Half-through bowstring arch bridge with vehicle and light rail on same layer and construction method thereof

A technology for tied arch bridges and light rails, applied in the field of new mid-support tied arch bridges, can solve the problems of high cost of cross engineering, difficult traffic organization, long approach bridges, etc. Stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

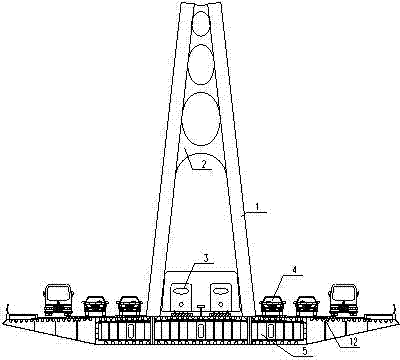

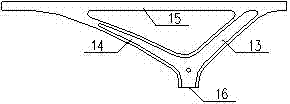

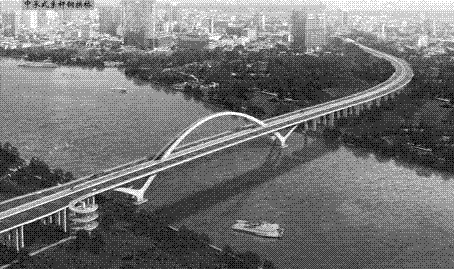

[0025] For each stressed member of the arch bridge such as Figure 1~3 , the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] On the bridge deck 12 on the same floor, the light rail load 3 is arranged between the two main arches 1, and the vehicle load 4 is arranged on the outside of the two main ribs 1. Iron on the same layer" method.

[0027] The bridge deck system 12 bears the load of the light rail, and transmits it to the main arch 1 through the suspender 6. The two main arches 1 lean against each other, and a number of cross braces with elliptical openings are set between them, forming a typical "basket arch" shape. Since the main arch 1 is in the Under the action of load, a horizontal thrust is generated, and the influence of the horizontal force on the arch foot foundation 9 is eliminated through the tie rod 7 .

[0028] The triangular rigid frame 8 is composed of front obliqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com