Turbocharger heat insulation cover

A technology for turbochargers and heat shields, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of high thermal stress on elastic folds, damage and fracture of superchargers, etc., to prolong service life, Reliable positioning and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

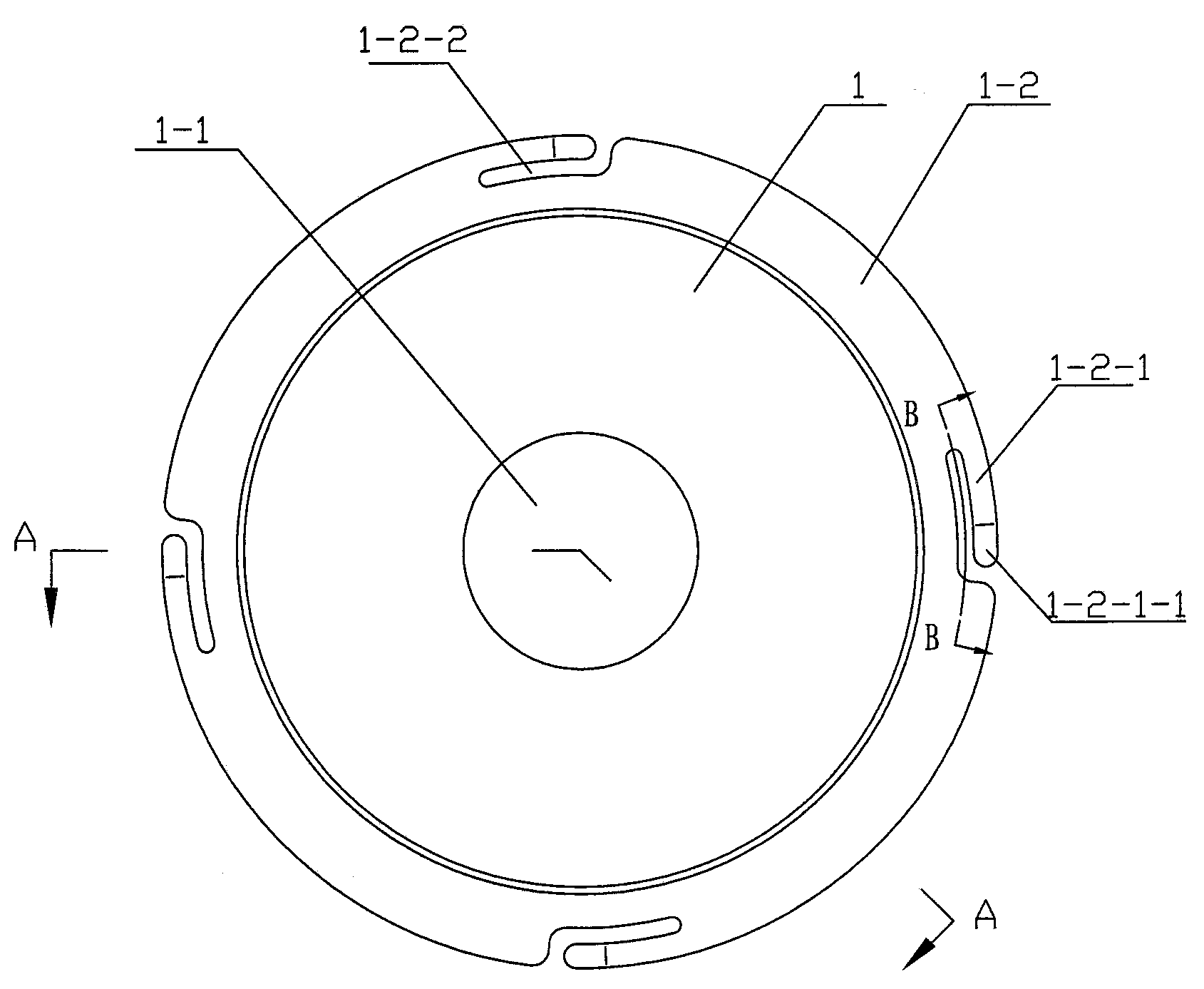

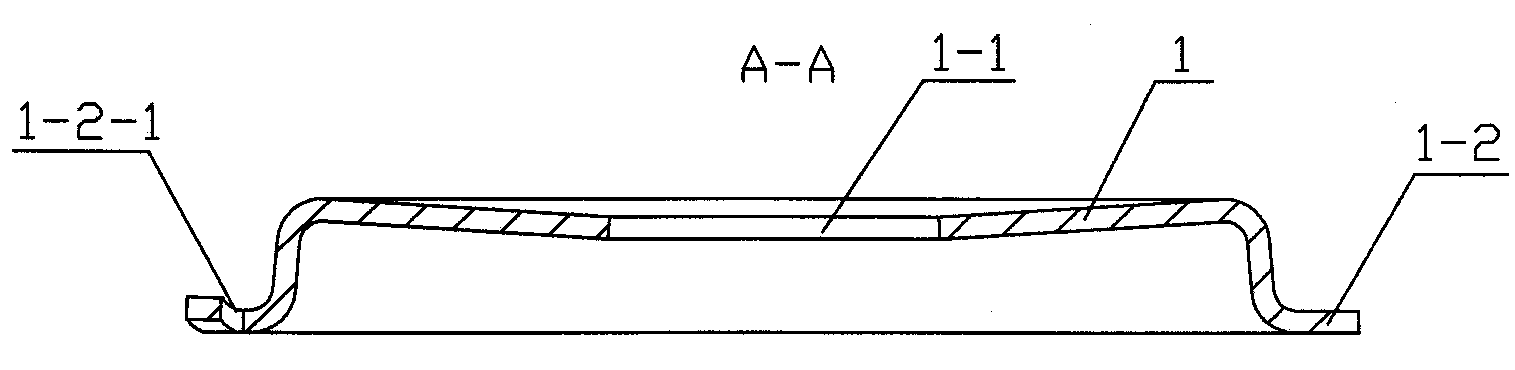

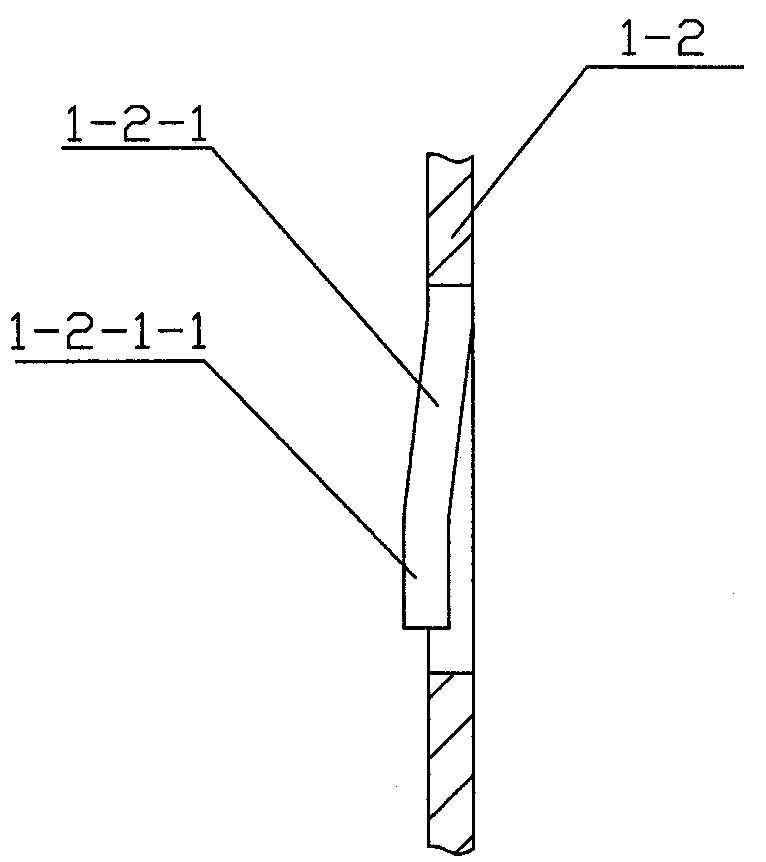

[0021] Embodiment 1. A heat shield for a turbocharger. The body of the heat shield 1 is an annular cover with a heat shield at one end and an opening at the other end. The center of the heat shield is provided with a central through hole. 1-1, the opening end of which is provided with a circle of flanging edges 1-2 turned outwards, the end plane of the flanging edge 1-2 is perpendicular to the axis line of the central through hole 1-1, and the edge of the flanging edge 1-2 There are four elastic tongue plates 1-2-1 protruding from the flange end plane, the elastic tongue plates 1-2-1 protrude toward the end with the heat insulation board, and the four elastic tongue plates 1-2-1 are uniform Arranged on the edge of the folded edge 1-2, the inner side of each elastic tongue plate 1-2-1 is provided with a strip-shaped arc-shaped insulating belt 1-2-2, and the top end of the elastic tongue plate 1-2-1 is bent Go out the pressing surface 1-2-1-1 parallel with the end plane of flang...

Embodiment 2

[0023] Embodiment 2. A heat shield for a turbocharger. The body of the heat shield 1 is an annular cover with a heat shield at one end and an opening at the other end. The center of the heat shield is provided with a central through hole. 1-1, the opening end of which is provided with a circle of flanging edges 1-2 turned outwards, the end plane of the flanging edge 1-2 is perpendicular to the axis line of the central through hole 1-1, and the edge of the flanging edge 1-2 There are six elastic tongues 1-2-1 protruding from the flanged end plane, the elastic tongues 1-2-1 protrude toward the end with the heat insulation board, and the six elastic tongues 1-2-1 are uniform Arranged on the edge of the folded edge 1-2, the inner side of each elastic tongue plate 1-2-1 is provided with a strip-shaped arc-shaped insulating belt 1-2-2, and the top end of the elastic tongue plate 1-2-1 is bent Go out the pressing surface 1-2-1-1 parallel with the end plane of flanging 1-2.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com