Preparation method for apple essence

A technology of apple essence and vanillin, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of excessive sweetness, not refreshing apple taste, and insufficient fresh taste, and achieve the effect of avoiding volatilization and increasing the refreshing taste of apples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

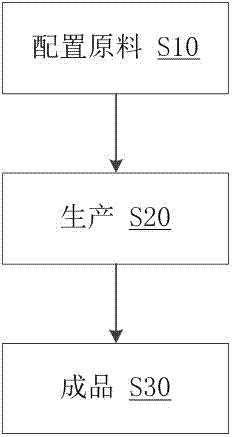

[0026] see figure 1 It is a step diagram of the method for preparing apple essence in Example 1 of the present invention, a method for preparing apple essence, which is characterized in that, comprising the following steps:

[0027] S10 configuration raw materials;

[0028] S20 production;

[0029] S30 finished product;

[0030] Wherein, in S10, the configuration raw materials and proportions are as follows (percent by weight): methyl acetate 0.51%, ethyl acetate 0.51%, phenylacetic acid 0.22%, n-hexanoic acid 0.35%, ethanolactone 0.46%, ethyl acetate Maltol 0.46%, ethyl formate 0.41%, propyl formate 1.31%, green apple oil 0.22%, vanillin 20.1%, apple extract 25.1%, propylene glycol 20.1%, the balance is distilled water;

[0031] Wherein, S20 includes the following steps:

[0032] S201, put vanillin, ethyl maltol, apple extract, green apple oil, propylene glycol;

[0033] S202, put in propylene glycol

[0034] S203, heated to 60°C;

[0035] S204, stirring until the soli...

Embodiment 2

[0040] The preparation process of this example is the same as that of Example 1, and the difference lies in the proportion of raw materials. Ethyl-Nonolactone 0.5%, Ethyl Maltol 0.5%, Ethyl Formate 0.45%, Propyl Formate 1.35%, Green Apple Oil 0.26%, Vanillin 20.5%, Apple Extract 25.5%, Propylene Glycol 20.5%, the remainder The amount is distilled water.

Embodiment 3

[0042] The preparation process of this example is the same as that of Example 1, and the difference lies in the proportion of raw materials. Ethyl nonolactone 0.47%, ethyl maltol 0.47%, ethyl formate 0.42%, propyl formate 1.32%, green apple oil 0.23%, vanillin 20.2%, apple extract 25.2%, propylene glycol 20.2%, the remainder The amount is distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com