Fat filtering filter screen and fat filtering stewpot

A filter screen and stew pot technology, which is applied in the field of grease filter screen, can solve the problems of artificially adding water, the soup is not clear, sweet and healthy, and troublesome, and achieves the effect of reducing the oil content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

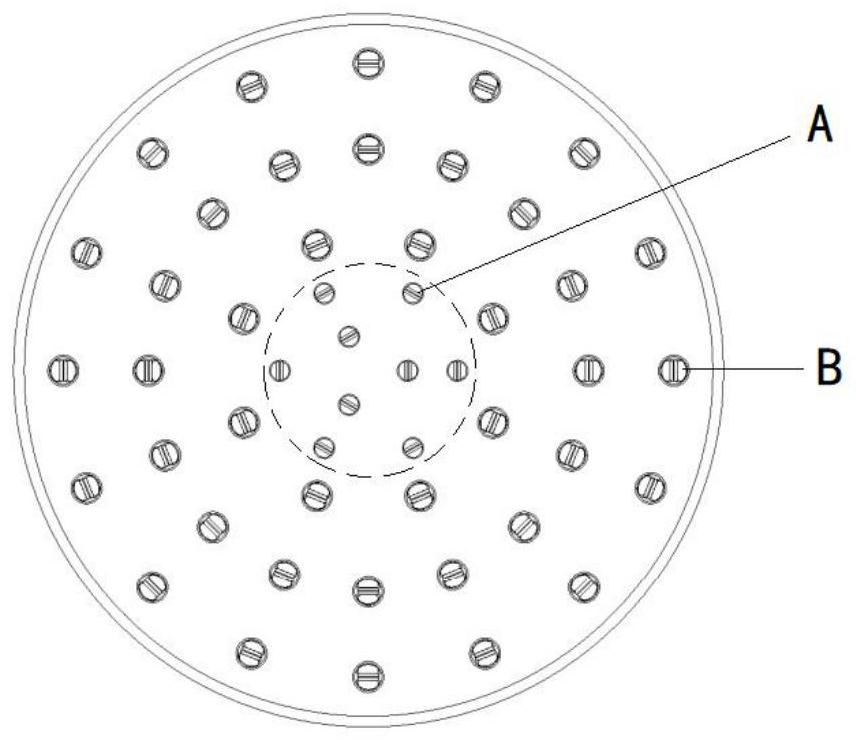

[0022] Below in conjunction with embodiment the present invention is described in further detail, a kind of grease filter stew pot that filter screen is installed, and this filter screen 13 is circular plate, is provided with a plurality of projections; The protrusion is facing downward A, and the protrusion near the periphery is upward B; the top of each protrusion is provided with a through slit, and the outer edge of the grease filter 13 is provided with a downward-turning button for buckling on the edge of the pot. Ring block C, this grease filter screen 13 is food-grade stainless steel material, as image 3 , as shown in 4 and 5.

