Steel wire balancer and special trolley provided with lifting arm support

A technology of balancer and wire rope, which is applied in the direction of cranes, etc., can solve the problem of large space occupied by balancing equipment, and achieve the effect of solving force and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

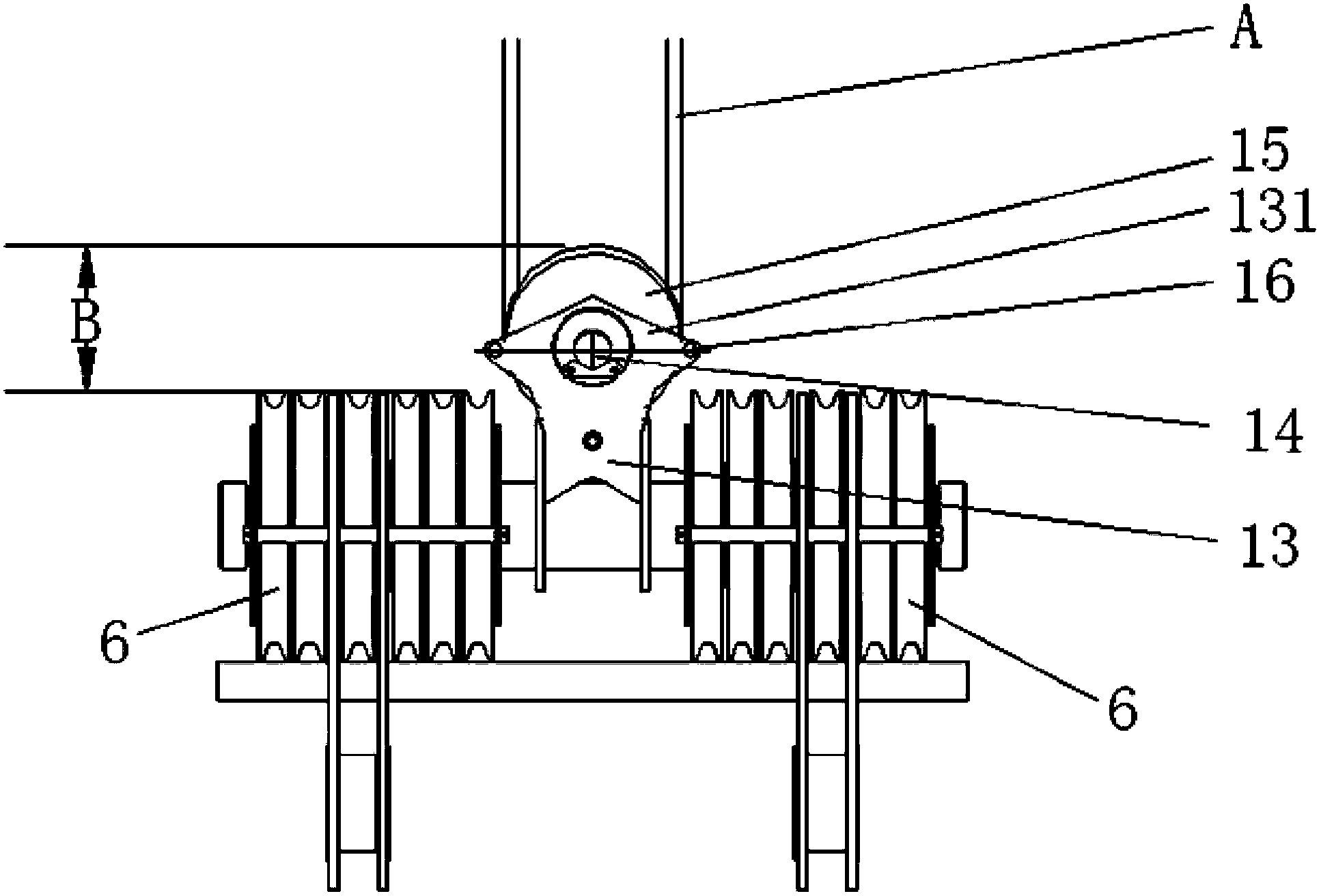

[0031] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

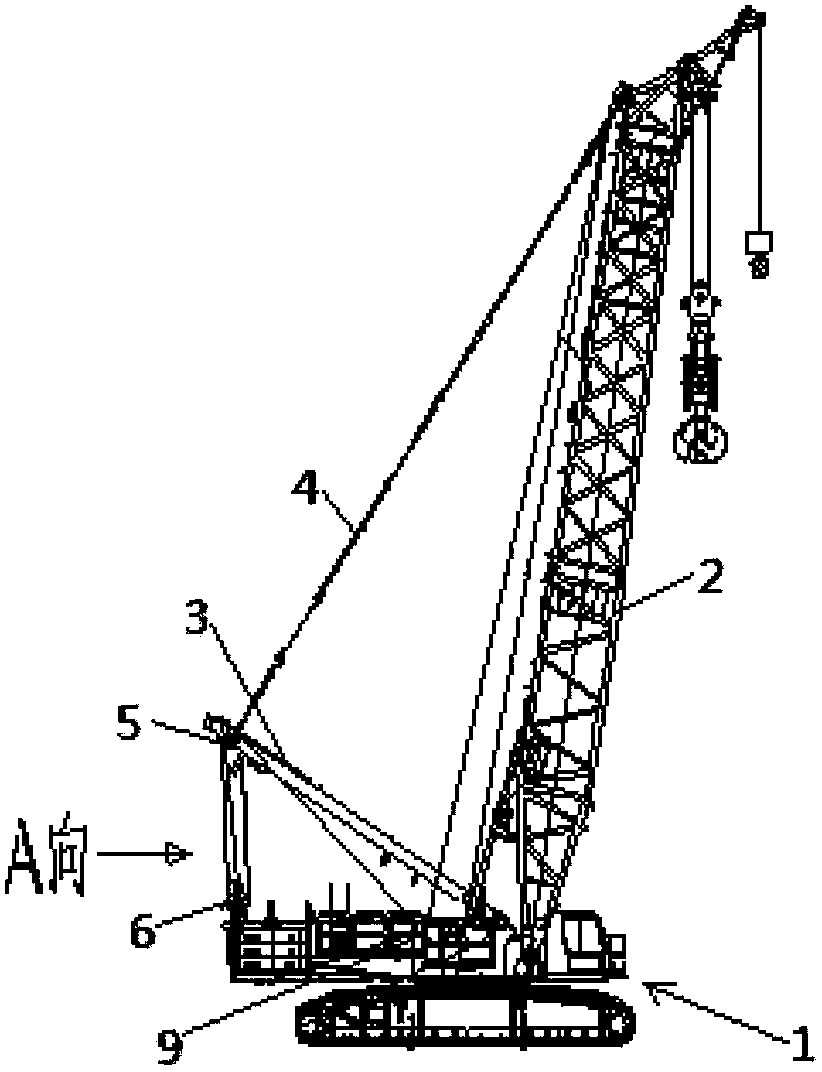

