Preparation method of compound material for inhibiting oxidation corrosion by using potassium oleate modified metal sulfide

A metal sulfide and oxidation-inhibiting technology, which is applied in the fields of semiconductors and photochemistry, can solve problems such as terminal treatment cannot be completely treated, secondary pollutants cannot be solved, and heavy metals are difficult to reuse, etc., to achieve inhibition of excessive dissolution, inhibition of excessive oxidation, and process easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A method for preparing a composite material that uses potassium oleate to modify metal sulfide to inhibit oxidation and corrosion, comprising the steps of:

[0018] (1) After the pyrite was ball milled for 5 minutes, passed through a 100-mesh sieve, washed five times with ultrapure water (volume 1:5), placed in a -20°C refrigerator for 12 hours, and then dried in a freeze dryer for 48 hours.

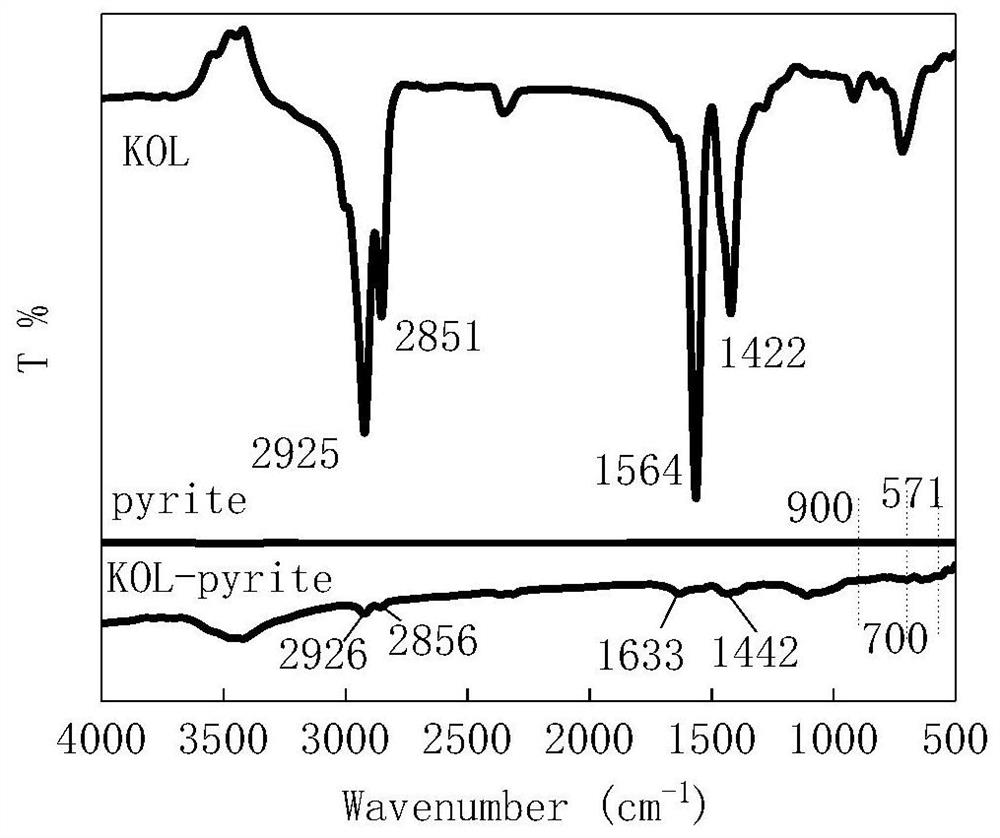

[0019] (2) Take potassium oleate and configure it into 5% (volume ratio) with ultrapure water, then take 1mL and 0.5g of pyrite samples into a 50mL beaker, shake the beaker so that the sample is evenly spread on the bottom of the beaker, put The composite material was obtained after drying in a fume hood.

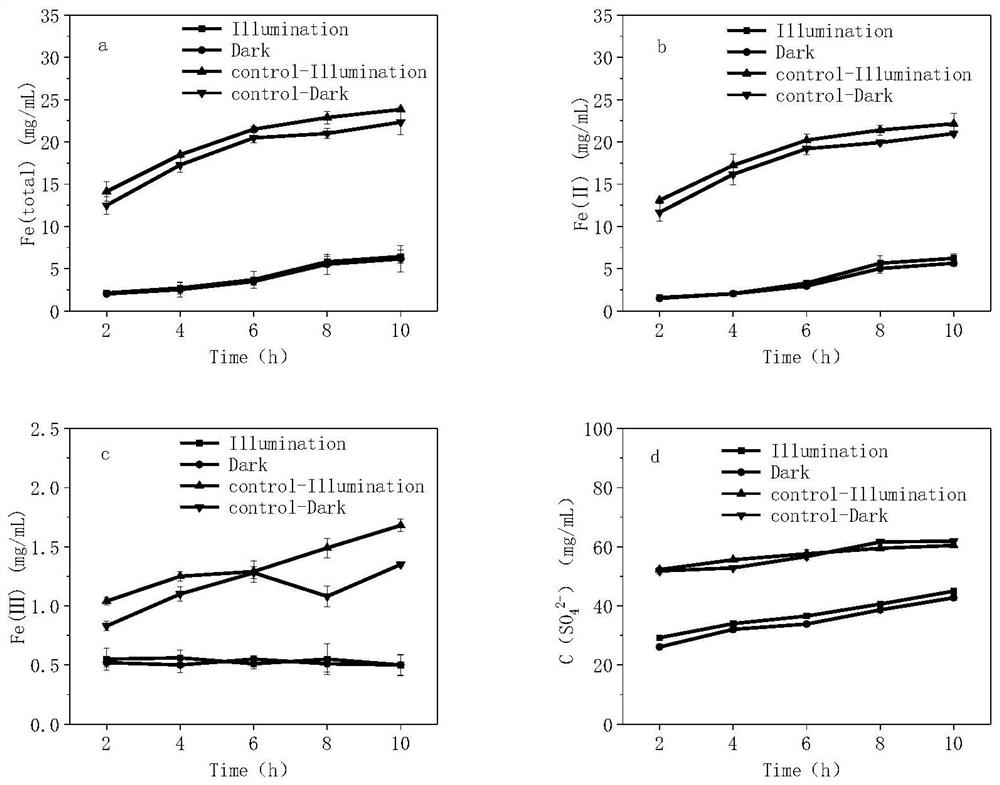

[0020] (3) Carry out pyrite ion leaching experiment in the hydrochloric acid solution of pH=2, gained solution is filtered with 0.45 μ m filter membrane, uses the content of iron ion in the solution of spectrophotometric measurement, uses ion chromatography to measure the conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com