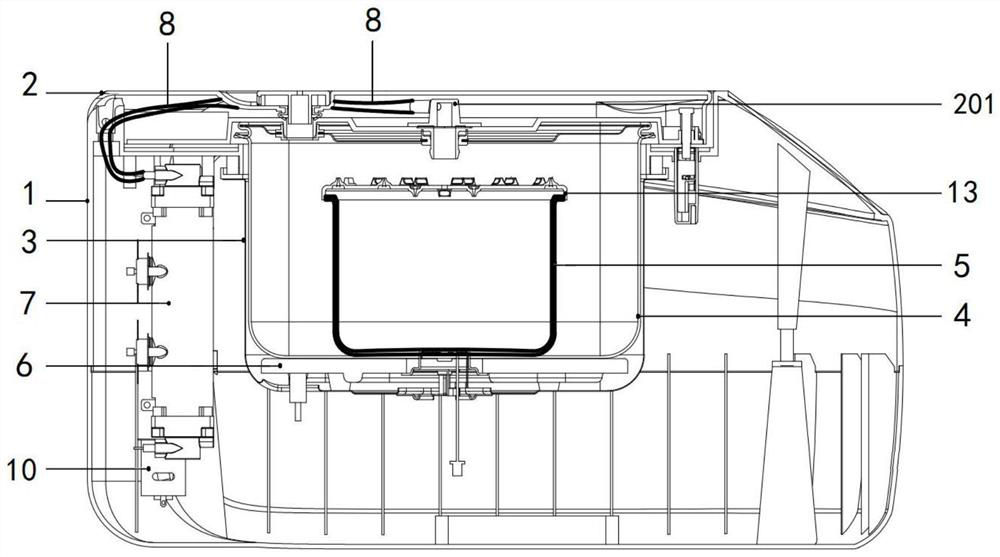

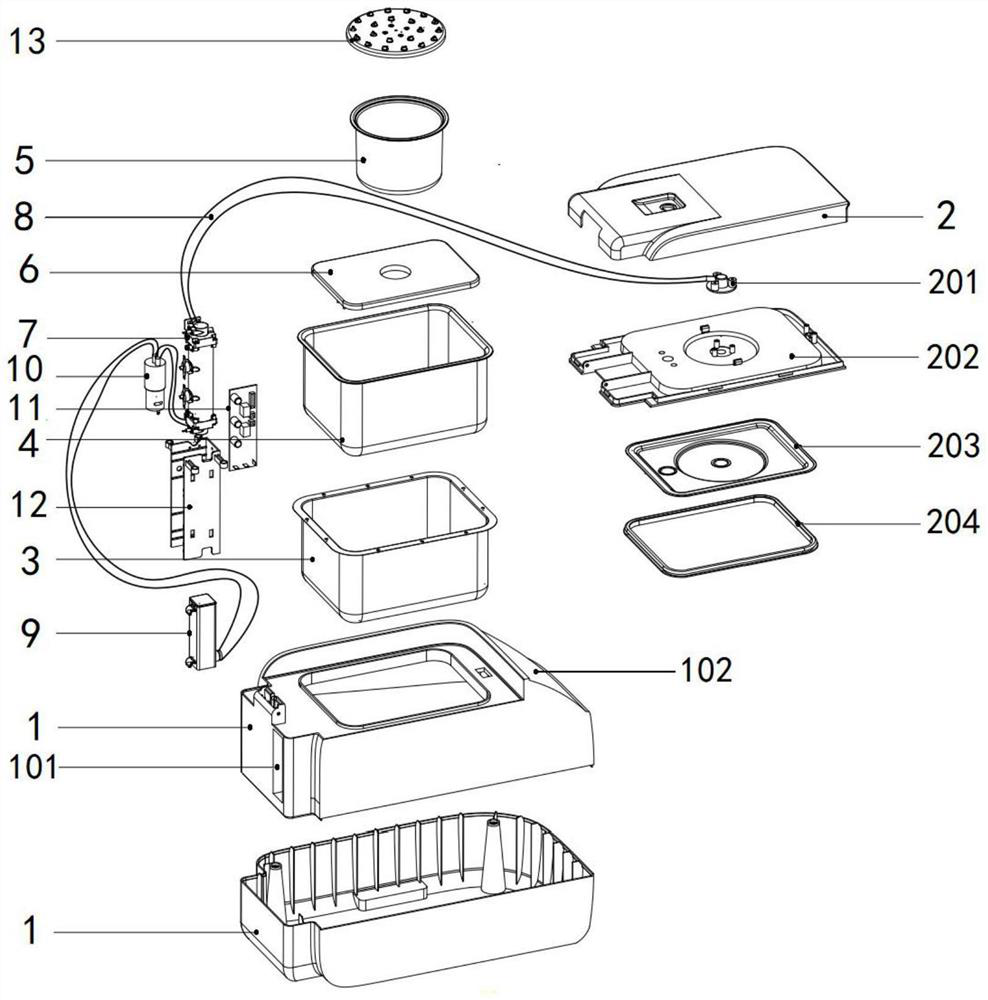

[0023] Such as figure 1 with 2 As shown, the fat filter stew is provided with a shell 1, a middle cover 3, an inner container 4 and a soup pot 5 successively from the outside to the inside, wherein a heating plate 6 is arranged between the bottom of the inner container 4 and the bottom surface of the middle cover 3, Cover 2 is provided above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com