Automatic punching equipment and method for industrial production

A technology of punching equipment and air holes, applied in metal processing equipment, perforating tools, manufacturing tools, etc., can solve the problems of unable to cool the punch, easy to reduce the hardness of the punch, and wear of the punch, so as to achieve good protection and easy pick-and-place Convenience and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

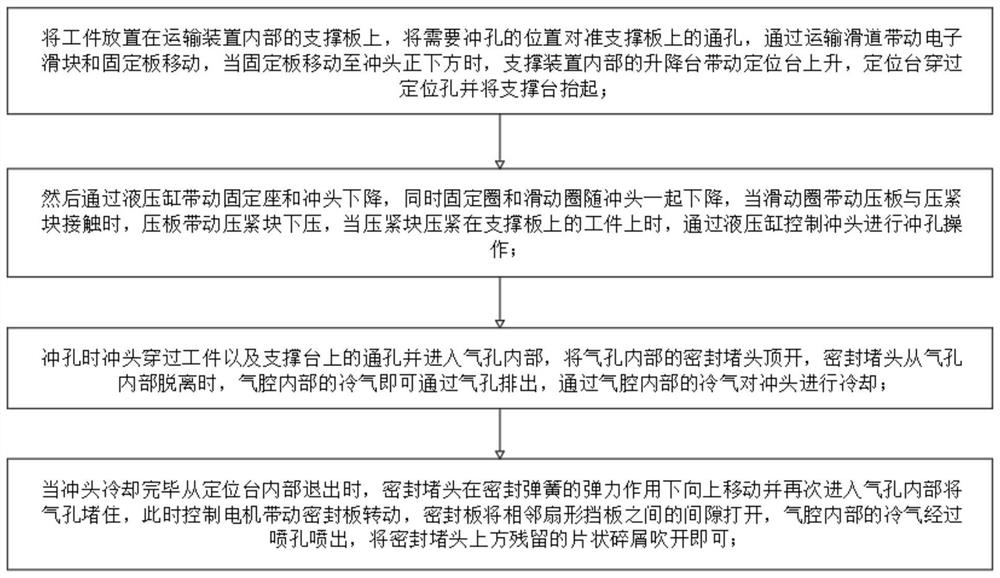

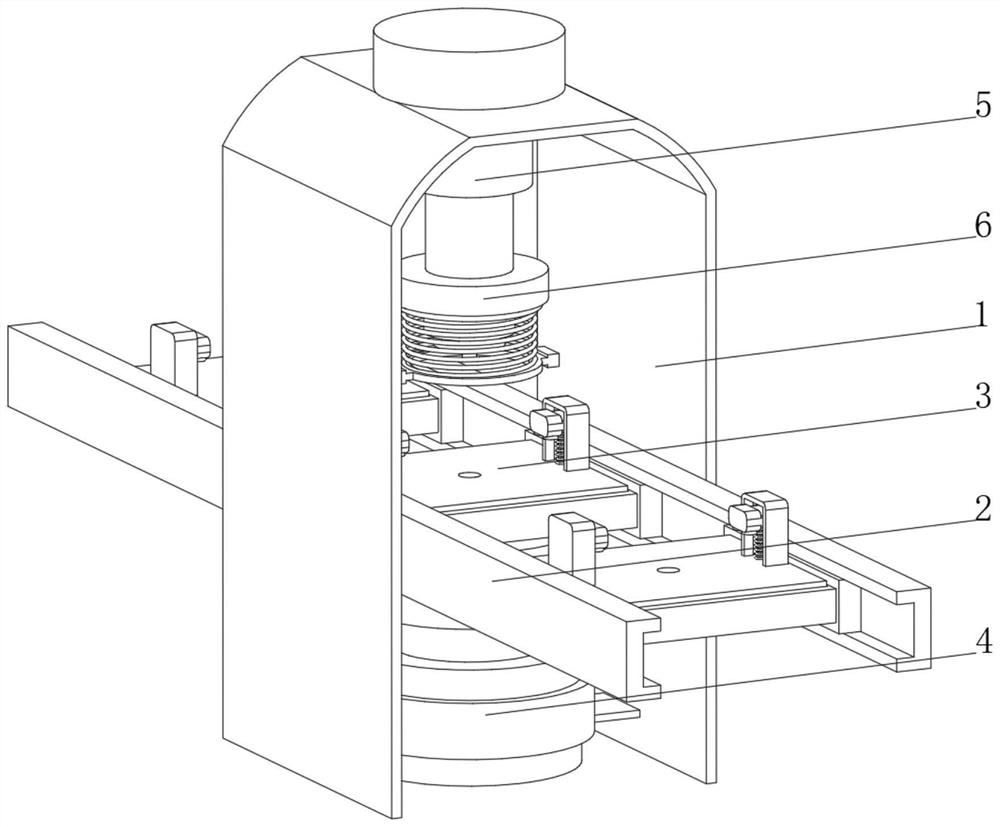

[0041] see Figure 2-4 , the present invention provides a technical solution: an automatic punching equipment for industrial production, specifically comprising:

[0042] A support frame 1, the inner wall of the support frame 1 is fixedly connected with a transport slideway 2, and the inner wall of the transport slideway 2 is slidably connected with a transport device 3;

[0043] A support device 4, the support device 4 is arranged inside the support frame 1, and the side of the support device 4 is fixedly connected to the inner wall of the support frame 1 through a connecting frame;

[0044] Hydraulic cylinder 5, the hydraulic cylinder 5 is fixed on the top of the support frame 1, the bottom of the hydraulic cylinder 5 is fixedly connected with a fixed seat 6, and the bottom of the fixed seat 6 is fixedly connected with a punch 7

[0045] Transport unit 3 includes:

[0046] A fixed plate 31, the bottom of the fixed plate 31 is provided with a positioning hole 32, the top of...

