Motor rotating shaft with spoke iron plates

A motor shaft and spoke iron technology, which is applied in the field of motor shafts with spoke irons, can solve problems such as broken shafts, no fundamental improvement in motor rotor ventilation, and large stress on spoke irons, and achieve low cost, poor ventilation, and processing and installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

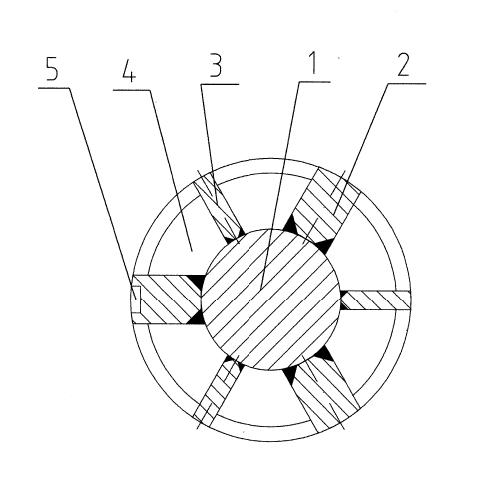

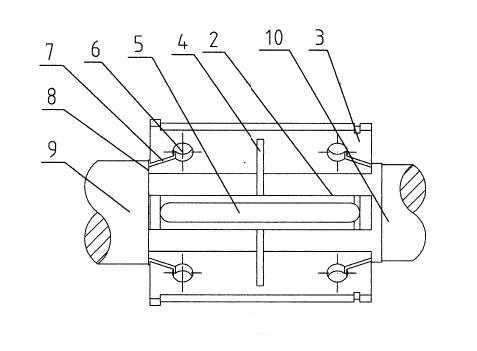

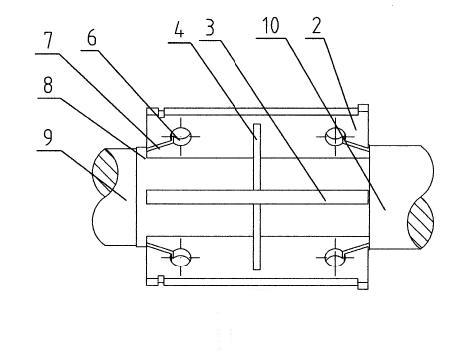

[0013] A motor rotating shaft with spoke iron, comprising a shaft 1, a wide-spoke iron plate 2, a narrow-spoke iron plate 3, a fan-shaped air blocking plate 4 and a keyway 5 arranged on a wide-spoke iron plate 2, the wide-spoke iron Both the plate 2 and the narrow-spoke iron plate 3 are fixedly arranged on the outer surface of the shaft 1 along the axial direction of the shaft 1, and the wide-spoke iron plates arranged on the outer surface of the shaft 1 are arranged on the circumference of the section perpendicular to the axis of the shaft 1. Evenly and equidistantly arranged, the narrow-radius iron plates arranged on the side of the shaft 1 are also arranged at uniform and equidistant intervals on the circumference of the cross-section perpendicular to the axis of the shaft 1, and the narrow-radius iron plates arranged on the side of the shaft 1 and The wide-radiated iron plates are arranged at intervals, and the distance from each wide-radiated iron plate to the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com