Patents

Literature

39results about How to "Solve the stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

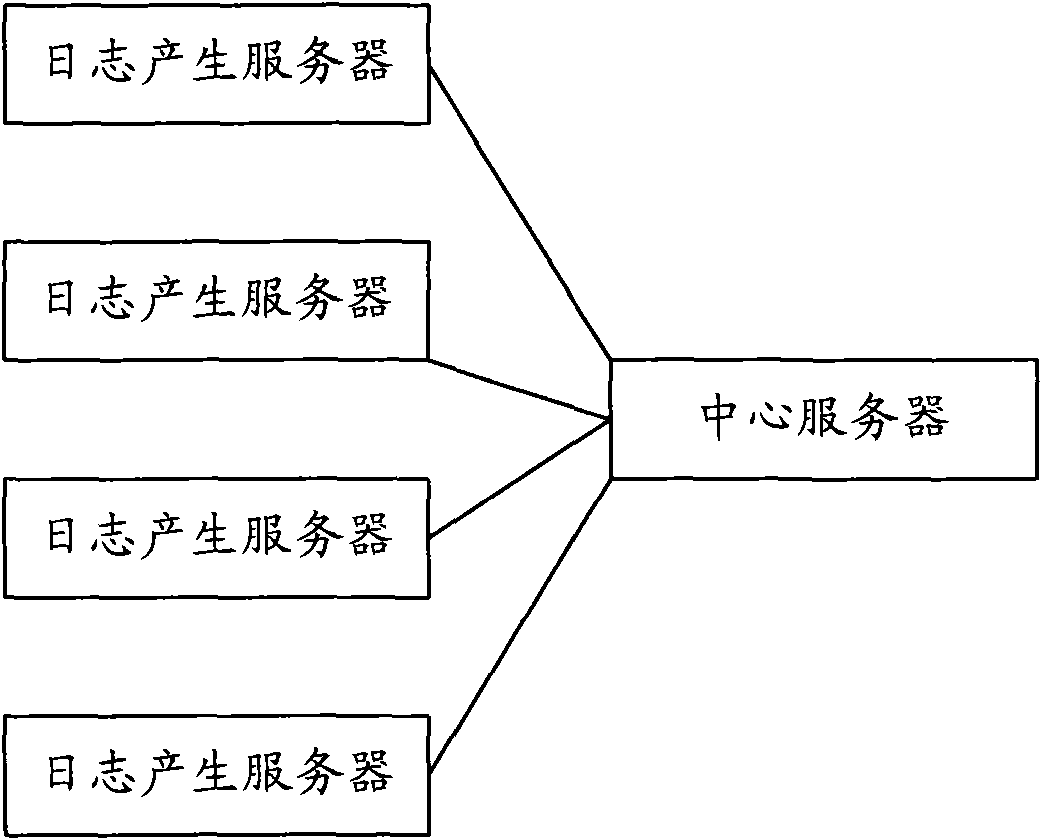

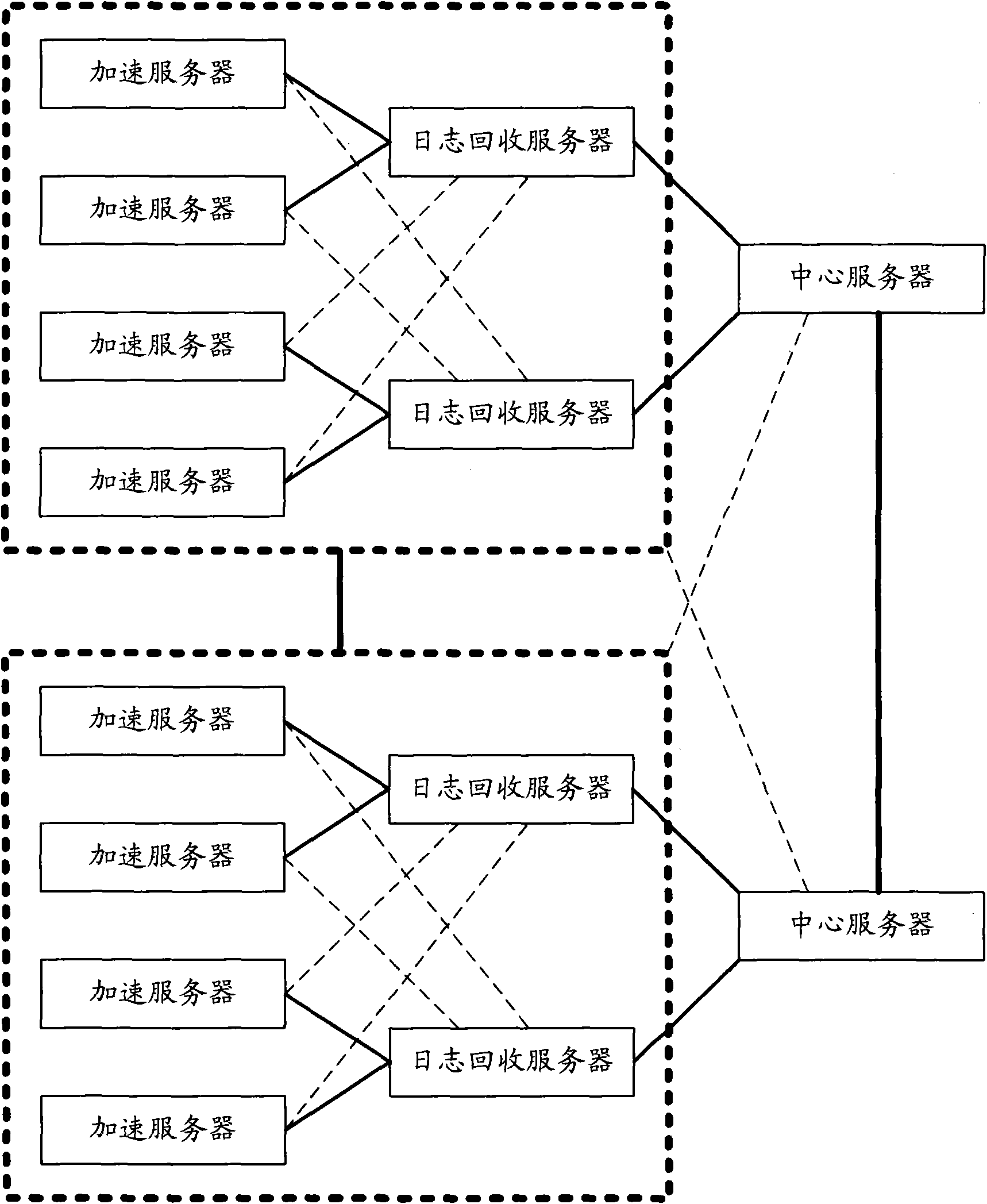

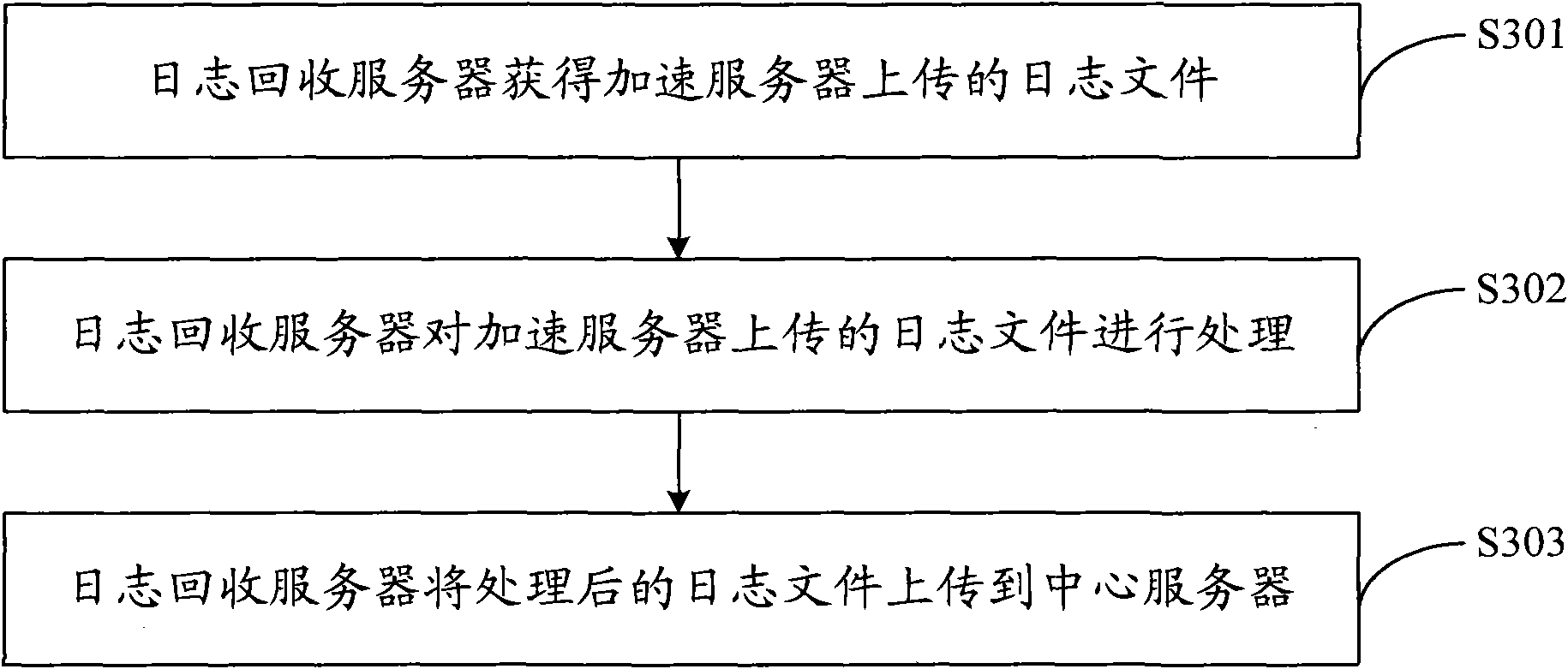

Log collecting system, log collection method and log recycling server

InactiveCN101964795ASolve the stressSolve stressHardware monitoringData switching networksLogfileCollection system

The invention relates to a log collection system, a log collection method and a log recycling server. The log collection system comprises acceleration servers, log recycling servers and a center server, wherein the acceleration servers are used for generating log files and uploading the log files to the log recycling server; the log recycling servers are used for receiving the log files uploaded by the plurality of acceleration servers and uploading the received log files to the center server; the center server is used for receiving log files uploaded by the plurality of log recycling servers; and the number of the log recycling servers is smaller than that of the acceleration servers. The log collection system, the log collection method and the log recycling server can effectively reduce the pressure of the center server and the network overhead, and improve transmission efficiency.

Owner:BEIJING 21VIANET DATA CENT

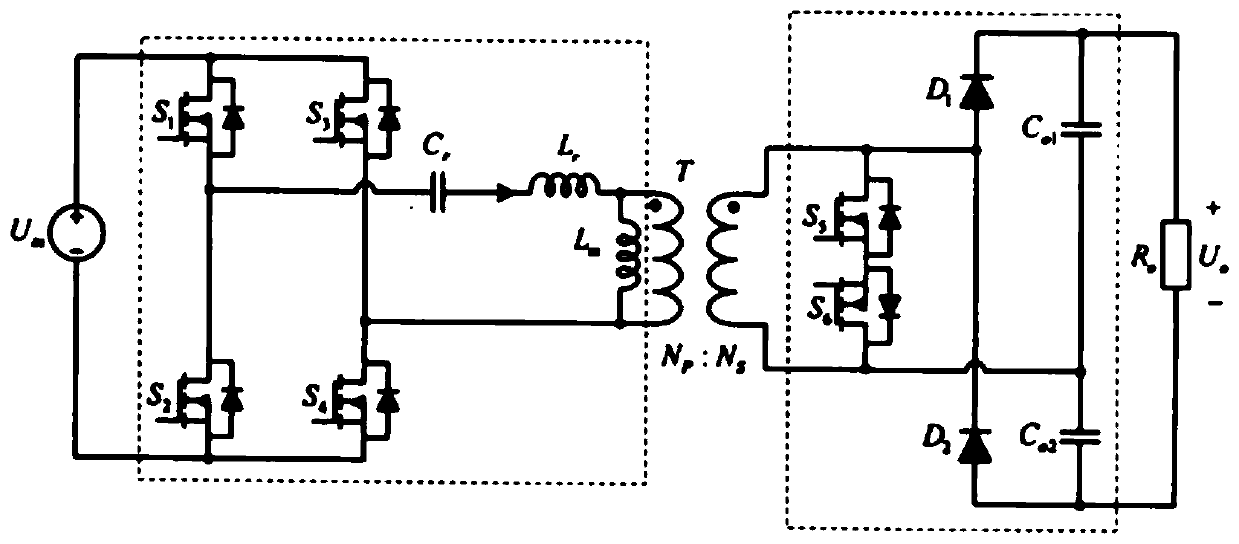

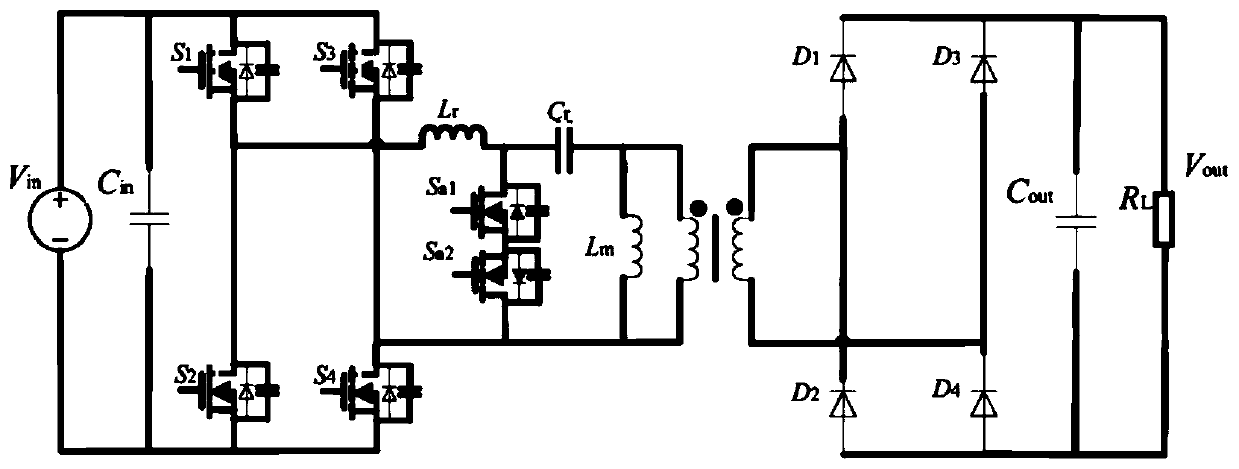

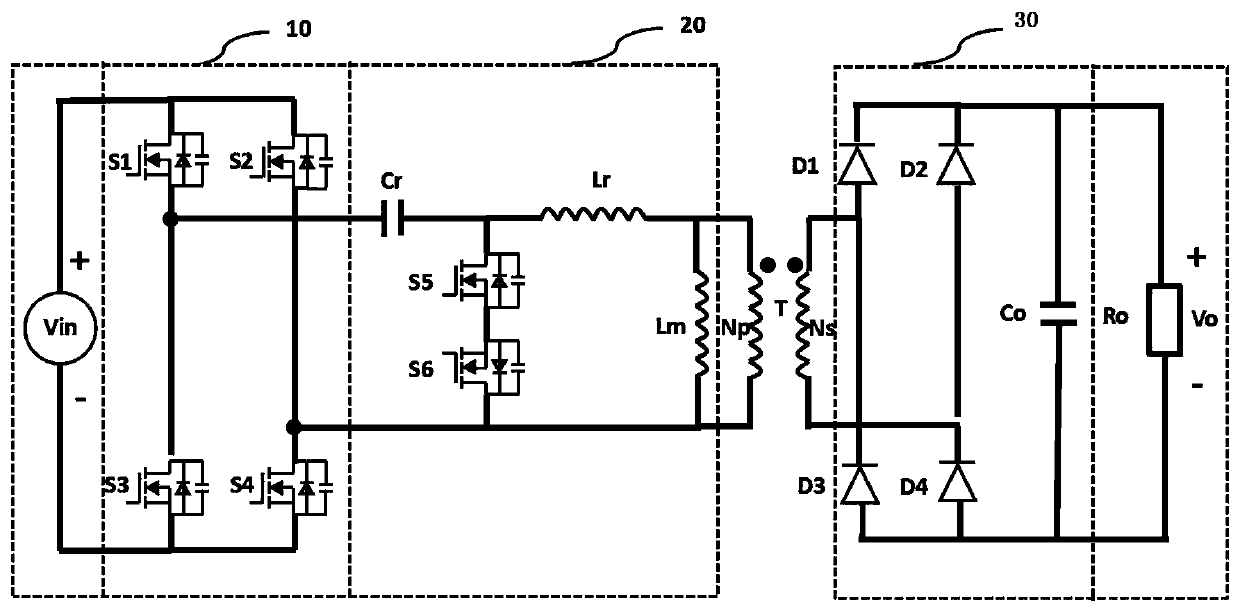

LLC resonant converter and control method

InactiveCN110707931AReduce difficultyReduce design difficultyEfficient power electronics conversionAc-dc conversionCapacitanceResonant capacitor

The invention discloses an LLC resonant converter and a control method, and the LLC resonant converter is lower in design difficulty, and comprises an inverter circuit, an LLC resonant cavity, a transformer and a rectification network which are sequentially connected from the input to the output. The LLC resonant cavity comprises a resonant inductor Lr, an excitation inductor Lm and a resonant capacitor Cr, and is additionally provided with a two-way switch; the resonant inductor Lr and the resonant capacitor Cr are connected in series between the first output end of the inverter circuit and the first end of the primary side coil of the transformer. The second output end of the inverter circuit is connected with the second end of the primary side coil of the transformer, the excitation inductor Lm is connected with the primary side coil of the transformer in parallel, the first end of the two-way switch is connected with the first end of the primary side coil of the transformer by being connected between the resonance inductor Lr and the resonance capacitor Cr, and the second end of the two-way switch is connected with the second end of the primary side coil of the transformer; theresonant inductor Lr is connected between the first end of the two-way switch and the first end of the primary side coil of the transformer, and the resonant capacitor Cr is connected between the first end of the two-way switch and the first output end of the inverter circuit.

Owner:MORNSUN GUANGZHOU SCI & TECH

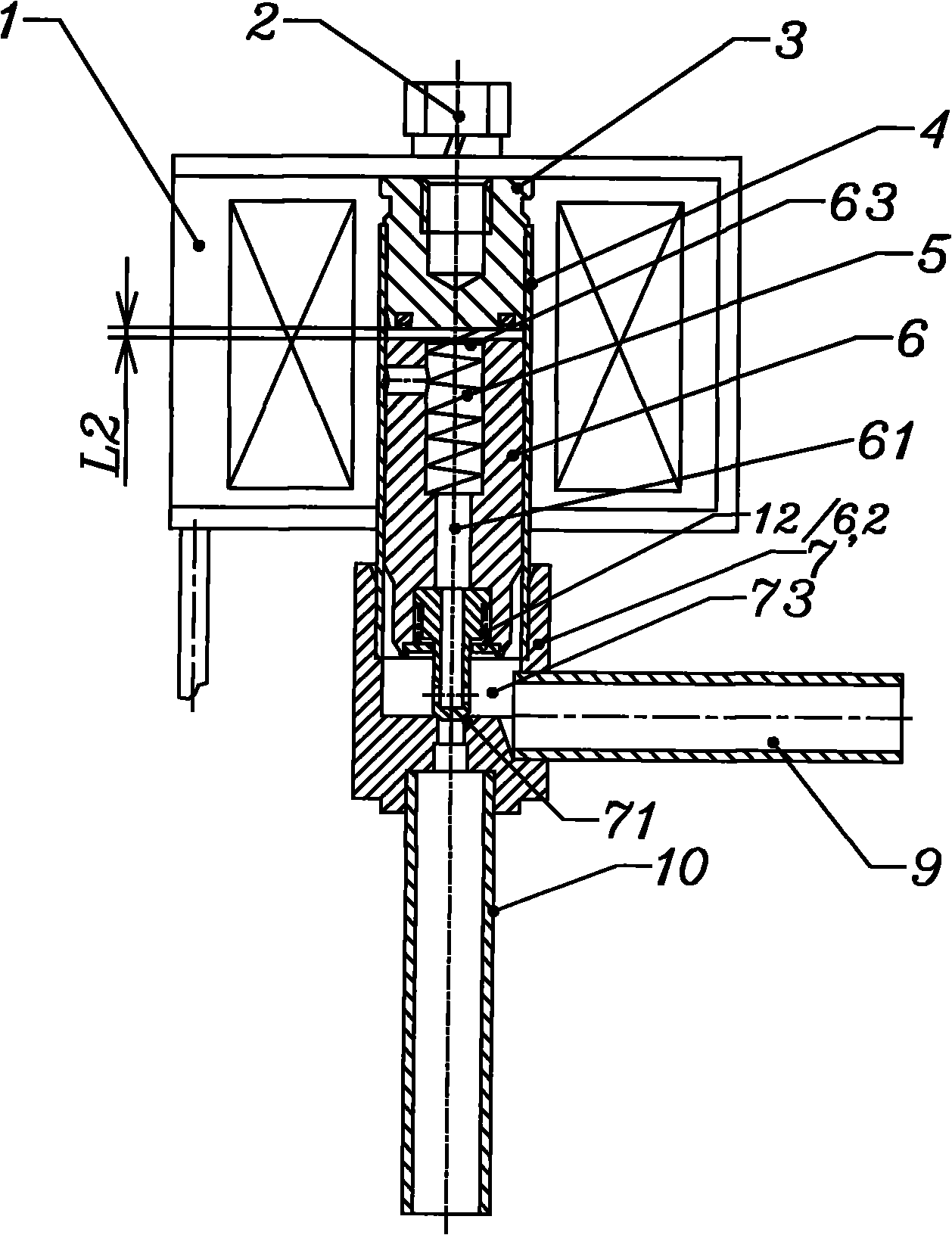

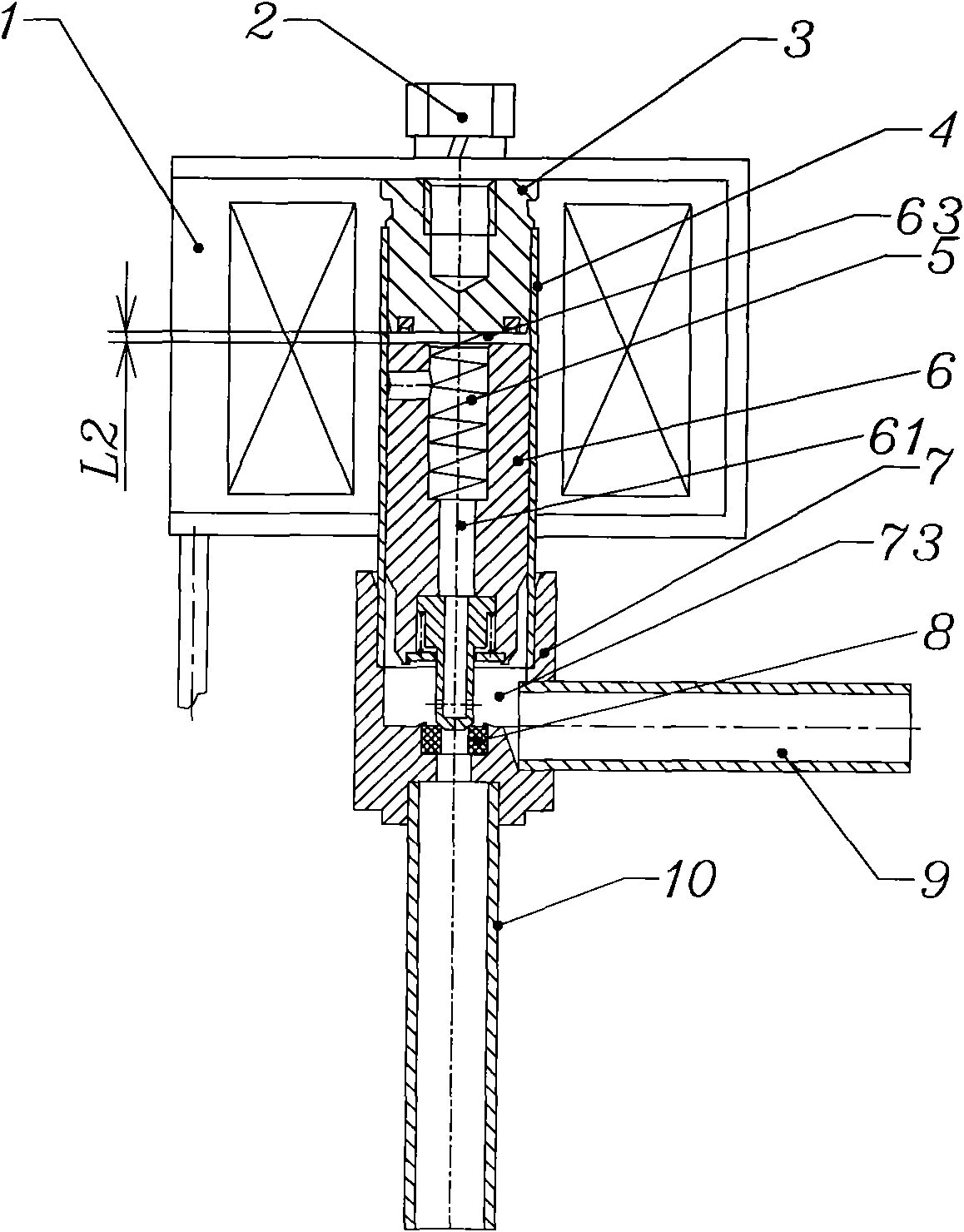

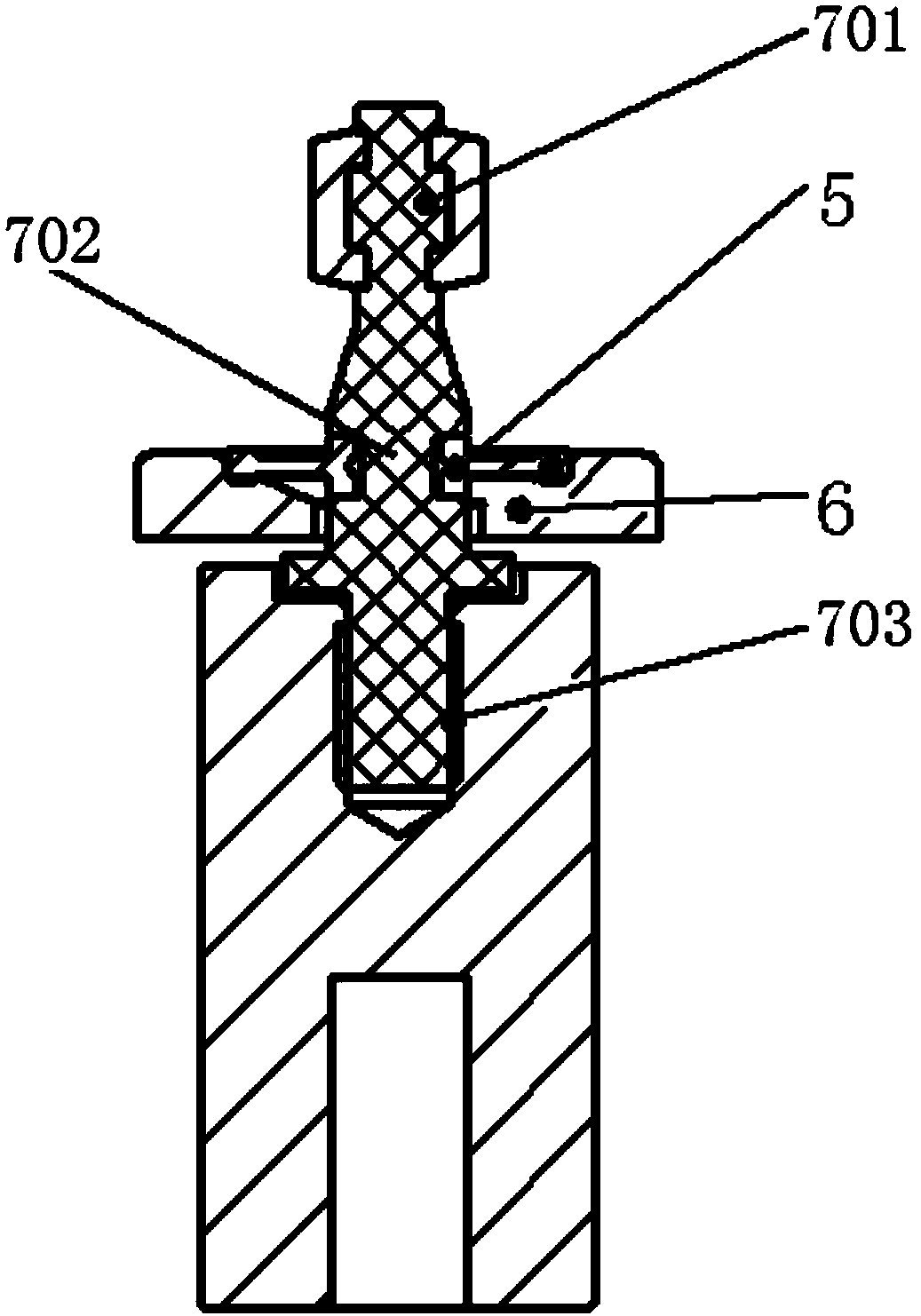

Magnetic valve

ActiveCN101988583ASolve the stressReduce wearOperating means/releasing devices for valvesValve members for absorbing fluid energyMagnetic valveEngineering