Embodiment 2

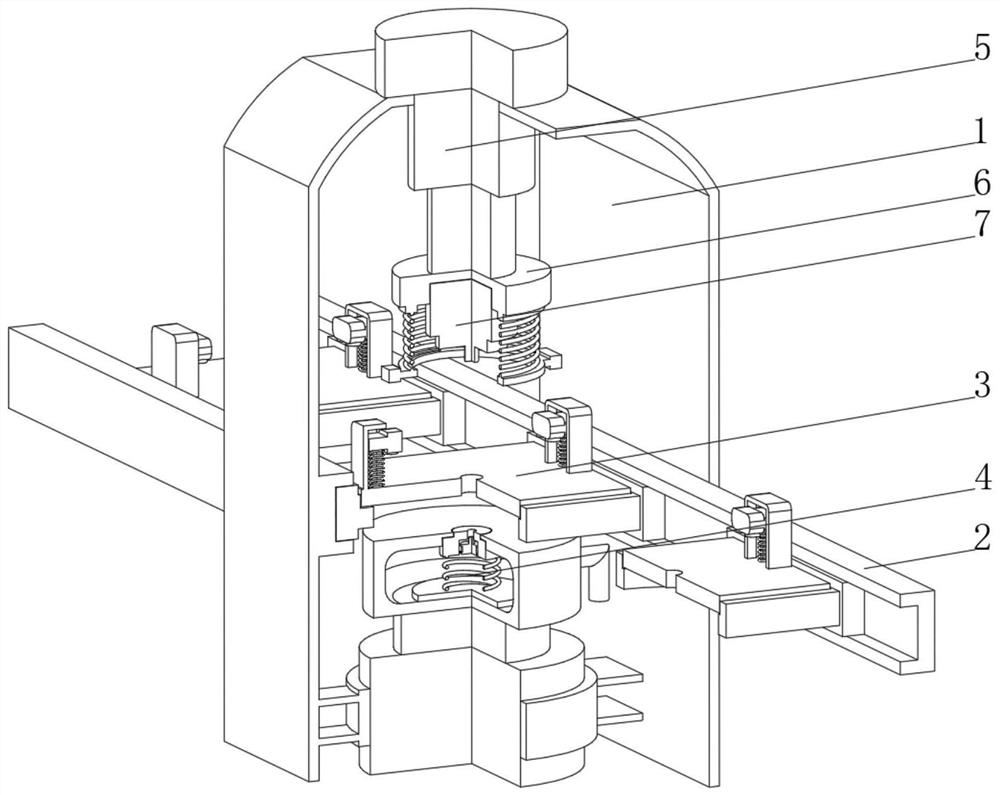

[0053] see Figure 2-5 On the basis of Embodiment 1, the present invention provides a technical solution: the supporting device 4 includes a lifting platform 41, a positioning platform 42 is fixedly connected to the top of the lifting platform 41, and an air cavity 43 is provided inside the positioning platform 42, and the top of the inner wall of the air cavity 43 An air hole 44 is set up, the bottom of the inner wall of the air chamber 43 is fixedly connected with a sealing spring 45, and the top of the sealing spring 45 is fixedly connected with a sealing plug 46 matching the air hole 44. One side of the air chamber 43 is connected with a cooling pipe 47, and the outside of the lifting table 41 The connecting frame is fixedly connected to the inner wall of the support frame 1, and the end of the cooling pipe 47 away from the air chamber 43 is connected with the external cold air pump. The shape and size of the positioning platform 42 are adapted to the positioning hole 32, a...

Embodiment 3

[0055] see Figure 2-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the sealing plug 46 includes a plug body 461, a control groove 462 is opened at the bottom of the plug body 461, and a control motor is fixedly connected to the inner wall of the control groove 462 463, the top of the inner wall of the control groove 462 is provided with a spray hole 464, the inner wall of the spray hole 464 is fixedly connected with a fan-shaped baffle 465, the drive shaft of the control motor 463 extends to the inside of the spray hole 464 and is fixedly connected with a fan-shaped baffle 465. The sealing plate 466, the plug body 461 is set inside the air hole 44 and is slidably connected with the inner wall of the air hole 44, the bottom of the plug body 461 is fixedly connected with the top of the sealing spring 45, the spray hole 464 is set eccentrically inside the control groove 462, and is provided with a sealing plug 46. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com