Light reinforced bar concrete binary structure system and method thereof

A light-weight concrete and light-weight steel technology, applied in building structure, building components, earthquake-proof and other directions, can solve the problems of building damage, acceptance drop, and difficulty in benefiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

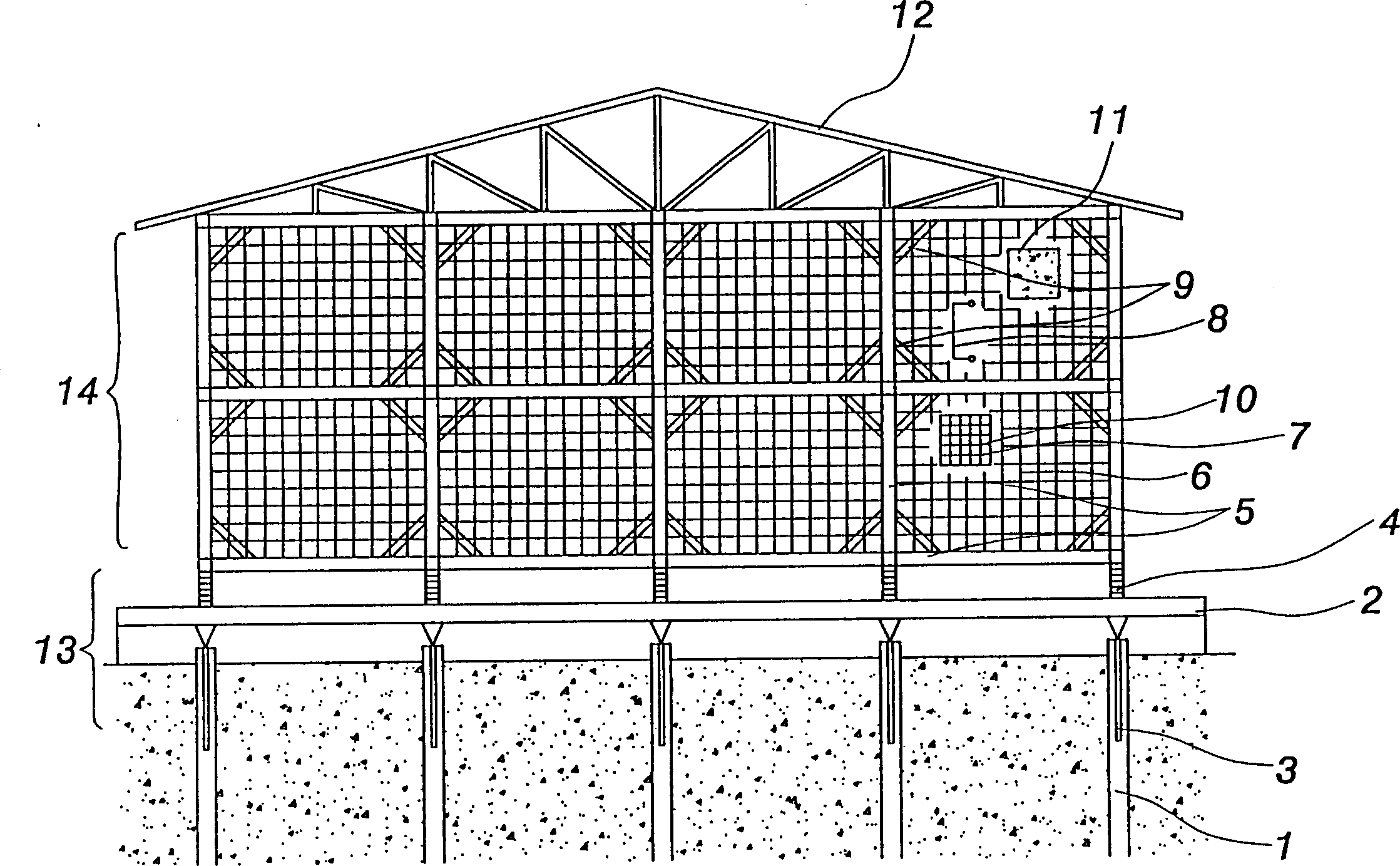

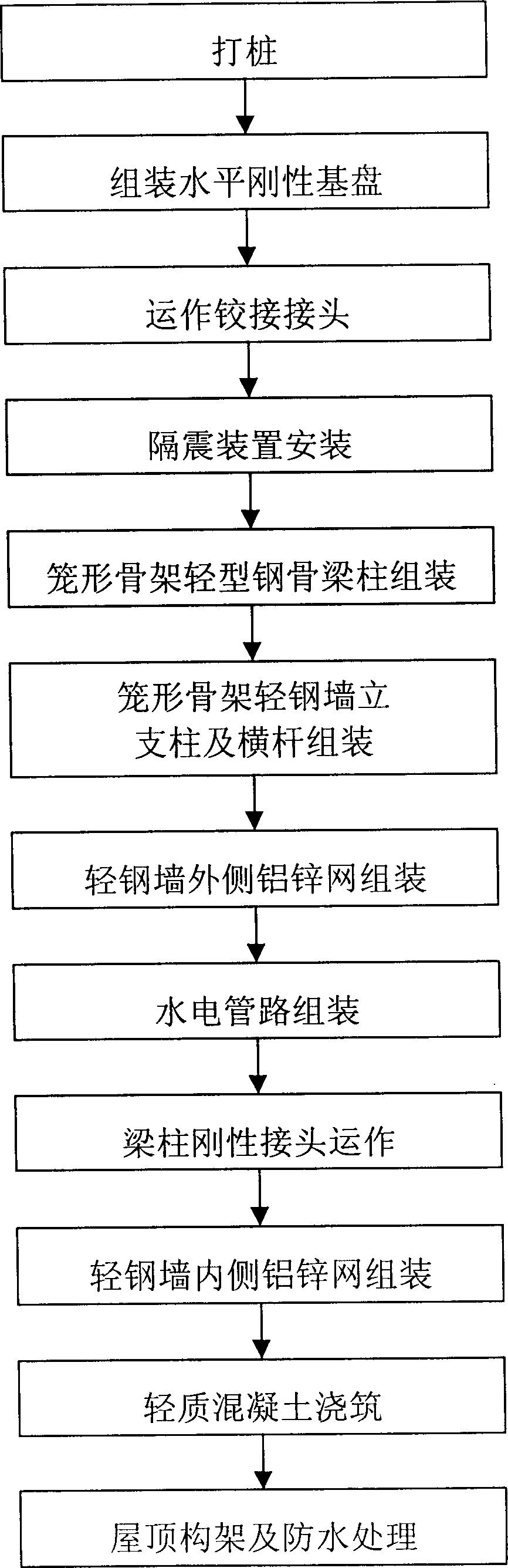

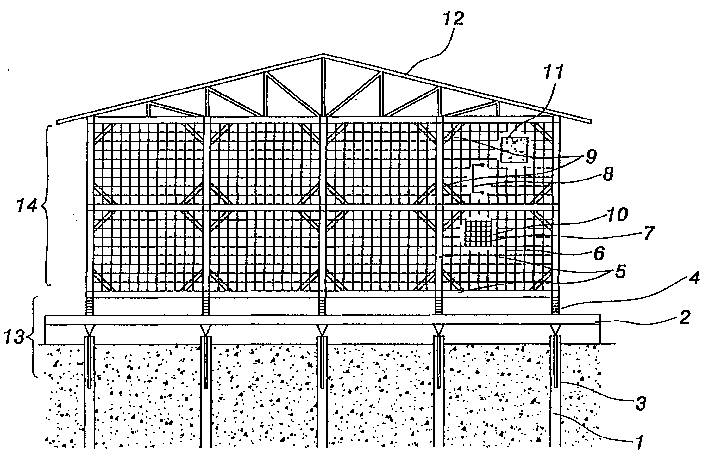

[0033] The present invention provides a lightweight steel-reinforced concrete binary construction system and its method. The invention of the light-weight steel-reinforced concrete binary construction system and method is to concretize the above-mentioned concept and differ from the traditional concept There are four main points:

[0034] First, in terms of basic cognition, the bigger, more rigid, and more connected the better, especially the deep-rooted thinking of the raft foundation.

[0035] Second, seismic isolation devices are generally regarded as high-tech products, which are expensive and cannot be economically used in ordinary residences.

[0036] Third, the heavy-duty steel frame building materials have high strength, regardless of the large stress concentration of the joints, and the strict construction quality requirements.

[0037] Fourth, the strength of lightweight concrete is weak, and there are safety concerns when it is used in the main structure.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com