Method for casting in-situ composite lightweight wall by detaching-free template and equipment thereof

A light-weight wall, formwork-free technology, applied in the on-site preparation of building components, the connection of formwork/formwork/work frame, walls, etc., can solve the problems of high cost, cracking of joints, and no molding. , to achieve the effect of saving building area, increasing floor height, and good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

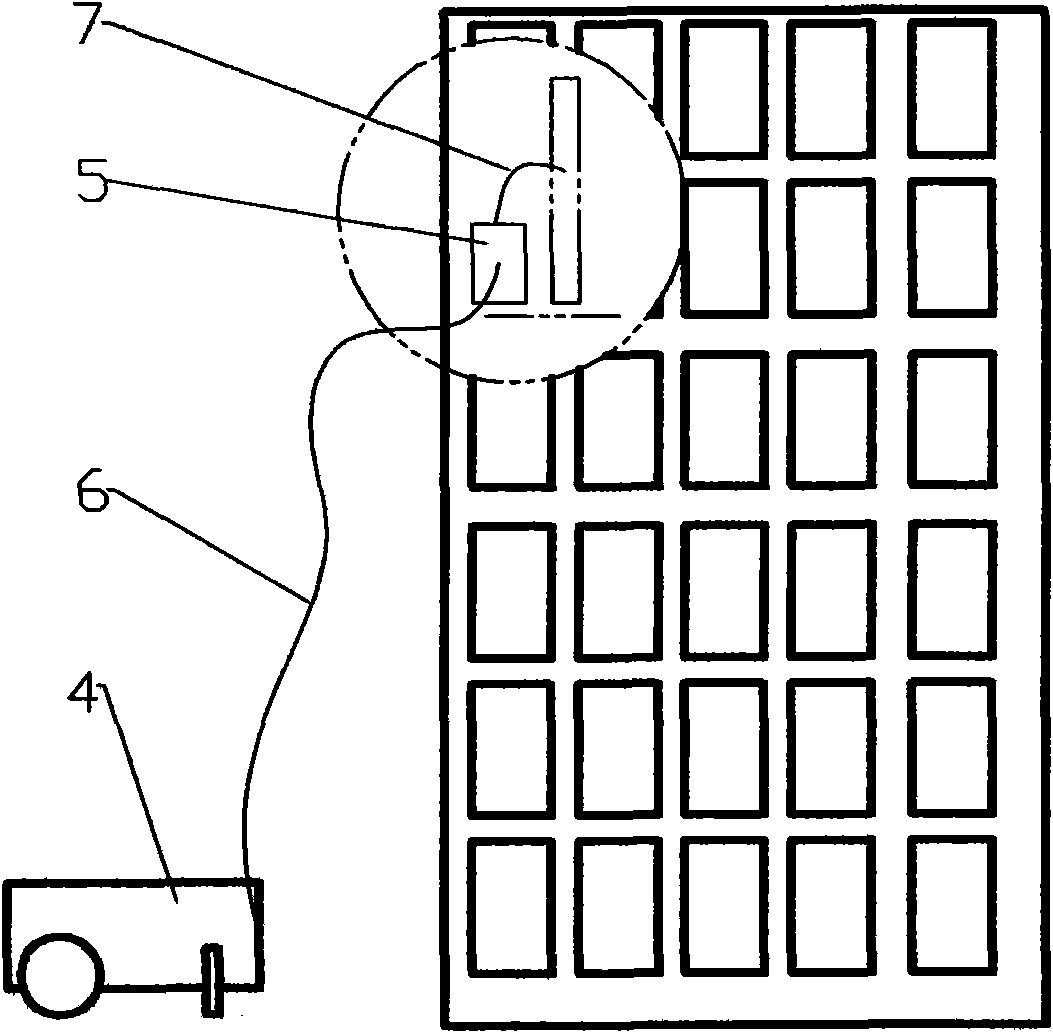

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

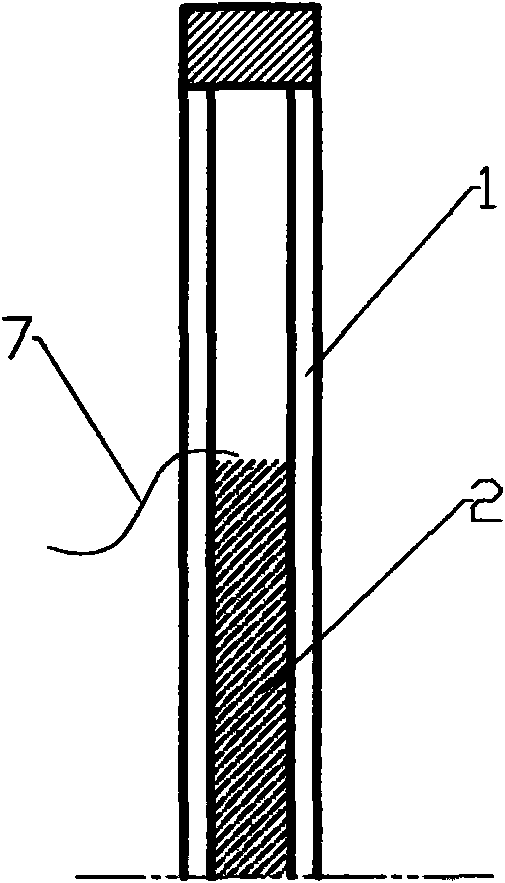

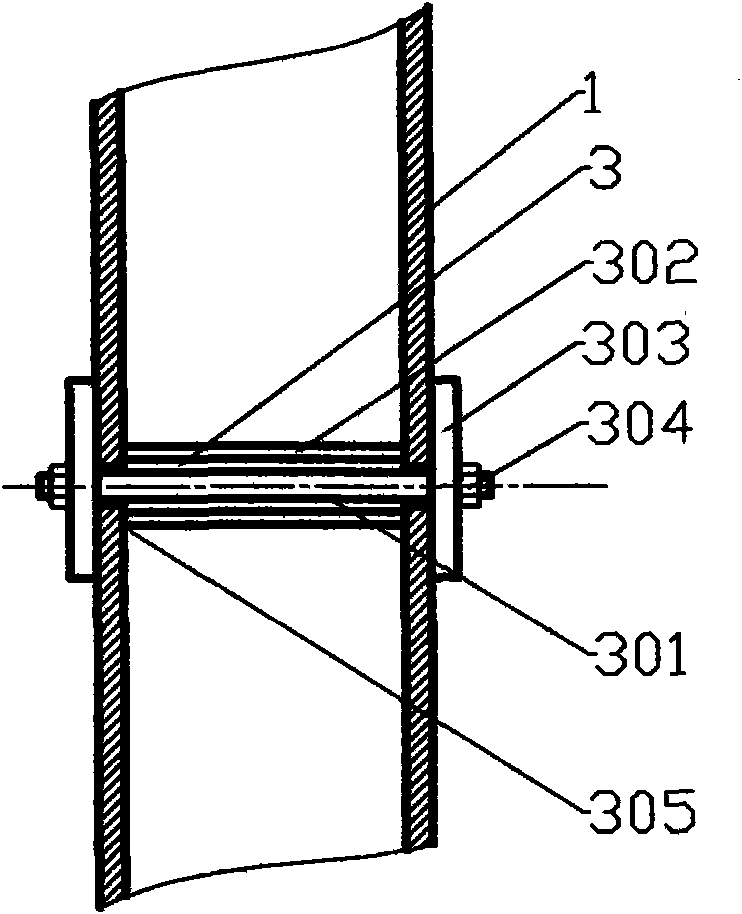

[0023] As shown in the figure, a method for cast-in-place composite light-weight walls without dismantling formwork, where light-weight walls need to be installed on the construction site, the pressure fiber cement board 1 is used as the outer layer of the wall and the dismantling-free formwork, pressure fiber cement board 1 The physical foamed concrete 2 is poured in the interlayer between the cement boards. After pouring, the physical foamed concrete and the pressure fiber cement board are integrated to form a light-weight wall. The surroundings of the light-weight wall are also integrated with the building structure.

[0024] The fixing method of the formwork adopts the light steel keel stipulated in GB / T 11981-2001 as the skeleton, and adopts the following appropriate sealing and strengthening measures: use double-sided adhesive sealant strips for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com