Epitaxial structure of UVB chip and UVB chip

An epitaxial structure and chip technology, applied in nanotechnology, electrical components, nanotechnology, etc. for materials and surface science, can solve problems such as affecting luminous efficiency, increasing material defect density, and poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

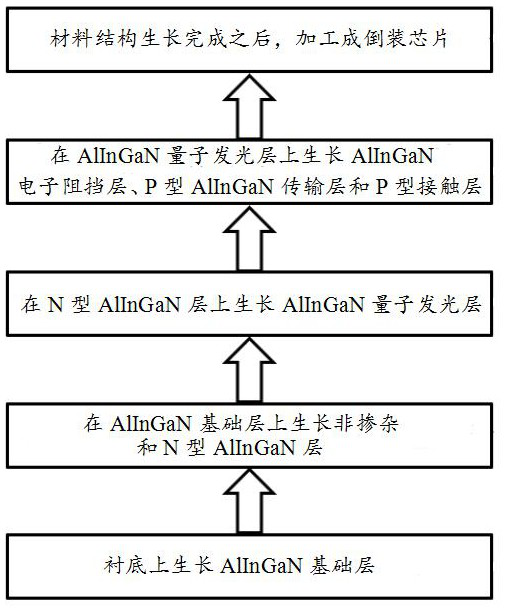

[0068] In the present invention, the preparation method of the epitaxial structure of the UVB chip, according to figure 1 The shown process preferably includes the following steps:

[0069] An AlInGaN base layer, a non-doped AlInGaN layer, an N-type AlInGaN layer, an AlInGaN quantum luminescent layer, an AlInGaN electron blocking layer, a P-type AlInGaN transport layer and a P-type contact layer are sequentially grown on the upper surface of the substrate to obtain the UVB chip. epitaxial structure.

[0070] Before the epitaxial structure is grown on the upper surface of the substrate, the substrate is preferably pretreated, and the pretreatment includes sequential baking and cleaning; in the present invention, the baking is preferably performed after the The substrate is placed in a reactor and baked at 1050°C in a hydrogen atmosphere. The present invention does not have any special restrictions on the cleaning process. It is carried out by a process well known to those skil...

Embodiment 1

[0095] Put the sapphire substrate into the MOCVD equipment, pass through hydrogen gas, and after baking at 1050°C, clean the oxides and impurities on the surface of the sapphire substrate;

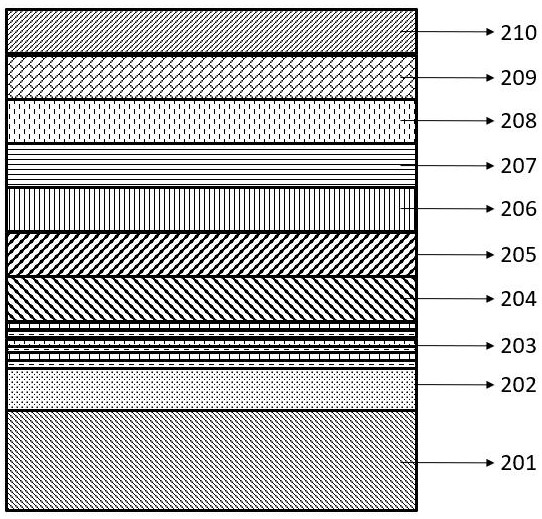

[0096] At a temperature of 1300 ° C, AlN layers (thickness 3 μm) were grown sequentially on the surface of the cleaned sapphire substrate, AlN layers (thickness 2 nm) and Al 0.8 Ga 0.2 N layer (thickness 4nm) 20 cycles, growth of non-doped Al 0.65 Ga 0.35 N layer (thickness 1μm), grow N-type doped Al 0.65 Ga 0.35N layer (thickness 0.5μm, N-type Si doping concentration 8×10 18 cm -3 ), growing N-type doped Al 0.5 Ga 0.5 N layer (thickness 0.5μm, N-type Si doping concentration 1.5×10 19 cm -3 ), growing Al 0.5 In 0.01 Ga 0.49 N quantum barrier layer (thickness 12nm), grown Al 0.2 In 0.01 Ga 0.79 N quantum well layer (thickness 2nm), in which the Al 0.5 In 0.01 Ga 0.49 N quantum barrier layer and Al 0.2 In 0.01 Ga 0.79 A lattice strain layer (Al x Ga 1-x N layer, with x...

Embodiment 2

[0103] Put the sapphire substrate into the MOCVD equipment, pass through hydrogen gas, and after baking at 1050°C, clean the oxides and impurities on the surface of the sapphire substrate;

[0104] At a temperature of 1250 ° C, AlN layers (2 μm in thickness) were grown sequentially on the surface of the cleaned sapphire substrate, AlN layers (2 nm in thickness) and Al 0.8 Ga 0.2 N layer (thickness 2nm) 50 cycles, growth of non-doped Al 0.6 Ga 0.4 N layer (thickness 1μm), grow N-type doped Al 0.6 Ga 0.4 N layer (thickness 0.6μm, N-type Si doping concentration 5×10 18 cm -3 ), growing N-type doped Al 0.45 Ga 0.55 N layer (thickness 0.5μm, N-type Si doping concentration 1×10 19 cm -3 ), growing Al 0.45 In 0.01 Ga 0.54 N quantum barrier layer (thickness 5nm), grown Al 0.2 In 0.01 Ga 0.79 N quantum well layer (thickness 3nm), in which the Al 0.45 In 0.01 Ga 0.54 N quantum barrier layer and Al 0.2 In 0.01 Ga 0.79 A lattice strain layer (Al x Ga 1-x N layer, x ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com