Flat plate type heat-insulation and energy-saving pipe carrier

A flat-panel, heat-insulating block technology is applied in the direction of protecting pipes, pipe supports, and pipes through heat insulation, which can solve the problems of poor heat insulation effect of heat-insulating pipe supports, inability to achieve heat-insulation, etc., and achieves simple structure and manufacturing. Easy and reliable installation, the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

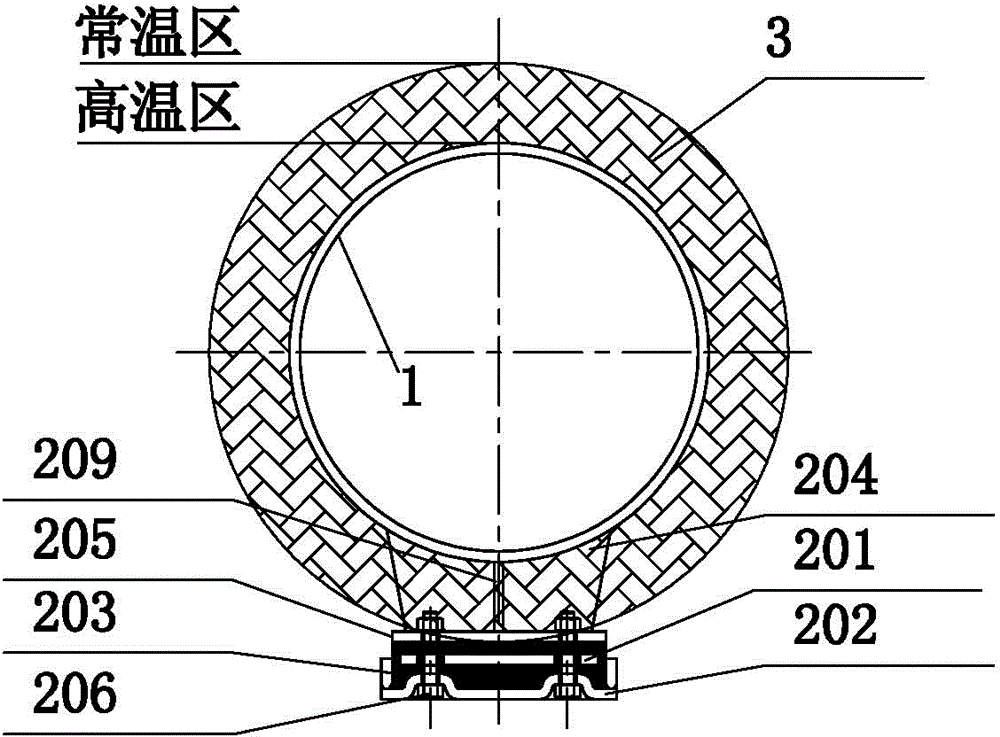

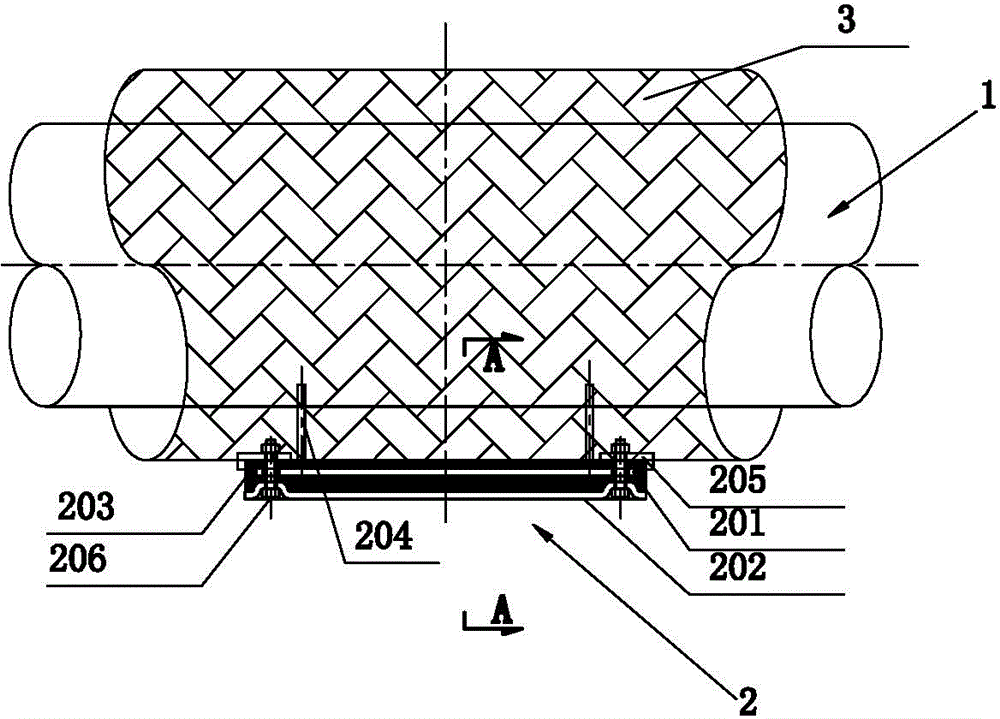

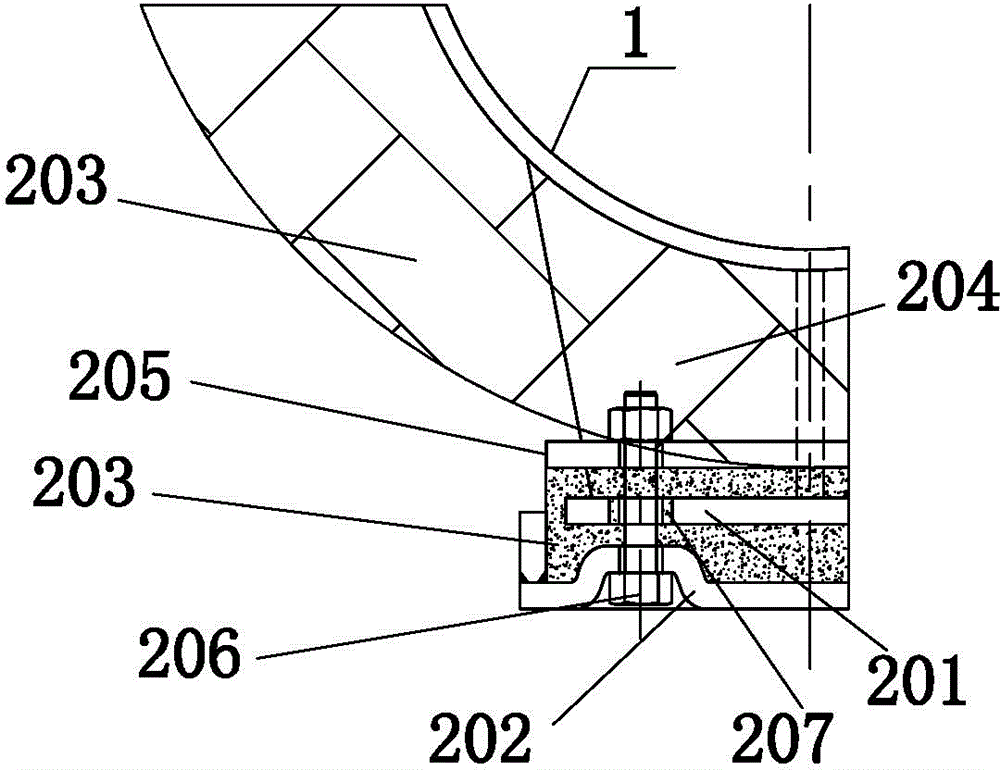

[0020] Such as Figure 1-4 shown.

[0021] A flat-plate double-insulated energy-saving pipe support, which includes a base 2 for supporting a pipeline 1 and an insulation layer 3 wrapped on the surface of the pipeline. The pipeline 1 is supported on the foundation through the base 2, such as figure 1 As shown, the base 2 is mainly composed of an upper base plate 201, a box-type lower base plate 202, an integral heat insulating block 203, a rib plate 204 and a pressing plate 205. The upper base plate 201 is cast on the integral heat insulating block 203 (eg Figure 4 ), the integral heat insulation block 203 is installed on the box-type lower base plate 202, and the upper base plate 201 and the box-type lower base plate 202 realize fixed heat-insulation connection through the compression plate 205 and the compression bolt 206 at both ends; the rib plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com