Linkage tracking photovoltaic power station

A photovoltaic power station and photovoltaic power generation technology, applied in the direction of photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of difficult installation, slow installation process, low installation efficiency, etc., and achieve the reduction of installation accuracy requirements, installation The effect of simplifying the connection structure and improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

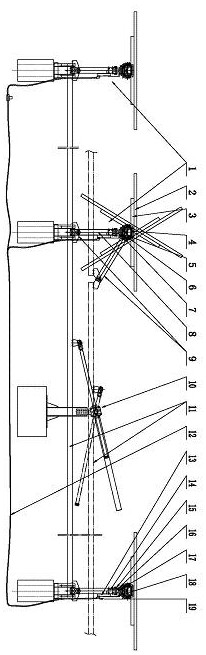

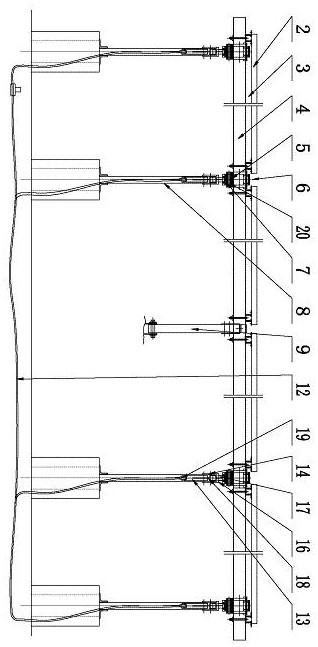

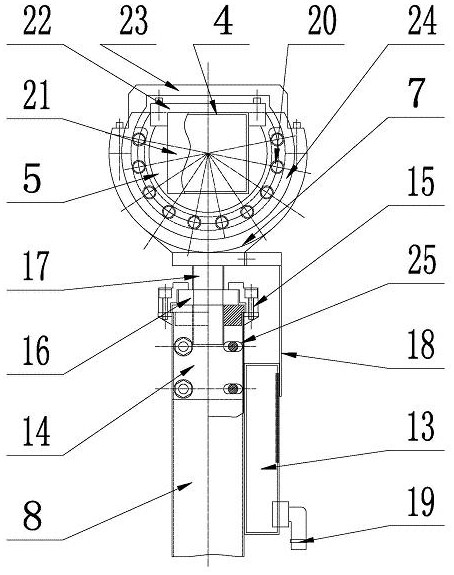

[0024] exist figure 1 and figure 2 In the linkage tracking photovoltaic power station shown, the photovoltaic power generation units 1 are arranged in several rows, each photovoltaic power generation unit 1 includes a photovoltaic module 2, and each photovoltaic module 2 is installed on the rectangular main beam 4 through several beams 3 along the length direction of the rectangular main beam 3 Above, the rectangular main beam 4 is supported on the column 8 through the main beam bearing 6, and the tracking driving arm 9 is connected to the rectangular main beam 4, and the tracking driving arm 9 in each photovoltaic power generation unit 1 communicates with the tracking driving device 10 through the linkage rod 11. Transmission connection, the tracking drive device 10 drives the rectangular main beam 4 in each photovoltaic power generation unit 1 to swing through the linkage rod 11, so as to realize the linkage tracking of the solar position by the photovoltaic modules 2 on each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com