A guide plate laser remanufacturing process and wear-resistant guide plate

A technology of laser remanufacturing and guide plate, applied in the direction of manufacturing tools, metal material coating process, metal rolling, etc., can solve the problems of increasing cracks, reducing work efficiency, easy wear, etc., to reduce the surface processing area, avoid The effect of hardness reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

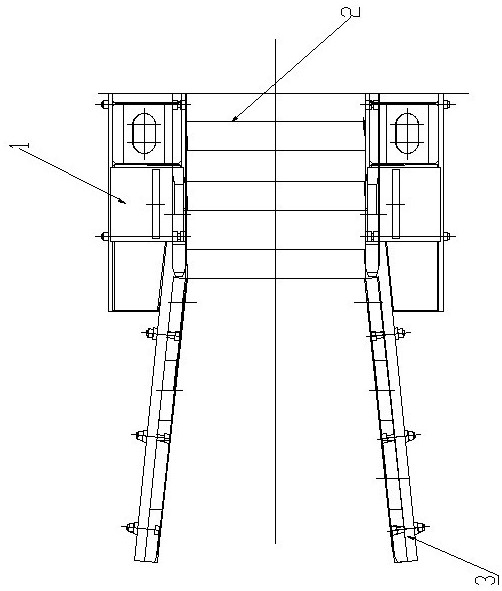

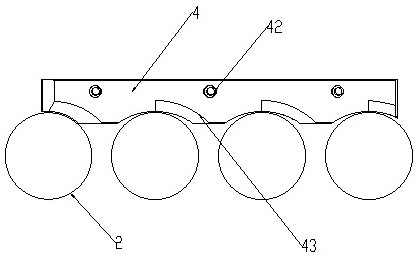

[0041] Such as Figure 2~3 Shown is a wear-resistant guide plate, which is used to solve the problem that the bottom of the guide arm in the prior art is worn and cannot be used and can only be replaced, which affects production efficiency and increases the cost of use. In addition, it also includes a guide plate 4, which is detachably installed at the bottom of the guide arm to replace the part of the guide arm that originally rubs against the steel plate. Due to the detachable connection, compared with replacing the entire guide arm, the replacement speed is faster , has the least impact on production efficiency. Furthermore, the surface treatment of the guide plate 4 is carried out through the laser reprocessing process to increase the hardness of the surface. To continue to use, thereby prolonging the service life and reducing the frequency of replacement; in addition, compared with other thermal cladding technologies, laser reprocessing has lower energy consumption and mo...

Embodiment 2

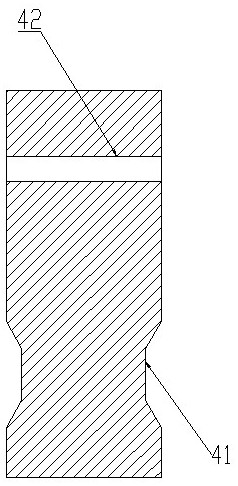

[0045] The difference between this embodiment and the previous embodiment is that a cooling channel 45 is provided in the axial direction of the guide plate 4, such as Figure 4 As shown, the cross-sectional shape of the cooling channel 45 is I-shaped, and the volume of the upper and lower parts is relatively large, which can store more water. The cold water flows into the cooling channel 45 from the bottom, and flows out from the top surface of the cooling channel 45, forming A channel, through the flow of water to take away the heat during use, so that the guide plate 4 is always at a lower temperature, avoiding the temperature rise of the guide plate 4 due to contact with the uncooled steel plate, and the high temperature will cause the hardness of the guide plate 4 to decrease. more prone to wear and tear.

[0046] Further, threaded holes are evenly arranged on the cladding groove 41, the threaded holes are arranged horizontally, and pass through the surface of the cooling...

experiment example 1

[0061] Experimental Example 1: Microhardness Test

[0062] Experimental sample:

[0063] a: The base material is the guide plate of 16Mn;

[0064] b: The base material is 16Mn, and the structure of the workpiece is as described in Example 1. On the basis of the original workpiece, the process of the prior art is used to process the cladding groove part of it by laser cladding to prepare a layer Wear-resistant metal layer;

[0065] c: the base material is 16Mn, the workpiece structure is as described in Example 2, and is processed by the above-mentioned steps;

[0066] The metal used for cladding is tungsten carbide alloy powder, the main components are W8%, Mo10%, Ni15%, Cr6%, Fe balance;

[0067] Process parameters of laser cladding: semiconductor laser is used; laser power is 3000W, scanning speed is 1000mm / min, and spot is square: 3*8mm.

[0068] Experimental equipment: HV-1000 microhardness tester.

[0069] experimental method:

[0070] Select the test force and turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com