The invention relates to a magnetic valve, comprising a valve seat, a sleeve fixedly connected with the valve seat, a coil arranged outside of the sleeve, a movable core arranged in the sleeve, a static core and a reset spring arranged between the movable core and the static core, wherein a sealing element is arranged at one end of the movable core opposite to the other end close to the static core, and a valve port is arranged at the side opposite to the sealing element in a valve body; and the sealing element comprises a major diameter part in the central cavity body at the end part of the movable core, a middle part and a minor diameter part which partially extends out of the central cavity body at the end part of the movable core. The magnetic valve also is provided with a balance channel passing through the sealing element, so that no pressure difference generates at the two sides of the sealing element, thus avoiding instable magnetic valve flow due to action of the sealing element resulted from the pressure difference, and solving the problem of larger stress of the sealing element, thereby reducing abrasion of the sealing element.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

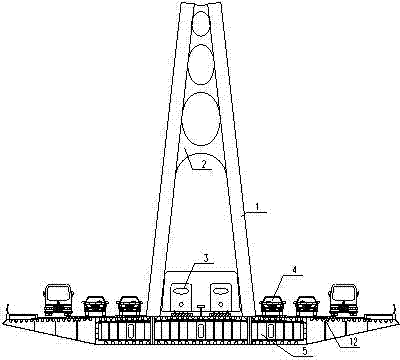

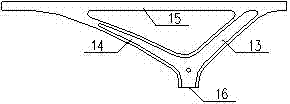

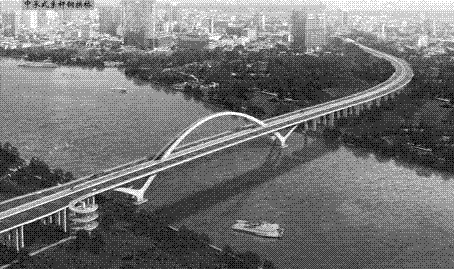

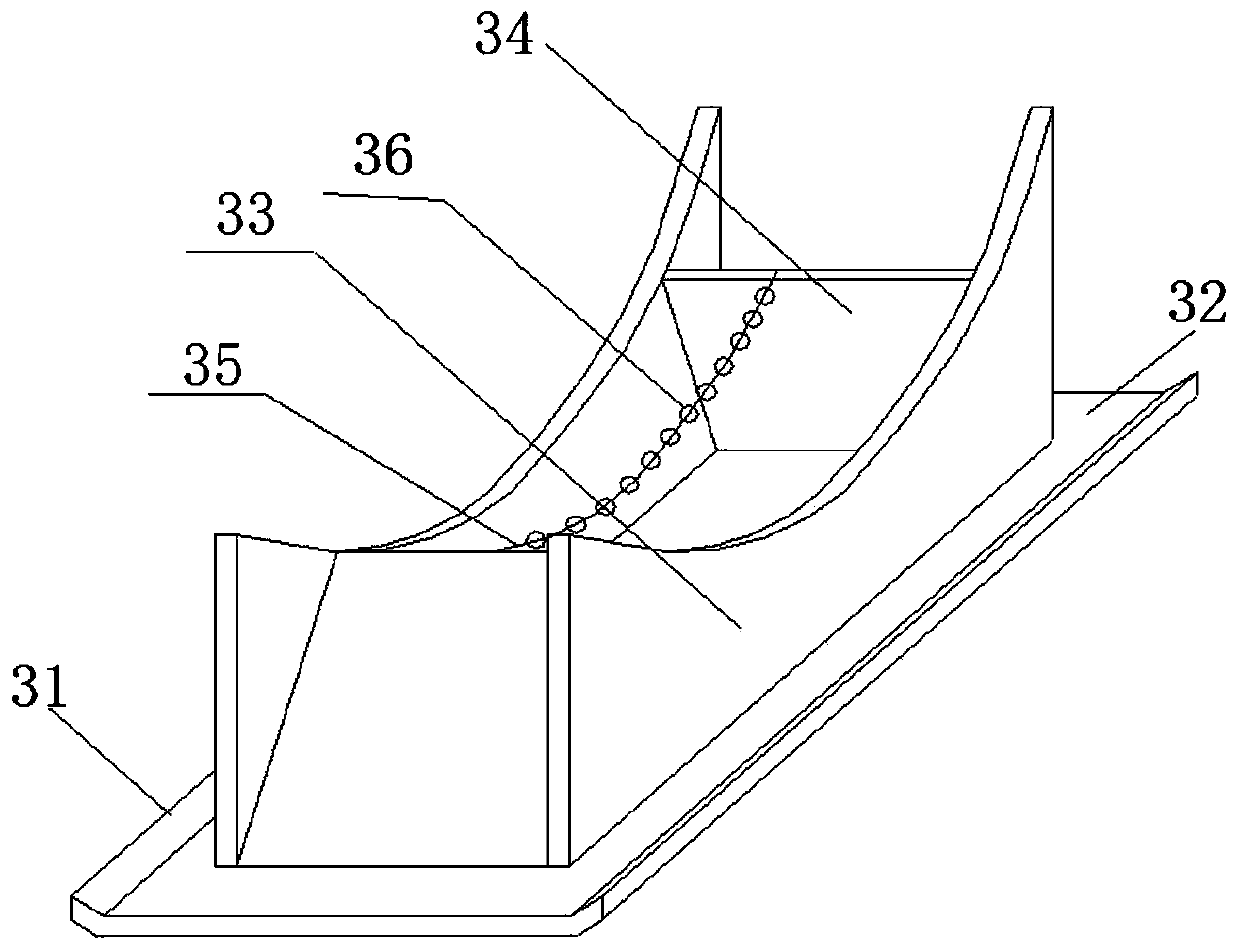

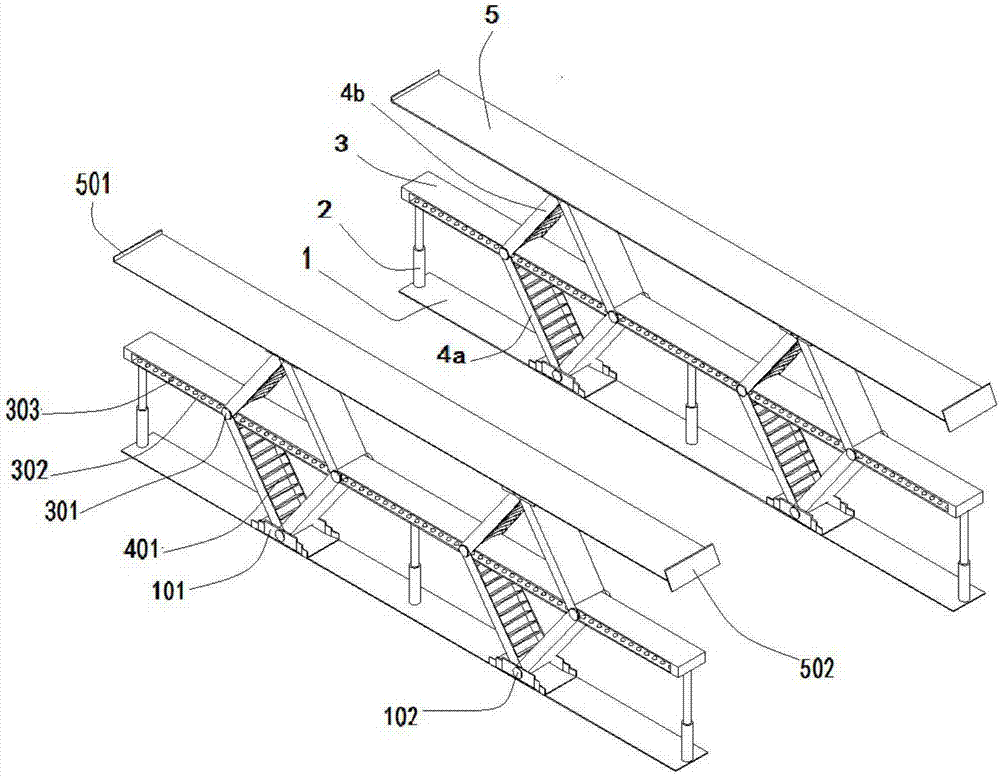

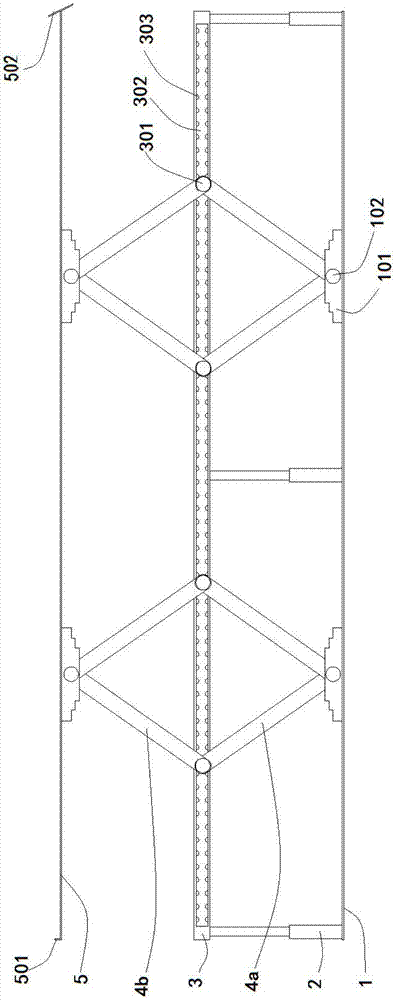

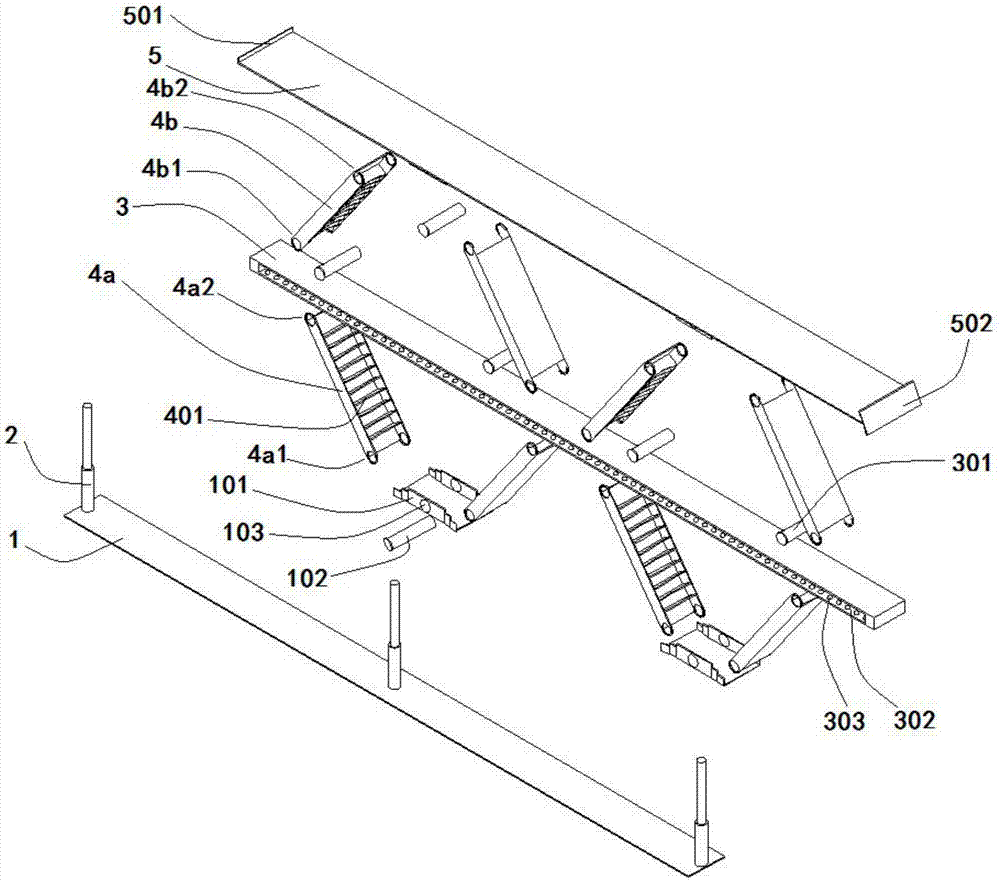

Half-through bowstring arch bridge with vehicle and light rail on same layer and construction method thereof

InactiveCN104846733AShorten the lengthRaising the bar for linear technologyBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention relates to a half-through bowstring arch bridge with a vehicle and a light rail on the same layer. A main beam of the arch bridge adopts a mixed structure; a side span main beam adopts a prestressed concrete structure; and a mid-span main beam adopts a steel box girder structure. The arch bridge is characterized by having a combined arch force transfer system; and the force transfer system comprises a lifting basket type steel box main arch and a back stay rope. As a novel structural design of a bridge building is adopted, the same-layer arrangement of improving the linear technology standard and reducing the manufacturing cost is realized, and the beauty and structure unification of the bridge building is realized.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

