Polyphenylene sulfide resin composition and application thereof

A technology of polyphenylene sulfide resin and composition, applied in the field of engineering plastics, can solve the problems of affecting the emission and transmission of electromagnetic signals, affecting the performance of the vibrator, and easily falling off of the bonding layer of the electroplating circuit, achieving strong application value and low molding shrinkage rate. , the effect of good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

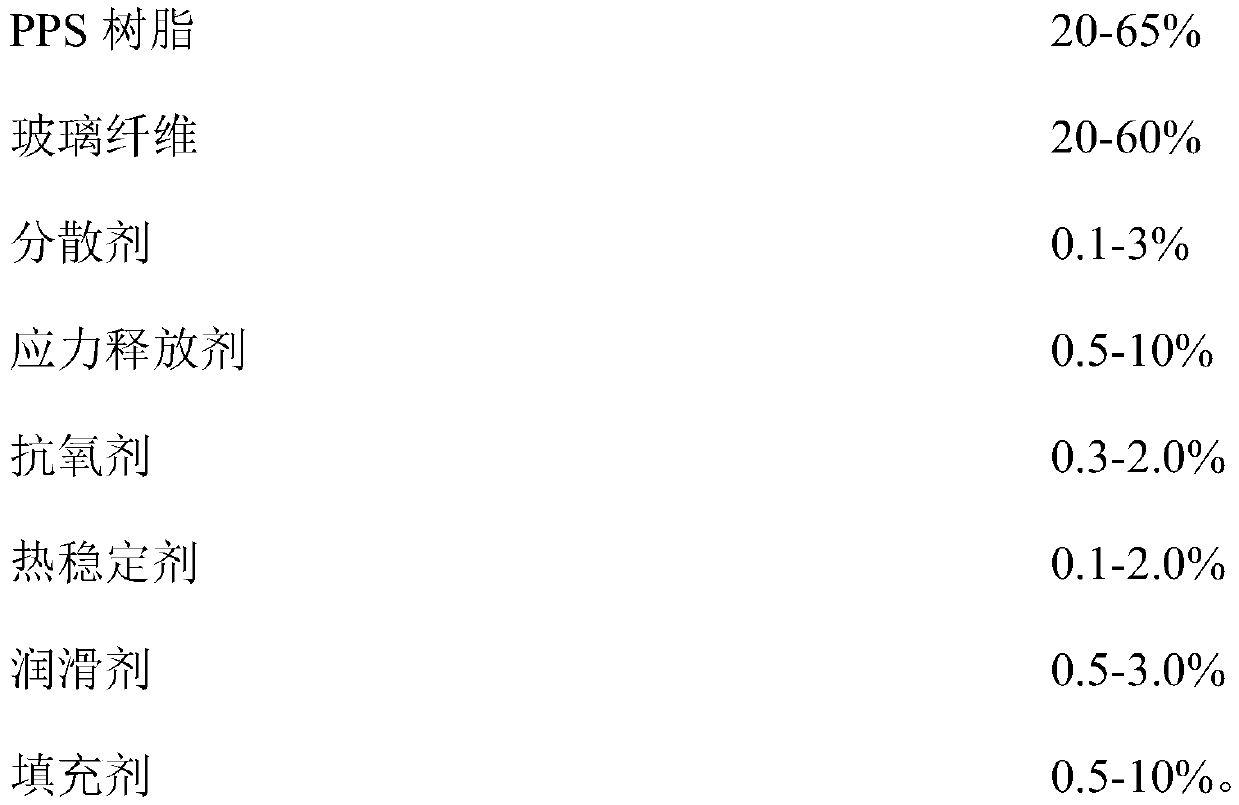

[0095] The present embodiment provides a kind of PPS resin composition, and formula is as follows:

[0096]

[0097]

[0098] The preparation method is as follows:

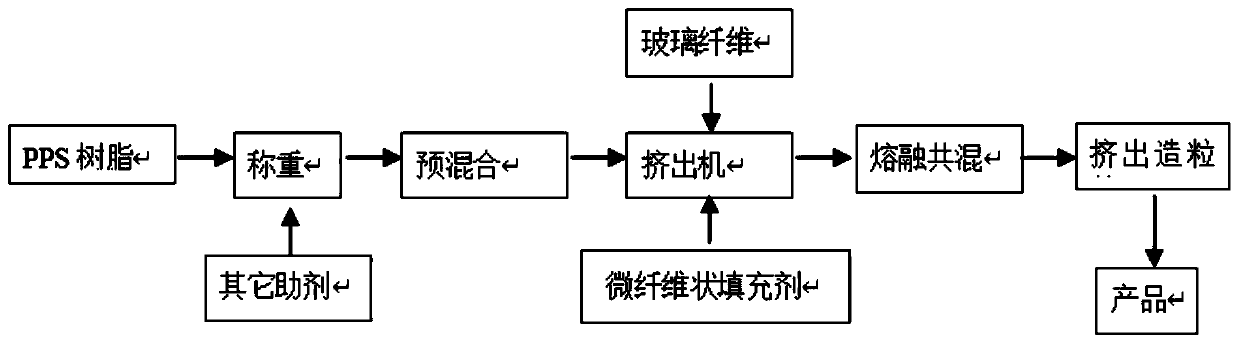

[0099] (1) After weighing the PPS resin, add the dispersant, stress release agent, antioxidant, lubricant in the formula, and pre-mix evenly to obtain the pre-mixture; the pre-mixture is extruded according to the twin-screw that has been preheated to a specific processing temperature machine;

[0100] (2) Side feeding Put the glass fiber and filler in the formula amount into the extruder, carry out melt blending and extrusion granulation, pull, cool, and test performance to obtain polyphenylene sulfide engineering plastic particles;

[0101] In step (2), the heating temperature of the extruder is as follows: 200°C for the first zone, 220°C for the second zone, 250°C for the third zone, 250°C for the fourth zone, 250°C for the fifth zone, 250°C for the sixth zone and 260°C for the machine head .

Embodiment 2

[0103] The present embodiment provides a kind of PPS resin composition, and formula is as follows:

[0104]

[0105]

[0106] The preparation method is the same as in Example 1.

Embodiment 3

[0108] The present embodiment provides a kind of PPS resin composition, and formula is as follows:

[0109]

[0110] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com