Wear-resistant steel above 500HB grade and production method thereof

A production method, 550HB technology, applied in the field of metallurgical engineering, can solve problems such as increased internal stress of slabs and steel plates, brittle fracture of slabs and steel plates, and difficult wear-resistant steel technology, so as to improve hardenability and benefit Martens body structure, and the effect of avoiding the probability of intergranular cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

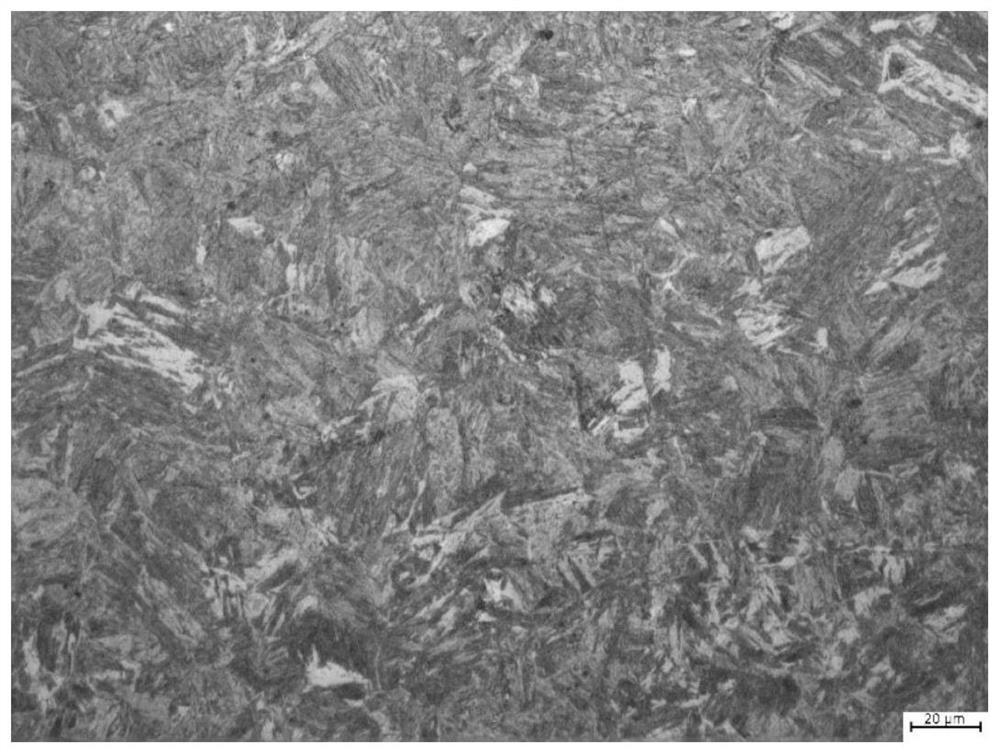

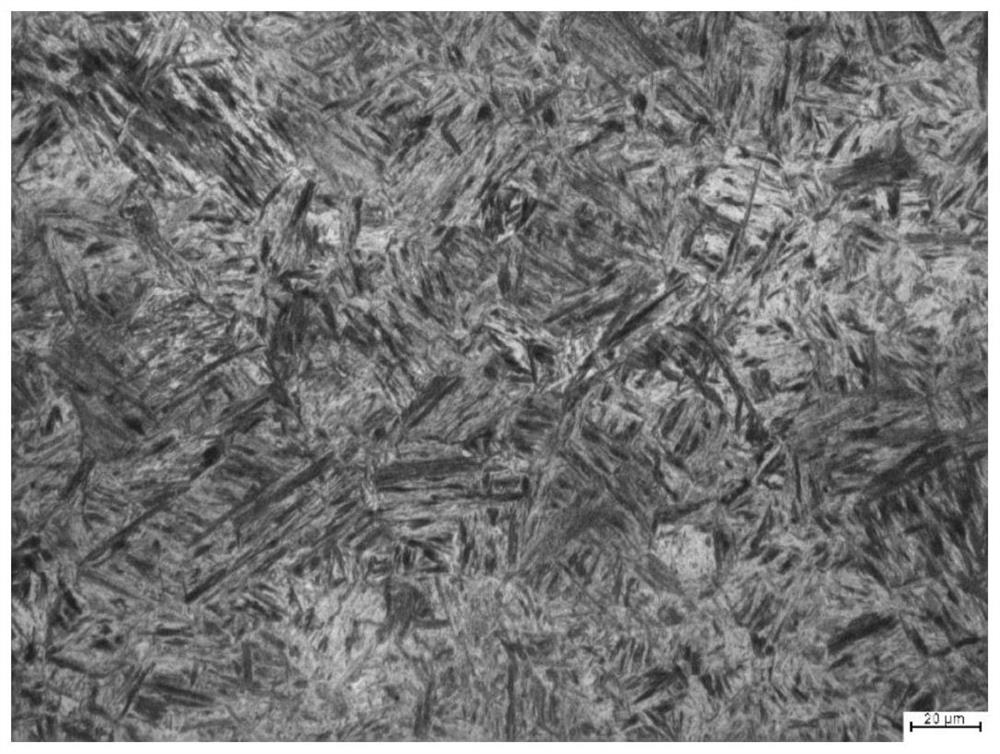

Image

Examples

Embodiment 1

[0031] A 500HB grade wear-resistant steel, its chemical composition and mass percentage are as follows: C: 0.15%, Si: 0.20%, Mn: 0.50%, P: 0.005%, S: 0.001%, V: 0.010%, Ti: 0.008% , Cr: 0.60%, Ni: 0.30%, Mo: 0.30%, Al: 0.025%, B: 0.0010%, Mg: 0.0010%, N: 0.0015%, the balance is Fe and inevitable impurities; steel-grade surface cloth The hardness is greater than or equal to 470HBW.

[0032] The above-mentioned production method of 500HB grade wear-resistant steel comprises the following steps:

[0033] S1. The molten iron after desulfurization is smelted in a smelting furnace, deoxidized and alloyed by LF, and then sent to RH vacuum treatment. The vacuum degree is less than or equal to 3.0 mbar. After meeting the vacuum degree requirements, the vacuum treatment time is 20 minutes. The length of the magnesium-aluminum wire is 200m, and after the magnesium treatment is finished, it is stirred for 15min;

[0034] S2. After the molten steel refining treatment is finished, it is s...

Embodiment 2

[0041]A 500HB grade wear-resistant steel, its chemical composition and mass percentage are as follows: C: 0.25%, Si: 0.30%, Mn: 1.00%, P: 0.010%, S: 0.002%, V: 0.020%, Ti: 0.016% , Cr: 0.80%, Ni: 0.60%, Mo: 0.45%, Al: 0.040%, B: 0.0020%, Mg: 0.0014%, N: 0.0030%, the balance is Fe and inevitable impurities; steel-grade surface cloth The hardness is greater than or equal to 470HBW.