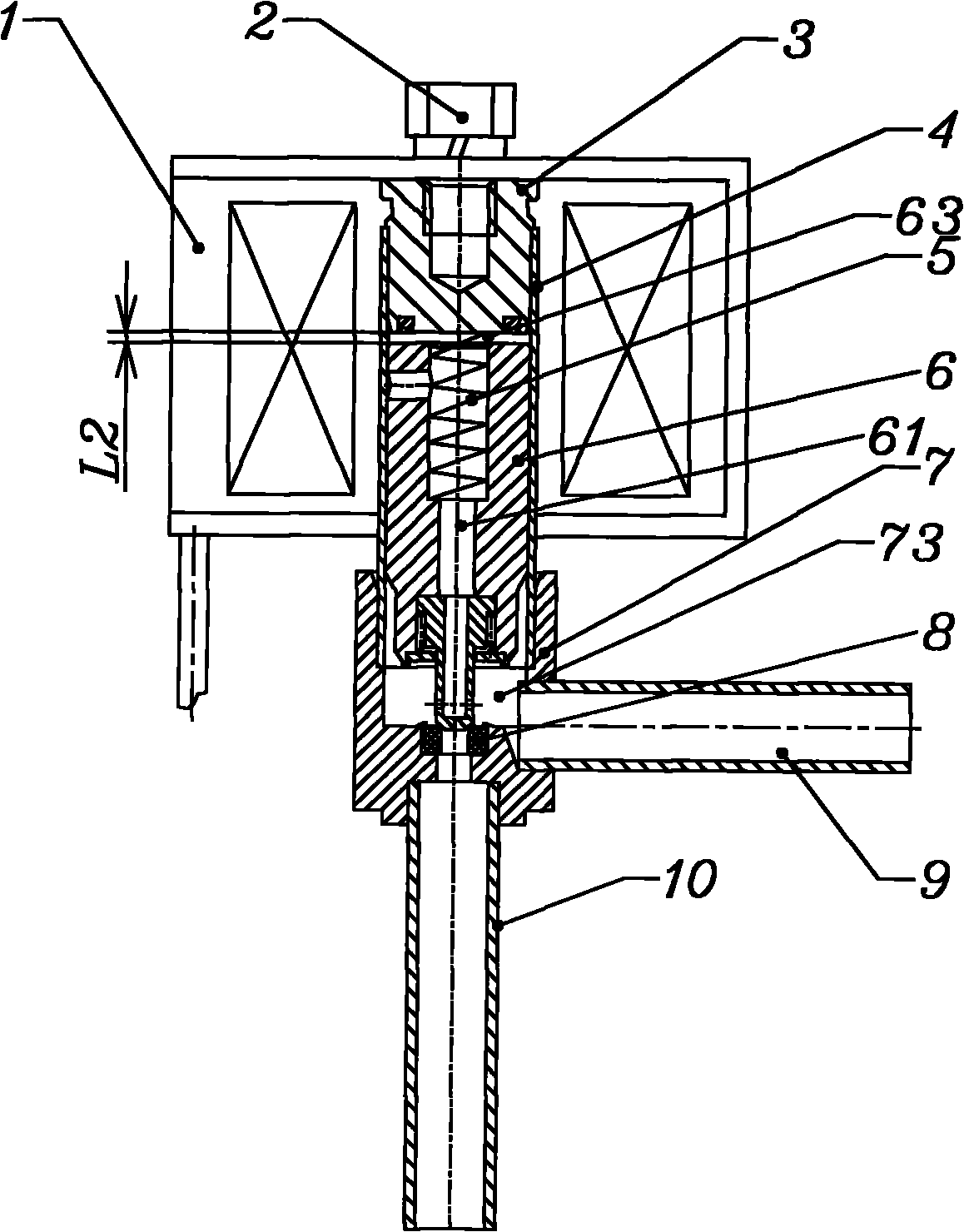

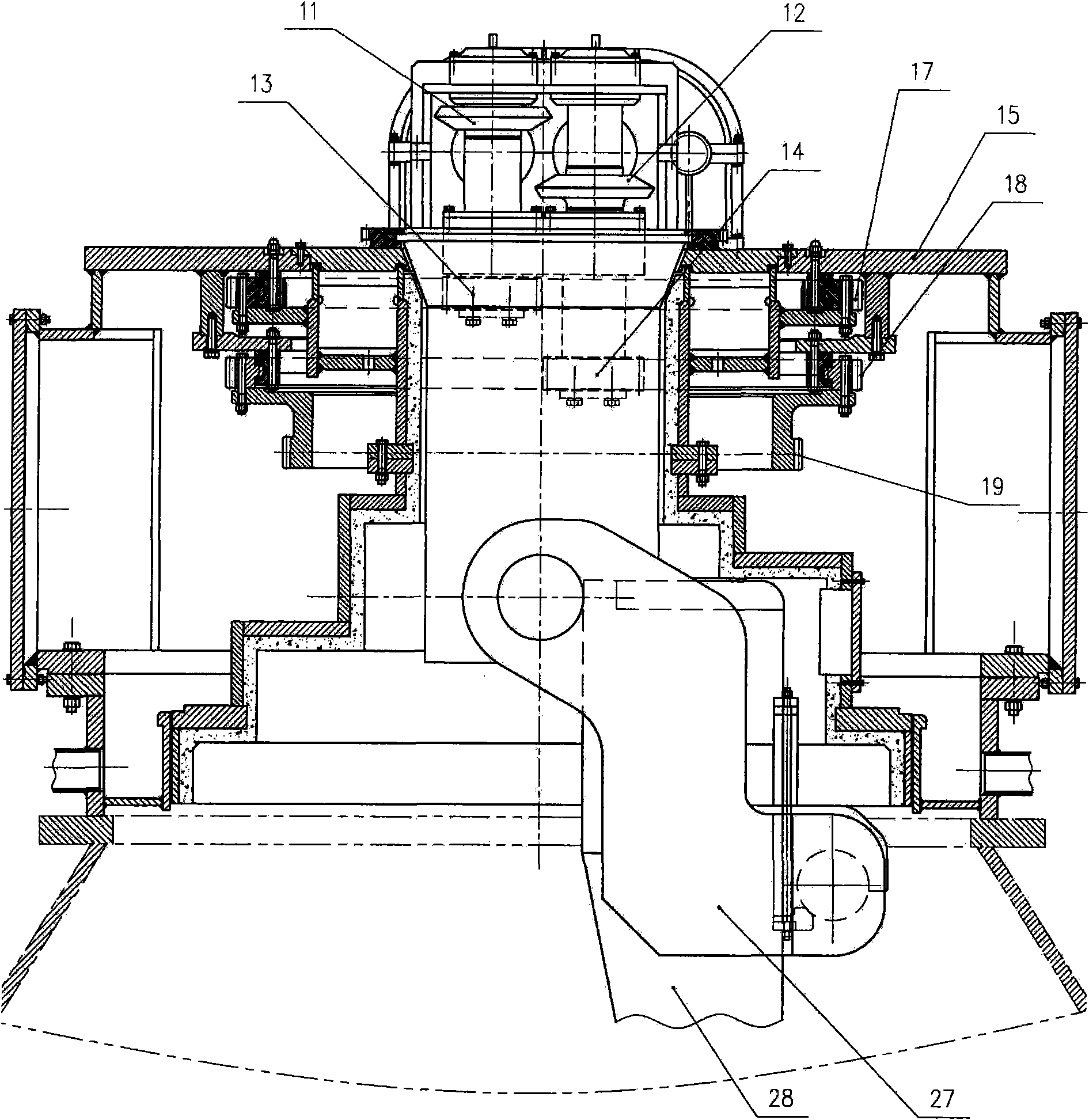

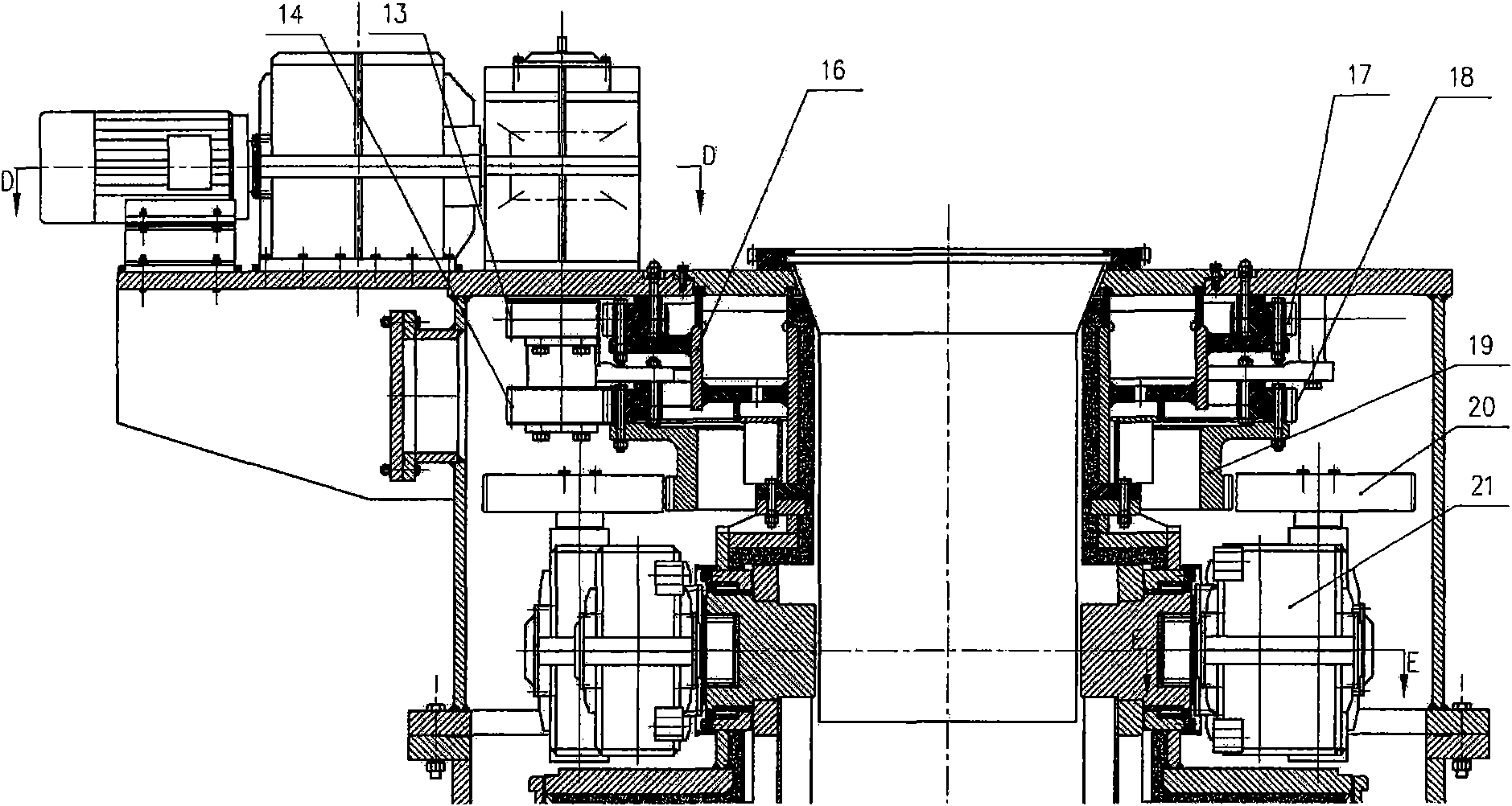

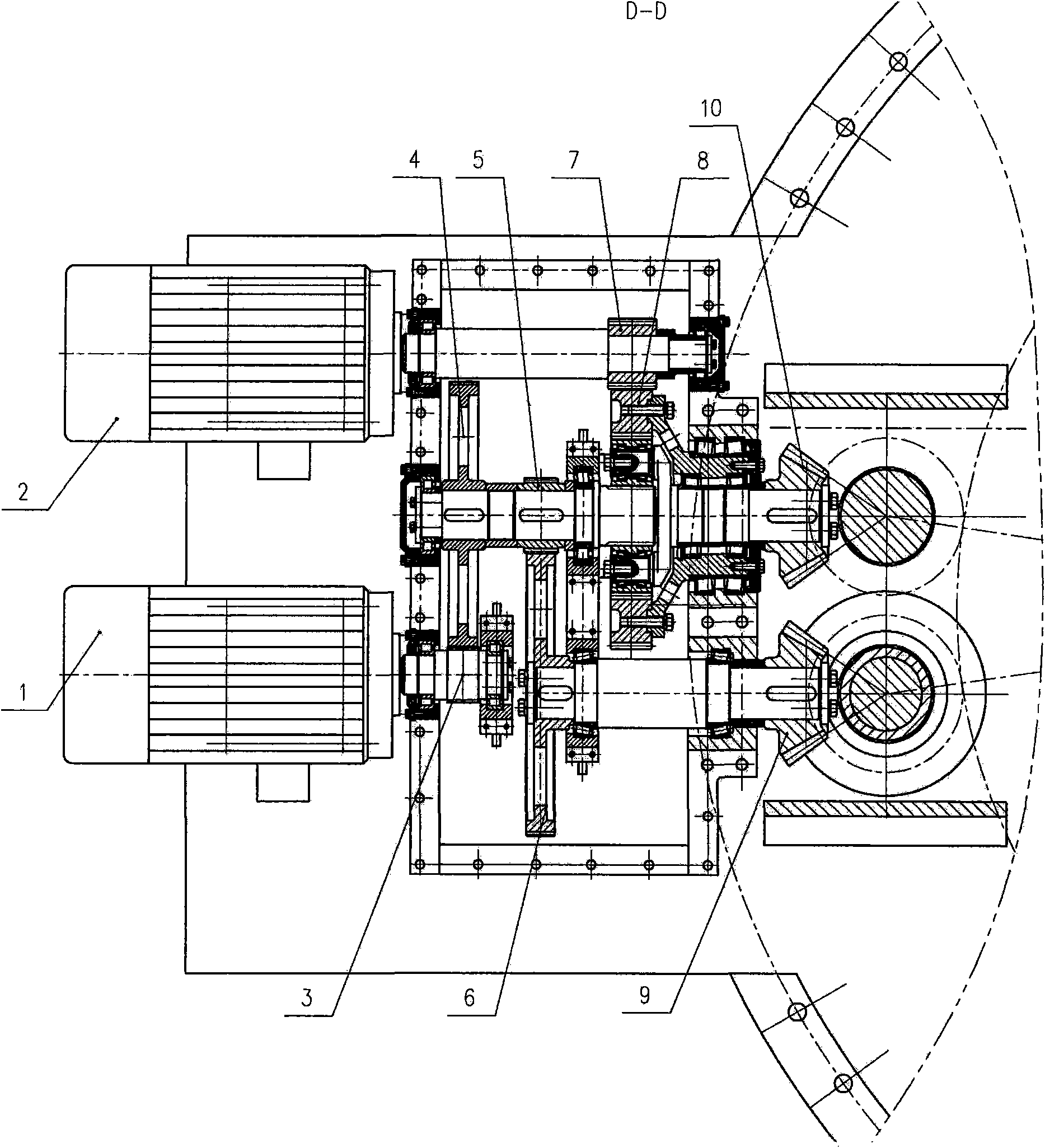

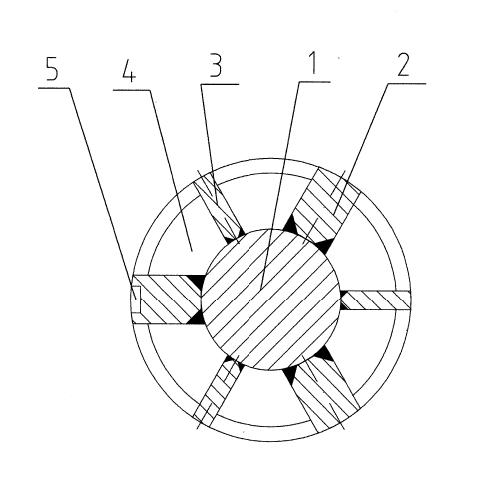

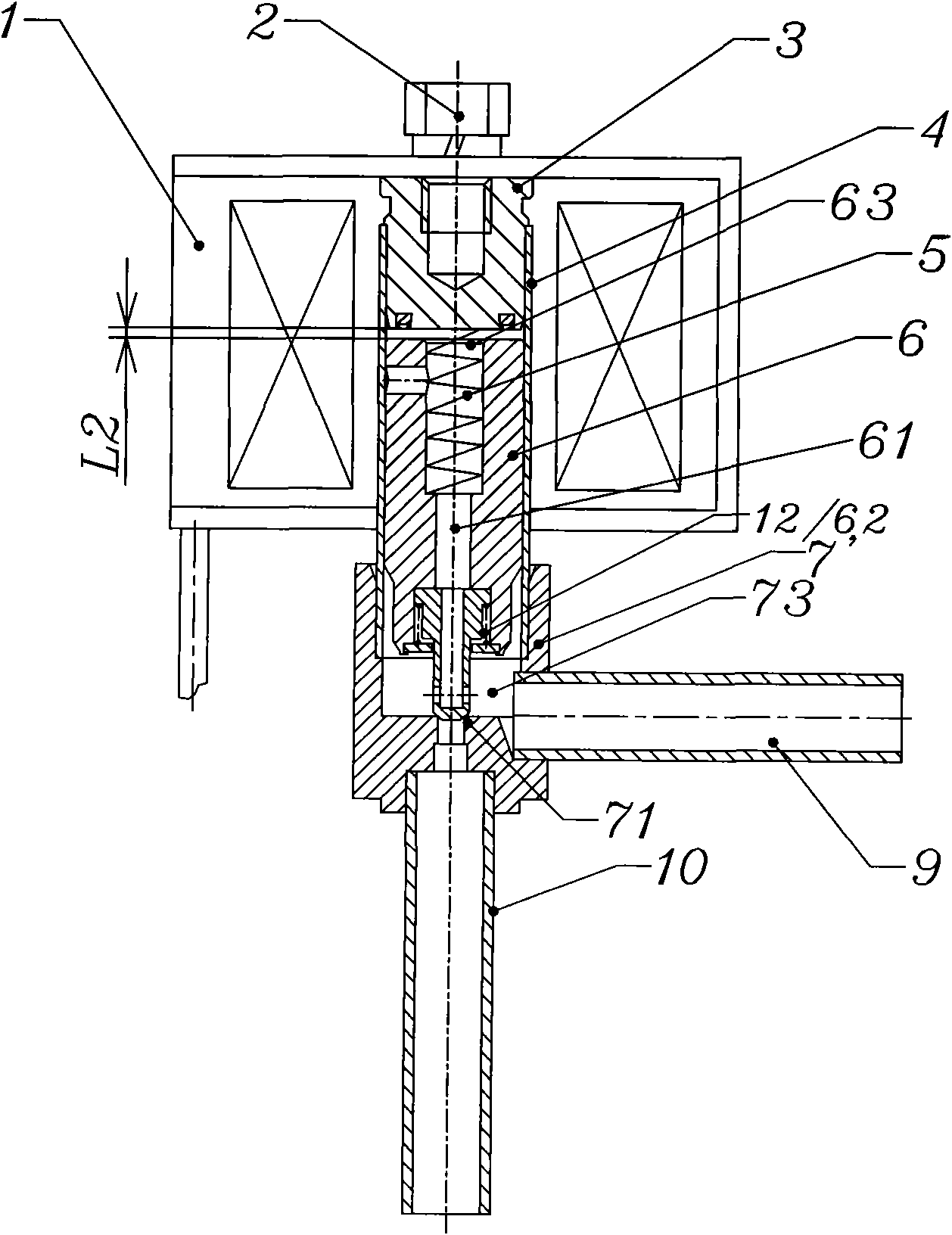

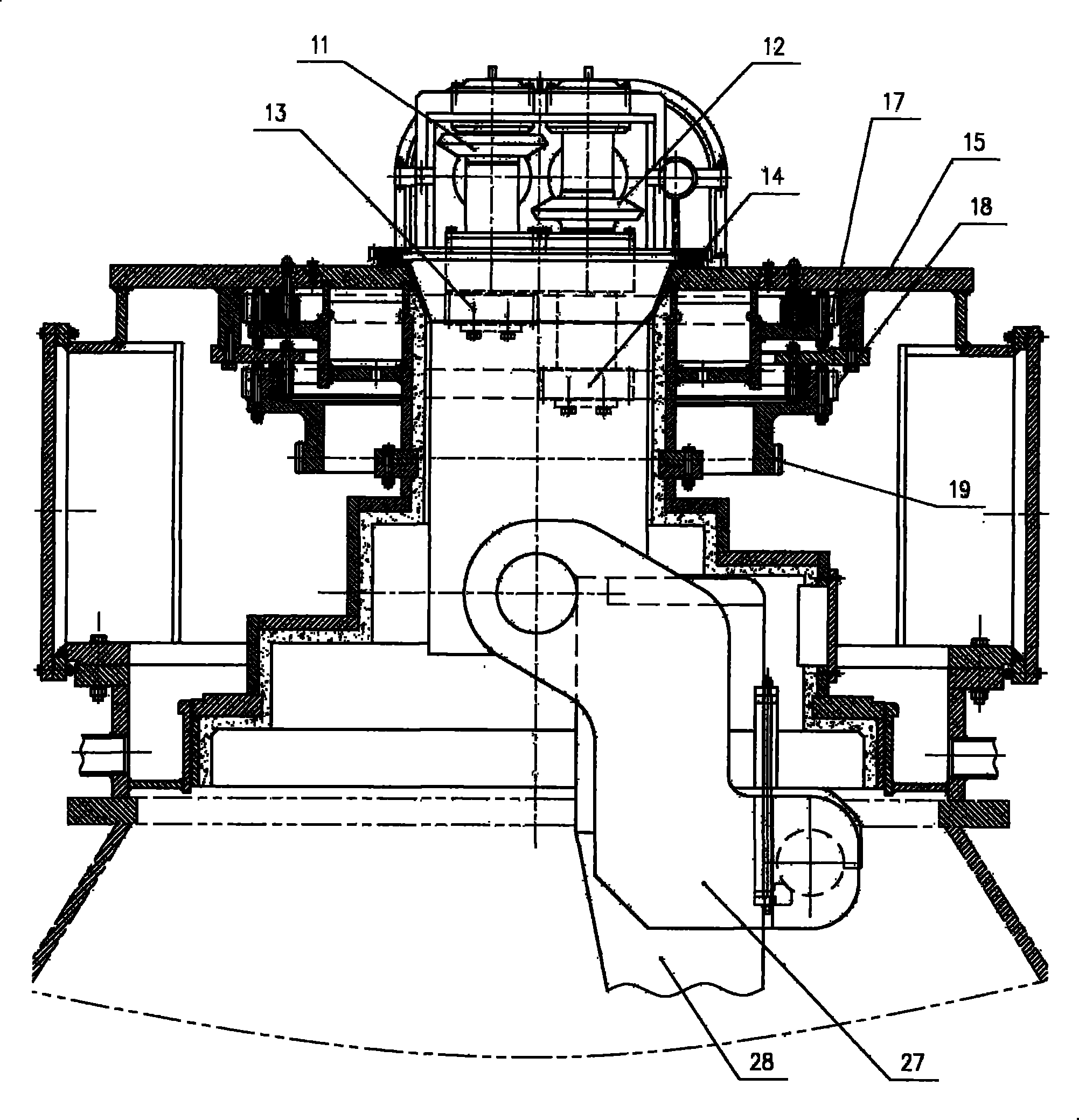

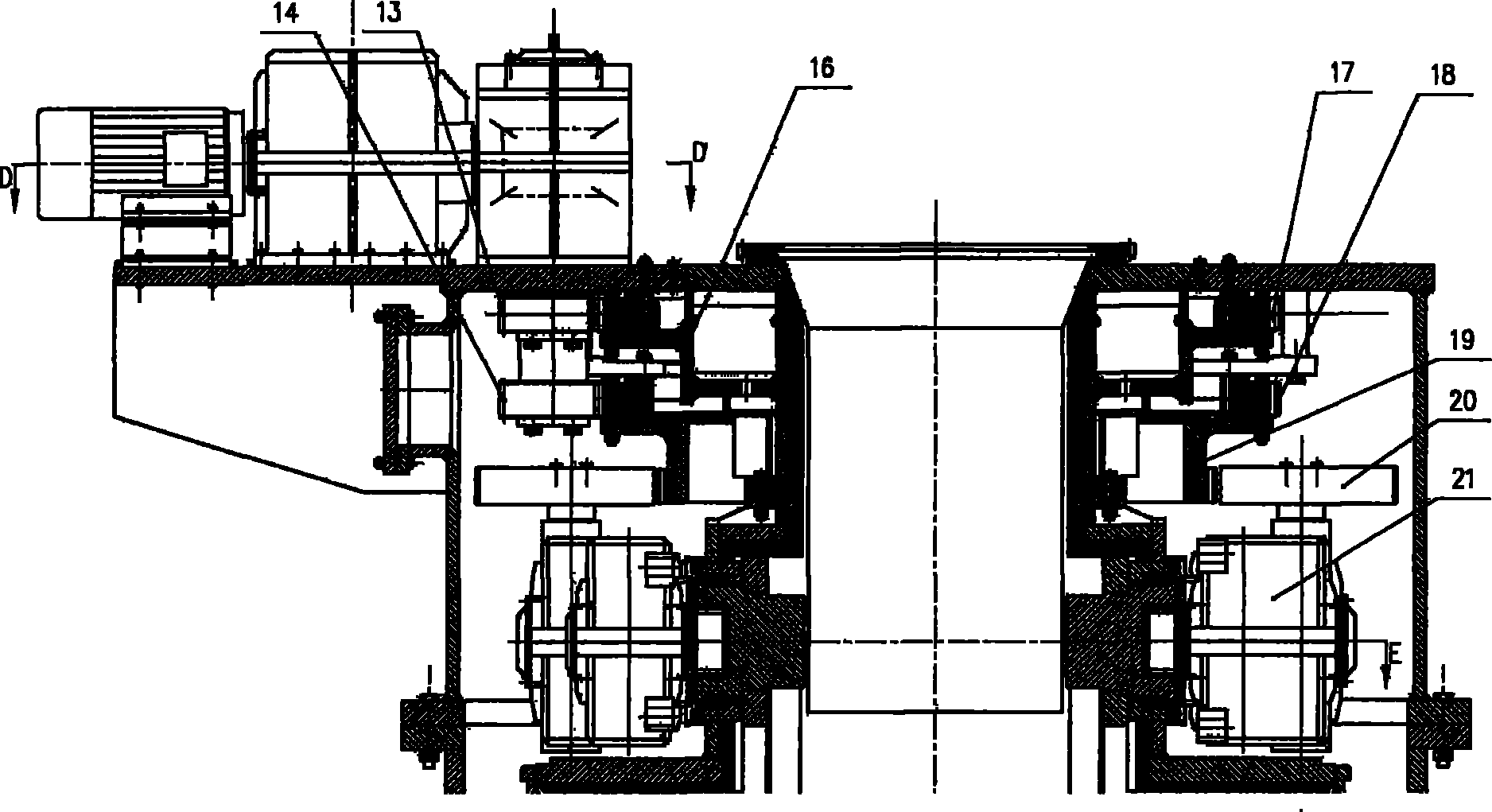

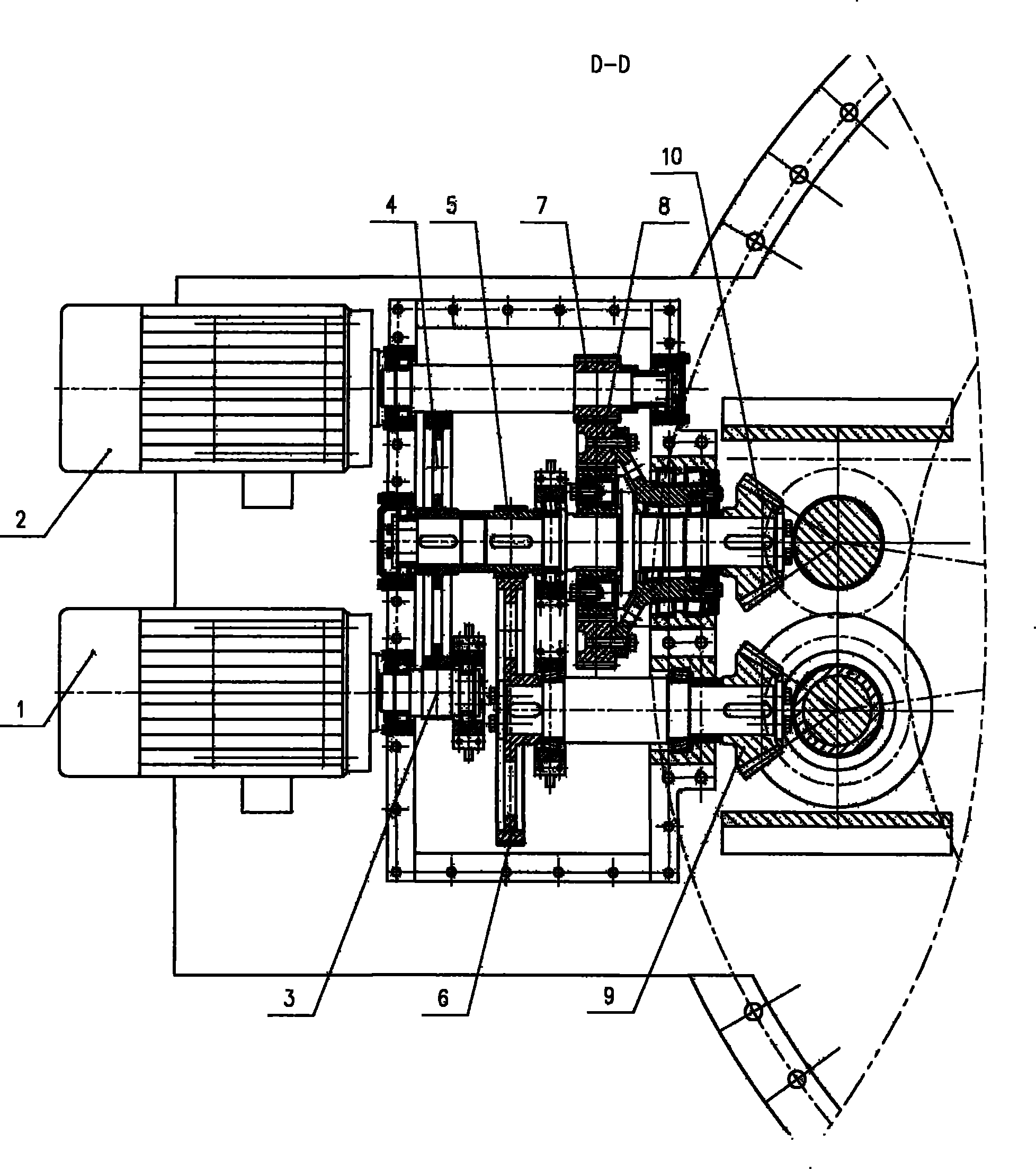

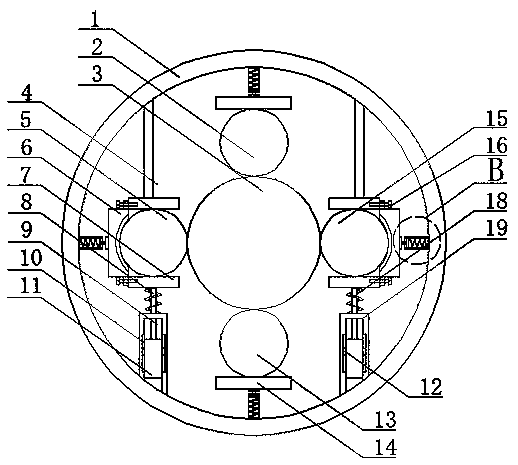

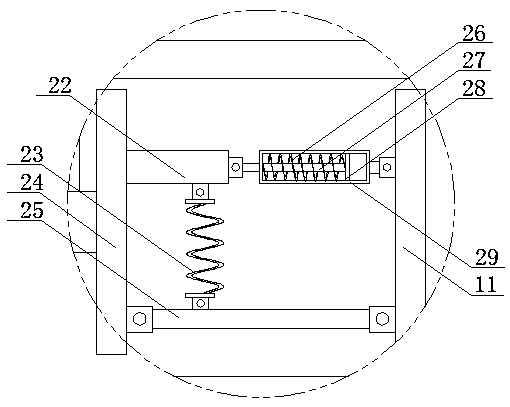

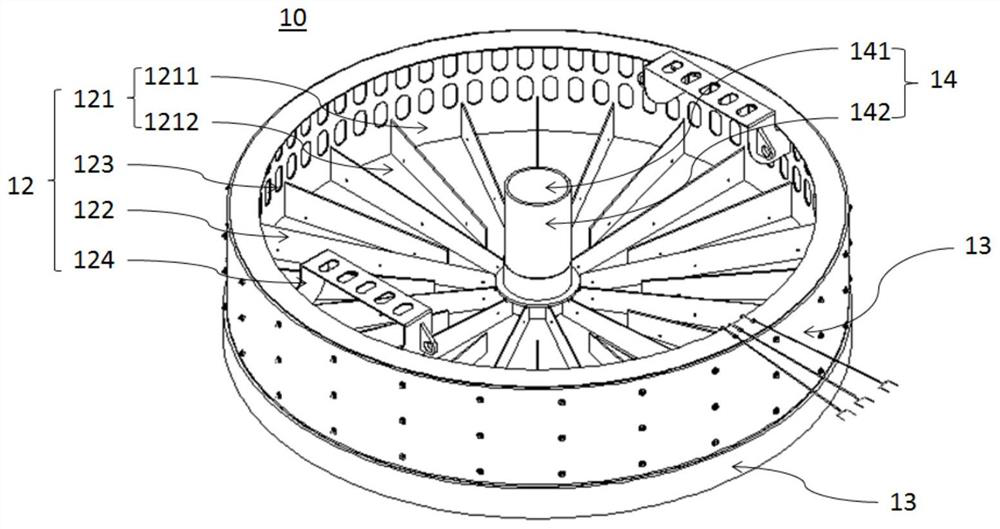

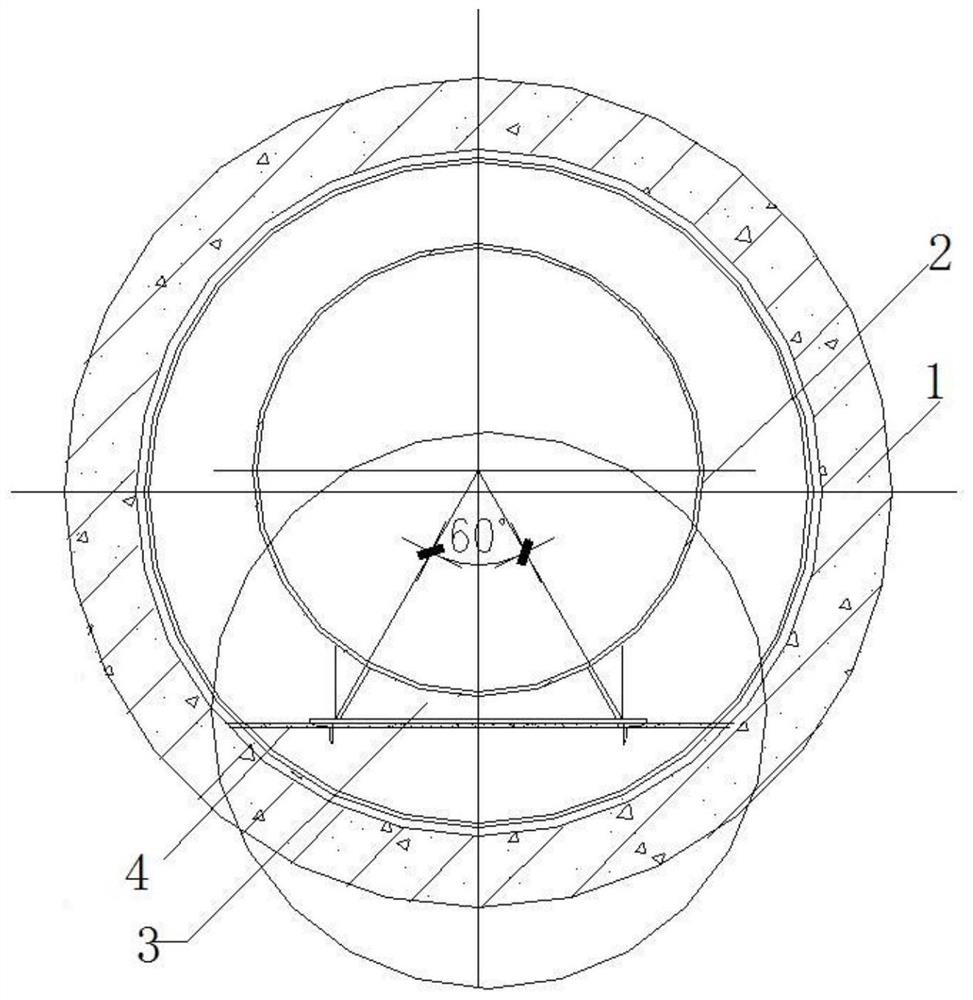

Furnace top distributing gear

ActiveCN101580885ACompact structureSmooth transmissionBlast furnace componentsBlast furnace detailsEngineeringGear drive

The invention discloses a furnace top distributing gear for distributing materials on the top of an iron-fining furnace, belonging to the technical field of mechanical engineering. A rotating motor and a tilting motor are independently driven by a set of differential mechanisms, wherein differential mechanism drive and previous-stage drive adopt all-gear drive, the previous-stage drive of a central sun wheel of the differential mechanism adopts gear drive with common drive ratio, and a furnace pot is tilted by a three-ring speed reducer. The furnace top distributing gear can realize the functions of furnace pot tilting, furnace pot rotation and furnace pot tilting and rotation, has the advantages of compact structure, reliable drive, stable work, high drive efficiency, long service life, little maintaining workload and convenient furnace pot replacement, can be used for blast furnace engineering of various types or other places where loose unpacked materials are delivered.

