Method for extracting fish collagen

A technology of fish collagen and extraction method, which is applied in the field of fish collagen extraction, can solve the problems of long operation time, pollution, low fat content, etc., and achieve the effect of less fat content, good water solubility and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

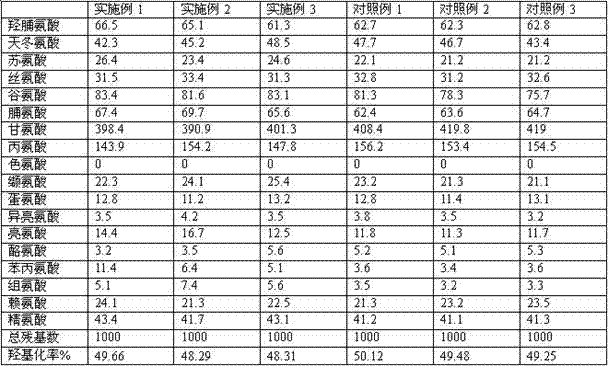

Embodiment 1

[0030] Step 1, tissue crushing: After thawing crucian carp skin, add water to make the weight ratio of fish skin to water 10:0.2, crush and grind the mixture, and apply ultrasonic action while crushing and grinding to obtain slurry ;

[0031] The second step is to remove salt-soluble impurities: mix the slurry with 4wt% NaCl solution, the weight ratio of slurry and NaCl solution is 1:5, stir evenly and soak for 10 hours, then centrifuge, remove the supernatant, and get first precipitation;

[0032]Step 3, remove lipids and alkali-soluble impurities: mix the first precipitate with 2wt% NaOH solution, the weight ratio of the first precipitate and alkali solution is 1:7, stir well and soak for 20 hours, then centrifuge to remove supernatant to obtain the second precipitate;

[0033] Step 4, remove acid-soluble impurities: mix the second precipitate with 5wt% citric acid solution, the weight ratio of the second precipitate and acid solution is 1:4, stir well and soak for 5 hours...

Embodiment 2

[0039] Step 1, tissue crushing: after the crucian carp skin is thawed, add water so that the weight ratio of fish skin to water is 10:1, crush and grind the mixture, and apply ultrasound while crushing and grinding to obtain a slurry ;

[0040] Step 2, remove salt-soluble impurities: mix the slurry with 10wt% NaCl solution, the weight ratio of slurry and NaCl solution is 1: 10, soak after stirring evenly, the soaking time is 30h, then go through centrifugation, remove the supernatant, and get first precipitation;

[0041] Step 3, remove lipids and alkali-soluble impurities: mix the first precipitate with 5wt% NaOH solution, the weight ratio of the first precipitate and alkali solution is 1: 12, stir well and soak for 35 hours, then centrifuge to remove supernatant to obtain the second precipitate;

[0042] Step 4, remove acid-soluble impurities: mix the second precipitate with 12wt% citric acid solution, the weight ratio of the second precipitate and acid solution is 1:8, st...

Embodiment 3

[0048] Step 1, tissue crushing: After thawing crucian carp skin, add water to make the weight ratio of fish skin to water 10:0.6, crush and grind the mixture, and apply ultrasonic action while crushing and grinding to obtain slurry ;

[0049] The second step is to remove salt-soluble impurities: mix the slurry with 6wt% NaCl solution, the weight ratio of slurry and NaCl solution is 1:7, stir evenly and soak for 20 hours, then centrifuge, remove the supernatant, and get first precipitation;

[0050] Step 3, remove lipids and alkali-soluble impurities: mix the first precipitate with 4wt% NaOH solution, the weight ratio of the first precipitate and alkali solution is 1:11, stir well and soak for 26 hours, then centrifuge to remove supernatant to obtain the second precipitate;

[0051] Step 4, remove acid-soluble impurities: mix the second precipitate with 5-12wt% citric acid solution, the weight ratio of the second precipitate to the acid solution is 1:6, stir well and then soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com