Compound stabilizing method for silty soil in Yellow River flooded areas

A stabilization method and technology for silt soil, which is applied to improve the properties of silt soil in yellow flooding areas, and can solve the problems that have not been seen in the use of sodium methyl silicate, so as to improve the unconfined compressive strength and impermeability Performance, low-carbon environmental protection, and wide-source effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

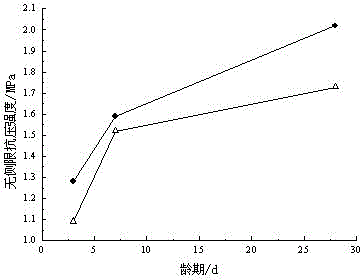

[0027] Mix 600g of air-dried silt soil, 300g of fly ash, 60g of lime, 10g of polyacrylamide with a molecular weight of 3 million, and 30g of sodium methyl silicate aqueous solution with a mass percentage of 15%, and mix them evenly. 203.1g, weighed three parts, respectively made into Φ50×50mm test blocks, sealed for standard health preservation. Using a computerized constant stress pressure testing machine, load the specimen continuously and uniformly at a speed of 0.05kN / s until the specimen is destroyed, and record the failure load. The measured 7d unconfined compressive strength is 1.59MPa, and the permeability coefficient of the formula sample tested according to the aforementioned experimental method is 8.84×10 -5 .

Embodiment 2

[0029] Mix 700g of air-dried silt soil, 200g of fly ash, 60g of lime, 10g of polyacrylamide with a molecular weight of 3 million, and 30g of sodium methyl silicate aqueous solution with a concentration of 15% by mass, and stir evenly. Each piece is 203.1g, and three parts are weighed, respectively made into Φ50×50mm test blocks, sealed for standard health preservation. Using a computerized constant stress pressure testing machine, load the specimen continuously and uniformly at a speed of 0.05kN / s until the specimen is destroyed, and record the failure load. The measured 7d unconfined compressive strength is 1.56MPa, and the permeability coefficient of the formula sample tested according to the aforementioned experimental method is 8.92×10 -5 .

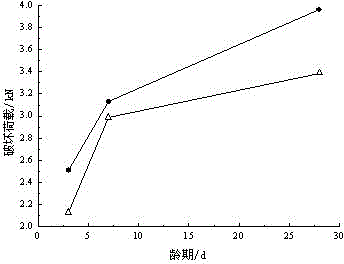

[0030] Depend on figure 1 It can be seen that for the same mix ratio, as the curing time increases, the required failure load increases. For different mix proportions, the failure load required for the stabilization of silt soil b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com