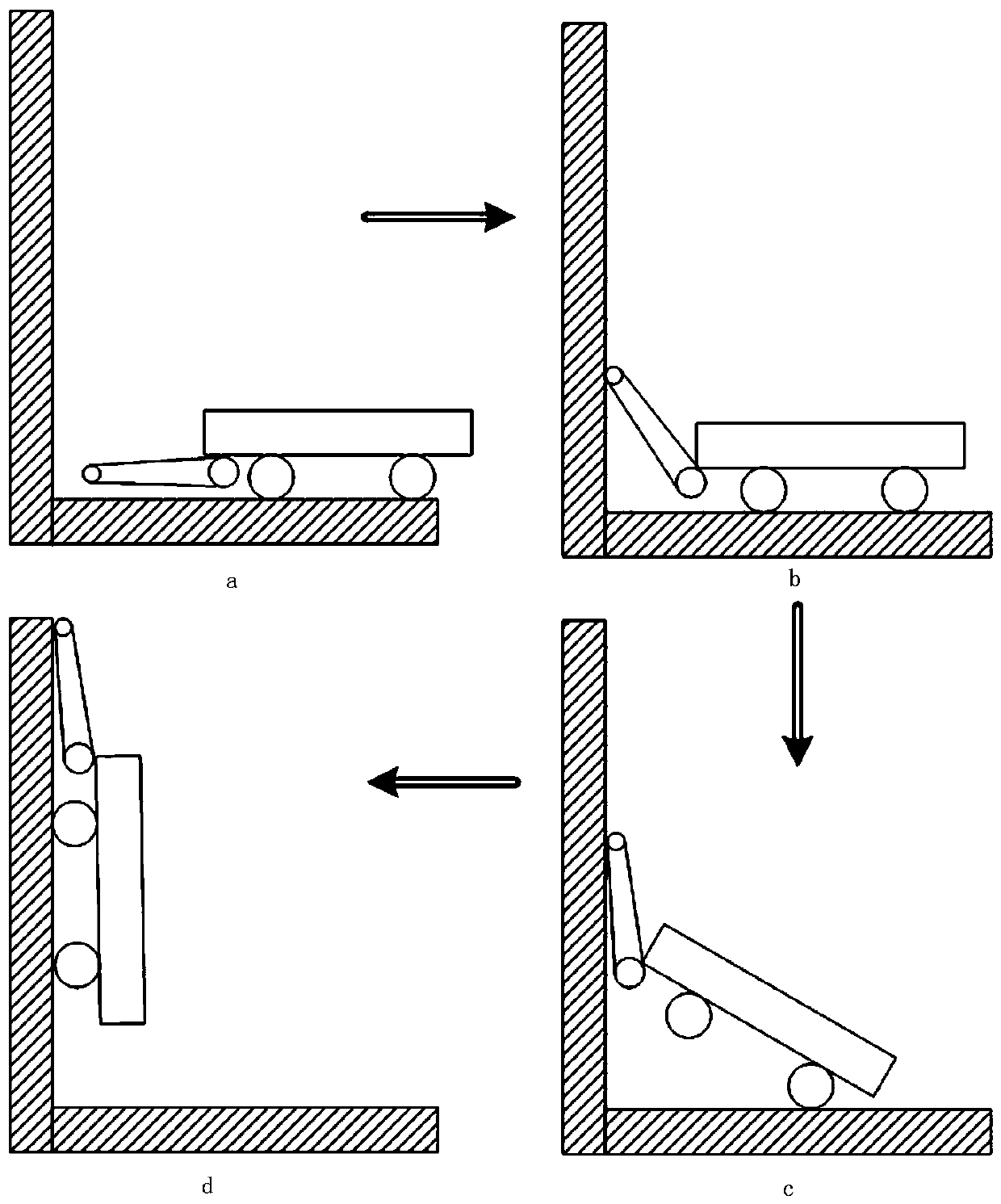

[0049] Such as figure 1 and figure 2 As shown, the top view and the left side view of the omnidirectional mobile wall-climbing robot for ships of the present invention are provided respectively. Platform 5, ducted propeller 6, laser radar 7, camera 8, forearm auxiliary mechanism 9, negative pressure pump 14, emergency power supply 16 and cable interface 17, frame 1 plays a role of fixing and supporting, and is used to form the wall climbing robot The chassis and the four corners of the vehicle frame 1 are provided with wheels 2, and each wheel 2 is driven by a separate wheel motor 3. In this way, the wheel motor 3 can control the rotation speed and steering of the wheels 2, and the robot can be controlled in the corresponding direction. Omnidirectional movement (forward, backward and turning) on the wall. A permanent magnet 4 is fixed around the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com