Ice cream with sweet potato powder added in base

A technology of sweet potato flour and base material, which is applied in frozen sweets, food preparation, food science, etc., can solve the problems of adding sweet potato flour and achieve the effect of reducing intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the ice cream with sweet potato powder added to the base material provided by the present invention may include the following specific steps: raw material pretreatment → mixing → homogenization → sterilization → cooling → aging → freezing → mold filling → inserting chopsticks → demoulding → packaging → Storage → Inspection → Finished product. The specific production process is as follows:

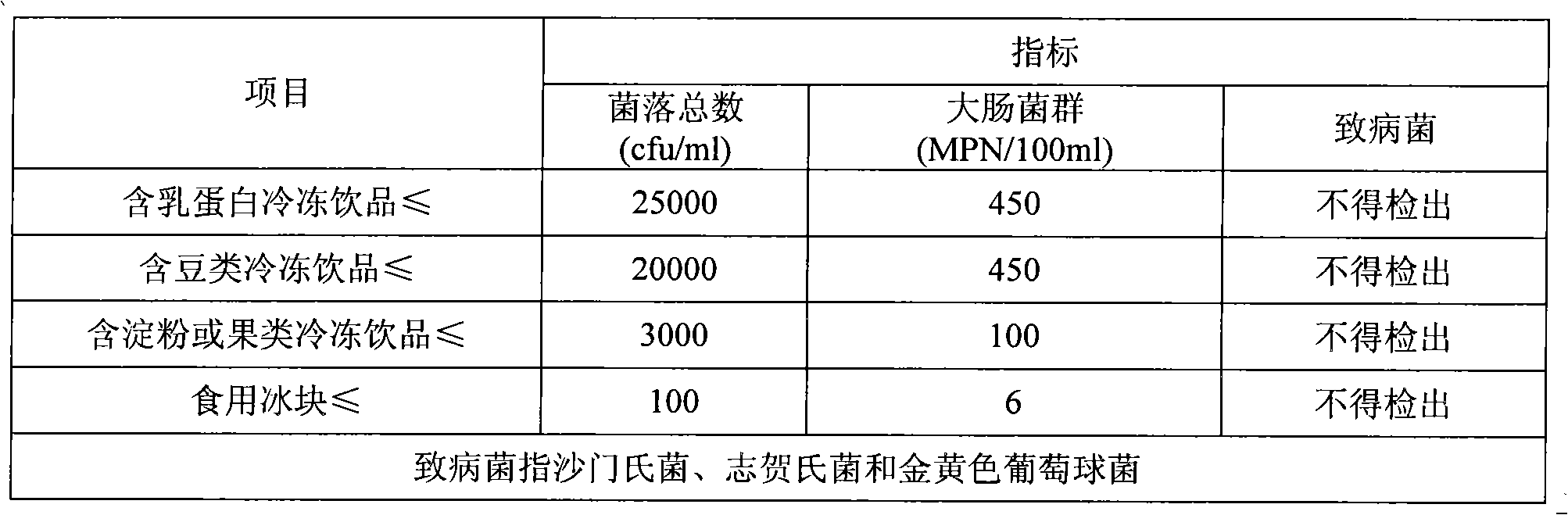

[0040] Raw material pretreatment: must go through sensory, physical and chemical tests, microbiological tests, no adulteration and other foreign matter;

[0041] Mixing: Add appropriate amount of water into the batching tank, and then add various raw materials and necessary ingredients according to the formula under stirring conditions to obtain the base material;

[0042] Homogenization: Homogenize the base material, in which the homogenization temperature is generally controlled at 65°C-75°C, the primary pressure is controlled at 15-20MPa, and the seconda...

Embodiment 1

[0055] Embodiment 1: sweet potato flour ice cream formula (1000 parts by weight):

[0056] Milk powder: 60 parts by weight; white granulated sugar: 130 parts by weight; caramel: 40 parts by weight; sweet potato flour: 30 parts by weight; butter: 70 parts by weight; Raw gum: 0.5 parts by weight; sodium carboxymethyl cellulose: 1 part by weight; essence: 1 part by weight; the rest is water.

Embodiment 2

[0057] Embodiment 2: sweet potato powder ice cream formula (1000 parts by weight):

[0058] Milk powder: 50 parts by weight; white sugar: 130 parts by weight; fructose syrup: 30 parts by weight; caramel: 20 parts by weight; vegetable oil: 50 parts by weight; whey powder: 20 parts by weight; sweet potato powder: 30 parts by weight; molecular distillation Monoglyceride: 1.5 parts by weight; Carrageenan: 0.5 parts by weight; Locust bean gum: 0.5 parts by weight; Sodium carboxymethyl cellulose: 1 part by weight; Essence: 0.5 parts by weight;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com