Special anticorrosion water paint for steel structure and preparation method thereof

A water-based paint, water-based technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of anti-stickiness, poor heat resistance, difficult to achieve water-resistant anti-corrosion performance, poor weather resistance, etc., to achieve good adhesion, excellent anti-corrosion Performance and weather resistance, effect of low air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

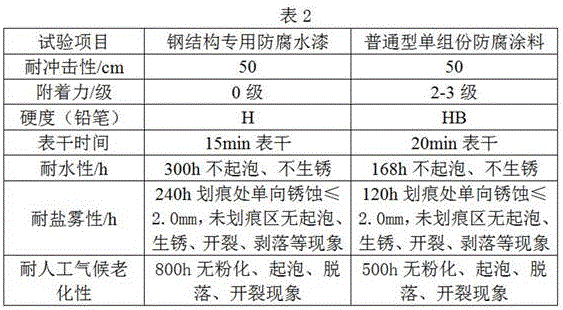

Image

Examples

Embodiment 1

[0035] The wetting and dispersing agent used in Example 1 is sodium polycarboxylate, the wetting and dispersing agent used in Examples 2-4 is a polymer dispersant, and the wetting and dispersing agent used in Example 5 is ammonium polycarboxylate.

[0036] The defoamer used in Examples 1-3 is a silicone defoamer, and the defoamer used in Examples 4 and 5 is a polyether siloxane copolymer type defoamer.

[0037] The anti-settling agent used in Examples 1 and 2 is a modified polyamide wax-type anti-settling agent, the anti-settling agent used in Example 3 is bentonite, and the anti-settling agent used in Examples 4 and 5 is magnesium lithium sodium silicate type anti-settling agent.

[0038] The used colored pigment of embodiment 1-5 is iron oxide red; Filler is light calcium carbonate.

[0039] The preparation method of embodiment 1-5 finished product is as follows:

[0040] Step a, add deionized water, neutralizer, dispersant, and defoamer to the stock preparation pot at one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com