Device and process for forming solid reinforcing rib from rotational molding container at one step

A technology for reinforcing ribs and containers, which is applied to other household appliances, coatings, household appliances, etc., can solve the problems of poor structural force, functional failure, quality safety, easy cracking and damage, etc., and achieves material cost saving, good product performance, The effect of easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

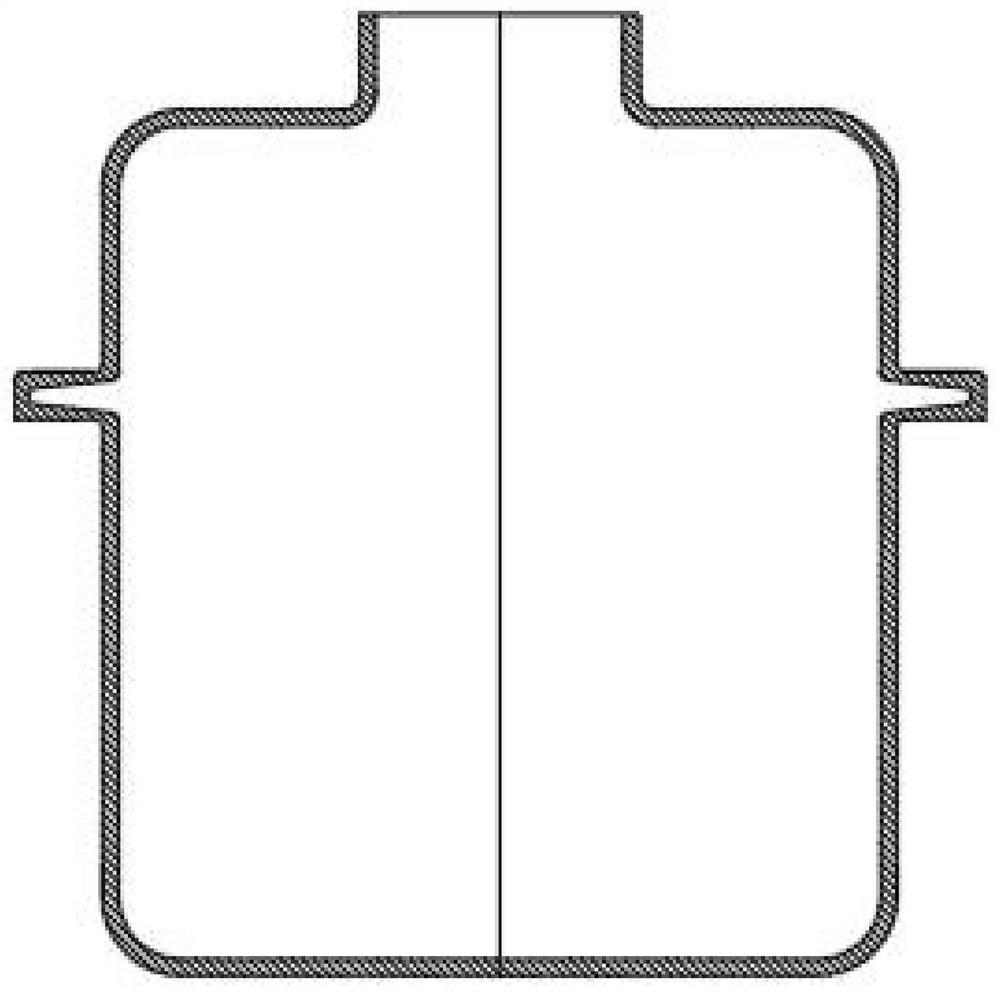

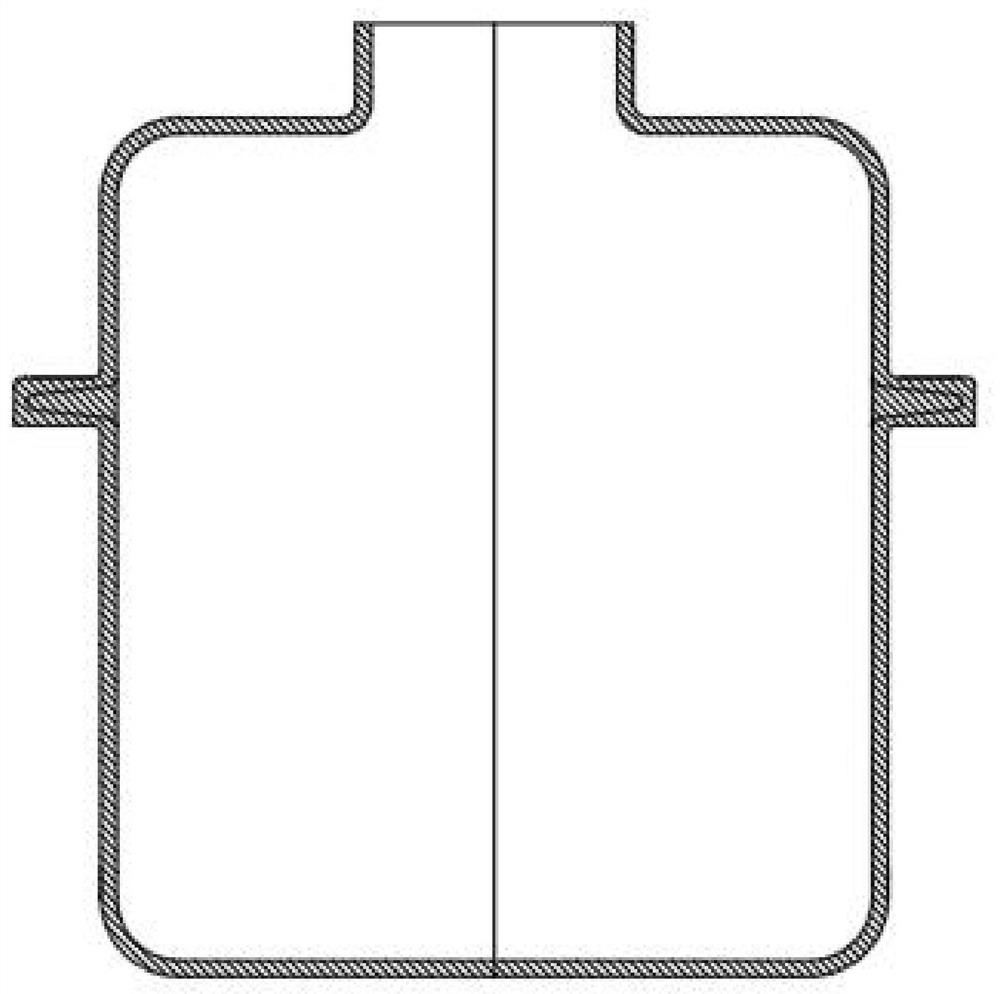

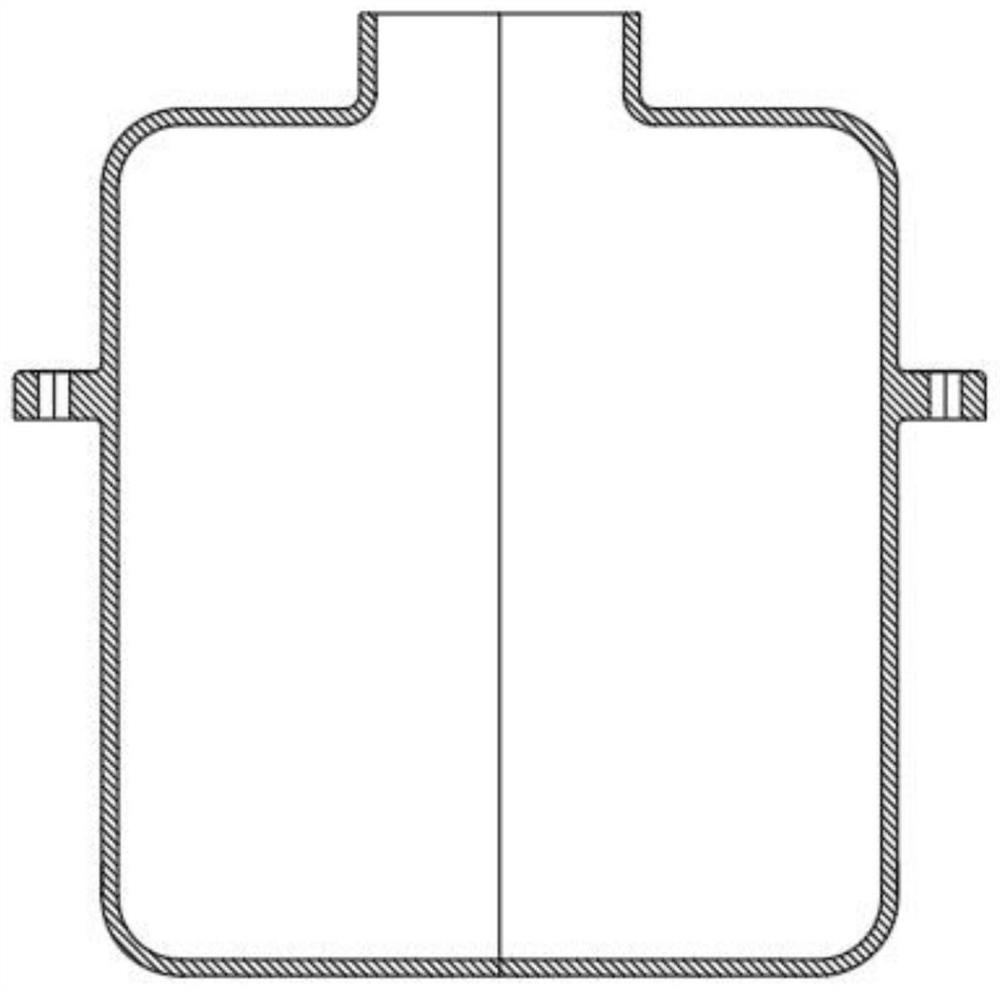

[0041] see Figure 1-13 As shown, a device for forming a rotomolded container into a solid rib at one time, including a rotomolding mold, a crank arm 7 and a heating box 9;

[0042] The rotomolding mold is arranged on the top surface of the turntable 8, the turntable 8 is connected with the crank arm 7, and the rotomolding mold is placed in the heating box 9 for heating and forming;

[0043] The rotomolding mold includes an upper mold 1, a lower mold 2, a push-pull cylinder 3, a return spring 4, a fluoroplastic plate 5, and a fluoroplastic ventilation pipe 6. The upper mold 1 is set on the outer wall of the lower mold 2, and the upper mold 1 follows the lower mold 2 to move axially in the vertical direction, the connection between the upper mold 1 and the lower mold 2 is provided with a ring-shaped reinforcing rib structure, the push-pull cylinder 3 is installed on the outer wall of the upper mold 1, and the output end of the push-pull cylinder 3 is passed through the bolt It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com