Owner:CISDI ENG CO LTD

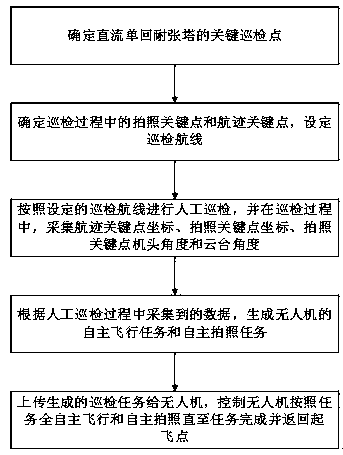

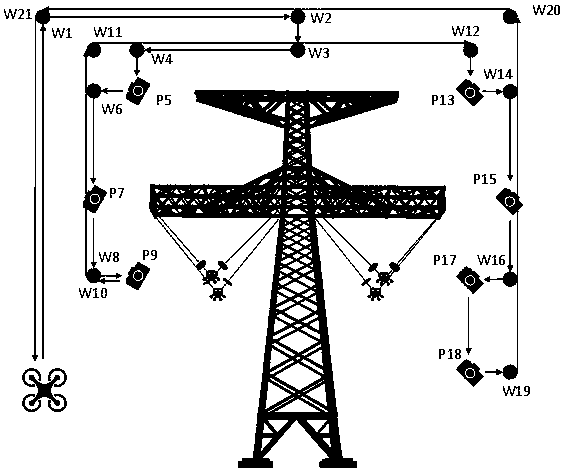

Unmanned aerial vehicle automatic patrolling method for direct current single-circuit tension tower

InactiveCN109460054ASolve the stressAvoid the problem of hitting the line and hitting the towerPosition/course control in three dimensionsApparatus for overhead lines/cablesCrucial pointAerospace engineering

The invention discloses an unmanned aerial vehicle automatic patrolling method for a direct current single-circuit tension tower. The method comprises the steps that S1, key patrolling points of the direct current single-circuit tension tower are determined; S2, shooting key points and flight path key points in the patrolling process are selected, and a patrolling flight route is set; S3, manual patrolling is conducted according to the set patrolling flight route, and in the patrolling process, coordinates of the flight path key points, coordinates of the shooting key points and angles of thehead of an unmanned aerial vehicle and a cloud deck at the shooting key points are collected; S4, according to the data collected in the manual patrolling process, an automatic flight task and an automatic shooting task of the unmanned aerial vehicle are generated; S5, the generated patrolling tasks are uploaded to the unmanned aerial vehicle, the unmanned aerial vehicle is controlled to automatically fly completely according to the tasks, when the unmanned aerial vehicle arrives at the shooting key points, the flight direction of the head of the unmanned aerial vehicle and the angle of the cloud deck are automatically adjusted, after in-place adjustment, a camera is trigged to shoot, and the unmanned aerial vehicle returns to the taking off point until all the tasks are completed. The method effectively solves the problems that manual patrolling for the direct current single-circuit tension tower is large in stress, low in safety and not high in efficiency.

Owner:成都优艾维智能科技有限责任公司 +1

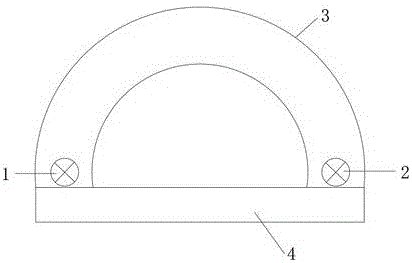

Foot positioning device comprising arched wide band with anti-skidding and anti-falling functions

InactiveCN105128806ASimple structureLow production costPedestrian/occupant safety arrangementAutomotive engineeringBody balance

Owner:蒋科富

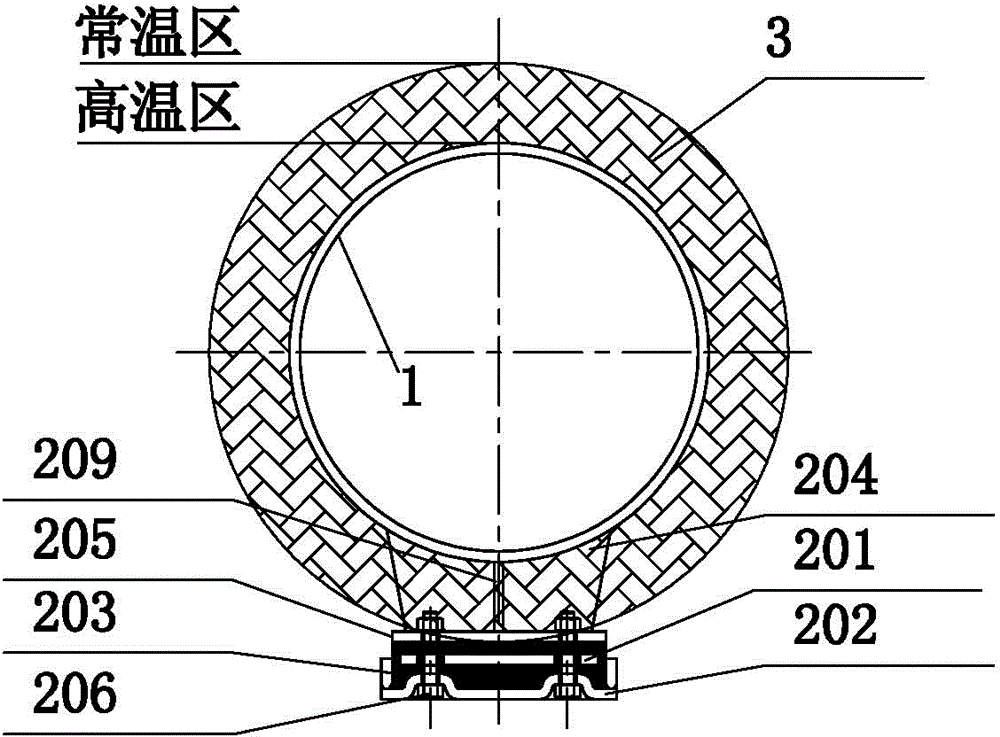

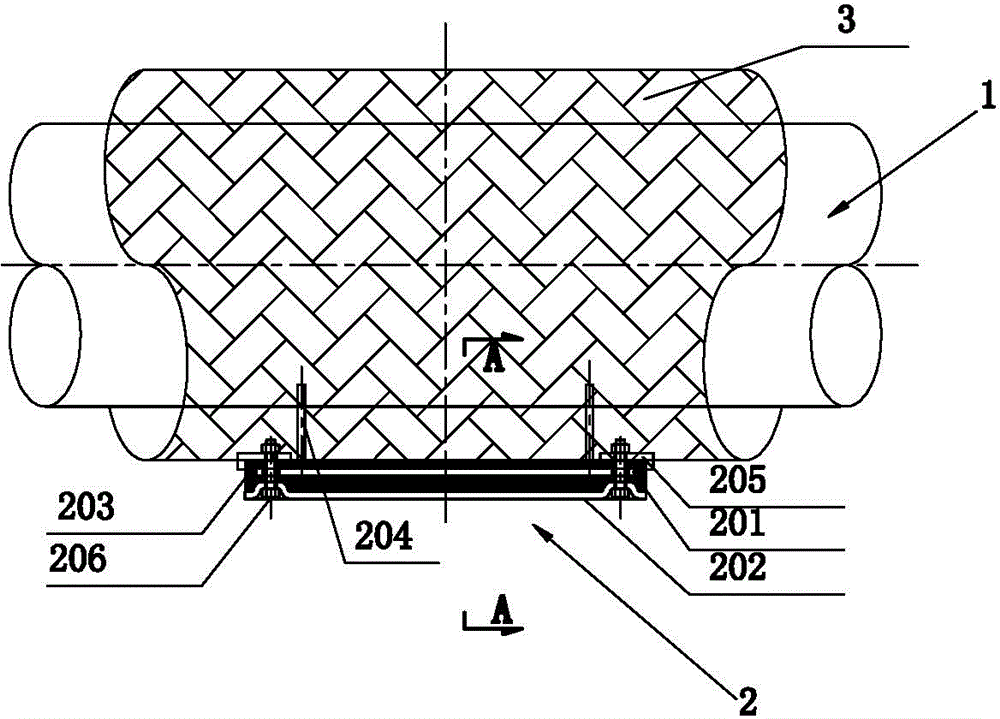

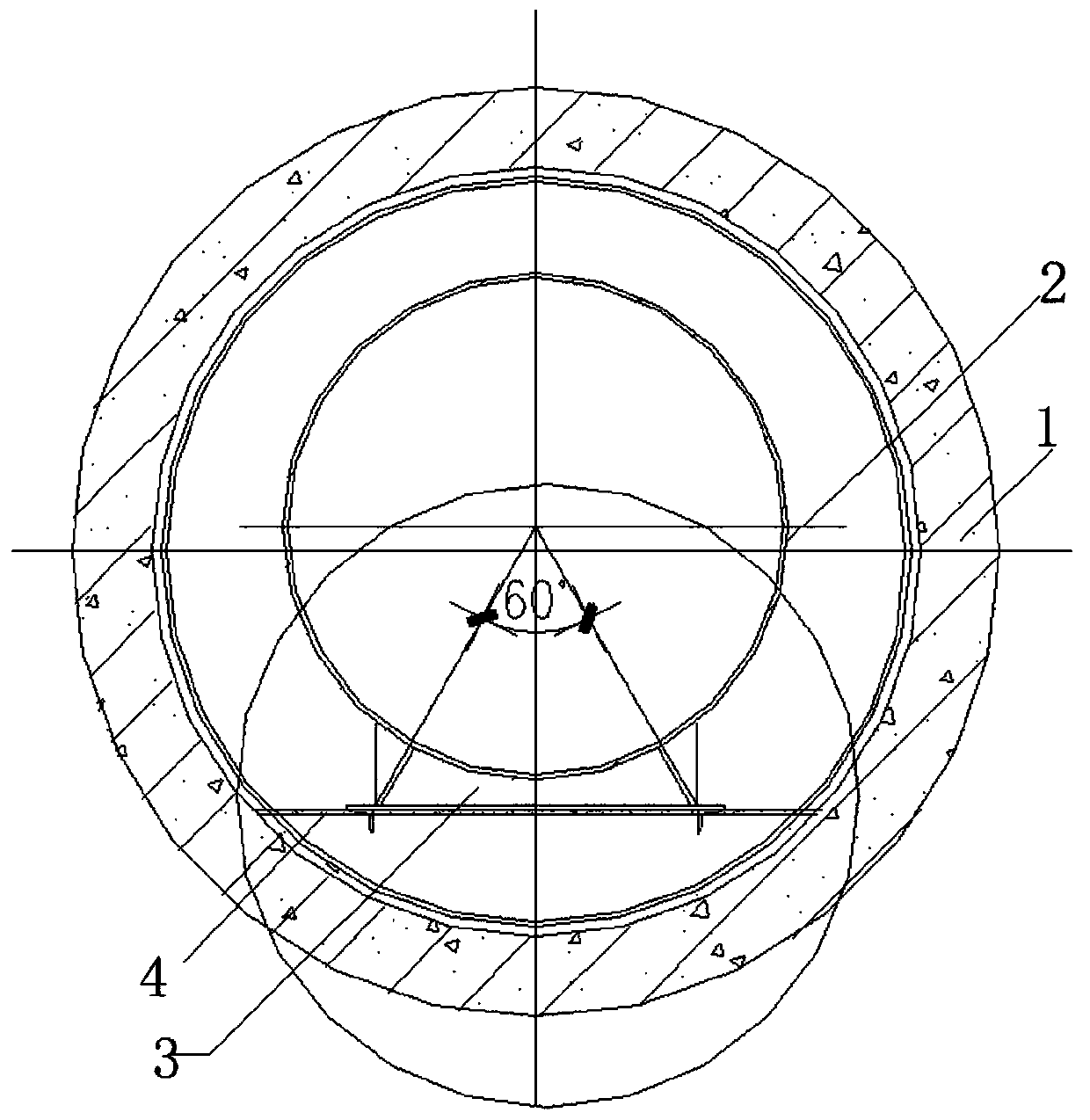

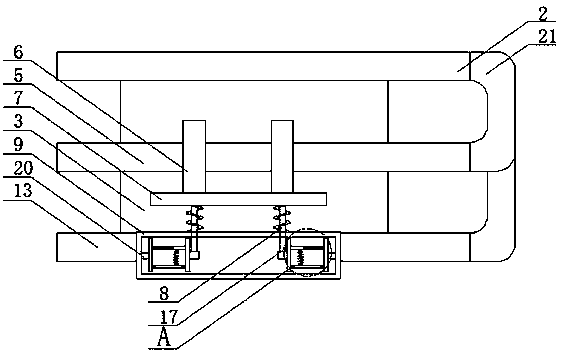

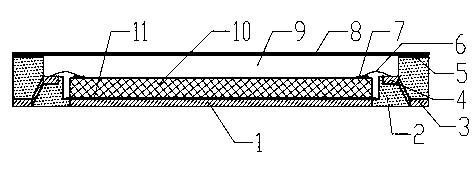

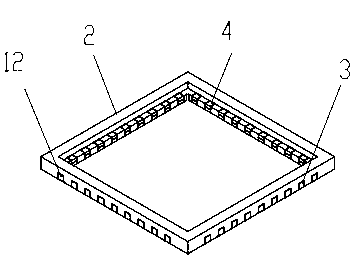

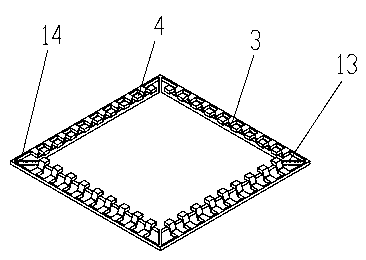

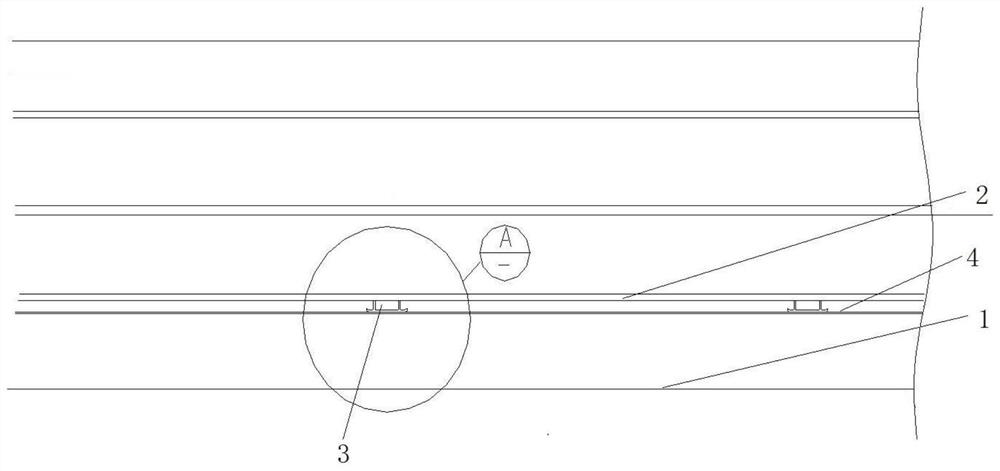

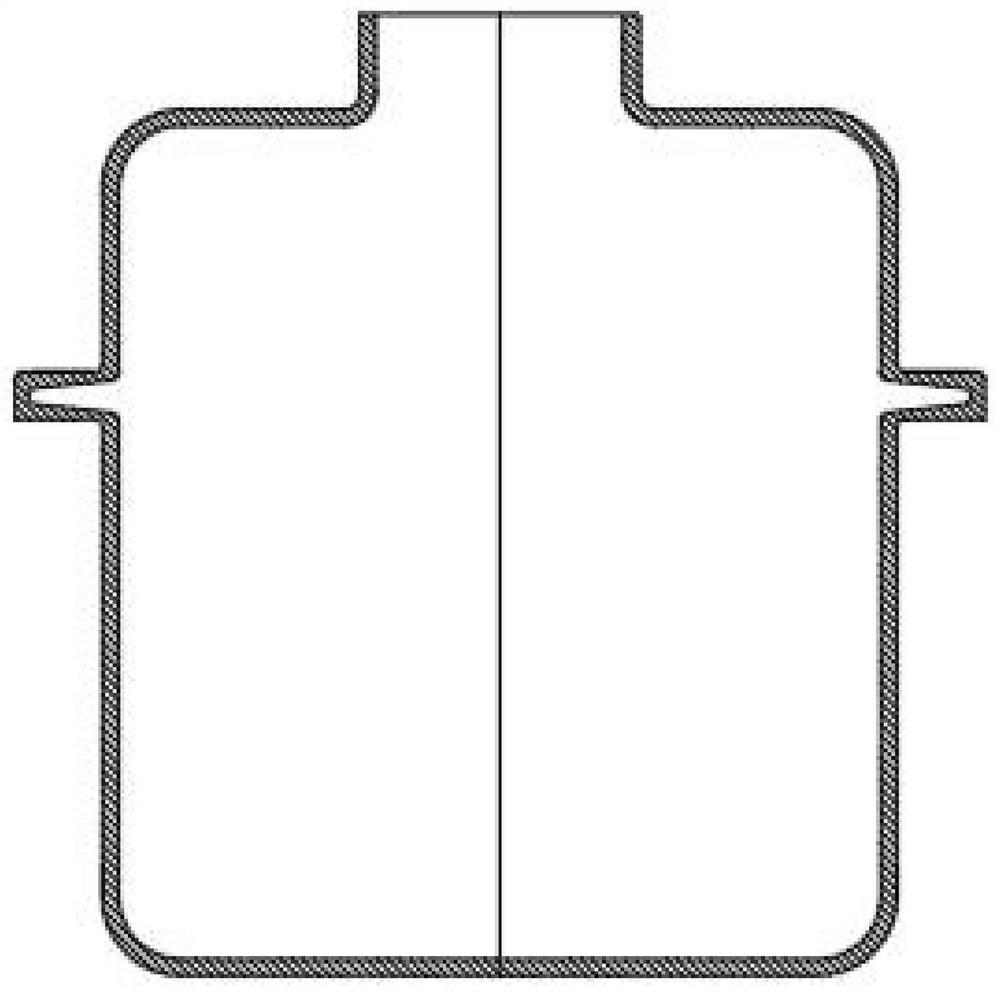

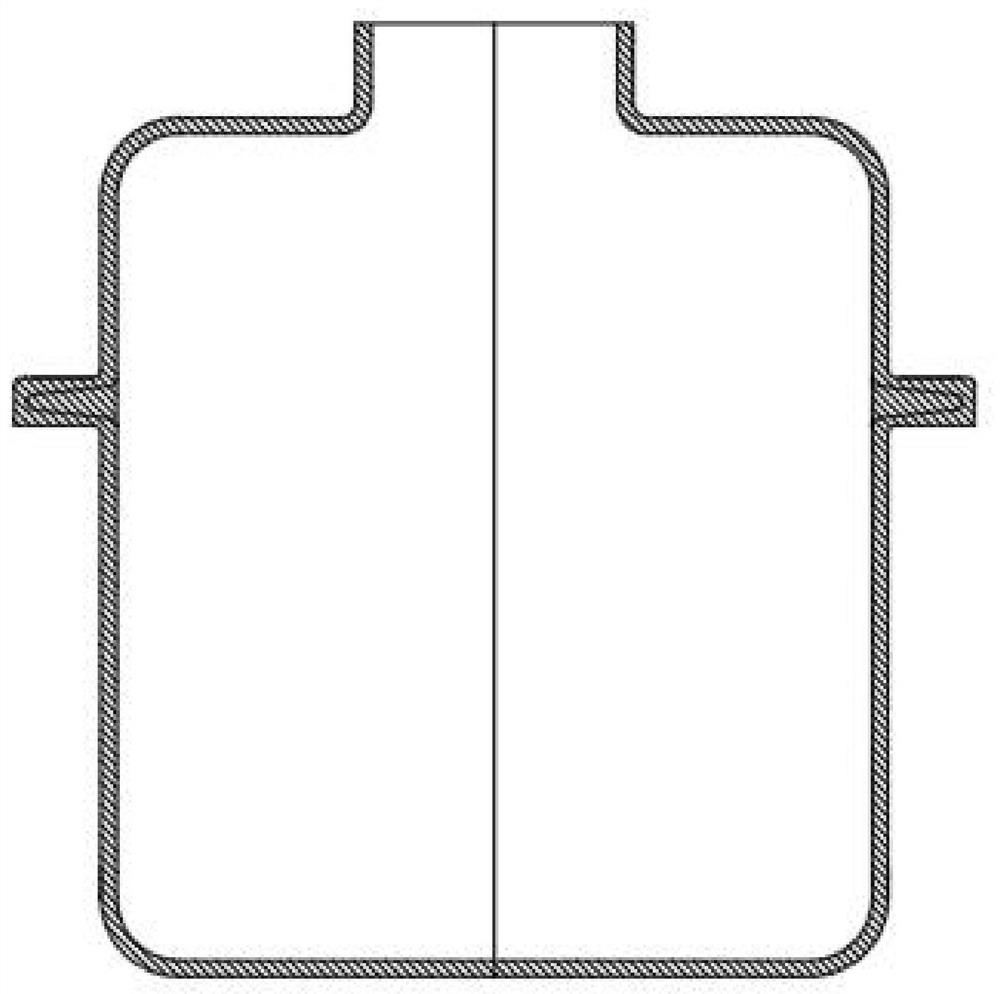

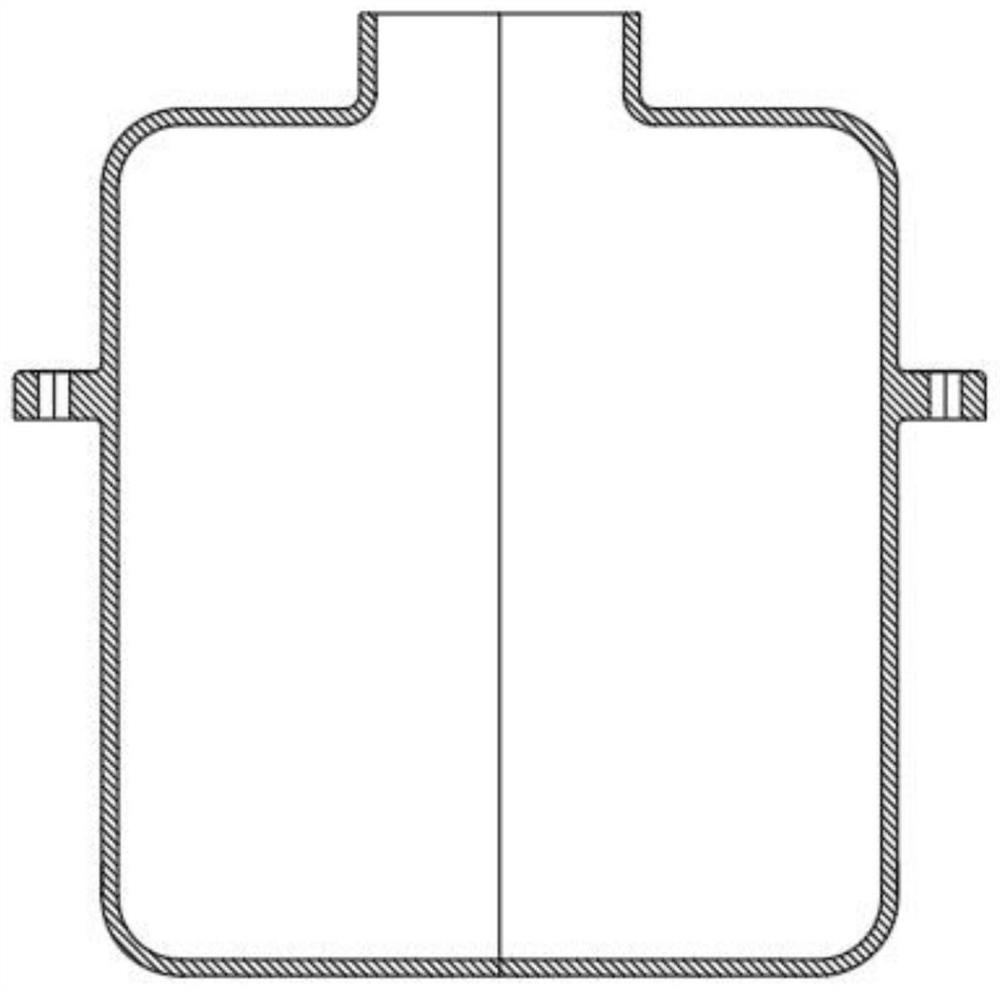

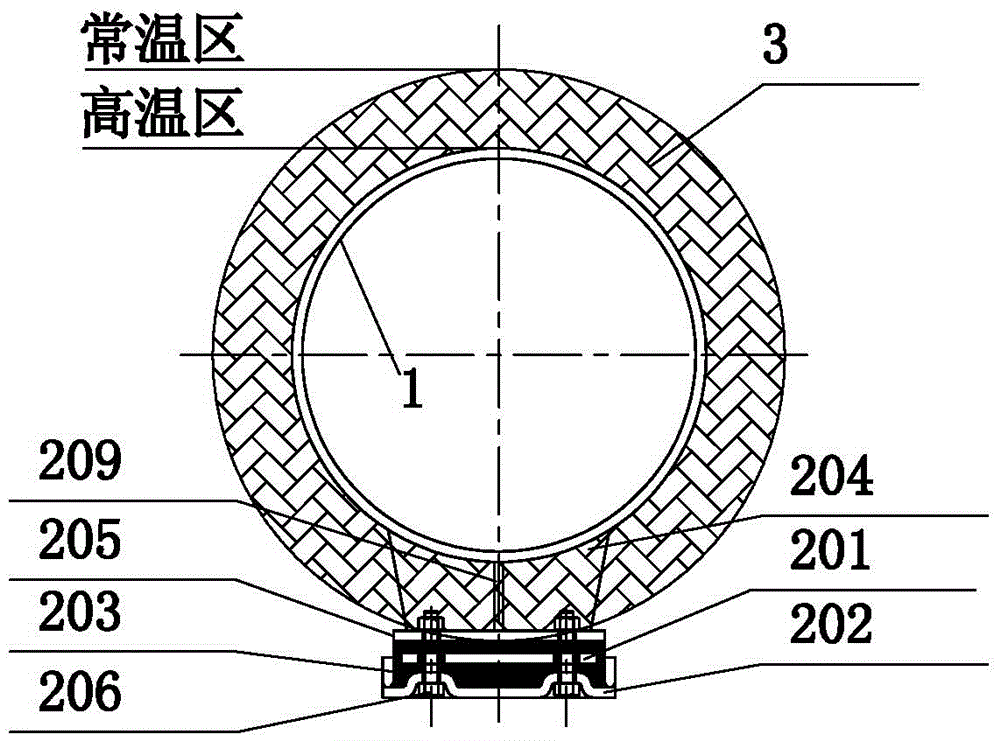

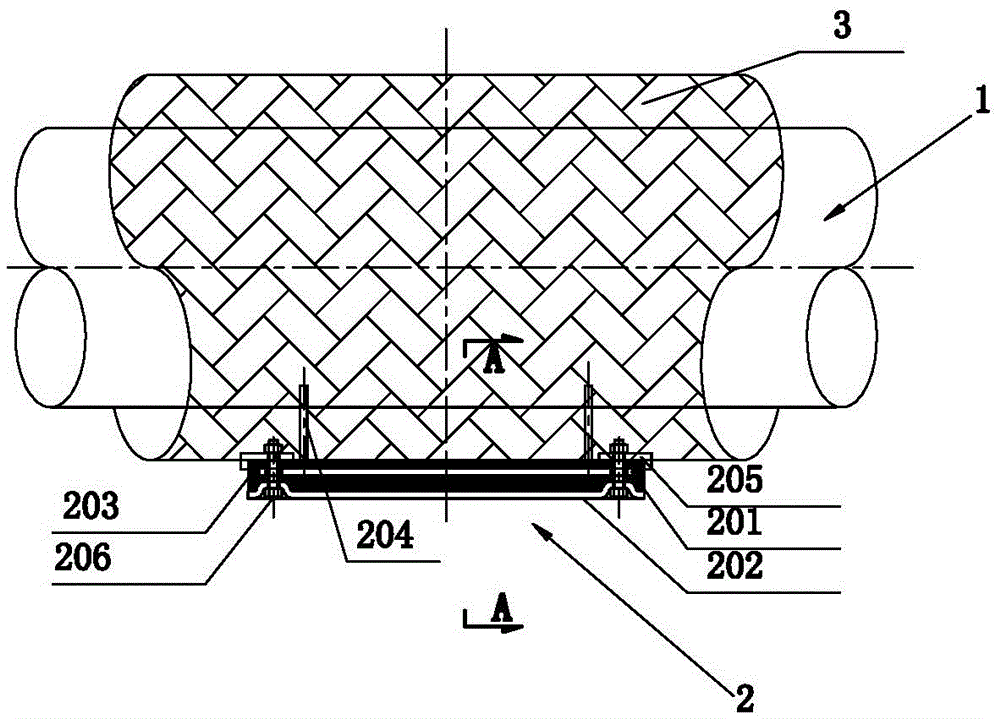

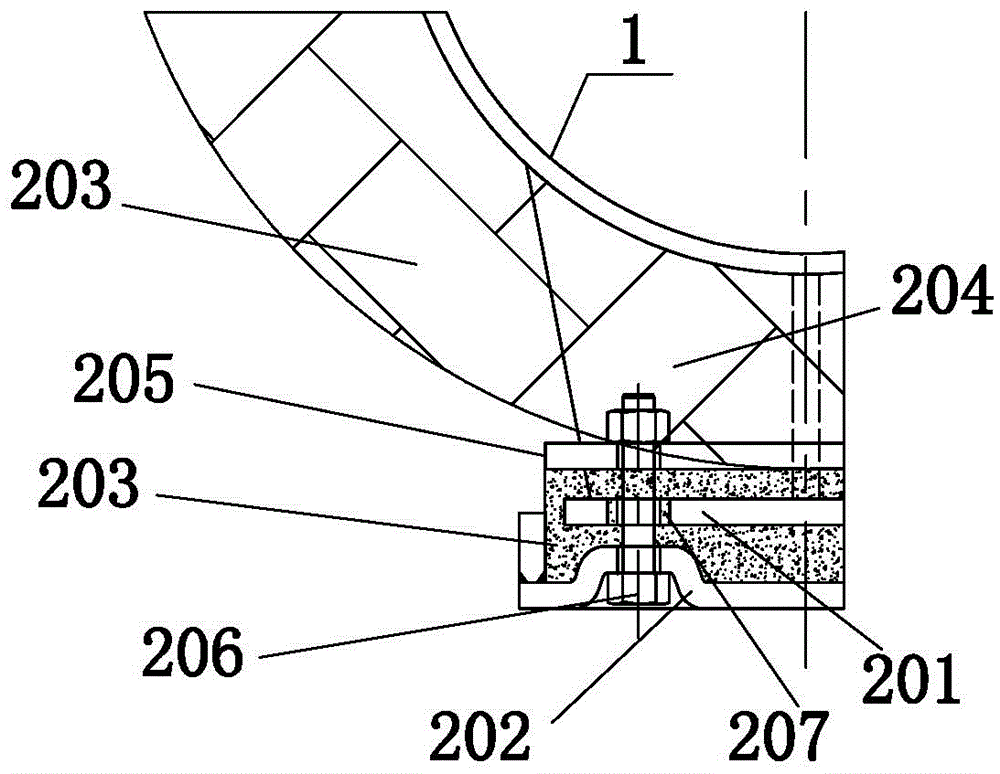

Flat plate type heat-insulation and energy-saving pipe carrier

ActiveCN104653875AReduce heat lossSimple structurePipe supportsThermal insulationInsulation layerEngineering

