Buckle and building template supporting steel pipe joist manufactured by using same

The technology of steel pipes and fasteners is applied in the field of steel pipe joists supported by building formwork, which can solve the problems of structural damage to the lower layer, increase construction safety risks, and difficulty in operation during dismantling, and achieve the effect of convenient operation and meeting the requirements of formwork support force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

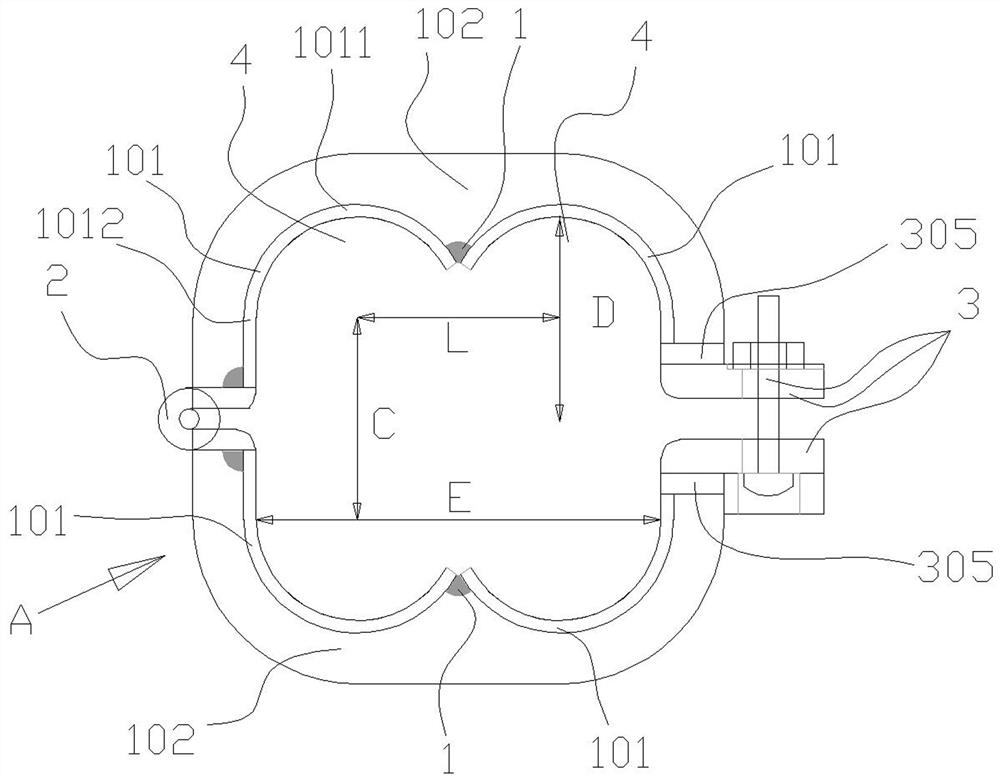

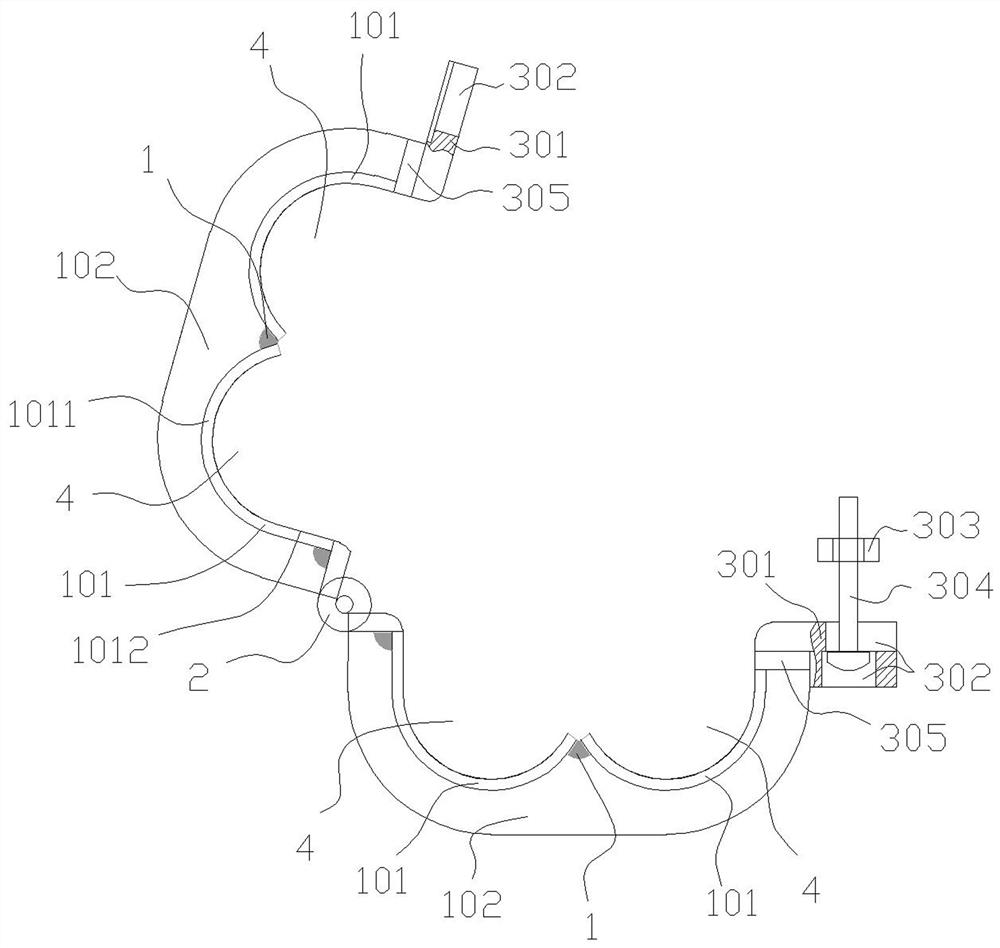

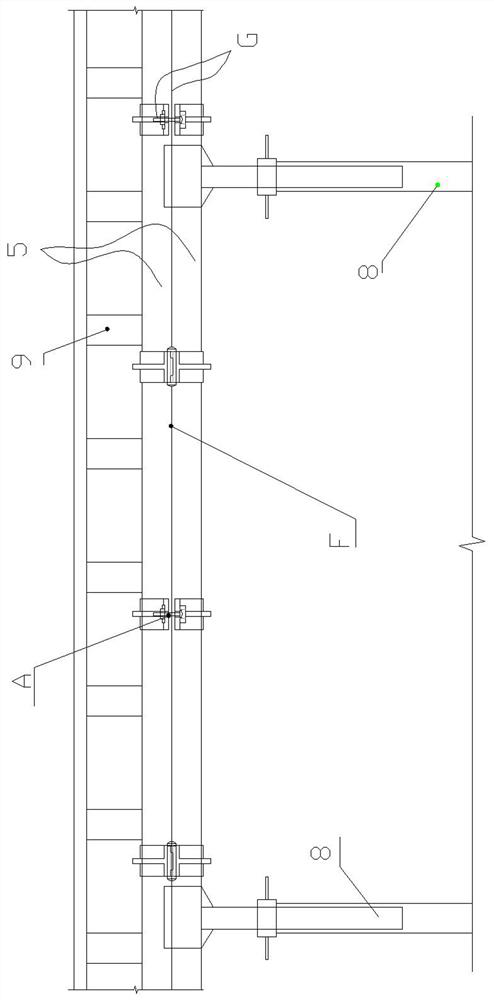

[0029] Button embodiment 1 of the present invention, such as figure 1 , 2 As shown, it includes two U-shaped fasteners 1, one end of the two U-shaped fasteners 1 is hinged together by a butterfly hinge 2, and the other end of the two U-shaped fasteners 1 is provided with a fixed connection structure 3, so that the two U-shaped fasteners After the other end of 1 is fixedly connected together by the fixed connection structure 3, an annular hoop A is formed. The inner bottom of the U-shaped fastener 1 is provided with two circular arc-shaped notches 4 with the same diameter side by side. The U-shaped fastener 1 The distance L between the centers of the two arc-shaped notches 4 is not less than the diameter D of the arc-shaped notches 4, and the distance C between the centers of the upper and lower two arc-shaped notches 4 of the ring hoop A is equal to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com