Connecting device capable of reducing stress of heating pipes of roasting furnace

A connecting device and heating tube technology, which is applied in the direction of pipes/pipe joints/fittings, pipe elements, siphons, etc., can solve the problems of welding seam tearing of heating pipes, affecting heating pipes, bursting pipes, etc., so as to reduce the stress, Easy to use and avoid tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

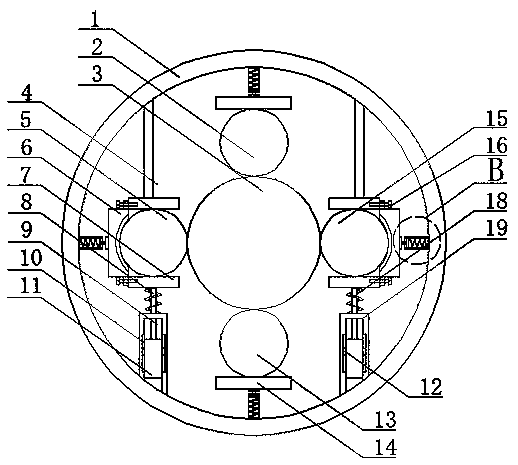

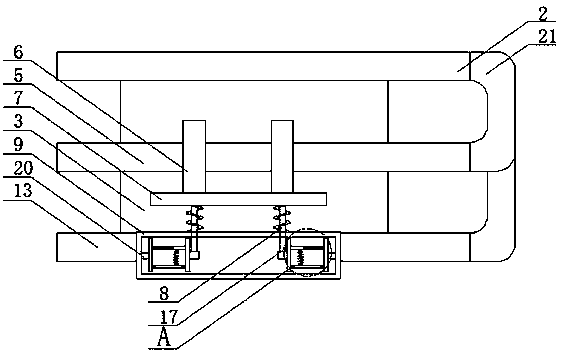

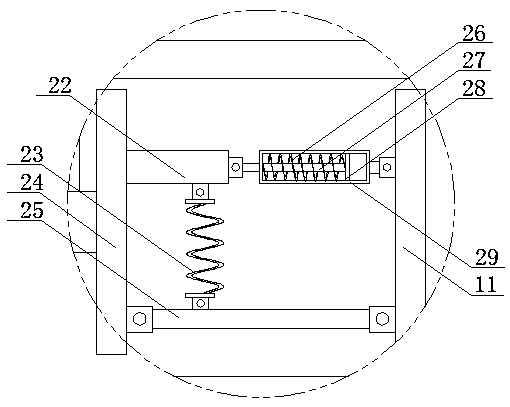

[0022] refer to Figure 1-4 , a connection device for reducing the stress of the heating tube of the calciner, comprising an outer furnace tube 1, an inner furnace tube 3 is arranged inside the outer furnace tube 1, and a first heating tube 2 and a second heating tube are respectively arranged around the inner furnace tube 3 5. The third heating pipe 13 and the fourth heating pipe 15, the first heating pipe 2 and the second heating pipe 5, the third heating pipe 13 and the fourth heating pipe 15 are all connected by an arc-shaped elbow 21, and the arc-shaped elbow 21 can reduce the stress concentration of each heating tube, and one end of the first heating tube 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com