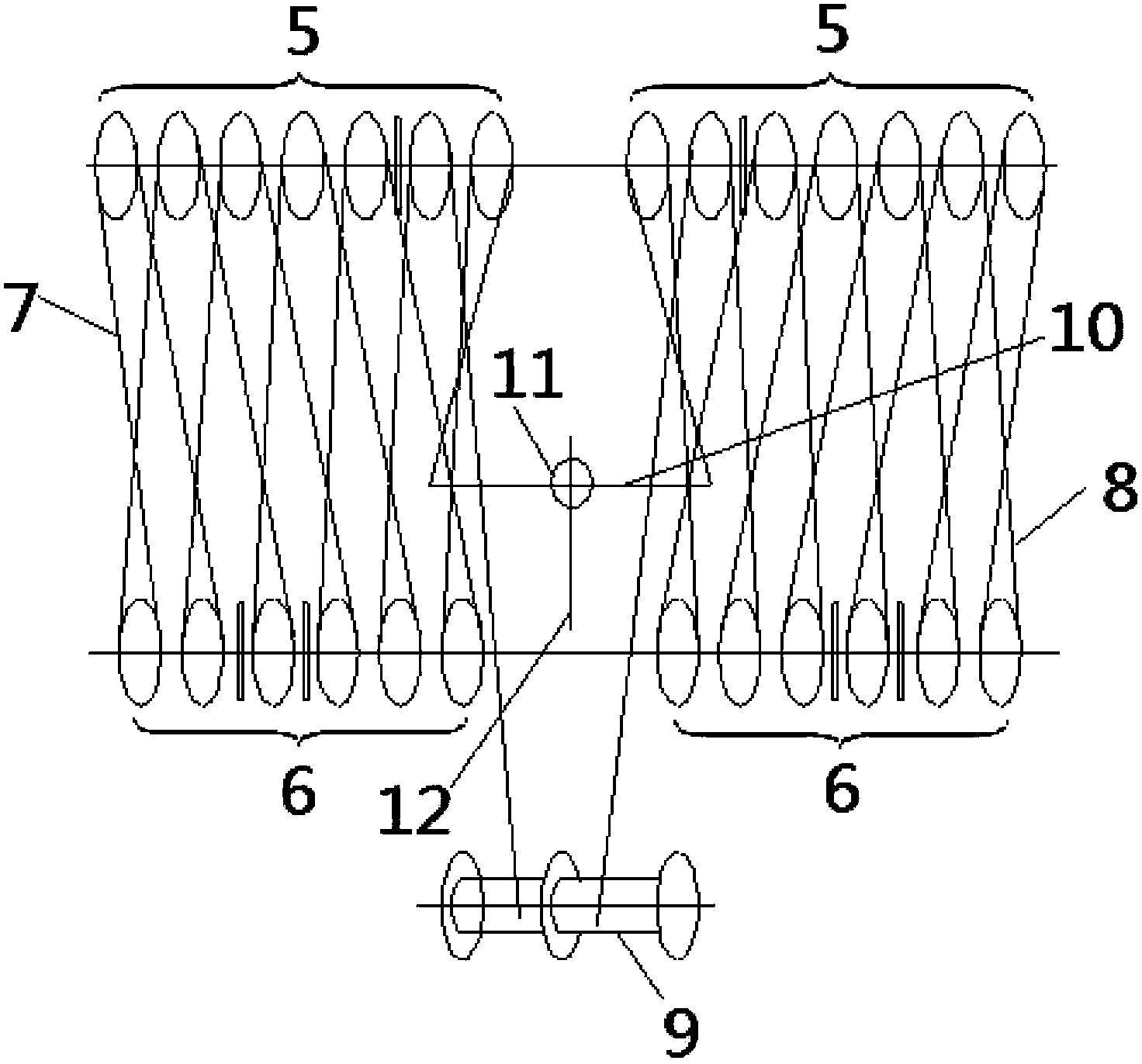

[0032] image 3 A schematic diagram of the connection relationship between the wire rope balancer and the lower mast pulley block provided by the present invention; Figure 4 It is a schematic diagram of the connection relationship between the wire rope balancer, the mast pulley block and the luffing hoist provided by the present invention. Such as image 3 , Figure 4As shown, the present invention is in order to be able to balance and adjust the connection between the first steel wire rope 7 wound on the left mast pulley block and the second steel wire rope 8 wound on the right mast pulley block in a small space. The difference in length is to solve the problem that the balance equipment occupies a large space in the prior art.

[0033] The wire rope balancer provided by the present invention includes a bracket 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com