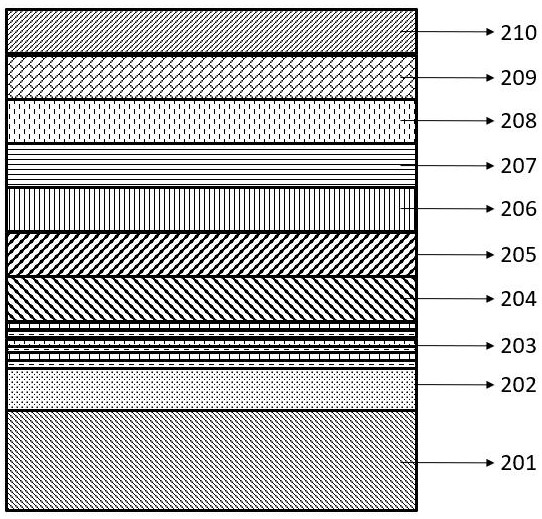

The invention relates to a flat plate type heat-insulation and energy-saving pipe carrier, which comprises a base (2) and a heat insulation layer (3), wherein the base (2) is used for supporting a pipeline (1), the heat insulation layer (3) coats the surface of the pipeline, and the pipeline is supported on a foundation through the base (2). The flat plate type double-heat insulation and energy-saving pipe carrier is characterized in that the base (2) mainly consists of an upper bottom plate (201), a box type lower bottom plate (202), an integral type heat insulation block (203), a rib plate (204) and a pressing plate (205), wherein the upper bottom plate (201) is cast in the integral type heat insulation block (203), the integral type heat insulation block (203) is arranged on the box type lower bottom plate (202), the upper bottom plate (201) and the box type lower bottom plate (202) are fixedly connected in a heat insulation way through the pressing plate (205) and a pressing bolt (206) at the two ends, the lower end of the rib plate (204) penetrates through the integral type heat insulation block (203) and is welded on the upper bottom plate (201), and the upper end of the rib plate (204) penetrates through the heat insulation layer (3) and is welded with the pipeline (1). The flat plate type heat-insulation and energy-saving pipe carrier has the advantages that the heat insulation effect is good, and the structure is simple.

Owner:JIANGSU HONGXIN REVOLVING COMPENSATOR TECH

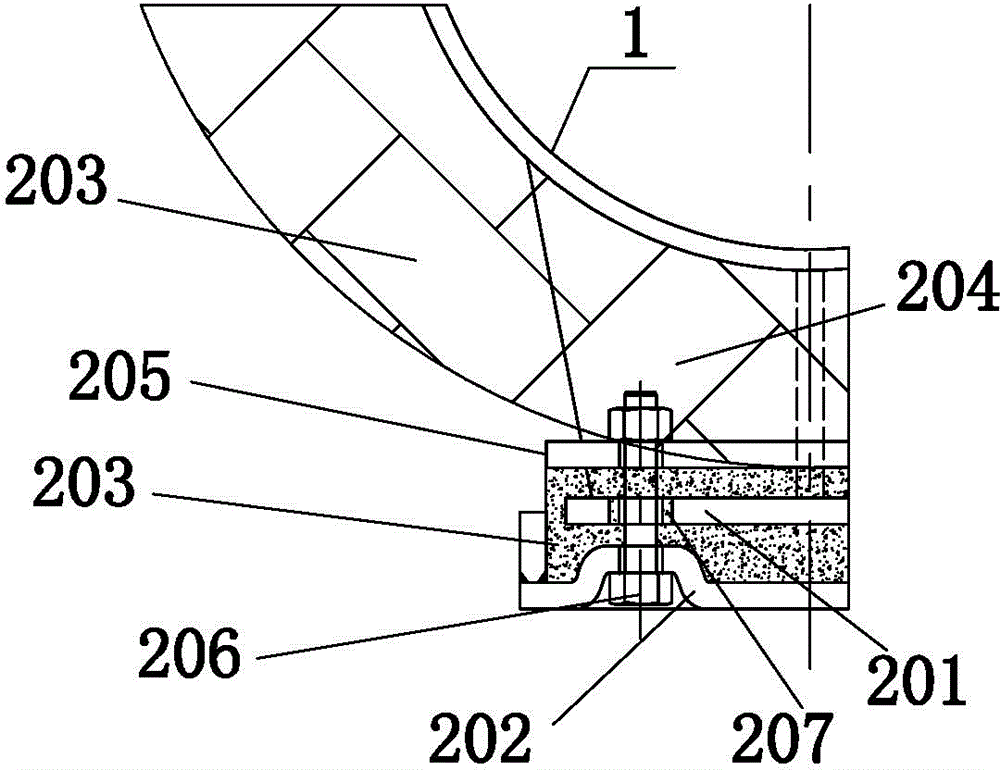

Motor rotating shaft with spoke iron plates

InactiveCN102606611AImprove internal ventilationSimple structureShaftsEngineeringStructural engineering

The invention discloses a motor rotating shaft with spoke iron plates, which solves the technical problems that the stress of the cross sections of spoke iron plates perpendicular to a shaft is large, and the shaft is easy to break in an existing motor rotating shaft with spoke iron plates. The motor rotating shaft comprises a shaft (1), the wide spoke iron plate, the narrow spoke iron plate and a fan-shaped air blocking plate (4), both the wide spoke iron plate (2) and the narrow spoke iron plate (3) are fixedly arranged on the shaft (1) along the direction of the shaft (1) and are evenly and equidistantly spaced, and a cylindrical unloading through hole (6) and an unloading groove (7) are symmetrically arranged on each of the wide spoke iron plate and the narrow spoke iron plate. The motor rotating shaft has the advantages of simple structure, low cost and convenience in processing and installation.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

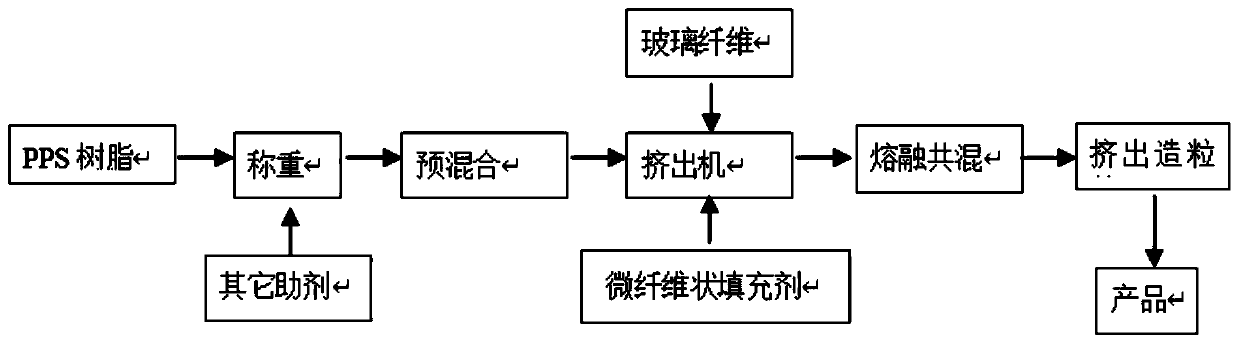

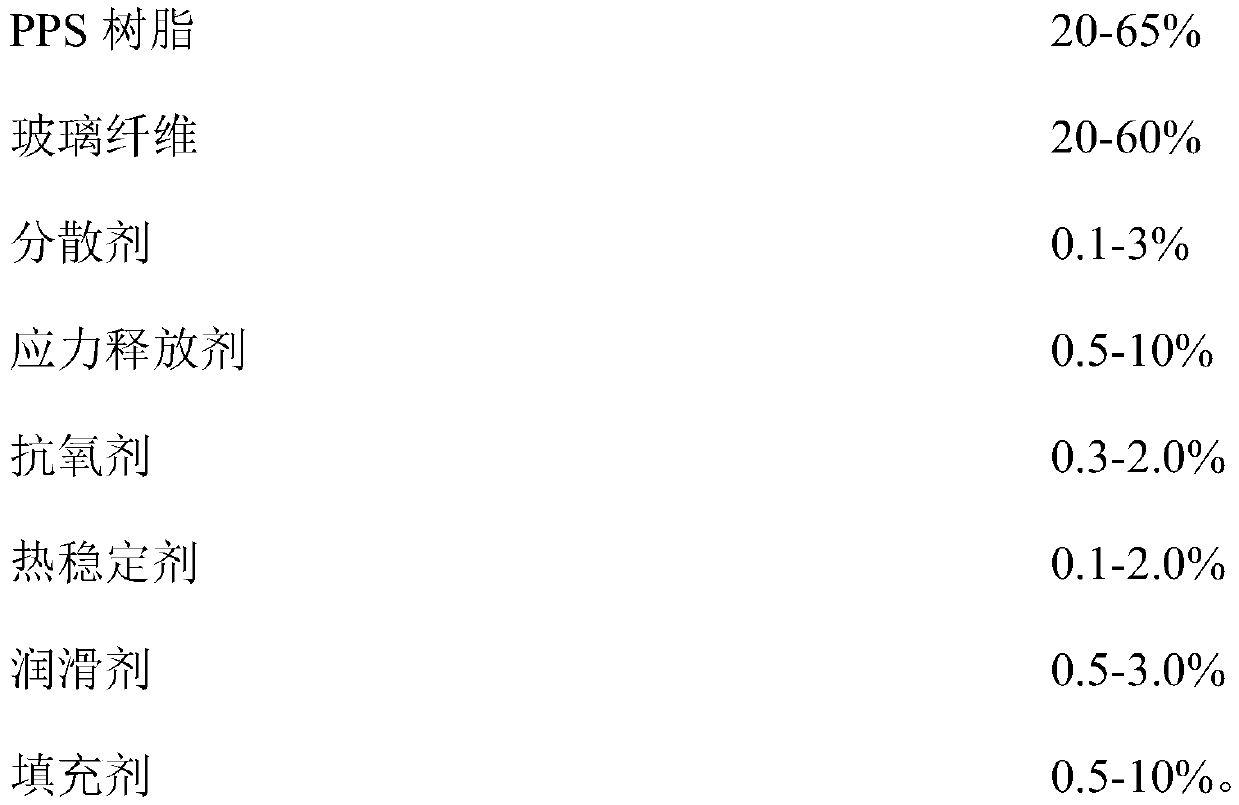

Polyphenylene sulfide resin composition and application thereof

The invention relates to a polyphenylene sulfide (PPS) resin composition and application thereof. The polyphenylene sulfide resin composition comprises the following components by mass percentage: 20-65% of PPS resin, 20-60% of glass fiber, 0.1-3% of a dispersing agent, 0.5-10% of a stress releasing agent, 0.3-2.0% of an antioxidant, 0.5-3.0% of a lubricating agent and 0.5-10% of a filling agent.According to the invention, the stress releasing agent is added into a PPS-glass fiber composition system, so that partial crystallization regularity of PPS is destroyed, also the free space volume among PPS molecules is also increased, and timely release of thermal stress and mechanical stress generated in the material processing process is facilitated; furthermore, all the components of the resin composition are compounded according to a specific proportion, so that the problem of large internal stress of the glass fiber reinforced PPS engineering plastic is effectively solved, the stabilityof an electroplated circuit is improved, and meanwhile, good mechanical properties, dielectric properties and processability are maintained.

Owner:SHENZHEN HALCYON NEW MATERIALS

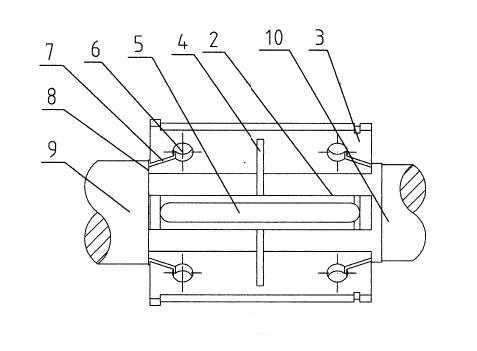

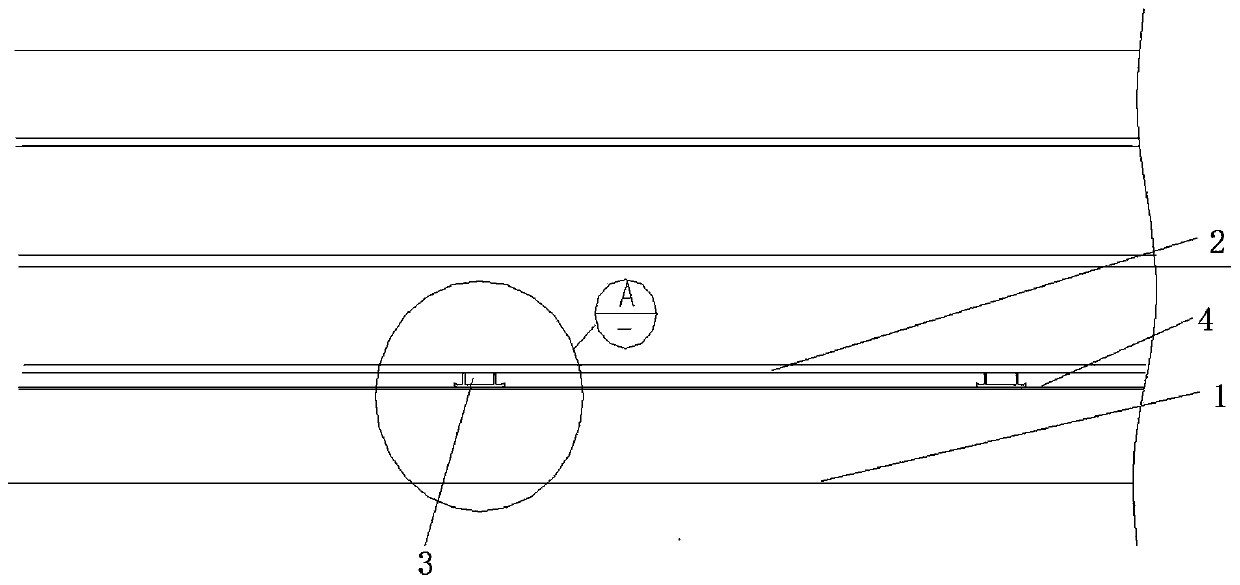

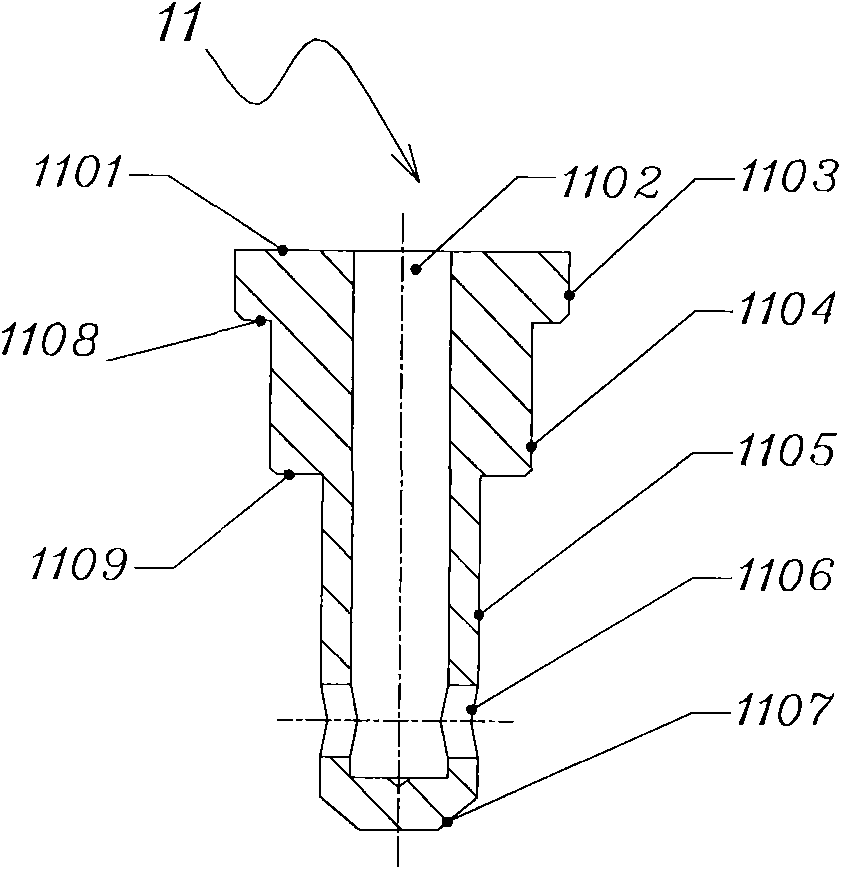

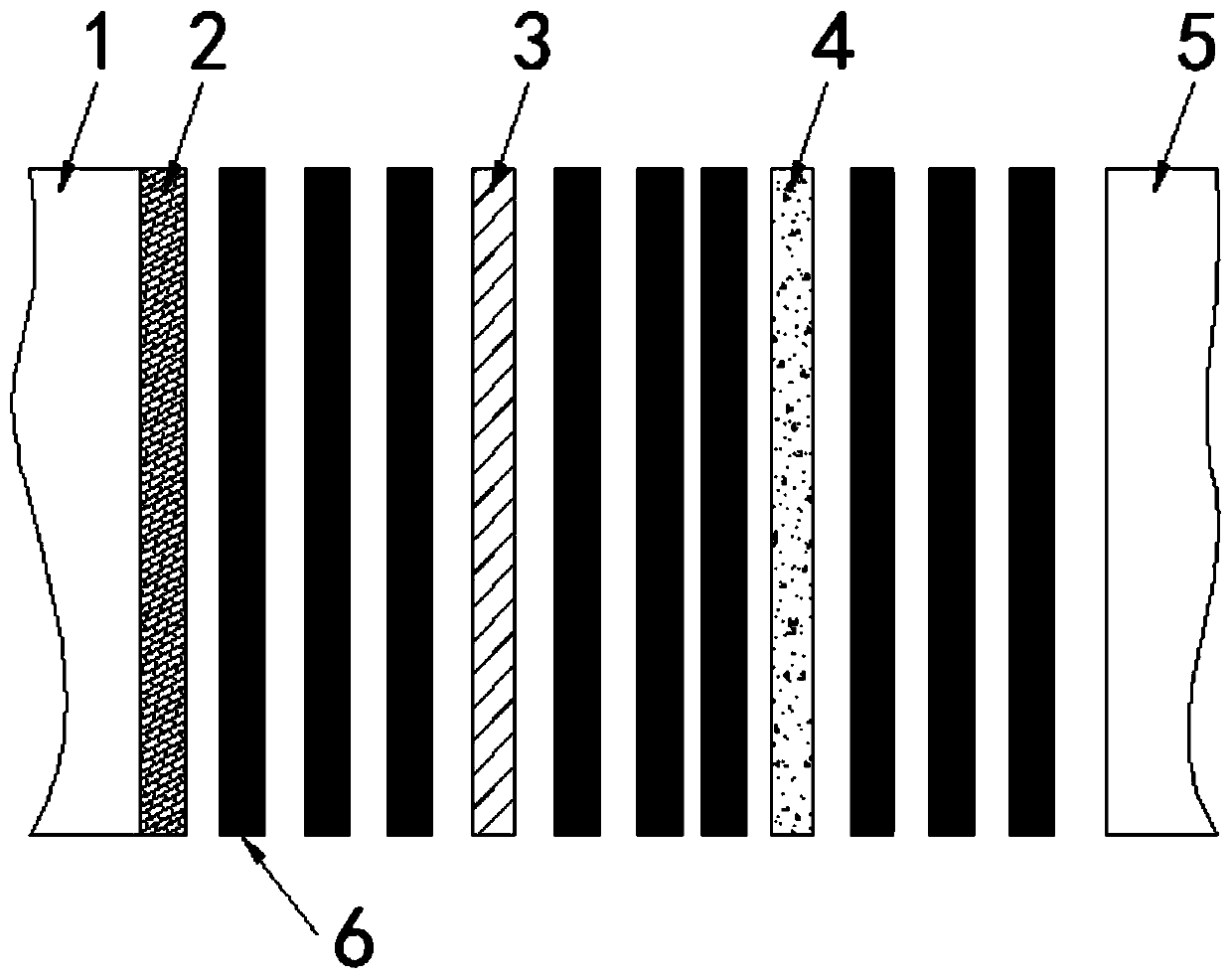

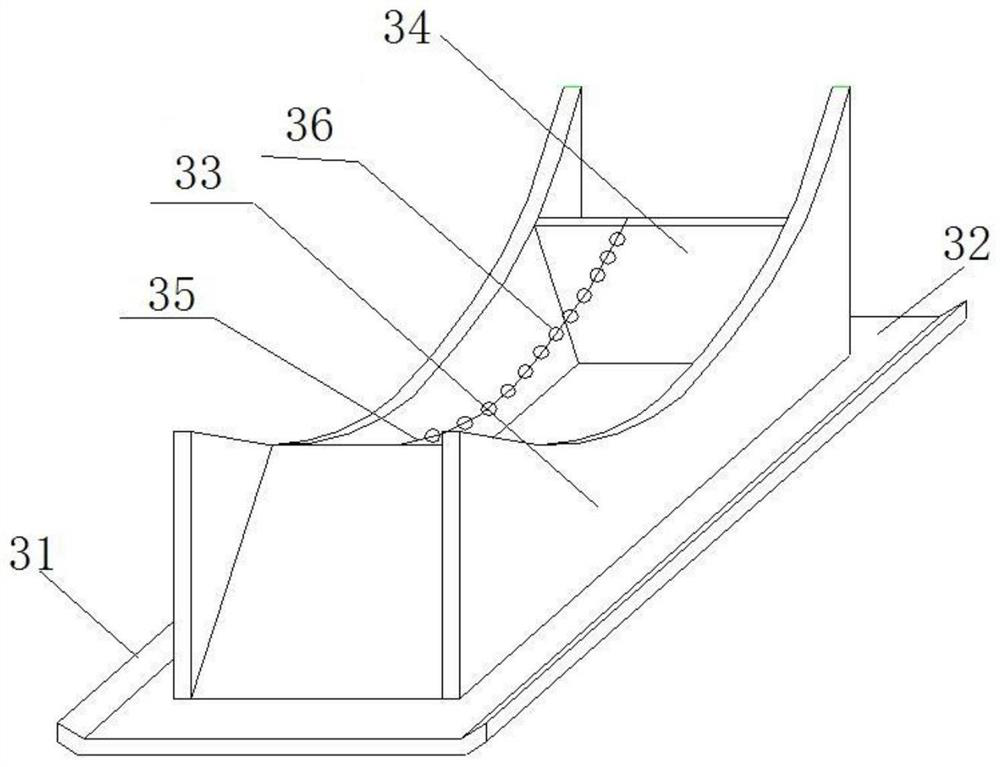

Pipe jacking sleeve built-in pipeline dragging structure and dragging method

ActiveCN110578832AGuarantee the construction qualityControl construction qualityPipe laying and repairPetroleum engineering

The invention discloses a pipe jacking sleeve built-in pipeline dragging structure. The structure involves a sleeve and a built-in pipe, wherein a plurality of bracket mounting plates are arranged atintervals in the sleeve in the length direction, a bracket is arranged on each bracket mounting plate, a sliding wheel device is arranged on each bracket, the built-in pipe is supported on the brackets, the built-in pipe can slide on the surfaces of the brackets, the bracket mounting plates are fixedly connected with the sleeve, and the bracket mounting plates are fixedly connected with the brackets. The technical problems that in the prior art, in the dragging process, the built-in pipe is damaged and a joint is prone to break are solved.

