A kind of manufacturing method of cemented carbide steel composite cutting tool

A technology of cemented carbide steel and composite cutting tools, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of reduced hardness of cemented carbide and high residual stress of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the composition of the cemented carbide blade and the steel blade plate welded by this embodiment are as shown in table 1;

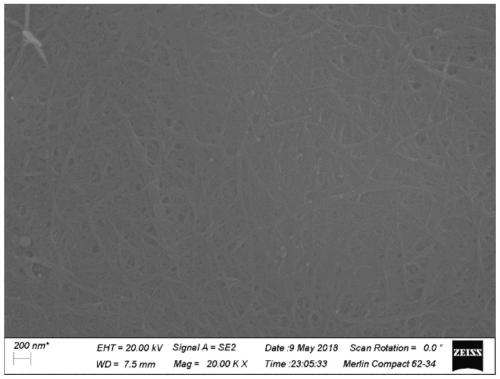

[0046] The manufacturing method of the cemented carbide steel composite cutting tool of the present invention is carried out according to the following steps: transfer the graphene to the surface of the cemented carbide to be welded, and then place a solder connecting plate between the surface of the cemented carbide to be welded and the surface to be welded of the steel knife plate , and then brazing is completed;

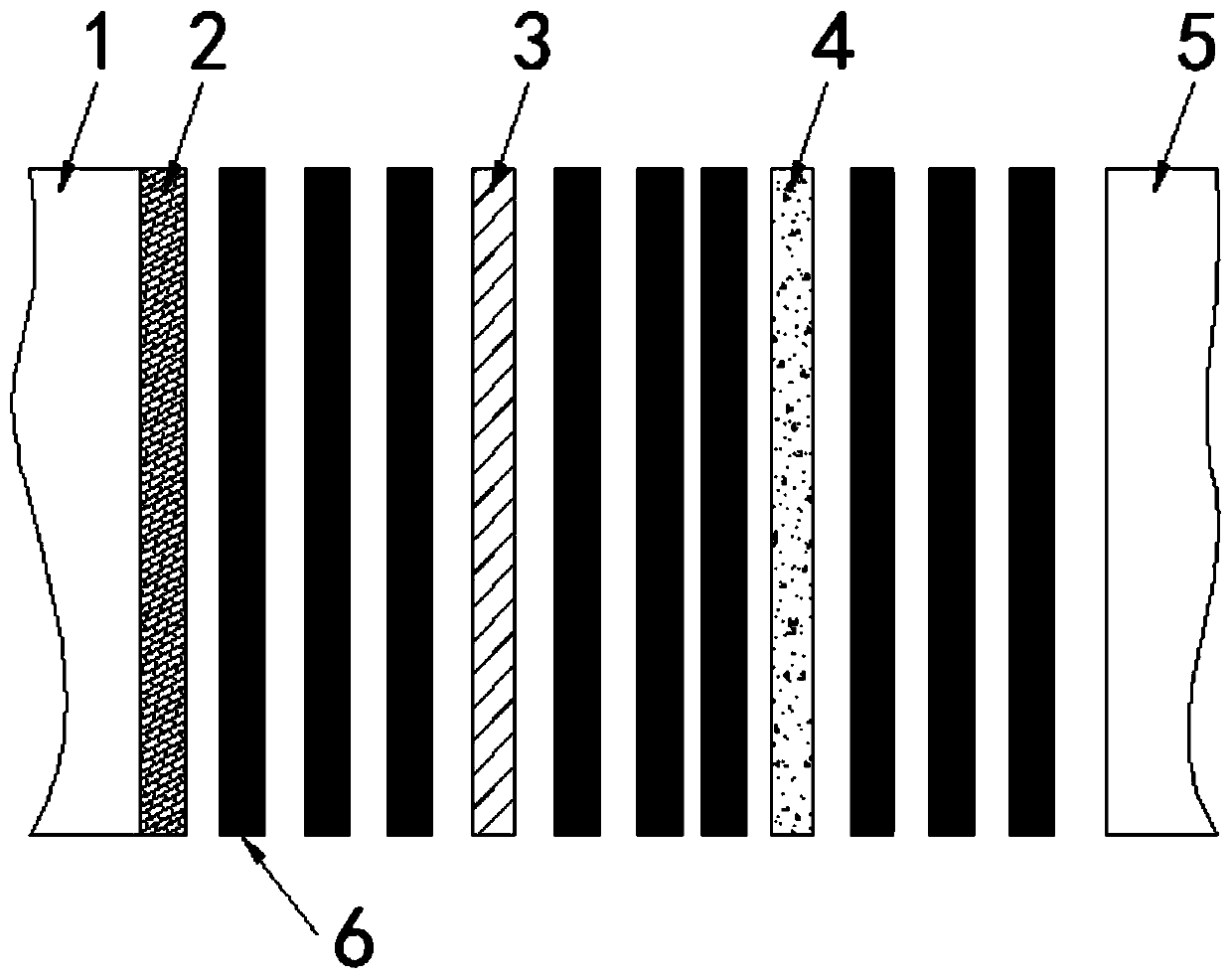

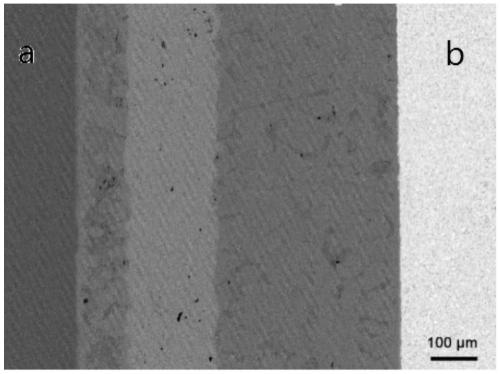

[0047] The solder connection plate is made of 9 layers of BNi 2 Solder foil, 1 layer of networked carbon nanotube sheet and 1 layer of Cu foil are stacked; There are 3 layers of BNi on both sides 2 Brazing foil with 3 layers of BNi on the other side of the Cu foil 2 Brazing material foil; during brazing, the side of the brazing material connecting plate provided with the meshed carbon nanotube sheet faces the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com