[0042] The above-mentioned production method of 500HB grade wear-resistant steel comprises the following steps:

[0043] S1. The molten iron after desulfurization is smelted in a smelting furnace, deoxidized and alloyed by LF, and then sent to RH vacuum treatment. The vacuum degree is less than or equal to 3.0mbar. After meeting the vacuum degree requirements, the vacuum treatment time is 22 minutes. The length of the magnesium-aluminum wire is 210m, and the static stirring is 20min after the magnesium treatment;

[0044] S2. After the molten steel refining treatment is finished, it is sent to con...

Embodiment 3

[0051] A 500HB grade wear-resistant steel, its chemical composition and mass percentage are as follows: C: 0.35%, Si: 0.40%, Mn: 1.60%, P: 0.015%, S: 0.003%, V: 0.030%, Ti: 0.025% , Cr: 1.00%, Ni: 0.90%, Mo: 0.60%, Al: 0.055%, B: 0.0030%, Mg: 0.0018%, N: 0.0045%, the balance is Fe and inevitable impurities; steel-grade surface cloth The hardness is greater than or equal to 470HBW.

[0052] The above-mentioned production method of 500HB grade wear-resistant steel comprises the following steps:

[0053] S1. The molten iron after desulfurization is smelted in a smelting furnace, deoxidized and alloyed by LF, and then sent to RH vacuum treatment. The vacuum degree is less than or equal to 3.0mbar. After meeting the vacuum degree requirements, the vacuum treatment time is 25min. The length of the magnesium-aluminum wire is 220m, and the static stirring is 25min after the magnesium treatment;

[0054] S2. After the molten steel refining treatment is finished, it is sent to continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com