Owner:CHINA FIRST METALLURGICAL GROUP

Magnetic valve

ActiveCN101988583BSolve the stressReduce wearOperating means/releasing devices for valvesValve members for absorbing fluid energyMagnetic valvePressure difference

The invention relates to a magnetic valve, comprising a valve seat, a sleeve fixedly connected with the valve seat, a coil arranged outside of the sleeve, a movable core arranged in the sleeve, a static core and a reset spring arranged between the movable core and the static core, wherein a sealing element is arranged at one end of the movable core opposite to the other end close to the static core, and a valve port is arranged at the side opposite to the sealing element in a valve body; and the sealing element comprises a major diameter part in the central cavity body at the end part of the movable core, a middle part and a minor diameter part which partially extends out of the central cavity body at the end part of the movable core. The magnetic valve also is provided with a balance channel passing through the sealing element, so that no pressure difference generates at the two sides of the sealing element, thus avoiding instable magnetic valve flow due to action of the sealing element resulted from the pressure difference, and solving the problem of larger stress of the sealing element, thereby reducing abrasion of the sealing element.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Portable foldable shear type lifter

The invention discloses a portable foldable shear type lifter. The portable foldable shear type lifter comprises bases, transitional plates, first shear arms, second shear arms and worktables. At least two hydraulic cylinders are fixed on the bases; the transitional plates are fixed on the end sides of telescopic rods of the hydraulic cylinders; the first connecting ends of the first shear arms are connected to the bases; the second connecting ends of the first shear arms are connected to the transition plates; the third connecting ends of the second shear arms are connected to the transitional plates; and the fourth connecting ends of the second shear arms are connected to the worktables. By designing a moving scheme of the shear type lifter, two ends of the first shear arms and the second shear arms are correspondingly hinged together according to the characteristics of parallelogram. The whole set of device is powered by a hydraulic system and the strokes of the pistons are changed to lift the lifter, so that the problems that an existing shear type lifter is slow in lifting speed, relatively large in stress of the hydraulic cylinders at the beginning of work, inconvenient to carry and poor in safety performance are solved.

Owner:合肥佳航机电设备有限公司

Furnace top distributing gear

ActiveCN101580885BCompact layoutMeet transmission requirementsBlast furnace componentsBlast furnace detailsGear driveMechanical engineering technology

The invention discloses a furnace top distributing gear for distributing materials on the top of an iron-fining furnace, belonging to the technical field of mechanical engineering. A rotating motor and a tilting motor are independently driven by a set of differential mechanisms, wherein differential mechanism drive and previous-stage drive adopt all-gear drive, the previous-stage drive of a central sun wheel of the differential mechanism adopts gear drive with common drive ratio, and a furnace pot is tilted by a three-ring speed reducer. The furnace top distributing gear can realize the functions of furnace pot tilting, furnace pot rotation and furnace pot tilting and rotation, has the advantages of compact structure, reliable drive, stable work, high drive efficiency, long service life, little maintaining workload and convenient furnace pot replacement, can be used for blast furnace engineering of various types or other places where loose unpacked materials are delivered.

Owner:CISDI ENG CO LTD

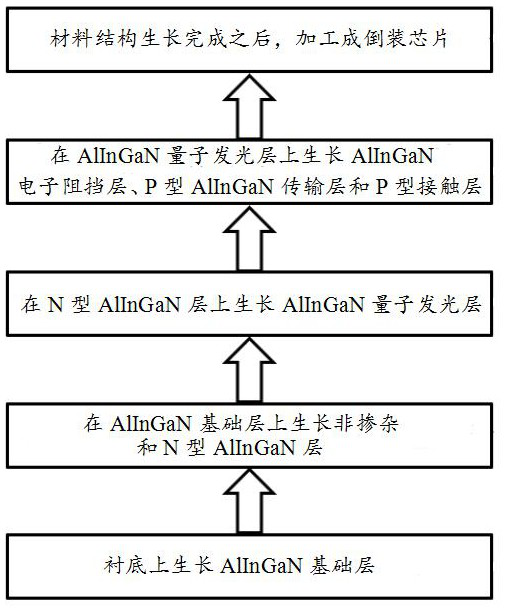

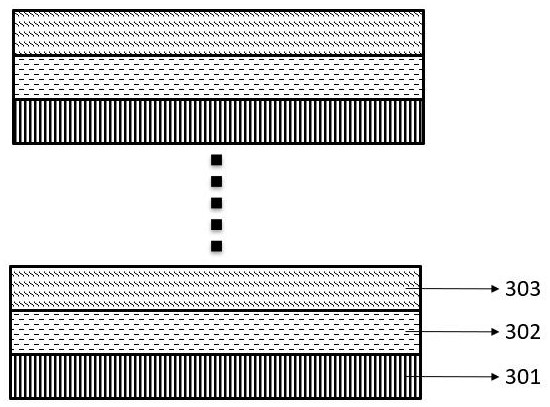

Epitaxial structure of UVB chip and UVB chip

PendingCN114068778ASolve the stressNo problem of high defect densityMaterial nanotechnologySemiconductor devicesQuantum wellUltraviolet lights

The invention relates to the technical field of ultraviolet light emitting diode chips, and particularly relates to an epitaxial structure of a UVB chip and the UVB chip. The lattice strain layer is arranged between the Alx1Iny1Ga1-x1-y1N quantum barrier layer with the high Al component and the Alx2Iny2Ga1-x2-y2N quantum well layer with the low Al component to play a role in connection and transition, and the problem of a large stress caused by a large lattice constant difference is efficiently solved; and meanwhile, the Al content in the lattice strain layer is between x1 and x2 so that the problem of high defect density caused by sudden and too fast migration of Ga is avoided, and the luminous efficiency is further improved.

Owner:ZHIXIN SEMICON (HANGZHOU) CO LTD

Connecting device capable of reducing stress of heating pipes of roasting furnace

ActiveCN108679351AAvoid tearingSolve the stressPipe supportsNon-rotating vibration suppressionWeld seamEngineering

The invention discloses a connecting device capable of reducing stress of heating pipes of a roasting furnace. The device comprises an outer furnace barrel in which an inner furnace barrel is arranged, wherein a first heating pipe, a second heating pipe, a third heating pipe and a fourth heating pipe are correspondingly arranged around the inner furnace barrel and are all connected through arc-shaped bends; one end of the first heating pipe and one end of the third heating pipe are provided with positioning plates; a damping device is arranged at one end of each positioning plate; two fixing rods are fixed to the sidewall of one inner end of the outer furnace barrel; and a mounting plate is fixed to the lower end of each fixing rod. According to the device, the problem that two sections ofexisting heating pipes at each layer are connected through an annular pipe which leads to high stress can be solved; the arc-shaped bends are used for connecting, so that the stress applied to the heating pipes of the roasting furnace is reduced, and welding seams of the heating pipes are prevented from tearing, and as a result, the running time of the heating pipes of the roasting furnace can beincreased; and the convenience of use is ensured.

Owner:HENAN JUNHUA DEV

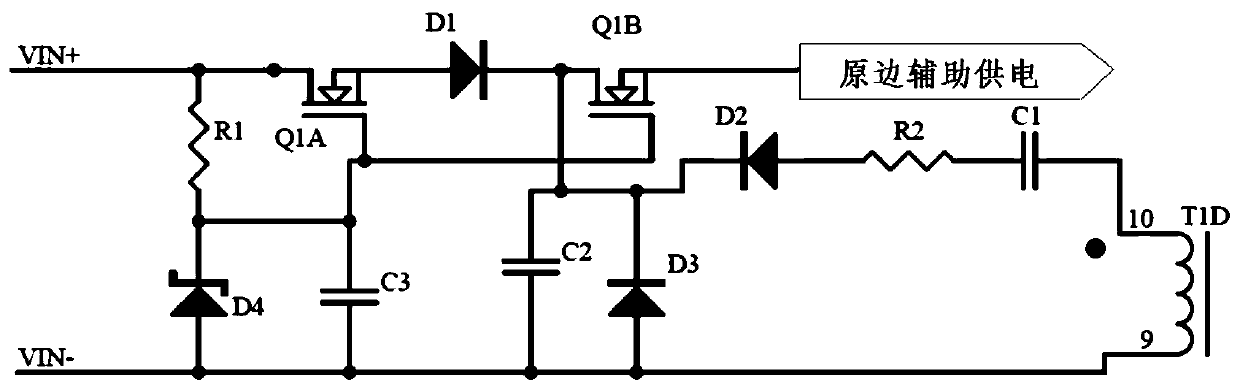

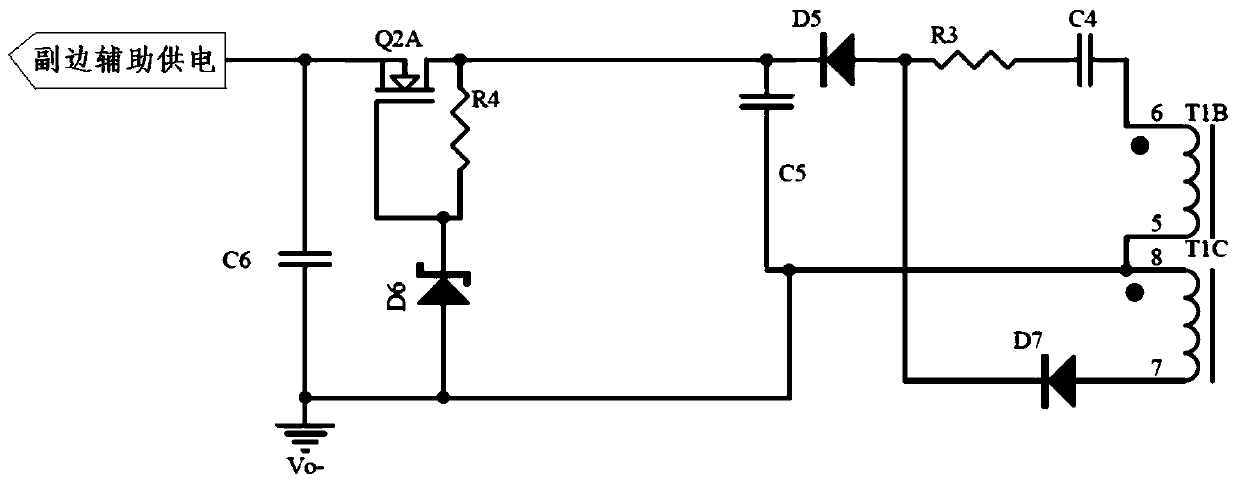

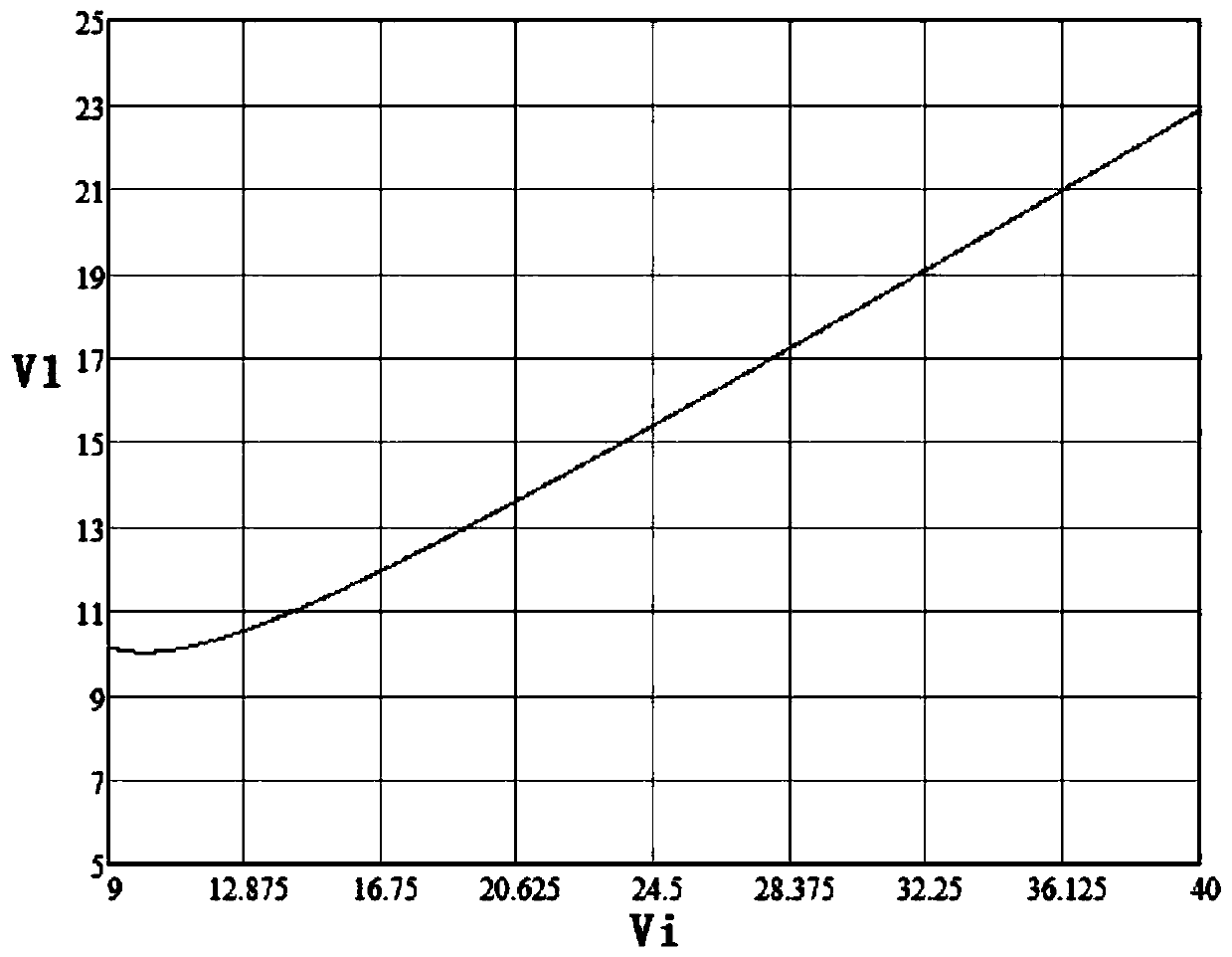

Auxiliary power supply circuit of wide-input-range power supply module

ActiveCN109980901ASolve the device stressInput stablePower conversion systemsIntegrated circuitVoltage

The invention discloses an auxiliary power supply circuit of a wide-input-range power supply module. The auxiliary power supply circuit comprises a primary auxiliary power supply circuit and a secondary auxiliary power supply circuit, wherein the primary auxiliary power supply circuit and the secondary auxiliary power supply circuit adopt a forward and reverse excitation power supply mode, the primary auxiliary power supply circuit comprises an auxiliary winding T1D, the auxiliary winding T1D is wound by adopting a single winding, the secondary auxiliary power supply circuit comprises an auxiliary winding T1B and an auxiliary winding T1C, the auxiliary winding T1B and the auxiliary winding T1C are wound by adopting a mode of superposing a forward excitation winding and a flyback winding, the auxiliary winding T1B adopts a half turn, and the auxiliary winding T1C is an integral turn; the method can meet the power supply demand for the integrated circuit when full-range input is performed and is small in stress of the device when a high-end voltage input is performed.

Owner:ECU ELECTRONICS INDAL

Hollow lead-free plastic flat package

InactiveCN102709256ASolve the stressSolve the problem that cannot be plastic sealedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

The invention discloses a hollow lead-free plastic flat package, belonging to the technical field of semiconductor packages. The hollow lead-free plastic flat package comprises a carrier, wherein a chip is fixed on the carrier, pins are uniformly distributed around the carrier, plastic package bodies are filled among the pins as well as between the pins and the carrier, the pins and chip are connected by bonding lines, a cover plate is arranged above the chip, the periphery of the cover plate is supported by the plastic package bodies, and a cavity is formed among the cover plate, the carrier and the plastic package bodies. The hollow lead-free plastic flat package solves the problem that an MEMS (Micro Electro Mechanical System) chip with an exposed movable structure and a photoelectric semiconductor chip are incapable of being subjected to plastic package and reduces the packaging stress.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

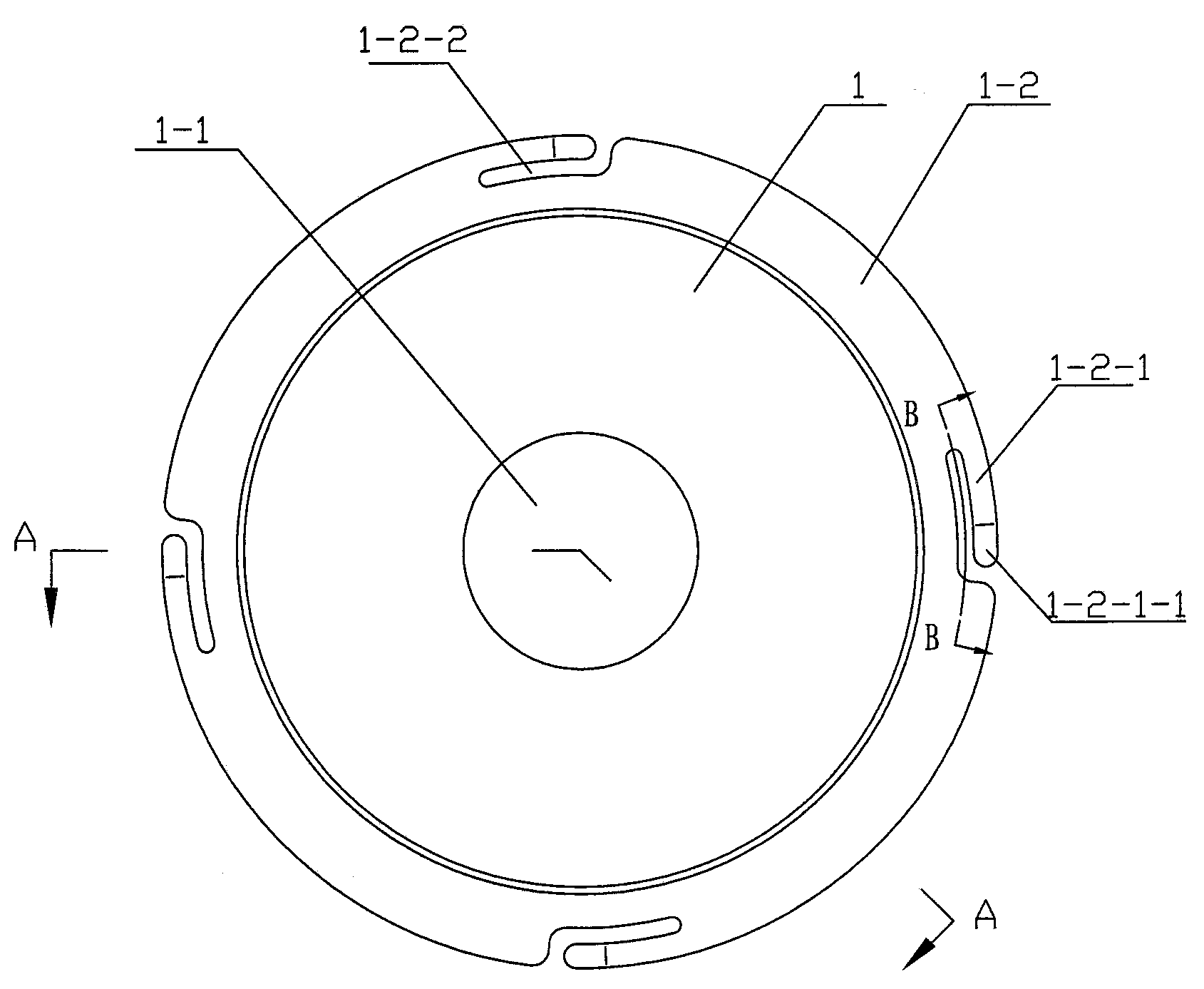

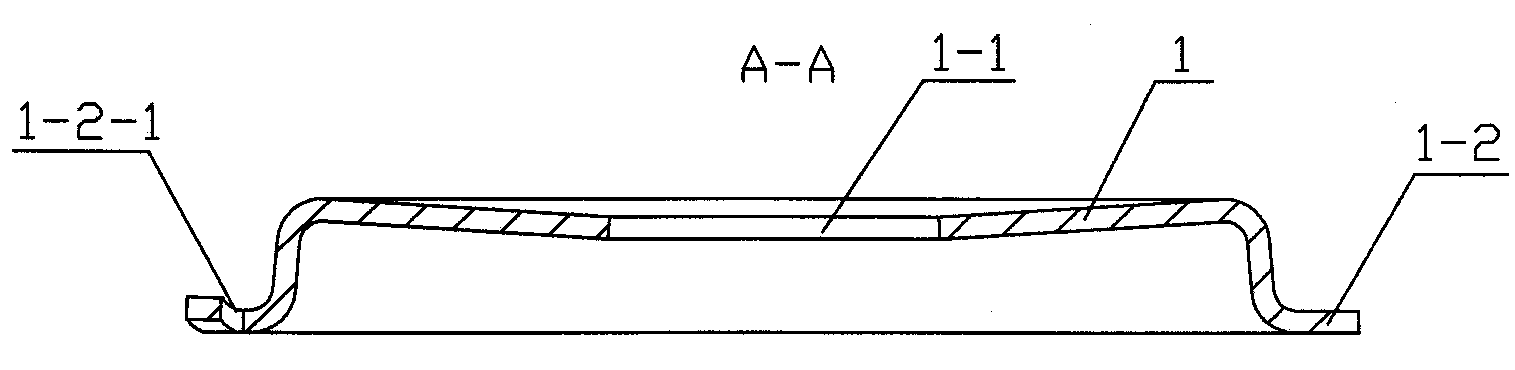

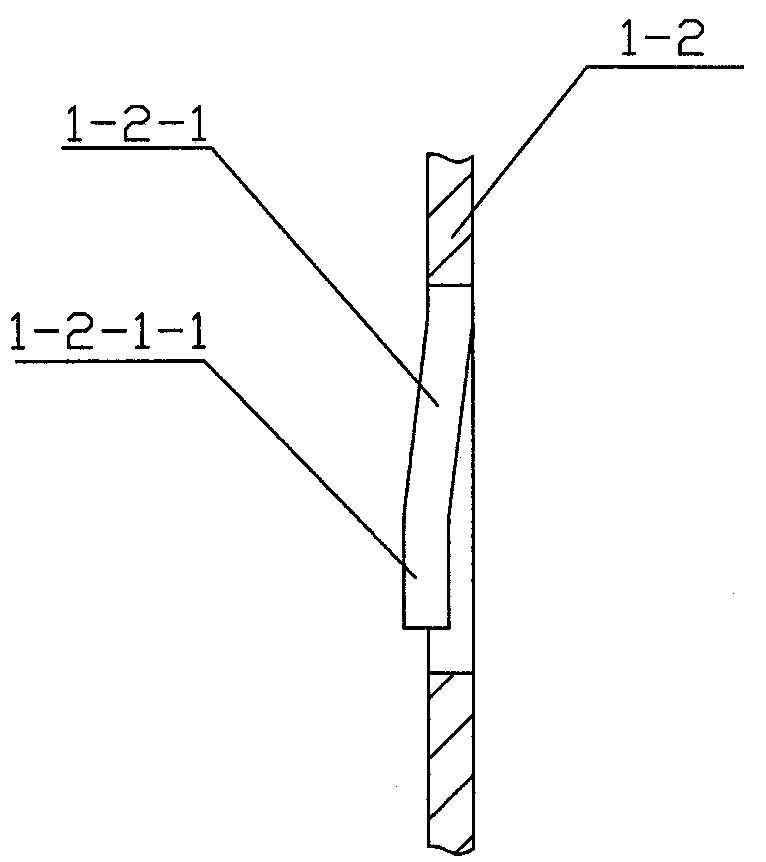

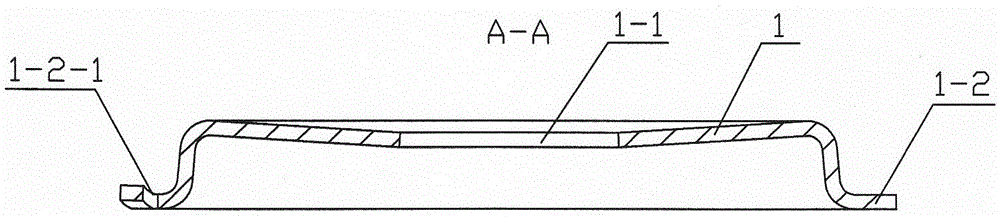

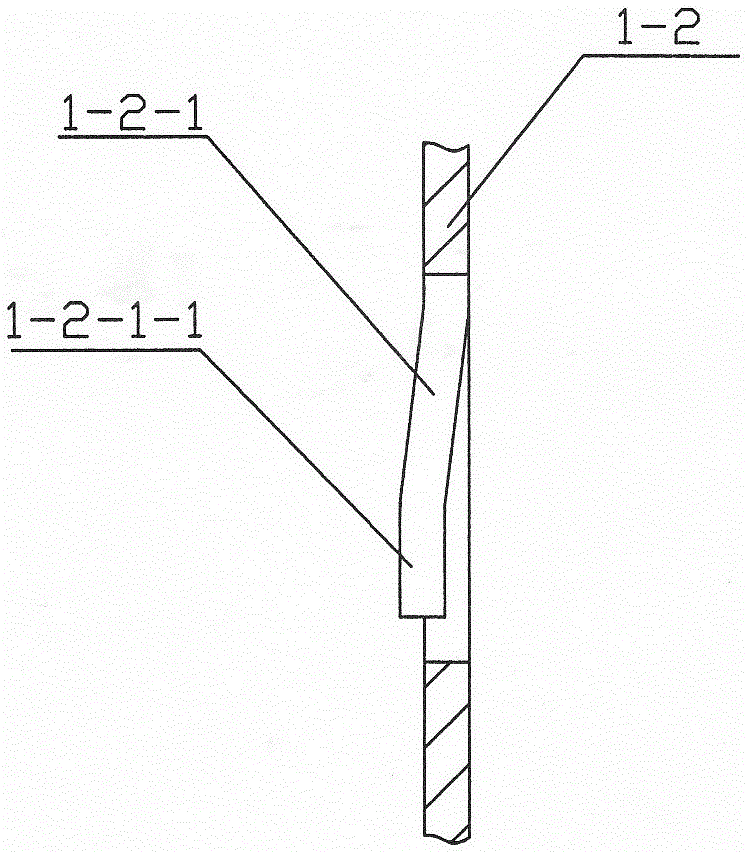

Turbocharger heat insulation cover

The invention provides a turbocharger heat insulation cover. A body of the heat insulation cover is an annular cover cap with one end provided with a heat insulation plate and the other end providedwith an opening, the center part on the heat insulation plate is provided with a center through hole, the opening end is provided with a circle of outwards flanged folding edge, the end plane of the folding edge is vertical to the axis line of the center through hole, the edge of the folding edge is provided with a plurality of elastic tongue plates projected out of the end plane of the folding edge, the elastic tongue plates are uniformly arranged on the edge of the folding edge, the inner side of each elastic tongue plate is provided with a stripped arc-shaped heat insulation belt, and a compression surface parallel to the end plane of the folding edge is formed at the top ends of the elastic tongue plates through folding and bending.

Owner:HUNAN TYEN MACHINERY

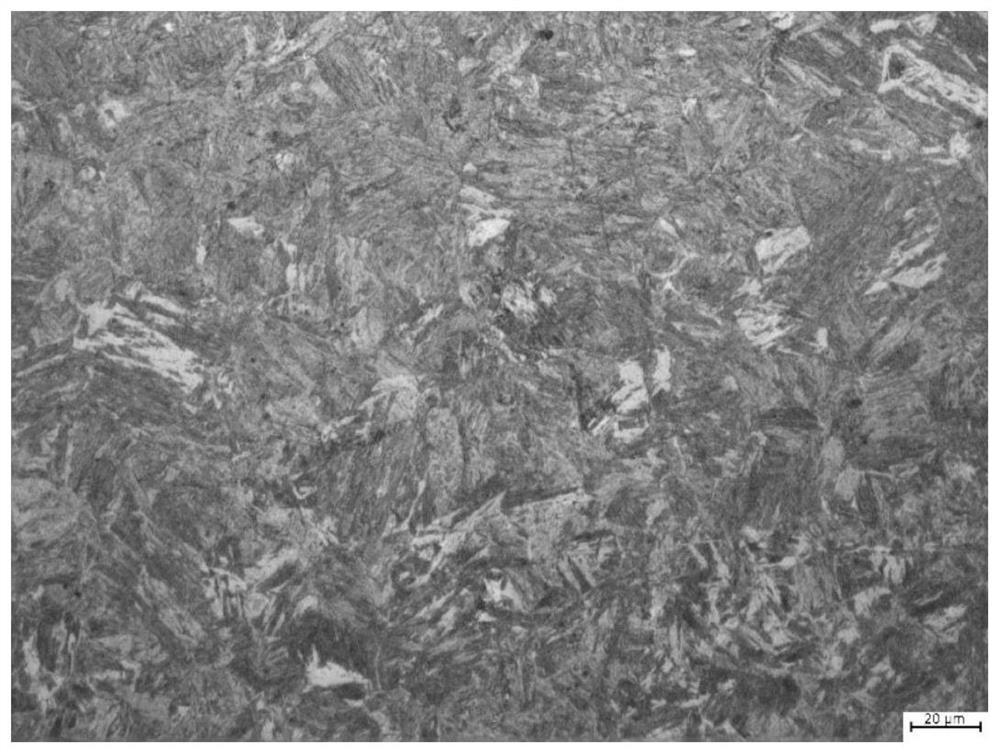

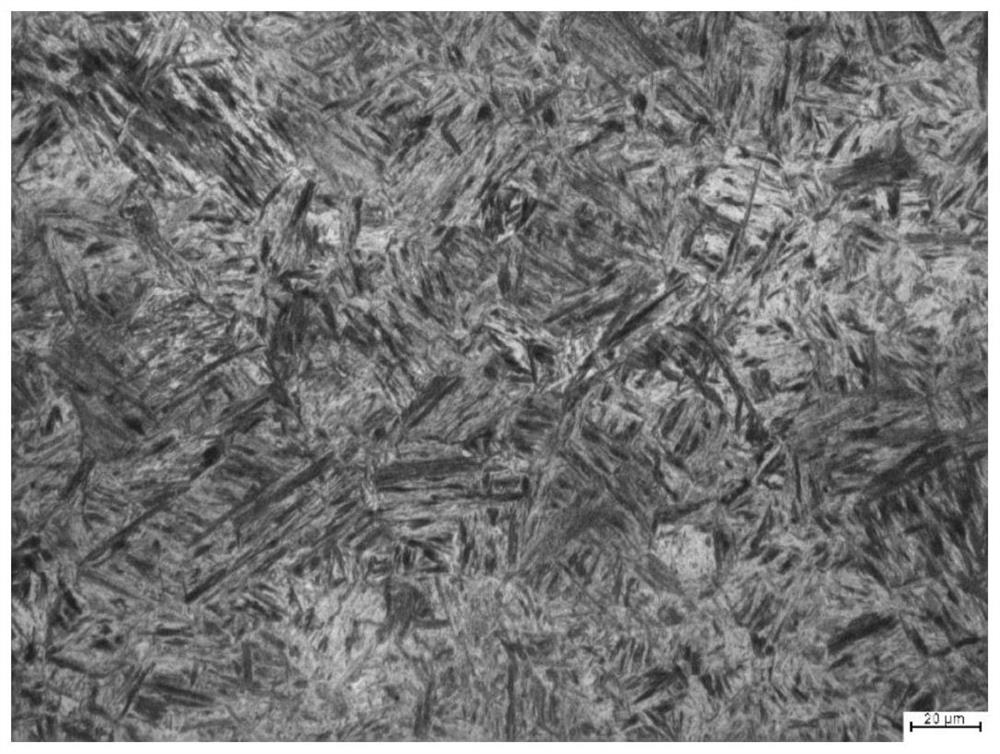

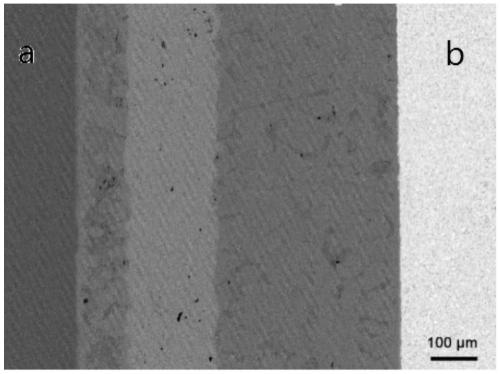

Wear-resistant steel above 500HB grade and production method thereof

The invention discloses wear-resistant steel with the grade of 500 HB or above. The wear-resistant steel comprises the following chemical components in percentage by mass: 0.15%-0.45% of C, 0.15%-0.50% of Si, 0.50%-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, less than or equal to 0.030% of V, less than or equal to 0.050% of Nb, 0.008%-0.025% of Ti, 0.50%-1.50% of Cr, less than or equal to 1.00% of Ni, 0.20%-0.80% of Mo, 0.025%-0.055% of Al, 0.0010%-0.0050% of B, 0.0010%-0.0018% of Mg, less than or equal to 0.0045% of N and the balance of Fe and inevitable impurities. The Brinell hardness of the steel-grade surface is greater than or equal to 470 HBW; the invention further discloses a production method of the wear-resistant steel. According to the high-strength wear-resistant steel plate for engineering machinery disclosed by the invention, the components of the wear-resistant steel with the steel grade of NM500-NM600 are formulated according to the national standard of GB / T 24186-2009 high-strength wear-resistant steel plate for engineering machinery, and the wear-resistant steel performance index meeting the national standard requirement is obtained.

Owner:NANJING IRON & STEEL CO LTD

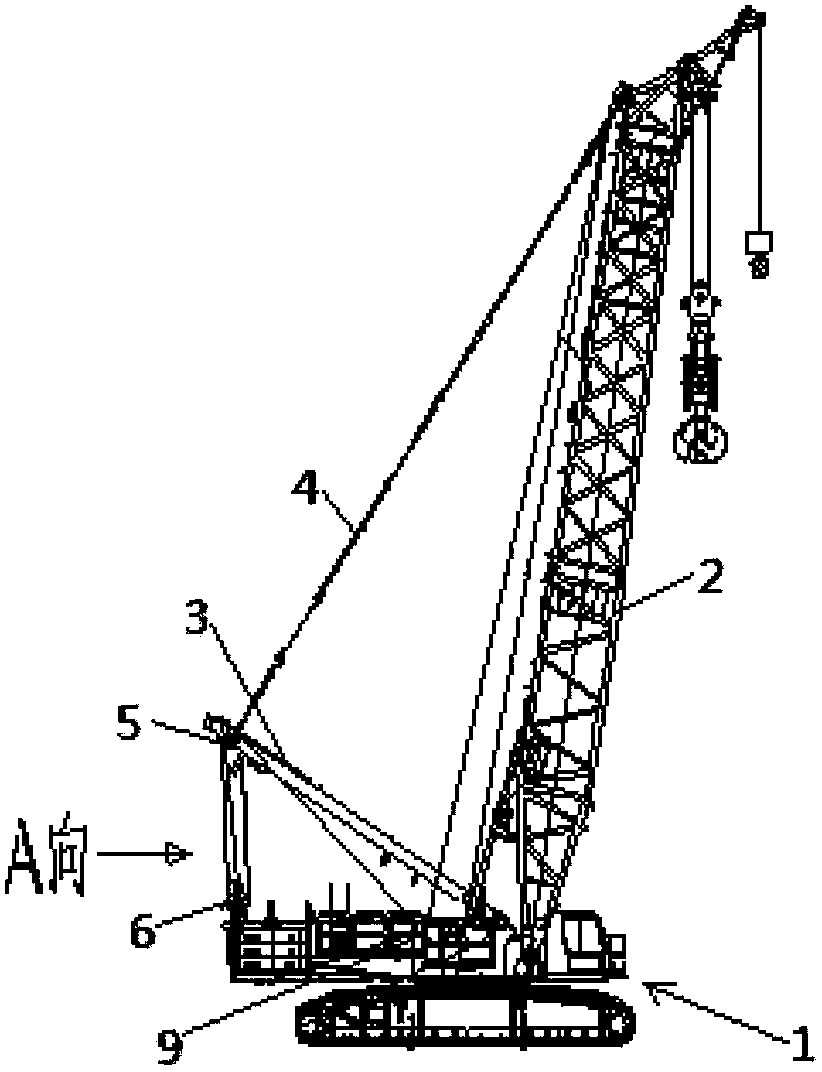

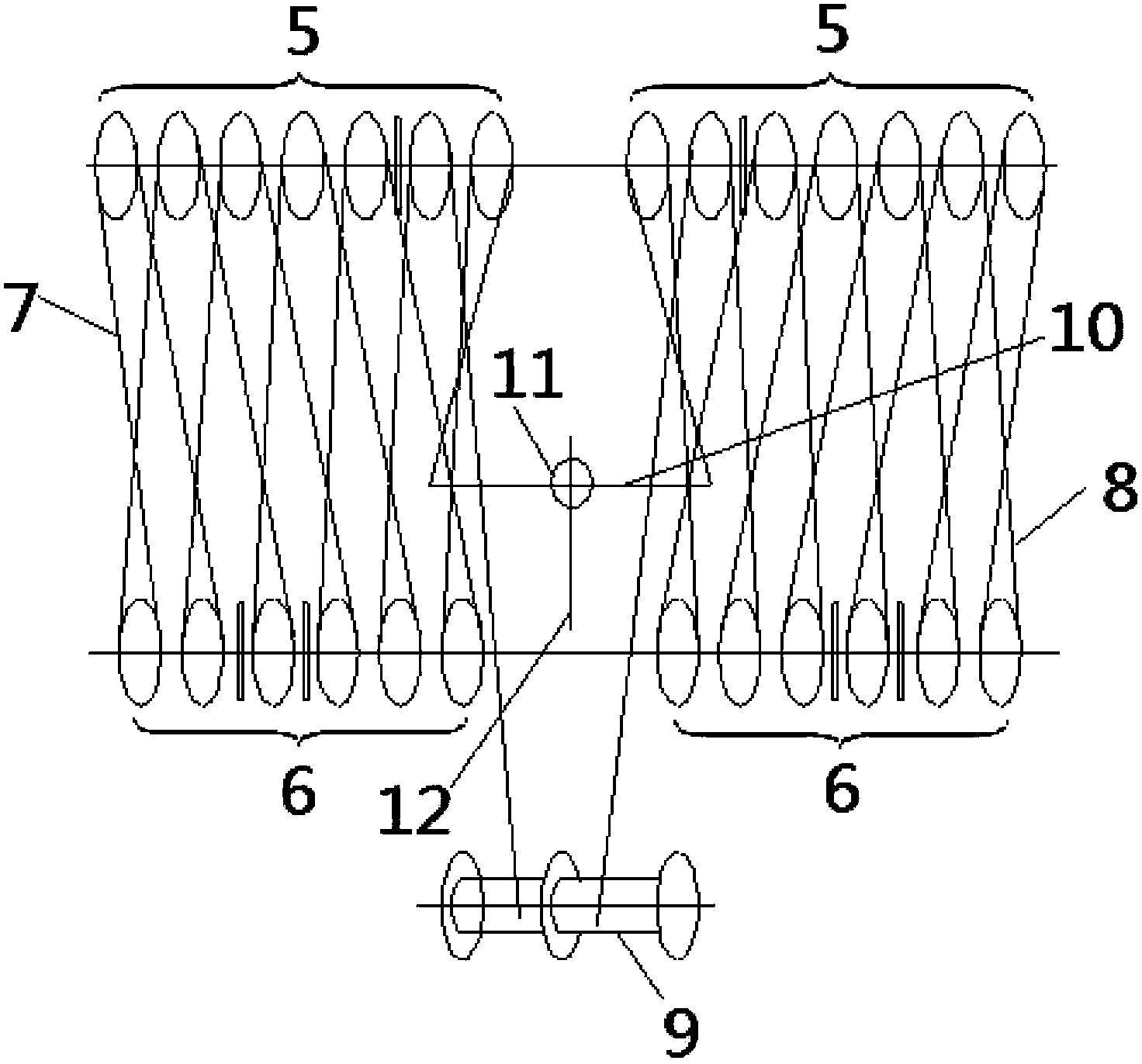

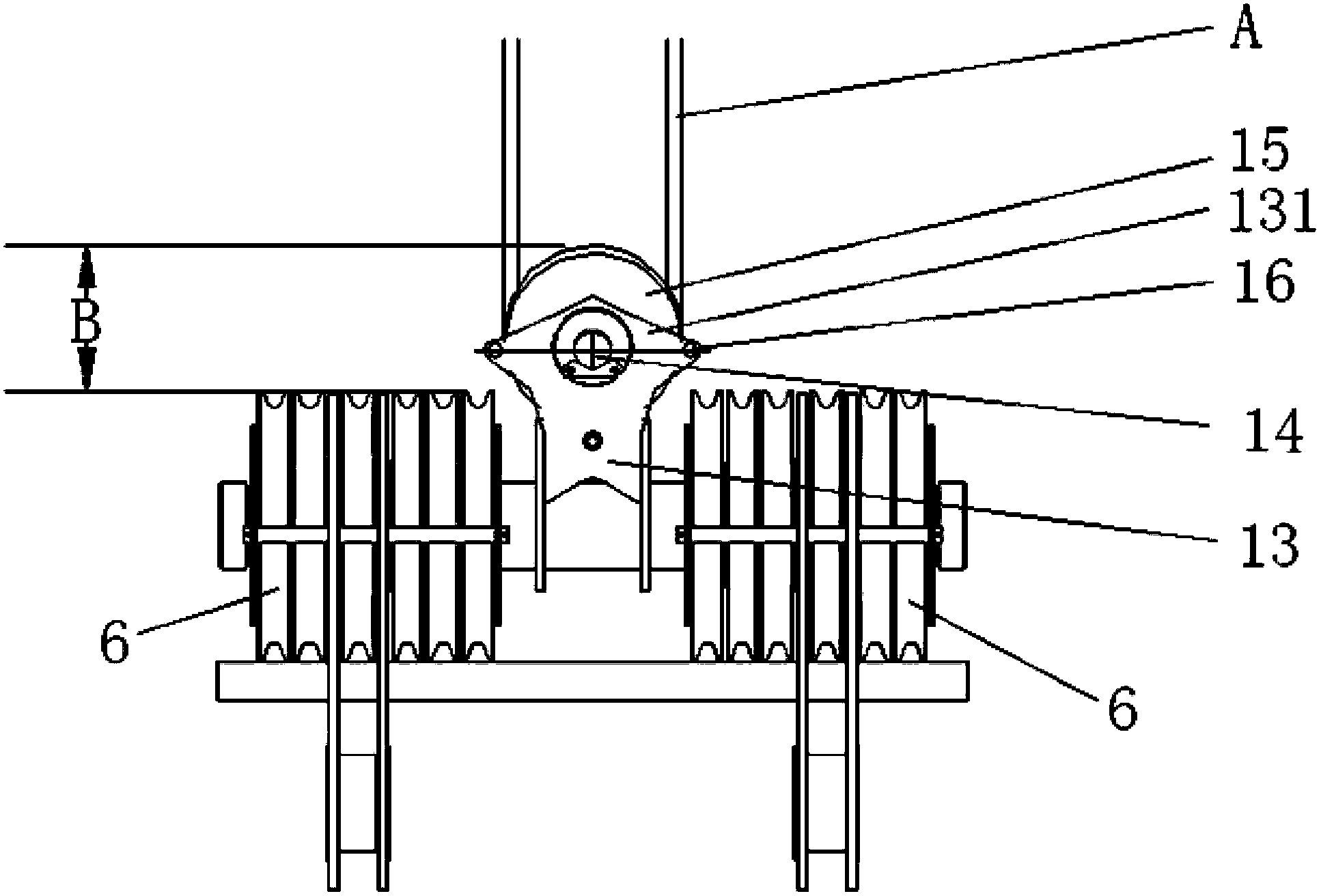

Steel wire balancer and special trolley provided with lifting arm support

The invention relates to a steel wire balancer and a special trolley provided with a lifting arm support. The steel wire balancer is used for balancing the length difference of steel wires wound on mast pulley blocks positioned on a left side and a right side, and the steel wire balancer comprises a support frame and a balance wheel, wherein the bottom of the support frame is fixed; the central hole of the balance wheel is connected to the support frame through a shaft; the axial line direction of the balance wheel is perpendicular to the mast pulley blocks; the side wall of the balance wheel is provided with an inner groove in a circle; and one end of one steel wire is fixed on a winding drum with variable amplitude winding, and the other end of the steel wire is wound on the mast pulley block positioned on one of the left side and the right side, then wound in the inner groove positioned on the lower middle part of the balance wheel and then wound on the mast pulley block positioned on the other one of the left side and the right side to be fixed on the winding drum with variable amplitude winding. The steel wire balancer disclosed by the invention has the advantages of small occupied space and limitless regulating quantity.

Owner:XCMG CONSTR MACHINERY

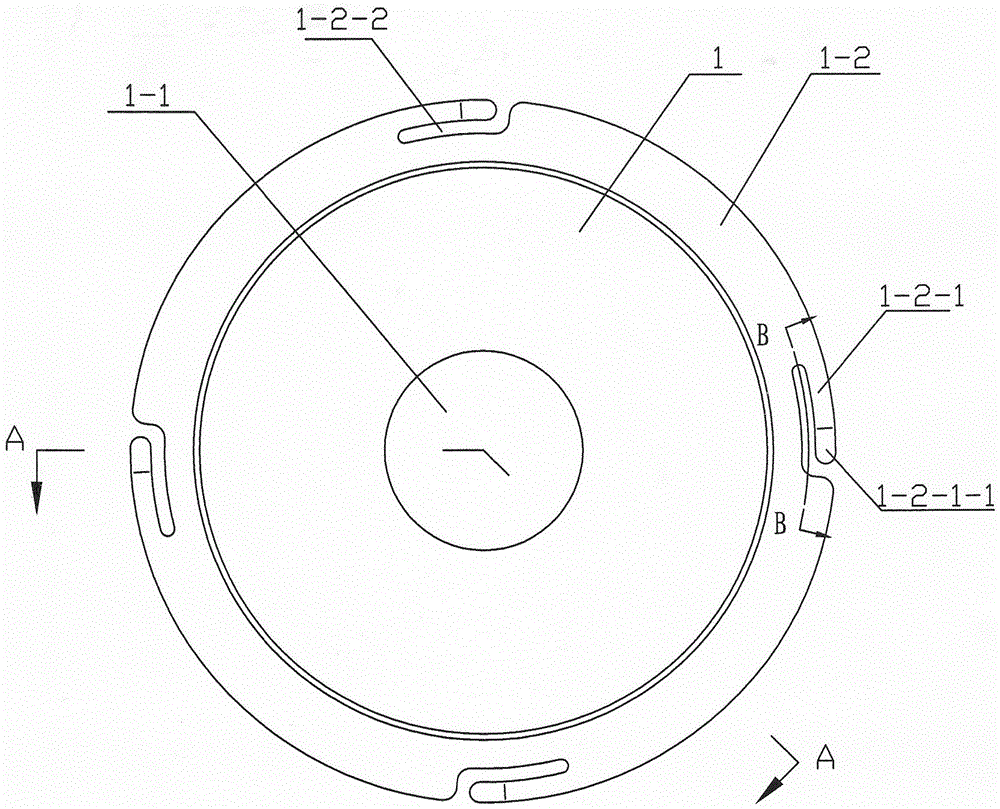

turbocharger heat shield

ActiveCN103850730BIncrease the lengthSolve the stressMachines/enginesEngine componentsTurbochargerEngineering

The invention provides a turbocharger heat insulation cover. A body of the heat insulation cover is an annular cover cap with one end provided with a heat insulation plate and the other end providedwith an opening, the center part on the heat insulation plate is provided with a center through hole, the opening end is provided with a circle of outwards flanged folding edge, the end plane of the folding edge is vertical to the axis line of the center through hole, the edge of the folding edge is provided with a plurality of elastic tongue plates projected out of the end plane of the folding edge, the elastic tongue plates are uniformly arranged on the edge of the folding edge, the inner side of each elastic tongue plate is provided with a stripped arc-shaped heat insulation belt, and a compression surface parallel to the end plane of the folding edge is formed at the top ends of the elastic tongue plates through folding and bending.

Owner:HUNAN TYEN MACHINERY

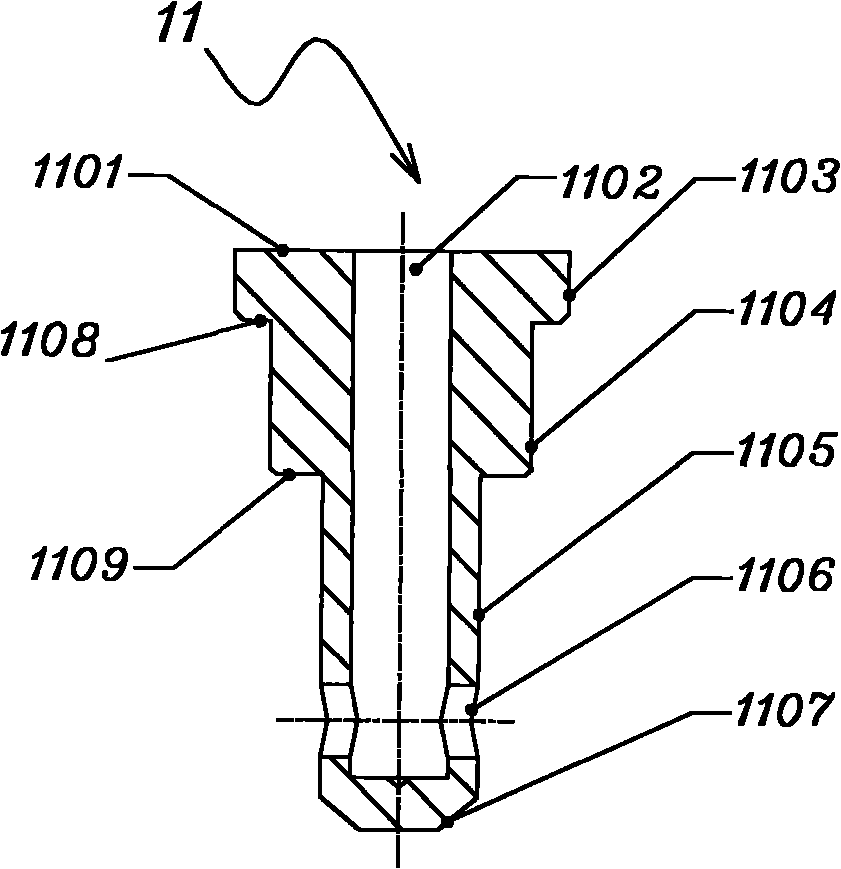

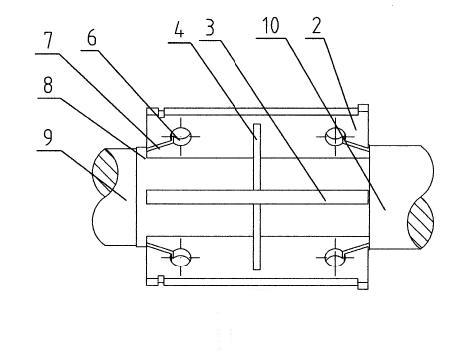

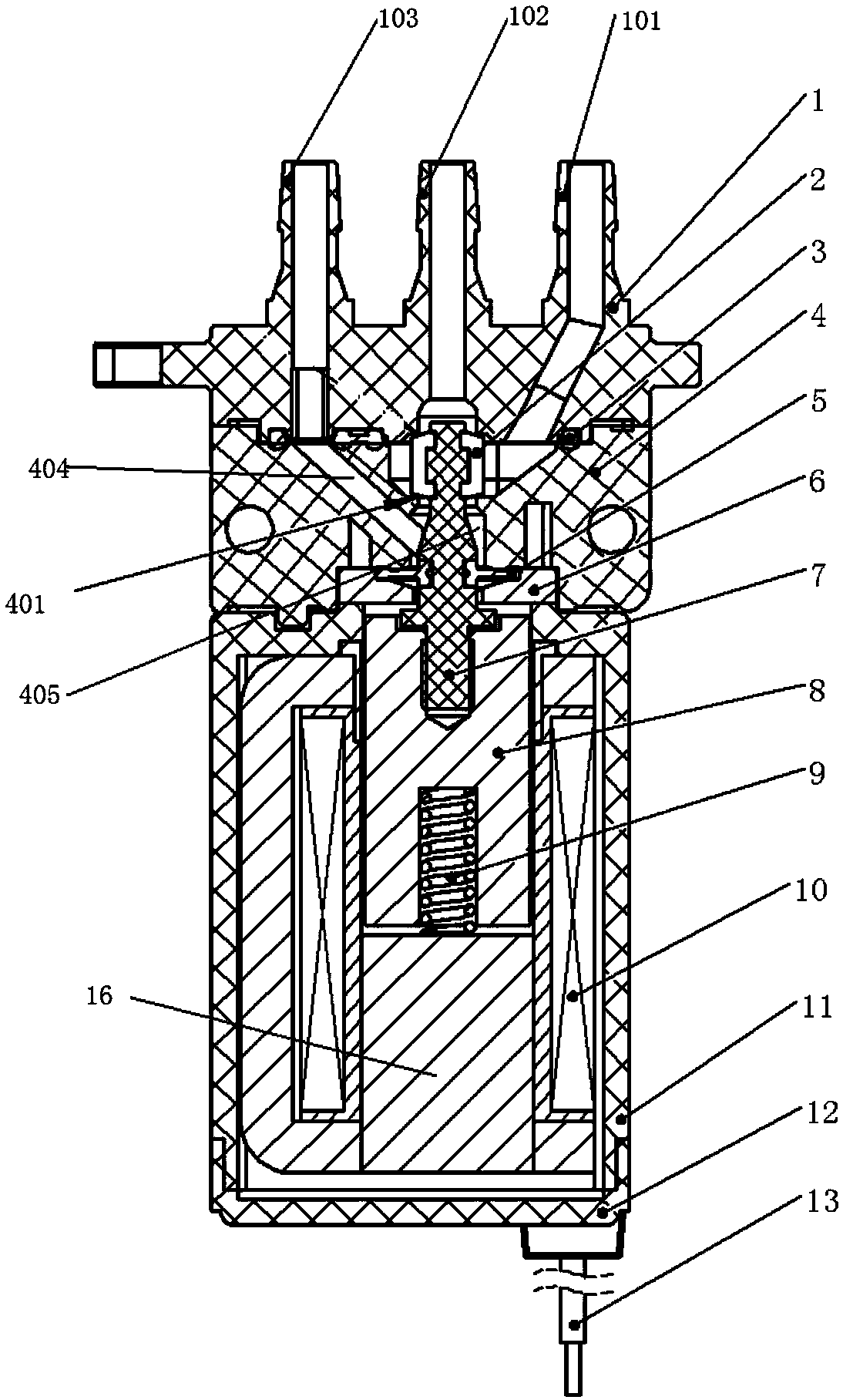

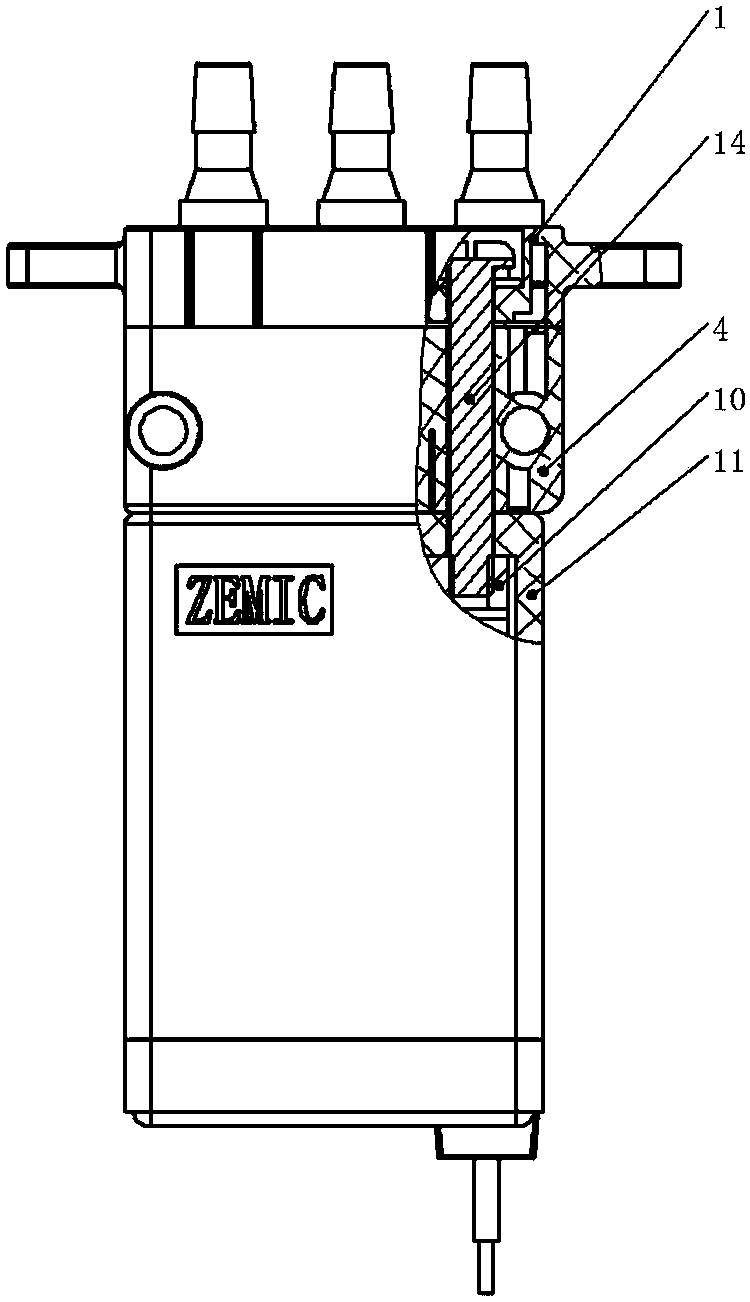

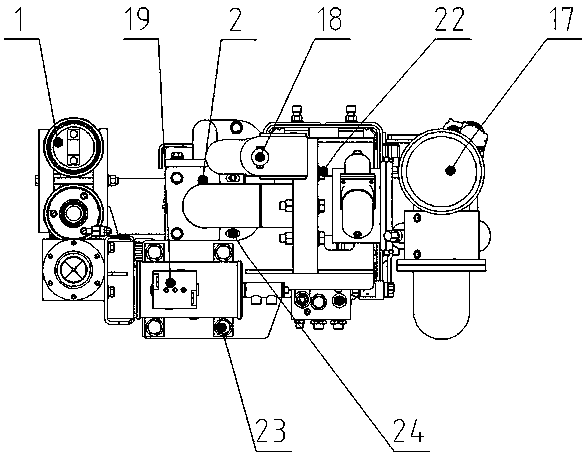

A three-way D-type solenoid valve and its application method

ActiveCN105443799BGuaranteed exercise spaceVarious installation methodsOperating means/releasing devices for valvesMultiple way valvesEngineeringControl valves

The invention belongs to the technical field of valves, and relates to a three-way D-shaped electromagnetic valve and an application method thereof. The electromagnetic valve comprises an upper valve body 1, a lower valve body 4, a shell 11 and a back cover 12; the back cover 12 is arranged at one end of the shell 11, and is fixedly connected with the shell 11; the upper valve body 1 and the lower valve body 4 are fixedly sealed at the other end of the shell 11; the lower valve body 4 is positioned between the upper valve body 1 and the shell 11; a first passage 101, a second passage 102 and a third passage 103 communicated with the upper valve body 1 are formed in the upper valve body 1; an electromagnetic control part is arranged in an inner cavity of the shell 11; one end of a control valve element is fixedly connected with the electromagnetic control part; the other end of the control valve element is aligned to the second passage 102; the electromagnetic control part drives the control valve element to move; and the stop or conduction among the first passage 101, the second passage 102 and the third passage 103 is controlled through movement of the control valve element. The electromagnetic valve has such characteristics as simple structure, small size and convenience for installation.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

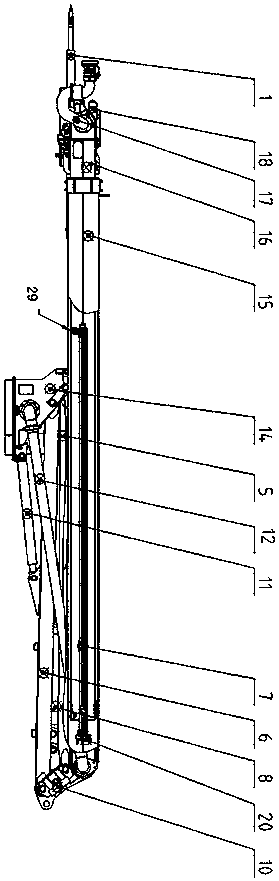

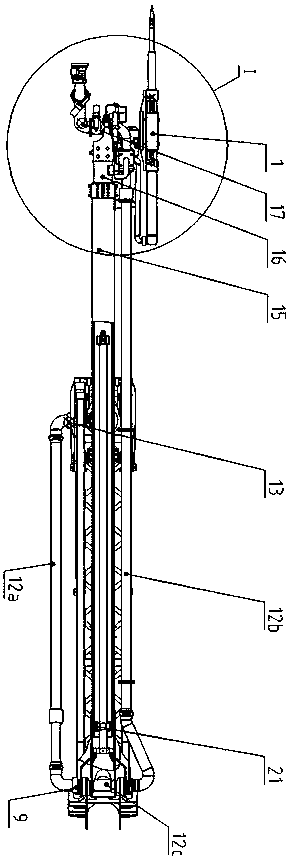

High-altitude fire extinguisher with puncture function

PendingCN108404327APrecise positioningExpand the spraying rangeAccumulator installationsFire rescueNacelleFire extinguisher

The invention discloses a high-altitude fire extinguisher with a puncture function. The high-altitude fire extinguisher with the puncture function comprise a puncture system, a waterway system, a firemonitor, a rotary table and a boom system, wherein the boom system is fixed onto the rotary table, rotates along with the rotary table, and comprises a telescopic arm I and a telescopic arm II; the telescopic arm II extends and retracts relative to the telescopic arm I; the puncture system and the fire monitor are fixed to two sides of the front end of the telescopic arm II; the puncture system is fixedly connected with the telescopic arm II through a swing motor; and a reversing ball valve is arranged at the front end of the waterway system, and is provided with three channels connected witha water pipe of the waterway system, the puncture system and the fire monitor. According to the high-altitude fire extinguisher with the puncture function provided by the invention, the puncture system and the fire monitor are operated independently and controlled independently so as to be flexibly and conveniently operated, so that the fire extinguishing efficiency and a fire extinguishing effect in a cabin can be improved.

Owner:WEIHAI GUANGTAI AIRPORT EQUIP CO LTD

A kind of manufacturing method of cemented carbide steel composite cutting tool

ActiveCN110315159BInhibit excess dissolutionAvoid Hardness LossOther manufacturing equipments/toolsWelding/cutting media/materialsBlade plateCarbon nanotube

The invention discloses a manufacturing method of a hard alloy steel composite cutter, and relates to the manufacturing method of the composite cutter. The manufacturing method aims to solve the problems that when the hard alloy steel composite cutter is prepared, the residual stress of a joint is high, and the hardness of a hard alloy is reduced. The method comprises the following steps that a graphene is transferred to a to-be-welded surface of the hard alloy, then a brazing filler metal connecting plate is placed between the to-be-welded surface of the hard alloy and a to-be-welded surfaceof a steel cutter plate, and then brazing is carried out, wherein the brazing filler metal connecting plate is formed by stacking a plurality of layers of BNi2 brazing filler metal foils, one layer ofnet-shaped carbon nano tube segments and one layer of Cu foil sheets. According to the method, the graphene is transferred to the to-be-welded surface of the hard alloy, dissolution of the hard alloyinto a brazing filler metal can be inhibited during brazing, and hardness reduction of the hard alloy is avoided; by adding the net-shaped carbon nano tube with the low expansion coefficient, the problem that the side stress of the hard alloy is large is solved; and the method is suitable for preparing the hard alloy steel composite cutter.

Owner:HARBIN INST OF TECH

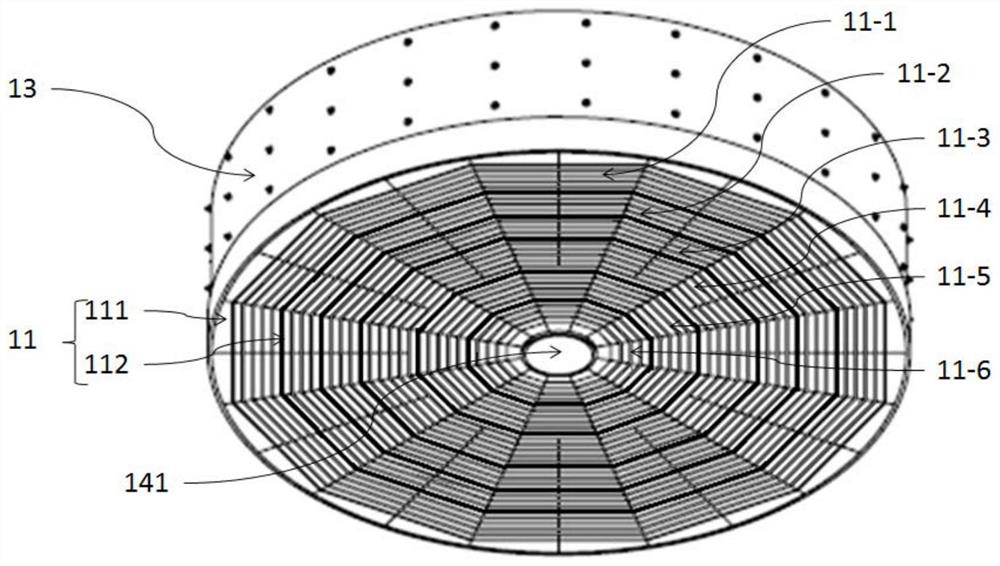

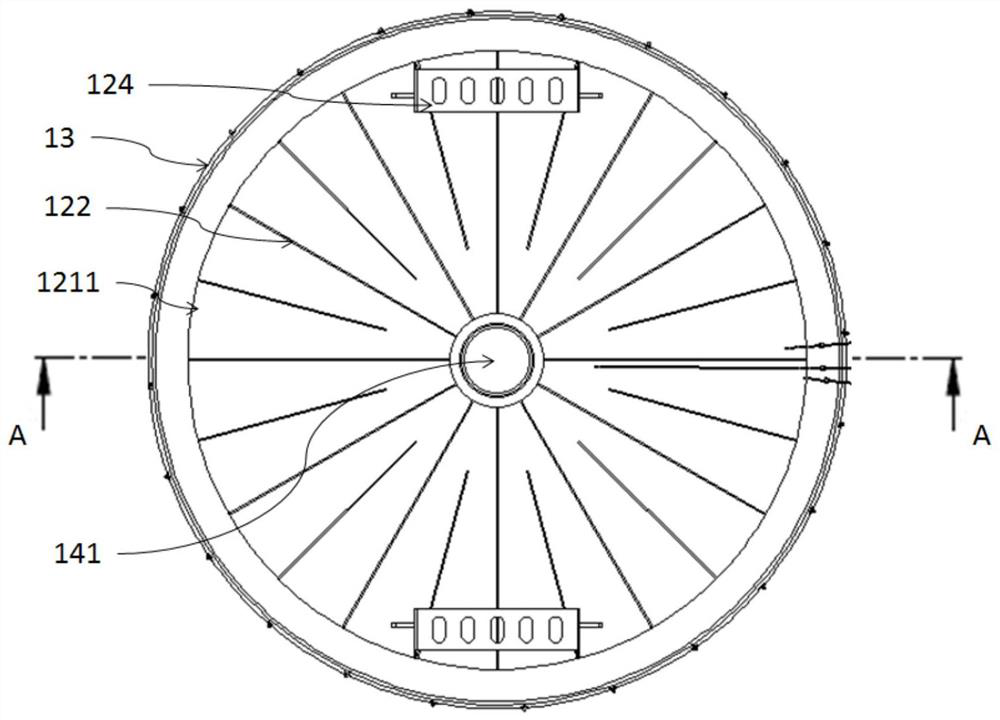

Soaking cover

PendingCN114751629AHeating evenlyEnsure uniformity of temperature fieldGlass shaping apparatusMolten glassGlass forming

The embodiment of the invention provides a soaking cover which is used for heating and preserving heat of molten glass flowing on a forming template, the soaking cover comprises a circular ring heater, a hanging bucket and a temperature control system, the hanging bucket is hung above the forming template, and the lower surface of the hanging bucket is parallel to the forming template, so that the surface of the molten glass is vertically heated; during vertical heating, heat is in a vertical plane downward radiation state, so that molten glass on the forming template can be radiated, and meanwhile, the heat of the molten glass can be prevented from being radiated upwards and excessively lost; the circular ring heater is arranged on the lower surface of the hanging barrel, and a plurality of annular heating areas are sequentially formed on the circular ring heater from the center to the edge of the circular ring heater; the temperature control system comprises a plurality of temperature controllers, each temperature controller is connected with one corresponding heating area so as to control the temperature of the corresponding heating area, and each temperature controller controls the corresponding heating area to keep the same temperature according to the temperature field requirement, so that the temperature field uniformity in the ultra-low expansion glass ceramic forming process is ensured.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

A pipe jacking casing built-in pipeline pulling structure and pulling method

ActiveCN110578832BGuarantee the construction qualityControl construction qualityPipe laying and repairClassical mechanicsStructural engineering

Owner:CHINA FIRST METALLURGICAL GROUP

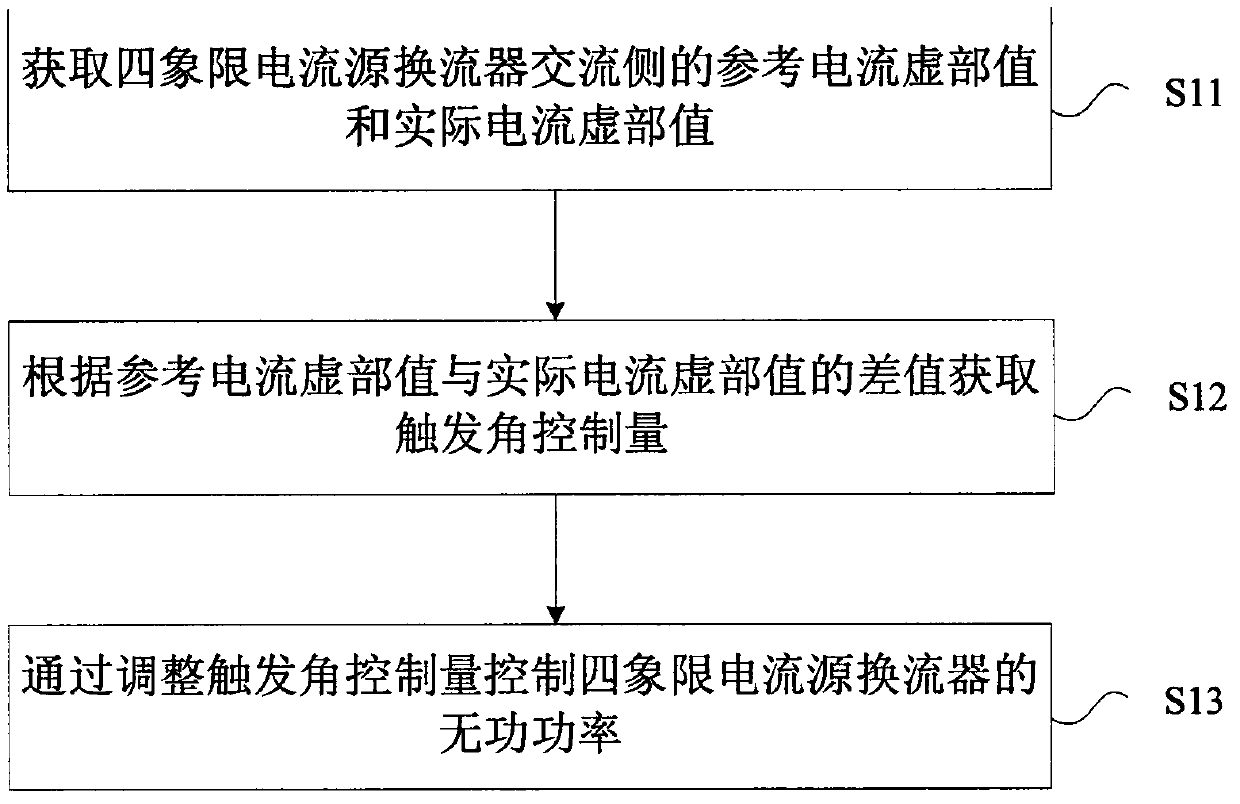

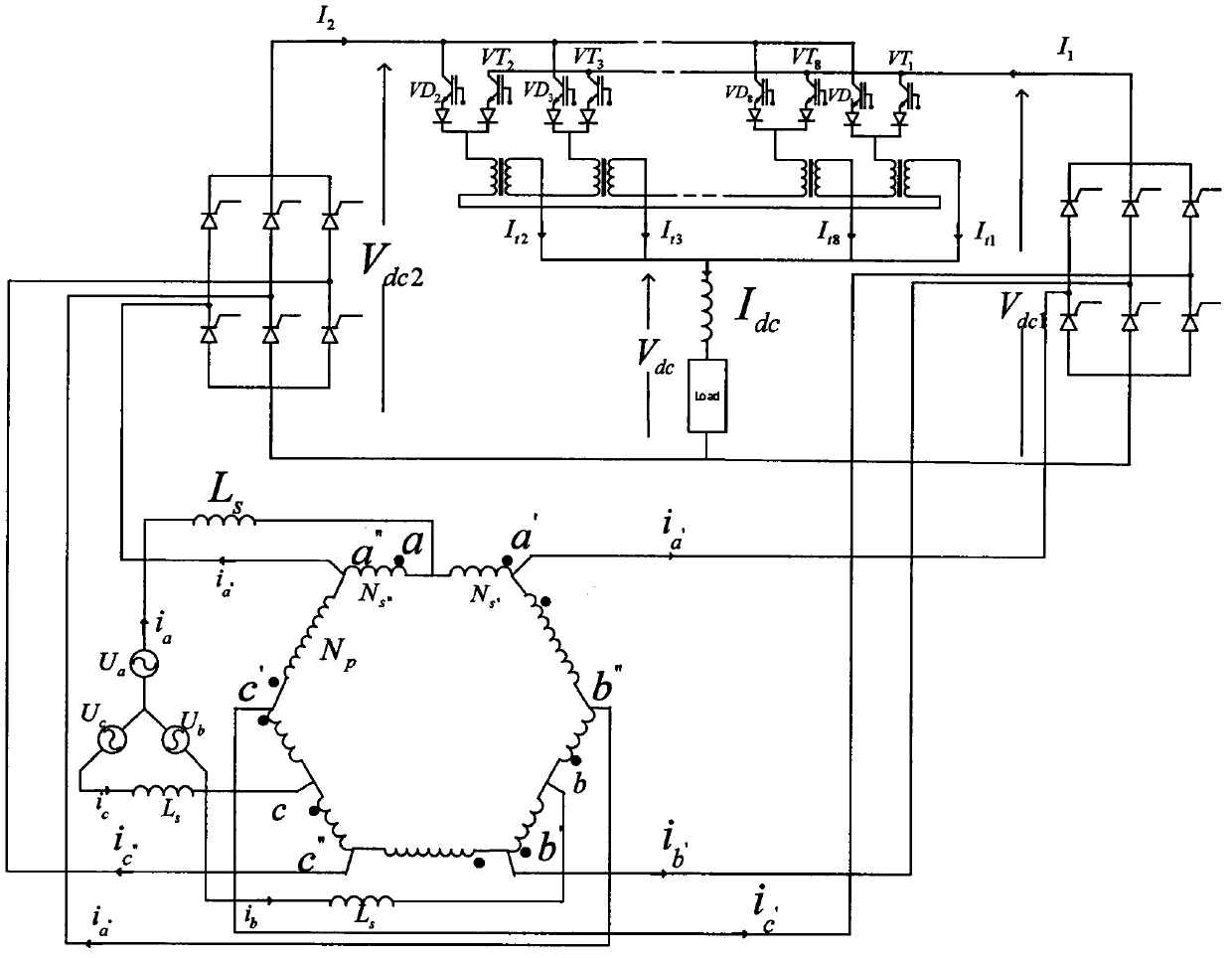

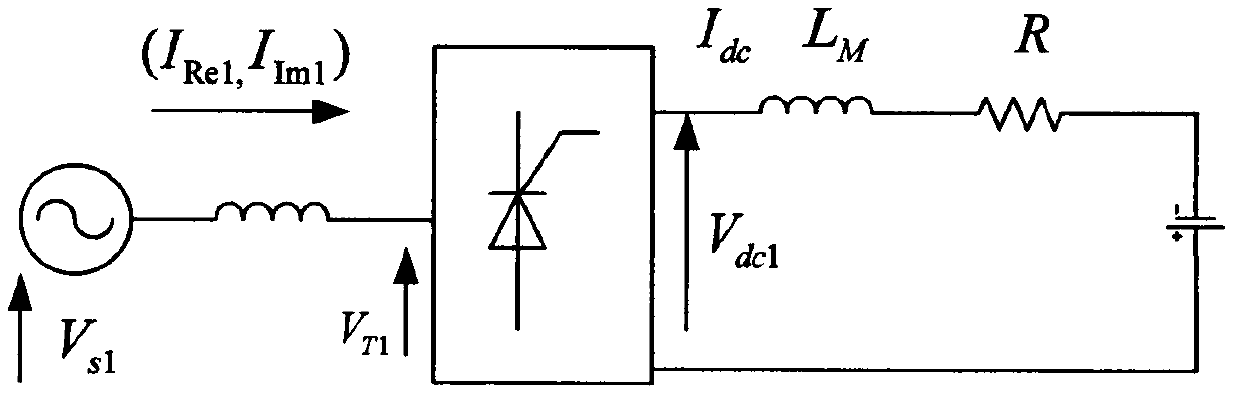

Reactive power control method and device for a four-quadrant current source converter

ActiveCN106058881BReduce dynamic lossSolve the stressReactive power adjustment/elimination/compensationReactive power compensationFour quadrantsReference current

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Device and process for forming solid reinforcing rib from rotational molding container at one step

The invention discloses a device for forming a solid reinforcing rib from a rotational molding container in one step. The device comprises a rotational molding mold, a crank arm and a heating box; the rotational molding mold is arranged on the top surface of a rotating disc, the rotating disc is connected with the crank arm, and the rotational molding mold is located in the heating box for heating forming; an upper die is arranged on the outer wall of a lower die in a sleeving mode and axially moves in the vertical direction of the lower die, an annular reinforcing rib structure is arranged at the joint of an inner cavity of the upper die and an inner cavity of the lower die, a push-pull air cylinder is installed on the outer wall of the upper die, the output end of the push-pull air cylinder is connected with the lower die through a bolt, and the upper die is connected with the lower die through a reset spring; and a fluoroplastic plate is arranged at an opening in the top of the upper die, and a fluoroplastic breather pipe is arranged in the middle of the fluoroplastic plate in a penetrating manner. The method has the advantages that one-time feeding and one-time forming of the local entity of the reinforcing rib of the rotational molding container product are achieved, secondary filling or welding of the local structure of the product is not needed, and the production and machining technological process becomes simple.

Owner:安徽省宁国天亿滚塑有限公司

Flat heat insulation and energy saving pipe support

ActiveCN104653875BIncrease pressureProtection from crushingPipe supportsThermal insulationInsulation layerEngineering

The invention relates to a flat plate type heat-insulation and energy-saving pipe carrier, which comprises a base (2) and a heat insulation layer (3), wherein the base (2) is used for supporting a pipeline (1), the heat insulation layer (3) coats the surface of the pipeline, and the pipeline is supported on a foundation through the base (2). The flat plate type double-heat insulation and energy-saving pipe carrier is characterized in that the base (2) mainly consists of an upper bottom plate (201), a box type lower bottom plate (202), an integral type heat insulation block (203), a rib plate (204) and a pressing plate (205), wherein the upper bottom plate (201) is cast in the integral type heat insulation block (203), the integral type heat insulation block (203) is arranged on the box type lower bottom plate (202), the upper bottom plate (201) and the box type lower bottom plate (202) are fixedly connected in a heat insulation way through the pressing plate (205) and a pressing bolt (206) at the two ends, the lower end of the rib plate (204) penetrates through the integral type heat insulation block (203) and is welded on the upper bottom plate (201), and the upper end of the rib plate (204) penetrates through the heat insulation layer (3) and is welded with the pipeline (1). The flat plate type heat-insulation and energy-saving pipe carrier has the advantages that the heat insulation effect is good, and the structure is simple.

Owner:JIANGSU HONGXIN REVOLVING COMPENSATOR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com